Yes, it did IAIMH! 👍

Your first link confirmed that a "simple" calculation: watts x temp coeff - does not lead to the correct above-ambient heatsink temperature.

Your second link confirmed that Al oxide pads are best.

Regards,

Andy

Your first link confirmed that a "simple" calculation: watts x temp coeff - does not lead to the correct above-ambient heatsink temperature.

Your second link confirmed that Al oxide pads are best.

Regards,

Andy

Aluminum nitride ceramic is multiple times better than aluminum oxide in W/mK. There are lots of AliExpress options (make sure you get the right dimensions for your transistors). I have not tried these, but with sink grease on either side of the little plate, should perform very well.

AliExpress

Good thread: Aluminum oxide/nitride interfaces

Good ol’ Keratherm has been enough for me, but I haven’t built the big-dissipation amps like you guys are discussing.

AliExpress

Good thread: Aluminum oxide/nitride interfaces

Good ol’ Keratherm has been enough for me, but I haven’t built the big-dissipation amps like you guys are discussing.

Last edited:

^ Great call out re: Aluminum Oxide vs. Aluminum Nitride. I've never actually looked at the difference, and went along my merry way just calling all the "hard white" materials Aluminum oxide and blindly thinking they were 'the best'.

Thanks!

I found a few files I had tucked away. These are the data taken (visually) from the Modoshop study. I plotted them for my own learning. The key to me (among many neat things) is that the temp coefficient is not constant throughout a range of heat loads for any given heatsink / load combination. Also, depending on how the tempco is calculated... it can be meaningfully different depending on application. When people tried to explain it to me, my mind went numb. The switch clicked when I plotted it out. I made a poor effort at running a regression model to predict temps for various shapes and sizes of 40mm Modushop sinks. It works okay, but truthfully people's recommendations from personal experience have been more useful. 🙂

Note - My tempcos were calculated using 27C ambient. That's generous, but it was the starting temp of the sinks in the data. So...

Hope it helps a bit further.

Cheers!

Thanks!

Awesome!Yes, it did IAIMH! 👍

Your first link confirmed that a "simple" calculation: watts x temp coeff - does not lead to the correct above-ambient heatsink temperature.

Your second link confirmed that Al oxide pads are best.

Regards,

Andy

I found a few files I had tucked away. These are the data taken (visually) from the Modoshop study. I plotted them for my own learning. The key to me (among many neat things) is that the temp coefficient is not constant throughout a range of heat loads for any given heatsink / load combination. Also, depending on how the tempco is calculated... it can be meaningfully different depending on application. When people tried to explain it to me, my mind went numb. The switch clicked when I plotted it out. I made a poor effort at running a regression model to predict temps for various shapes and sizes of 40mm Modushop sinks. It works okay, but truthfully people's recommendations from personal experience have been more useful. 🙂

Note - My tempcos were calculated using 27C ambient. That's generous, but it was the starting temp of the sinks in the data. So...

Hope it helps a bit further.

Cheers!

Attachments

^ I am past the editing period - I looked back at some of the data in the Modushop study. I haven't viewed it in some time. The university ran a 2U / 400 chassis out to 180C for the max temp on the sinks. 90C on the fins. 250W dissipation on a single 2U / 400 sink.

Needless to say, I didn't include measurements like those in the graphs. No use in my applications.

Back to our regularly scheduled AN programming.

Needless to say, I didn't include measurements like those in the graphs. No use in my applications.

Back to our regularly scheduled AN programming.

I think much of the problem arises from the temperature that the heatsink rating is measured. Many manufacturers use 80C; FAR too high for most semiconductors. The thermal capacity looks much better if you use a much higher temperature; Newton's Law of Cooling (Q = h.A(Tt-Tenv) ) means the transfer is far greater if the temperatures between the heatsink and the environment is higher. Accordingly by selecting 80C they can give their heat coefficient a higher rating, helping sales! At say 40C the transfer coefficient is much lower.

And of course there are other issues like the package, the paste, and even the torque on the single device bolt. And forced air can reduce the coefficient by up to three times if the airflow is high.

HD

And of course there are other issues like the package, the paste, and even the torque on the single device bolt. And forced air can reduce the coefficient by up to three times if the airflow is high.

HD

Aluminum nitride ceramic is multiple times better than aluminum oxide in W/mK. There are lots of AliExpress options (make sure you get the right dimensions for your transistors). I have not tried these, but with sink grease on either side of the little plate, should perform very well.

AliExpress

Good thread: Aluminum oxide/nitride interfaces

Thanks - I've just ordered a batch of aluminium nitride insulating pads. 👍

After drawing the outline of a 400m deep Dissipante case on some graph paper - and making some paper templates of the 150x100 SLB PS boards and 90x90 AN boards and moving them around ... I have decided to:

* buy a 400mm deep case - rather than a 500 deep case (which, yes, would run at lower heatsink temperatures)

* and re-arrange my layout.

Life is always a compromise and it seemed to me that, from Vunce's AN 8R data ... sure, my heatsinks will not be at 50 deg (with my extra heat load) - but by being a bit more careful of where I position the AN 4R's output devices, I should be able to reduce the current 72 deg (with the 300mm deep case) to around 60 deg with a 400mm case.

That will be acceptable - and much better in terms of longevity than 72 deg - and the 400mcase will look more attractive than a 500mm deep case!

* buy a 400mm deep case - rather than a 500 deep case (which, yes, would run at lower heatsink temperatures)

* and re-arrange my layout.

Life is always a compromise and it seemed to me that, from Vunce's AN 8R data ... sure, my heatsinks will not be at 50 deg (with my extra heat load) - but by being a bit more careful of where I position the AN 4R's output devices, I should be able to reduce the current 72 deg (with the 300mm deep case) to around 60 deg with a 400mm case.

That will be acceptable - and much better in terms of longevity than 72 deg - and the 400mcase will look more attractive than a 500mm deep case!

I was thinking about running 2 18 gauge Drain lines On Alpha Nirvana Board to the Snubber boards since they have 2 Drain connectors On each of them that is we’re the most current is,

Any thoughts?

Thanks

Scott

Any thoughts?

Thanks

Scott

An 18AWG wire for chassis wiring can carry at most 16 amps. (2) 18 AWG wires = 12 AWG which can carry at least 30 amps of current.

It’s up to you. The single 18 AWG is probably enough for an Alpha Nirvana amp that is low powered anyway. It isn’t a high powered Class AB amp however, it is a single ended Class A with quiescent current recommendations of at least 1.3-1.7A for 8 ohm builds and 2-3A for 4 ohm builds.

I would use 18AWG or ”as big as you can fit” wire for the source pins which is the amplifier signal output.

I recommend stranded wire for both as it is more flexible than solid wire which can be strained. Remember, this is all inside on an enclosure that gets very warm.

A hint with regards to how thick of a wire one needs is to look at the MOSFET pins themselves and the data sheet. The diameters of the pins are listed, and there is a reason why they are a certain thickness.

Best,

Anand.

It’s up to you. The single 18 AWG is probably enough for an Alpha Nirvana amp that is low powered anyway. It isn’t a high powered Class AB amp however, it is a single ended Class A with quiescent current recommendations of at least 1.3-1.7A for 8 ohm builds and 2-3A for 4 ohm builds.

I would use 18AWG or ”as big as you can fit” wire for the source pins which is the amplifier signal output.

I recommend stranded wire for both as it is more flexible than solid wire which can be strained. Remember, this is all inside on an enclosure that gets very warm.

A hint with regards to how thick of a wire one needs is to look at the MOSFET pins themselves and the data sheet. The diameters of the pins are listed, and there is a reason why they are a certain thickness.

Best,

Anand.

Hi guys,

Does C121/0 on back of board need to be populated even though there is a through hole in that C122 location but they are of different values and that location on back is circled instead of open end markings

That leads me to believe it is not optional but should be used.

Any thoughts?

Does C121/0 on back of board need to be populated even though there is a through hole in that C122 location but they are of different values and that location on back is circled instead of open end markings

That leads me to believe it is not optional but should be used.

Any thoughts?

Attachments

If you have the through hole part already installed on the other side then you don’t need it. It’s got options for people who like to use SMT equivalents.

Thanks X.

I am trying to dial this thing in vocals are a bit to bright and fatiguing for my taste.

Nice punch but to much upper end.

Maybe it just needs a good long burn in.

Tried 3 different input caps, I wonder if I used the npo cog in place of the 2 silver micas

And maybe a Silmic 470uf in place of the Muse would help?

Scott

I am trying to dial this thing in vocals are a bit to bright and fatiguing for my taste.

Nice punch but to much upper end.

Maybe it just needs a good long burn in.

Tried 3 different input caps, I wonder if I used the npo cog in place of the 2 silver micas

And maybe a Silmic 470uf in place of the Muse would help?

Scott

Last edited:

Hi Scott,

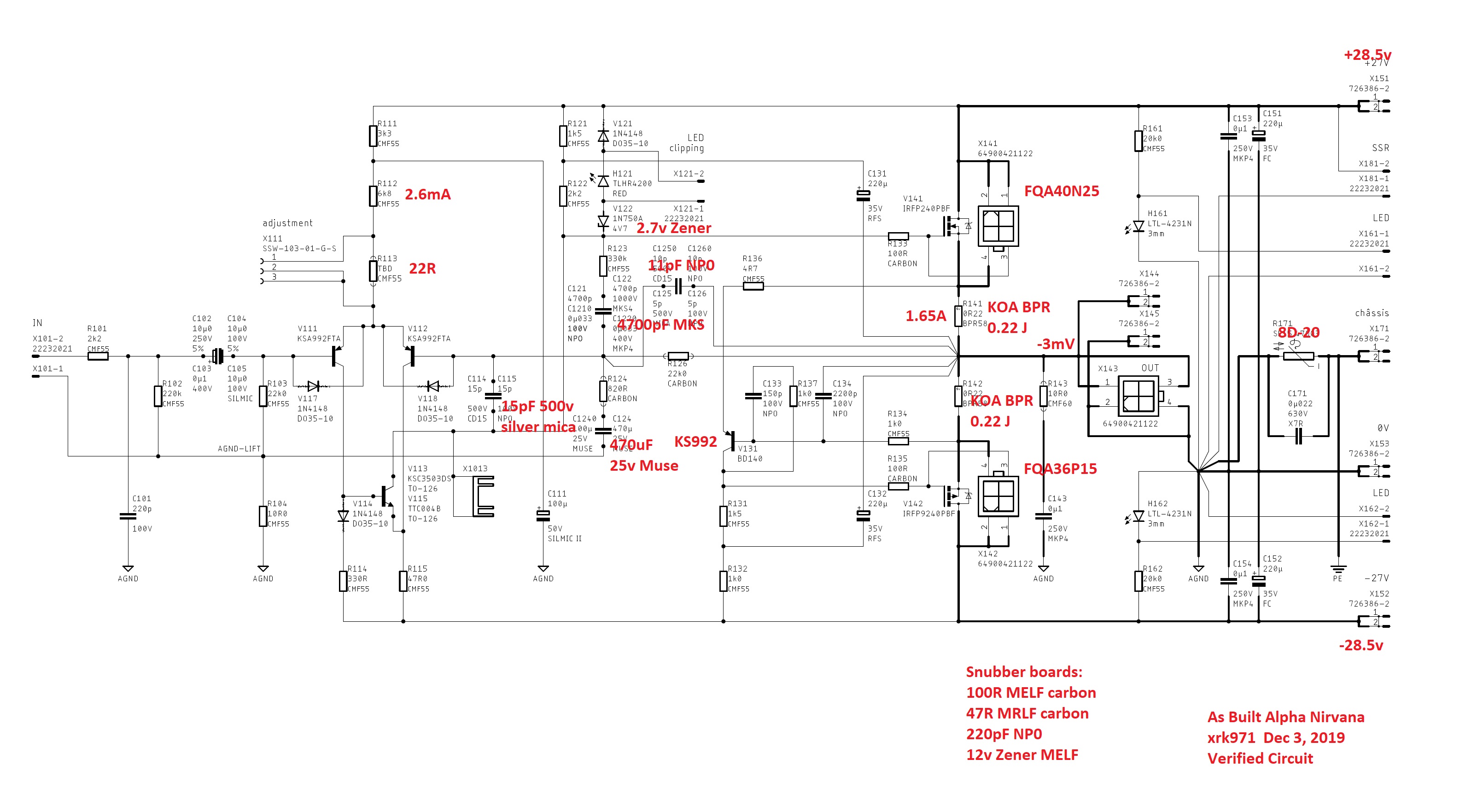

The Alpha Nirvana, if buil properly, is anything but fatiguing. So if it sounds harsh, there may be an issue with it perhaps oscillating at ultrasonic frequencies. Can you show us a close up photo of the top side and bottom side?

The critical cap here is C125/126 or C1250/C1260. Nominally 10pF but maybe try 15pF silver mica or NP0. If you are using 5pF that may be too low.

Other important one is C114/115 and needs to be 15pF NP0 or silver mica.

These are the keys to the sound being just right with dynamics and liveliness but not fatiguing.

The Alpha Nirvana, if buil properly, is anything but fatiguing. So if it sounds harsh, there may be an issue with it perhaps oscillating at ultrasonic frequencies. Can you show us a close up photo of the top side and bottom side?

The critical cap here is C125/126 or C1250/C1260. Nominally 10pF but maybe try 15pF silver mica or NP0. If you are using 5pF that may be too low.

Other important one is C114/115 and needs to be 15pF NP0 or silver mica.

These are the keys to the sound being just right with dynamics and liveliness but not fatiguing.

Yeah C126 right now is 5pf Silver Mica That is what the BOM called for

But I could throw a cog 15pf on there

As I have no extra 15pf Silver Mica.

Scott

But I could throw a cog 15pf on there

As I have no extra 15pf Silver Mica.

Scott

- Home

- Amplifiers

- Solid State

- Alpha Nirvana 39w 8ohm Class A Amp