http://www.royann.ca/sva/KLH 10 Turntable.htm

I've checked out the original pics as well.

some observations :

Platter / subplatter is one piece and should be higher than 2lbs.

The subchassis is an extremely nice casting.

The main bearing is good,but needs inspecting for wear.

A ball bearing (or 2) should be involved at the bottom.

If 1 then perhaps the thrust pad pushes out through a

hole in the bottom of the bearing ? cannot really tell.

The arm is like the AR arm, a long horizontal bearing, the vertical

is difficult to tell but hopefully there is no free play vertically.

The arm appears to be quite decent, a bit of blutack in the slide

in headshell (cartridge carrier slides in) will make it fairly sound.

The electric cueing is exactly that.

Seems to have a solenoid of some sort - which may need

cleaning and re-greasing to get a smooth cueing action.

Given its a one piece platter/subplatter and the electronic speed

switching arrangements I am somewhat perplexed as to what

type of motor is fitted and what the electronics board does.

The Text on the motor would be useful.

🙂/sreten.

I've checked out the original pics as well.

some observations :

Platter / subplatter is one piece and should be higher than 2lbs.

The subchassis is an extremely nice casting.

The main bearing is good,but needs inspecting for wear.

A ball bearing (or 2) should be involved at the bottom.

If 1 then perhaps the thrust pad pushes out through a

hole in the bottom of the bearing ? cannot really tell.

The arm is like the AR arm, a long horizontal bearing, the vertical

is difficult to tell but hopefully there is no free play vertically.

The arm appears to be quite decent, a bit of blutack in the slide

in headshell (cartridge carrier slides in) will make it fairly sound.

The electric cueing is exactly that.

Seems to have a solenoid of some sort - which may need

cleaning and re-greasing to get a smooth cueing action.

Given its a one piece platter/subplatter and the electronic speed

switching arrangements I am somewhat perplexed as to what

type of motor is fitted and what the electronics board does.

The Text on the motor would be useful.

🙂/sreten.

Re: Sony was sent yesterday. I'll have to find the reciept...

Thanks Stew. Did you get that email?

The motor looks the same as the one in the AR turntable posted by sreten. Maybe it's OK? Anyway, i haven't tried it yet with the belt on to see well it copes with the heavy platter.

Nanook said:I gotta look closer at your pix though

Thanks Stew. Did you get that email?

The motor looks the same as the one in the AR turntable posted by sreten. Maybe it's OK? Anyway, i haven't tried it yet with the belt on to see well it copes with the heavy platter.

sreten said:

some observations :

Platter / subplatter is one piece and should be higher than 2lbs.

The subchassis is an extremely nice casting.

The main bearing is good,but needs inspecting for wear.

A ball bearing (or 2) should be involved at the bottom.

If 1 then perhaps the thrust pad pushes out through a

hole in the bottom of the bearing ? cannot really tell.

The arm is like the AR arm, a long horizontal bearing, the vertical

is difficult to tell but hopefully there is no free play vertically.

The arm appears to be quite decent, a bit of blutack in the slide

in headshell (cartridge carrier slides in) will make it fairly sound.

The electric cueing is exactly that.

Seems to have a solenoid of some sort - which may need

cleaning and re-greasing to get a smooth cueing action.

Given its a one piece platter/subplatter and the electronic speed

switching arrangements I am somewhat perplexed as to what

type of motor is fitted and what the electronics board does.

The Text on the motor would be useful.

Hi sreten,

The motor has this on it:

A.W.HAYDON COMPANY

A NORTH AMERICA PHILIPS COMPANY

US PATENT 3508091

SYNCHRONOUS MOTOR

VOLTS 115 HZ 60 1.5 WATTS

CAP 0.1 MFD ROT C.W.

RPM 300

J81317

The solenoid for the cueing clicks, so the coil is not open. I will try to find the time over the next few days to start disassembly. There really doesn't seem to be much to the cueing mechanism.

The tone arm is solid, with no free play - it moves only the way it should move (up-down pilot, side to side arc)

I'm probably wrong about the platter weight, as I'm not good at guessing. The shaft that extends down from the platter has a single ball bearing in the end. As to what is in the socket this fits in, I don't know yet.

As for wear, I'm not sure how much use this table has had. There is not much slack between the sleeve bearing in the socket and the shaft, and the shaft doesn' t show any signs of wear.

So it has some potential? Money well spent? Thanks again for finding it.

I want to start by systematically taking it apart and inspecting/cleaning the parts. Find the cueing malfunction and fix it.

Any other suggestions?

The motor in this table apparently is very similar to the AR, but unlike the AR the platter is a single piece. I had a similar table at one point and reinstalling the belt after tinkering required nothing more than a stiff piece of solid wire shaped as a hook to slip it over the motor pulley.

The main bearing arrangement looks a lot like the one used on the AR-XA. Should be a hardened steel plate at the bottom of the bearing well.

I am assuming there is a fork to slide the belt from one step to the other to change speeds.

I've seen one of these, although not in the recent past. My impression at the time was it was a competent performer. AR and KLH are closely related, Henry Kloss founded KLH somewhat later, and was a co-founder at AR IIRC. It would not surprise me in the least if the designer of both tables was the same individual. (Sadly although I live near the original homes of AR, KLH, and HH Scott there is nothing really comparable going on around here today. Grado in Brooklyn NY is one of the very last holdouts from that era.)

The main bearing arrangement looks a lot like the one used on the AR-XA. Should be a hardened steel plate at the bottom of the bearing well.

I am assuming there is a fork to slide the belt from one step to the other to change speeds.

I've seen one of these, although not in the recent past. My impression at the time was it was a competent performer. AR and KLH are closely related, Henry Kloss founded KLH somewhat later, and was a co-founder at AR IIRC. It would not surprise me in the least if the designer of both tables was the same individual. (Sadly although I live near the original homes of AR, KLH, and HH Scott there is nothing really comparable going on around here today. Grado in Brooklyn NY is one of the very last holdouts from that era.)

kevinkr said:

...and reinstalling the belt after tinkering required nothing more than a stiff piece of solid wire shaped as a hook to slip it over the motor pulley.

The main bearing arrangement looks a lot like the one used on the AR-XA. Should be a hardened steel plate at the bottom of the bearing well.

I am assuming there is a fork to slide the belt from one step to the other to change speeds.

Hi Kevin,

I installed the belt tonight to give it a spin. There are two holes in the platter that line up with the motor pulley. Using a nail, I was able to get the belt in the pulley.

There is no speed change mechanism, it appears this needs to be done manually, in the same way I installed the belt. Not very convenient, but I don't own a single 45 so it won't bother me.

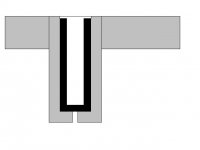

There is a small hole in the bottom of the aluminum casting where the bearing socket is. It looks to me like (I used a flashlight) the bearing is a solid one piece affair and the hole is there so it can be driven out. I have atached a crude graphic - the black u-shaped thing is the bearing.

Attachments

MJL21193 said:

The motor has this on it:

A.W.HAYDON COMPANY

A NORTH AMERICA PHILIPS COMPANY

US PATENT 3508091

SYNCHRONOUS MOTOR

VOLTS 115 HZ 60 1.5 WATTS

CAP 0.1 MFD ROT C.W.

RPM 300

J81317

Now I am perplexed. The buttons on the front appear to be

for speed change. There are two buttons marked 33 and 45.

Above are marked POWER and below are marked PUSH.

Given you have one piece platter manual speed change is

not an option.

So how does it work !? I'm lost because there is no simple

way of switching the speed of a synchronous motor, i.e.

you cannot adjust voltage or current to change speed.

Does the motor pulley only have one size, if so very confused ....

If it it has two sizes then there must be have been another solenoid ....

MJL21193 said:

So it has some potential? Money well spent?

Any other suggestions?

Hi,

Absolutely, oh yes especially if the retroness also appeals.

.....but five minutes of listening was enough to prompt me to deep six that Mitsubishi.

The AR absolutely creamed the fancy Japanese table sonically -

I've built/rebuilt/modded around ten similar turntables and if

sympathetically rebuilt and modded and all is working (e.g. motor

is not worn out) as it should then you can confindently expect an

even better (after suggested tweaks/mods) repeat performance.

Whilst not being the last word in neutrality or coloration what

it will do everywhere else most turntables will not come close.

Given information I will have plenty of suggestions as to

how to tweak the performance without going over the top.

Do you intend to repair (missing veneer) the plinth or new plinth ?

Can you get hold of spray bitumen based car underseal ?

An externally hosted image should be here but it was not working when we last tested it.

This will be your major friend in tweaking the turntable because

basically no modifications (e.g. a new subchassis) are not required.

🙂/sreten.

sreten said:

Now I am perplexed. The buttons on the front appear to be

for speed change. There are two buttons marked 33 and 45.

Above are marked POWER and below are marked PUSH.

Given you have one piece platter manual speed change is

not an option.

So how does it work !?

Given information I will have plenty of suggestions as to

how to tweak the performance without going over the top.

Do you intend to repair (missing veneer) the plinth or new plinth ?

Can you get hold of spray bitumen based car underseal ?

Hi,

The motor pulley is double, two sizes. The belt has to be manually moved from one groove to the other.

The buttons on the front are "on", "off", "cue up, "cue down".

The undercoat is to damp the sheet metal deck?

I will completely replace the plinth with a solid hardwood (not sure what type yet). Do you recommend leaving the bottom open or closing it?

Any suggestions to restore/improve this TT would be much appreciated.

Hi,

JFI the creamed Mitsubishi is above.

OK, what I assumed was 33/45 is in fact ON/OFF.

Well 33 only then. Setting up to work well with both speeds can

be a pain (the belt keeps falling off on the lower pulley, and if you

raise the motor too high it limits the suspension travel) as you

have no 45's simply do not buy any.

I would assume only the thrust pad can be pushed out from the bottom.

If so if it comes out relatively easily it should be inspected for wear.

The ball bearing may be "stuck" to the shaft - if there are no signs

of wear then this can be left as is.

Everything obviously needs cleaning and re-oiling / greasing.

Cleaning up the wiring and possibly replacing some components.

Try the AR forum at vinylengine.com for advice on oiling the motor.

The bitumen spray can be used pretty every, on the topplate,

the subchassis, the springs and the platter. A bottom plate

(with holes for the main bearing and the adjustment points

(using a nut runner) and four soft rubber feet are needed.

An externally hosted image should be here but it was not working when we last tested it.

I'd make the bottom plate out of hardboard sprayed with the

bitumen used to attach aluminium foil to both sides and topped

off with another layer of bitumen.

Modding arms is a delicate operation and depends on how easily

it comes apart. If it does not, not to worry. If it does then all

joints should be epoxied. Possibly some damping tubing

inserted into the arm tube if none exists.

The top can be resprayed if necessary.

Phono sockets + earth post and mains socket added to the plinth.

Move the arm rest ?

Cartridge choice : if the arm is fairly lightweight alloy tube and

the headshell plastic is not too chunky then a good choice is :

Search e-bay for AT92E - $50 cartridge for $20.

(note : need to checlk non-adjustable arm height.)

Is the arm tube marked for tracking force ?

What does it indicate at 0.4 of the arm tube length ?

The stock mat is perfectly usable - it does seem not quite the

full 12" and consequently would be difficult to replace unless

the sound of a felt mat is preferred.

Also needed for best performance is a rigid lightweight

stand for solid floors or wall shelf for suspended floors.

The shelf can be drilled for nut runner access.

plenty to chew on .......

🙂/sreten.

Hi Sreten,

Never thought I would see one of those again, and wouldn't want to in person... 😀

The headshell is not original, other than than that it looks exactly like the one so quickly disgraced by the $25 AR-XA.. I paid over $300 for that DP-EC7 in the early 1980s.. Tack on the cost of a midrange Ortofon cartridge which was IIRC an LM20H and you are around $450. The AR was both much older and a lot cheaper than that Mitsubishi.

I really aspired to a TD-150 at the time, but didn't have the funds. Now I own a TD-125MKI which I have restored and a TD-124 soon to be on the way. (Which version I as yet don't know.)

Changing speeds on the old AR was a minor PITA, sounds like the KLH would be a bit more difficult.

I used synthetic motor oil on mine, but there are better oils out there now. Check Vinylengine for recommendations.

Never thought I would see one of those again, and wouldn't want to in person... 😀

The headshell is not original, other than than that it looks exactly like the one so quickly disgraced by the $25 AR-XA.. I paid over $300 for that DP-EC7 in the early 1980s.. Tack on the cost of a midrange Ortofon cartridge which was IIRC an LM20H and you are around $450. The AR was both much older and a lot cheaper than that Mitsubishi.

I really aspired to a TD-150 at the time, but didn't have the funds. Now I own a TD-125MKI which I have restored and a TD-124 soon to be on the way. (Which version I as yet don't know.)

Changing speeds on the old AR was a minor PITA, sounds like the KLH would be a bit more difficult.

I used synthetic motor oil on mine, but there are better oils out there now. Check Vinylengine for recommendations.

sreten said:

Modding arms is a delicate operation and depends on how easily

it comes apart. If it does not, not to worry. If it does then all

joints should be epoxied. Possibly some damping tubing

inserted into the arm tube if none exists.

The top can be resprayed if necessary.

Phono sockets + earth post and mains socket added to the plinth.

Move the arm rest ?

Cartridge choice : if the arm is fairly lightweight alloy tube and

the headshell plastic is not too chunky then a good choice is :

Search e-bay for AT92E - $50 cartridge for $20.

(note : need to checlk non-adjustable arm height.)

Is the arm tube marked for tracking force ?

What does it indicate at 0.4 of the arm tube length ?

The stock mat is perfectly usable - it does seem not quite the

full 12" and consequently would be difficult to replace unless

the sound of a felt mat is preferred.

I think I'll leave the arm alone, except to glue the head shell on(?) - it's very loose.

I took your advice, found that cartridge and bought it. It comes with an elliptical stylus.

The tube has lines on it, spaced about 1 inch apart but no numbers or other markings.

The mat is in good shape. The seller send a felt mat with it.

I'm looking forward to playing with this. 🙂

MJL21193 said:

I think I'll leave the arm alone, except to glue the head shell on(?) - it's very loose.

Do you mean the carrier or the slide ?

again photos would help but presumably the carrier is held onto

the arm with a screw from underneath You are saying that this

arrangement between carrier and arm tube is very loose ?

Buy all means then epoxy it but make sure its glued parallel to the platter.

Pictures of the slide / carrier arrange would be good.

What is the height to the mat with the arm tube level ?

MJL21193 said:I took your advice, found that cartridge and bought it. It comes with an elliptical stylus.

The TP4 body needs epoxying to the 1/2" carrier and then as the

epoxy gets thicker a goop of it should be applied between the

carrier and the cartridge body, to fill the obvious gap.

A 0.3 x 0.7 is pretty good for a bushed elliptical, most are 0.4 x0.7.

I've seen places charging $70 for it, at $20 it should be a steal.

Track at 1.6g +/- 0.1g.

MJL21193 said:

The tube has lines on it, spaced about 1 inch apart but no numbers or other markings.

One would assume these are spaced at 1 gram intervals.

MJL21193 said:

The mat is in good shape. The seller send a felt mat with it.

The felt mat supplied can be cleaned and cut to the correct size.

Then bitumastic spray the reverse side if you like, to keep it on.

Personally I'd expect the rubber mat to be the best, felt a bit livelier.

MJL21193 said:

I'm looking forward to playing with this. 🙂

Presumably your going to get it going to see what its like before

the full new plinth and bitumen spray nearly everywhere rebuild ?

If nothing goes wrong (early attempts) getting to the nitty-gritty

of what makes a turntable sound good and improving it, often for

peanuts, I found quite rewarding, the skill is in not overdoing it.

🙂/sreten.

sreten said:

Do you mean the carrier or the slide ?

Buy all means then epoxy it but make sure its glued parallel to the platter.

Pictures of the slide / carrier arrange would be good.

What is the height to the mat with the arm tube level ?

A 0.3 x 0.7 is pretty good for a bushed elliptical, most are 0.4 x0.7.

I've seen places charging $70 for it, at $20 it should be a steal.

Track at 1.6g +/- 0.1g.

Presumably your going to get it going to see what its like before

the full new plinth and bitumen spray nearly everywhere rebuild ?

Hi,

The carrier is loose on the shaft. There doesn't appear to be a screw in the bottom. The slide fits snug, but the wires that connect the cartridge are in rough shape - need to be re-soldered.

I have attached a picture.

The stylus is .3 x .7. I bought this for $14.95 plus shipping for a total of $21.00.

When I get the new cartridge, I'll give it a spin. If there is a problem with the motor, how hard are they to find? Would it be wise to replace with a different manufacturers motor, or should I stick with an original?

Attachments

Re: did u get the Sony?

Hi Stew,

No, I didn't get it yet. Email me with the cost please.

Nanook said:let me know when it arrives. email me direct if you prefer

Hi Stew,

No, I didn't get it yet. Email me with the cost please.

I received the new cartridge and gave the KLH a spin. I have one problem though - the phono amp in my old Pioneer is not working properly. It seems to be a bad connection on the selector switch, when i jiggle it the left channel cuts in and out. Normal state is one channel working.

I'll need to put together a pre amp.

On a positive note, the table seems to play fine, the motor gets the heavy platter up to speed quickly.

I'll need to put together a pre amp.

On a positive note, the table seems to play fine, the motor gets the heavy platter up to speed quickly.

MJL21193 said:I received the new cartridge and gave the KLH a spin. I have one problem though - the phono amp in my old Pioneer is not working properly. It seems to be a bad connection on the selector switch, when i jiggle it the left channel cuts in and out. Normal state is one channel working.

I'll need to put together a pre amp.

On a positive note, the table seems to play fine, the motor gets the heavy platter up to speed quickly.

Maybe you can fix the switch, give it a good cleaning & check contact alignment.

A dedicated high quality diy phono stage is a really good investment over the long term.

Hi Kevin,

I went ahead and built the one on Rod Elliot's site:

http://sound.westhost.com/project06.htm

I used NE5532's for the op-amps. Sounds very good.

I guess you were refering to phono amp such as the ones on your site? The tube amps? Very nice. Does it make that much of a difference between solid state and tubes for this?

I went ahead and built the one on Rod Elliot's site:

http://sound.westhost.com/project06.htm

I used NE5532's for the op-amps. Sounds very good.

I guess you were refering to phono amp such as the ones on your site? The tube amps? Very nice. Does it make that much of a difference between solid state and tubes for this?

Hi John,

I wasn't specifically thinking of tube pre-amplifiers when I made the comment, but I do have a marked preference for tubes.. 😀

Should you feel so inclined I would recommend building a tube phono stage, and not necessarily one of my designs either. 😉 There will be lots of people to help out. The important thing is that any tube phono stage you choose be able to drive the relatively low impedance of your receiver line level inputs.

I wasn't specifically thinking of tube pre-amplifiers when I made the comment, but I do have a marked preference for tubes.. 😀

Should you feel so inclined I would recommend building a tube phono stage, and not necessarily one of my designs either. 😉 There will be lots of people to help out. The important thing is that any tube phono stage you choose be able to drive the relatively low impedance of your receiver line level inputs.

Well Kevin, I do have a multi tap toroid with dual 260V/26VA secondaries. Just need to be inspired.

Maybe a tube phono stage plus a tube input stage with a solid state output stage (toroid has dual 30-0-30/230VA).

Any thoughts / ideas?

Maybe a tube phono stage plus a tube input stage with a solid state output stage (toroid has dual 30-0-30/230VA).

Any thoughts / ideas?

Seems like a very good idea. Mosfet hybrids with beefy tube driver circuitry would seem to be the ticket. Enough power to run an integrated - all you would need is a filament supply which preferably would run off a small toroid.

Suitable candidates for driving mosfets would be 5687, D3A, etc.. Might want to consider a servo to keep the dc on the output to a minimum. Lots of heat sinking required for the outputs..

Just don't copy Counterpoint designs, the output mosfets fail instantaneously when shorted.

How skilled are you? 😀

Speakers?

Suitable candidates for driving mosfets would be 5687, D3A, etc.. Might want to consider a servo to keep the dc on the output to a minimum. Lots of heat sinking required for the outputs..

Just don't copy Counterpoint designs, the output mosfets fail instantaneously when shorted.

How skilled are you? 😀

Speakers?

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Alpage (Alpine) Turntable - Opinions?