+3 on the graphite!

I was thinking Hibachi Mauve

, but Graphite works, I guess...

, but Graphite works, I guess... Fantastic work on those! I am eager to listen vicariously.

I like the white... wnder if they glow in the dark?

dave

Ahhh. The days of blacklights

Ahhh. The days of blacklights

Using one as a nightlight in my office... dug it out to look at Bernie's solid locust cabinets.

dave

Hi Guys,

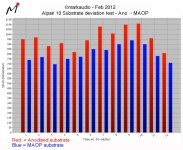

Keeping you updated regarding testing. For the first time, I'm revealing some of my cone development tradecraft. Take a look at the attached Substrate deviation graph.

Please DON'T copy, re-post or re-distribute this graph from this post. Its ©Markaudio and must remain in the Markaudio section of this forum.

It illustrates the amount of physical substrate surface deviation from a static position (above mechanical oscillation) between an Alpair 10 standard Anodized cone (red bars) and an MAOP cone (blue bars) while under a given load set.

The test cones were housed in complete drivers using the current components. This includes the current Alpair 10 rectangle coil and the latest Matsubara san spider. Both drivers were measured prior to the deviation test being matched @ +/-0.1bB output anechoic. The input signal in the deviation test was generated from a CD (Naxos) that combined vocal and instrumental in a measured range from 2700Hz to 5750Hz.

So there's no confusion, this is a micro-measurement of part of the mechanical property set (while under load) of each test cone. It is NOT a frequency test. This work is from my own isolation lab.

As expected, the MAOP substrate has an damping effect, reducing the amount of surface deviation. In particular, what's most noticeable is the overall "smoothing" of the output from the MAOP cone compared to the standard version. This is to expected and confirms the feedback coming from Japan:

http://blog.fidelitatem-sound.com/?p=383

http://blogs.yahoo.co.jp/linfof/61108074.html

http://masahi.cool.ne.jp/linfofbbs/joyful/joyful.cgi?list=pickup&num=8514

Now fellas, what does this particular micro-measurement tell us: MAOP cones will deliver a bit flatter response, helping to iron out some of the more "peaky" CD's or digital source music in your collection, or anyone with a "bright" amp also may benefit. If you're into wanting a more "concert like" rendition, the MAOP coned drivers would be an interesting choice.

Certainly from my engineering perspective, MAOP cones are performing much as predicted. As with so many things audio, beauty is in the ears of each individual beholder. If you chose to buy a pair of MAOP drivers, you can be satisfied with the knowledge that each pair of drivers will be personally built and checked by Kita san, Taniguchi san, Evan Yu or myself. Each cone set is matched, along with all the other components. Each driver set will be signed off by the these guys and me for the pairs I make.

Cheers

Mark.

Keeping you updated regarding testing. For the first time, I'm revealing some of my cone development tradecraft. Take a look at the attached Substrate deviation graph.

Please DON'T copy, re-post or re-distribute this graph from this post. Its ©Markaudio and must remain in the Markaudio section of this forum.

It illustrates the amount of physical substrate surface deviation from a static position (above mechanical oscillation) between an Alpair 10 standard Anodized cone (red bars) and an MAOP cone (blue bars) while under a given load set.

The test cones were housed in complete drivers using the current components. This includes the current Alpair 10 rectangle coil and the latest Matsubara san spider. Both drivers were measured prior to the deviation test being matched @ +/-0.1bB output anechoic. The input signal in the deviation test was generated from a CD (Naxos) that combined vocal and instrumental in a measured range from 2700Hz to 5750Hz.

So there's no confusion, this is a micro-measurement of part of the mechanical property set (while under load) of each test cone. It is NOT a frequency test. This work is from my own isolation lab.

As expected, the MAOP substrate has an damping effect, reducing the amount of surface deviation. In particular, what's most noticeable is the overall "smoothing" of the output from the MAOP cone compared to the standard version. This is to expected and confirms the feedback coming from Japan:

http://blog.fidelitatem-sound.com/?p=383

http://blogs.yahoo.co.jp/linfof/61108074.html

http://masahi.cool.ne.jp/linfofbbs/joyful/joyful.cgi?list=pickup&num=8514

Now fellas, what does this particular micro-measurement tell us: MAOP cones will deliver a bit flatter response, helping to iron out some of the more "peaky" CD's or digital source music in your collection, or anyone with a "bright" amp also may benefit. If you're into wanting a more "concert like" rendition, the MAOP coned drivers would be an interesting choice.

Certainly from my engineering perspective, MAOP cones are performing much as predicted. As with so many things audio, beauty is in the ears of each individual beholder. If you chose to buy a pair of MAOP drivers, you can be satisfied with the knowledge that each pair of drivers will be personally built and checked by Kita san, Taniguchi san, Evan Yu or myself. Each cone set is matched, along with all the other components. Each driver set will be signed off by the these guys and me for the pairs I make.

Cheers

Mark.

Attachments

Last edited:

Hi Mark,

So just to understand this a bit better, is the vertical axis a measure of deflection from what would be perfect rigidity?

Hi Simon,

Ummmmmph, "perfect rigidity", that's rather another design issue, not primarily related to this test as we're in the resonant phase of cones operation in this instance. This vertical axis is a measurement outcome made from the cone's non-excited static position.

The MAOP cone is made using the same Mutliform process and the same base alloy as the standard cone. Effectively, both MAOP and standard cones are the same apart from the application of the surface treatment. Structural base rigidity remains effectively the same for both types of cone.

The purpose of issuing this particular test outcome was it illustrates a measurable difference in the micro-reonant output properties of MAOP when compared to traditional alloy coatings.

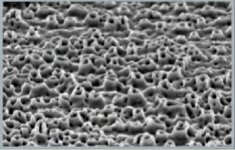

Possibly some of the potential confusion is in the understanding and application of a MAOP for mechanical-acoustic transmissive purposes. In the case of MAOP, this particular process chemically converts the boundary surface layer of the cone's alloy into a crystalline structure (see pic). Such a structure exerts a markedly different displacement value on the cone boundary layer to that of traditional coatings. From the pic (MAOP surface layer magnified), you can observe the porous nature of the structure. Effectively, its acting a bit like a sponge, its pores absorbing part of the resonant pattern traveling out across the cone. Thus its influence on the transmissive property of a cone in the resonant phase is measurably different to standard cones.

I haven't had time to measure at lower frequencies where the driver's power-train is mechanically oscillating. I do have rig for this but wey more time consuming and I'm pretty sure the audible differences in the LF region will be markedly less noticeable.

The limitation of this particular test is that it applies to 1 location on the cone and is limited to 1 set of non-linear frequencies. All the same, it is a fair indication of the difference in output from MAOP and standard cones.

I'm pretty much confirming what is intuitively known by many Diyer's, that coatings of various kinds may likely apply what may be best described as a "damping effect" on a cone's output. The really interesting question for me as a driver designer, is how mechanically efficient is MAOP and what losses occur under various loads? Given that MAOP is a conversion process rather than a coating process, how good does it sound compared to other cones? This last question is much in the hands of custom builders and end-users, hence the significant amount of listener input currently happening in Japan with the MAOP genesis pair of drivers.

Thx

Mark.

Attachments

Last edited:

Alp 10 MAOP LATEST NEWS

Hi Guys,

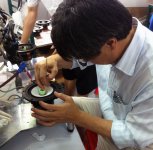

Bringing you up to date on MAOP. The first batch were completed last month. Please see the pics of the white and graphite drivers, these illustrate the actual production units.

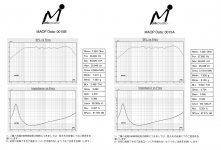

Paired serial Numbers 0001 to 0026 (26 pairs) were completed by Evan Yu and Jeff Taniguchi san. Each pair was personally built, tested and matched by these 2 engineers. Each pair is personally signed by these 2 engineers. Individual data sheets are printed for each driver and serial number to the matched pairs. The quality produced by these guys is impeccable.

All 26 pairs were pre-sold. The bulk of production (19 pairs) was pre-purchased by the main dealers in Tokyo and Osaka in Japan. 4 pairs were purchased by Tony Wong (Twin Audio) in Hong Kong. The remaining 2 pairs were purchased by private audio collectors on Hong Kong Island and the remaining pair is reserved for a beta tester in Europe.

Plans to make further pairs are likely to go ahead. Possibly we might build another 10 pairs next month. Please contact your dealer, ask them to contact me directly. Any difficulties, please email me: support@markaudio.com

Cheers

Mark.

Hi Guys,

Bringing you up to date on MAOP. The first batch were completed last month. Please see the pics of the white and graphite drivers, these illustrate the actual production units.

Paired serial Numbers 0001 to 0026 (26 pairs) were completed by Evan Yu and Jeff Taniguchi san. Each pair was personally built, tested and matched by these 2 engineers. Each pair is personally signed by these 2 engineers. Individual data sheets are printed for each driver and serial number to the matched pairs. The quality produced by these guys is impeccable.

All 26 pairs were pre-sold. The bulk of production (19 pairs) was pre-purchased by the main dealers in Tokyo and Osaka in Japan. 4 pairs were purchased by Tony Wong (Twin Audio) in Hong Kong. The remaining 2 pairs were purchased by private audio collectors on Hong Kong Island and the remaining pair is reserved for a beta tester in Europe.

Plans to make further pairs are likely to go ahead. Possibly we might build another 10 pairs next month. Please contact your dealer, ask them to contact me directly. Any difficulties, please email me: support@markaudio.com

Cheers

Mark.

Attachments

-

Evan-MAOP-1.jpg151.6 KB · Views: 332

Evan-MAOP-1.jpg151.6 KB · Views: 332 -

Jeff-san-MAOP-1.jpg130.2 KB · Views: 335

Jeff-san-MAOP-1.jpg130.2 KB · Views: 335 -

Alp-10_MAOP-White-2.jpg81.7 KB · Views: 330

Alp-10_MAOP-White-2.jpg81.7 KB · Views: 330 -

Alp-10-MAOP-white-4-sml.jpg80.1 KB · Views: 160

Alp-10-MAOP-white-4-sml.jpg80.1 KB · Views: 160 -

Alp10-MAOP-Graphite-2-sml.jpg88.8 KB · Views: 165

Alp10-MAOP-Graphite-2-sml.jpg88.8 KB · Views: 165 -

Alp10-MAOP-Graphite-4-sml.jpg90.2 KB · Views: 159

Alp10-MAOP-Graphite-4-sml.jpg90.2 KB · Views: 159 -

0015AB.jpg151 KB · Views: 173

0015AB.jpg151 KB · Views: 173

Last edited:

How do we arrange to buy a pair? Also, It stands to reason that the 7.3 may benefit in an even greater way that the 10.2 from this process. Have you considered it as a possible MAOP version?

Hi Buzz,

Talk to Brian at Madisound. If they don't want to handle the sale, contact me directly.

I've been considering an Alpair 7 MAOP but no plans yet to make them. It doesn't stand to reason that a 7 MAOP will automatically work. I only wish low mass full range driver making were so simple. I'll be dong allot of testing before a let a 7 MAOP on the market. Given the staggering cost of the cones and the potential high reject rates, I'll be thinking hard before committing to any new MAOP drivers.

Cheers

Mark.

Last edited:

Hi Boris,

Alpair 10 MAOP will be demoed in Tuen Mun later.

Thanks,

Tony.

Alpair 10 MAOP will be demoed in Tuen Mun later.

Thanks,

Tony.

Mark, will they be demoed in Tony's showroom in Tuen-mun?

Hi Buzz, John,

Guys, we're taking about CUSTOM drivers.

The MAOP process is mighty costly, reject rates are high. The cones and cap sets are individually balance moulded before going through MAOP, getting the mass tolerance with +/-2.25% (net g). The Japanese coils are all custom with a price tag to match. They aint pushed off a line by a 19 year old kid pressing a button on a machine while talking to his mate on a mobile.

Evan and Jeff san bust their backs making these drivers. Each driver individually built, individually ran, individually anechoic tested then pair matched; Hour upon hours of work.

Naturally, you decide at the end of the day what to buy. But I can't give this level of technology and customisation away for basement money. 500 bucks is too low when working at this level.

Thanks

Mark.

Guys, we're taking about CUSTOM drivers.

The MAOP process is mighty costly, reject rates are high. The cones and cap sets are individually balance moulded before going through MAOP, getting the mass tolerance with +/-2.25% (net g). The Japanese coils are all custom with a price tag to match. They aint pushed off a line by a 19 year old kid pressing a button on a machine while talking to his mate on a mobile.

Evan and Jeff san bust their backs making these drivers. Each driver individually built, individually ran, individually anechoic tested then pair matched; Hour upon hours of work.

Naturally, you decide at the end of the day what to buy. But I can't give this level of technology and customisation away for basement money. 500 bucks is too low when working at this level.

Thanks

Mark.

Mark, will they be demoed in Tony's showroom in Tuen-mun?

Hi Boris,

Give Tony a call, as he might also play them at Kenneth's place in Fotan. Remember these are custom drivers, so won't sell cheap.

Cheers

Mark.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- More Vendors...

- Planet 10 hifi

- Alpair 10 Gen. MAOP Prototype TW-1