Since you're using the hardwood, why don't you run hardwood 1/4 rounds up the corners?Coulomb said:

The cases are not finished, I have to do something with the corners. There will be a Hardwood trim on the bottom on the front and sides with the I/O on the lower back.

Regards

Anthony

roddyama said:

Since you're using the hardwood, why don't you run hardwood 1/4 rounds up the corners?

Well that's an Idea, though I do not want it to look Kitchy.

Anthony

Would that be something that looked like it came from Kitchener?🙂Coulomb said:

Well that's an Idea, though I do not want it to look Kitchy.

Anthony

roddyama said:

Would that be something that looked like it came from Kitchener?🙂

No more like over the top, almost to the point of being tacky.

Anthony

Sorry Anthony, I knew that, I was just kidding.Coulomb said:

No more like over the top, almost to the point of being tacky.

Anthony

You could use structural aluminum angle in the corners and anodize them to a color that suits your taste. The large radii of the structural angle will help to give it that "finished" look.

Coulomb,

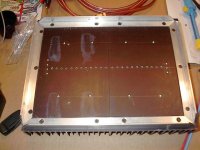

from what I can see I would rate your enclosure for 300W maybe 350W f anodized black. So I don't know if 8amp 27V is going to work. There is something to be said about putting 4 heatsinks with relatively thinly spaced fins in close proximity.

I would experiment first.

from what I can see I would rate your enclosure for 300W maybe 350W f anodized black. So I don't know if 8amp 27V is going to work. There is something to be said about putting 4 heatsinks with relatively thinly spaced fins in close proximity.

I would experiment first.

roddyama said:

Sorry Anthony, I knew that, I was just kidding.

You could use structural aluminum angle in the corners and anodize them to a color that suits your taste. The large radii of the structural angle will help to give it that "finished" look.

Yeah Rodd, that is more like what I was thinking.

🙂

Anthony

grataku said:Coulomb,

from what I can see I would rate your enclosure for 300W maybe 350W f anodized black. So I don't know if 8amp 27V is going to work. There is something to be said about putting 4 heatsinks with relatively thinly spaced fins in close proximity.

I would experiment first.

Grataku so you think that 100 Watts TOP per channel is the max this chassis will handle?

Anthony

I think you might be a little low on your estimate Grataku. Anthony's case is about the same width and depth as the Aleph 1.2 and it's a bit taller. It should do pretty good as 200wpc (~300 wpc @ 4ohms) monoblocks.grataku said:Coulomb,

from what I can see I would rate your enclosure for 300W maybe 350W f anodized black. So I don't know if 8amp 27V is going to work. There is something to be said about putting 4 heatsinks with relatively thinly spaced fins in close proximity.

I would experiment first.

The heatsinks as shown (not anodized) get pretty fricken hot. My AX chassis is about as big and at 250W the temp is around 55.

It should be good for an x160 clone, I think.

I would also advice to use perforated sheets for the top and bottom covers to let the stuff inside breathe. See the "cheff" post...

It should be good for an x160 clone, I think.

I would also advice to use perforated sheets for the top and bottom covers to let the stuff inside breathe. See the "cheff" post...

Regarding this spreadsheet.

x berekening-nania v3 b.zip

I thought the RMS output power was about half of the peak, not .707

Correct me if I'm wrong.

x berekening-nania v3 b.zip

I thought the RMS output power was about half of the peak, not .707

Correct me if I'm wrong.

Here is the comment from the author of the original spreadsheet on this version #3.labjr said:Regarding this spreadsheet.

x berekening-nania v3 b.zip

I thought the RMS output power was about half of the peak, not .707

Correct me if I'm wrong.

http://www.diyaudio.com/forums/showthread.php?postid=275874#post275874

Rms power = rms voltage x rms current = (peak voltage/ 2^0.5) x (peak current/2^0.5) = peak voltage x peak current / 2

william

william

Thanks Guys, I was thinking of a small intake fan at the bottom suing a temp sense circuit to control it's speed. I will Perforate the top as suggested.

See this link below if you want to see more pics of my work in progress. I am working on an awsome CD player you might find interesting. Will be posting more pics tonight.

Thanks

Anthony

http://24.70.80.252/gallery/view_album.php?set_albumName=album04

See this link below if you want to see more pics of my work in progress. I am working on an awsome CD player you might find interesting. Will be posting more pics tonight.

Thanks

Anthony

http://24.70.80.252/gallery/view_album.php?set_albumName=album04

Instead of perfing the top, consider drilling small holes in the base of the heat sinks near the middle (of hieght) to exaust air through heat sinks and in effect give you forced air cooling rtheta numbers for the sinks.

That's what I did with my oversized Aleph 2. I haven't ran them with the case closed yet to see how much of a difference it makes, but It sounds good in theory.

The four holes on top and bottm row are for fets, The row in the middle is exaust holes, the thre and four on the sides are for turret terminals to hold busses.

That's what I did with my oversized Aleph 2. I haven't ran them with the case closed yet to see how much of a difference it makes, but It sounds good in theory.

The four holes on top and bottm row are for fets, The row in the middle is exaust holes, the thre and four on the sides are for turret terminals to hold busses.

Attachments

Thanks Brian, I will contemplate your suggestion. On a side note, how does your spouse feel about you using the Dining room table to work on? 🙂

Regards

Anthony

Regards

Anthony

Brian Donaldson said:Instead of perfing the top, consider drilling small holes in the base of the heat sinks near the middle (of hieght) to exaust air through heat sinks and in effect give you forced air cooling rtheta numbers for the sinks.

You are joking, right? How did you come up with that idea?

You need LOTS of positive air flow to get forced air behavior, and flow needs to happen along the fins not across. I am not a fluid dynamic physicist but I have the feeling that the small holes do absolutely NOTHING at all.

For effective convection you needs lots of open space and constant air velocity.

Regardless of direction, airflow will increase dissapation. If for no other reason, Because I'll have cool air between the fins rather than the 160 deg air that is there now.

But the real reason for the fans is to keep the inside (electrolyc caps) cool. Two slabs of 160 deg aluminum and 4 slabs of around 120 deg aluminum will yeild 130 - 140 deg caps.

After I get the case closed, I'll post real measured data and you can decide for yourself. My guess is I can drop sink temp 15 to 20 deg without enough added noise to be noticed.

Check out the R Theta website's r theta calculator. You could reason that rtheta should be proportional to size, but it's not because adjacent fins heat the air in the vacinity of their neighboring fins and decrease temp diff and adversly affect rtheta. But by moving fresh air in, you can reduce that effect.

Grataku,

You are correct that I won't aproach forced air r theta numbers, but I would wager that a small amount of forced airflow through the holes in the sinks will inprove cooling by 50%.

PS that's what I do when she's out of town visiting her family😉

But the real reason for the fans is to keep the inside (electrolyc caps) cool. Two slabs of 160 deg aluminum and 4 slabs of around 120 deg aluminum will yeild 130 - 140 deg caps.

After I get the case closed, I'll post real measured data and you can decide for yourself. My guess is I can drop sink temp 15 to 20 deg without enough added noise to be noticed.

Check out the R Theta website's r theta calculator. You could reason that rtheta should be proportional to size, but it's not because adjacent fins heat the air in the vacinity of their neighboring fins and decrease temp diff and adversly affect rtheta. But by moving fresh air in, you can reduce that effect.

Grataku,

You are correct that I won't aproach forced air r theta numbers, but I would wager that a small amount of forced airflow through the holes in the sinks will inprove cooling by 50%.

PS that's what I do when she's out of town visiting her family😉

Hot air rises... so holes on the top cover too will help a lot to dissipate warm air to the amp's surroundings. Holes on the bottom plate will force some cold air into the box as the warm air rises. At least that's how I remember thermodynamics.

But if you're in TX during summer the noise of airconditioning will be louder than a fan

But if you're in TX during summer the noise of airconditioning will be louder than a fan

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- Aleph-X: High-Power Version