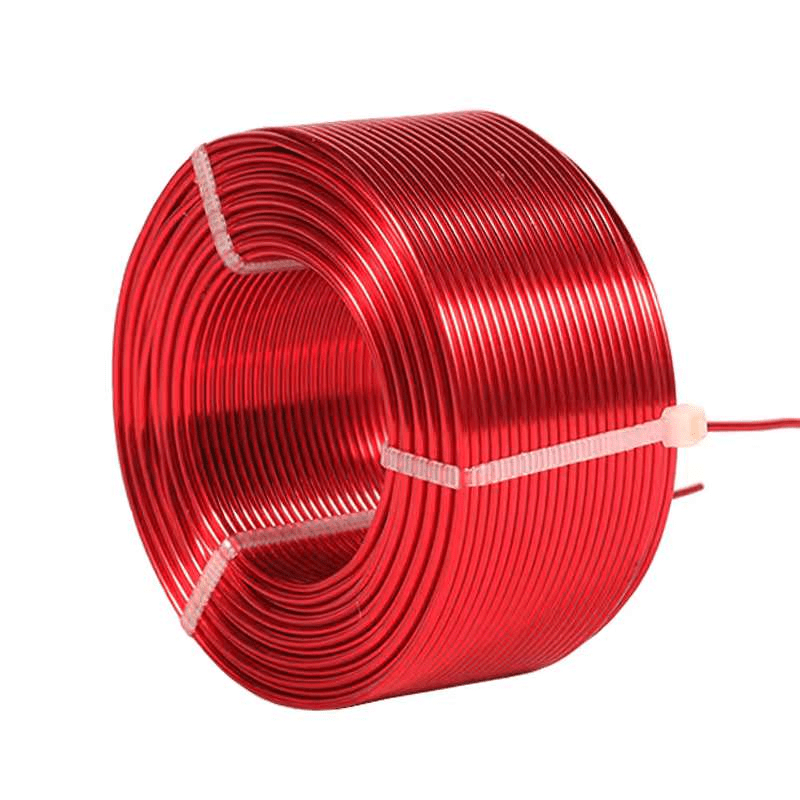

I found a company in China is able to custom made air coil inductor with vary DCR. I want to use this air coil type to replace the iron coil in the crossover. Any comments?

Watch out for losses due to proximity effect if you're hoping to use them beyond 1kHz or so. Also arrange multiple coils orthogonally to minimize interactions.

Assuming the copper quality is good and the DCR isn't drastically different, in my experience the air core chokes have been an upgrade over iron core in passive crossovers, especially in the mid and upper frequencies.

What level are caps are currently in place?

What level are caps are currently in place?

Itll be interesting to hear how much they 'sing' along vs those wound on cores. You can literally hear a tinny version of what's playing on a mates xo with air coils.

He ended up potting them.

He ended up potting them.

In case it is relevant to the discussion, Tubenstein wrote in his previous thread of replacing a 2 mH iron core inductor in the crossover of the bass section of his 3-way speaker.

The crossover has very poor electrolytic and film capable there.Assuming the copper quality is good and the DCR isn't drastically different, in my experience the air core chokes have been an upgrade over iron core in passive crossovers, especially in the mid and upper frequencies.

What level are caps are currently in place?

I'll upgrade to Vishay MKT1822.

However, still use iron coil for the bass.

nope. Only 1mH with air coil and the 2mH still has iron coil there but better quality use.In case it is relevant to the discussion, Tubenstein wrote in his previous thread of replacing a 2 mH iron core inductor in the crossover of the bass section of his 3-way speaker.

I wonder if there is a difference in the Q factor of the air core versus the iron core? This could hold some relevance at the knee/transition frequency.

Last edited:

You probably don't want to use those caps for that purpose...they are physically small, and probably can't handle the power they will need to, the ripple current rating probably isn't high enough, and there is a high probability in my opinion of damage or failure...and some caps fail to short circuit, and that would be bad. Something like this is way more appropriate:

Film and Foil Crossover Capacitors

Mike

Film and Foil Crossover Capacitors

Mike

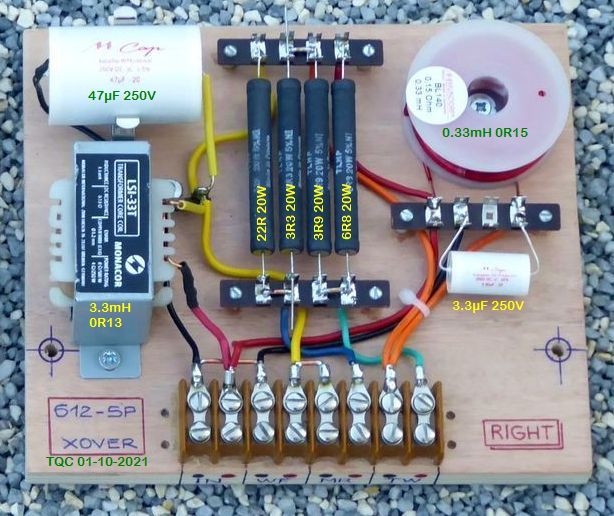

I use Iron-Core coil inductors when needed, the justification of that choice is the low RDC factor in high inductance value coils :

T

T

The OP is seeking to upgrade his 1 mH iron cored coil with an air cored one.

@Tubenstein:The DC resistance of the Chinese custom made air core coil should be as low as that of the iron core coil (typically around 0.2 ohm) in order not to alter the crossover function.

Would that be obtainable? You haven't given a link to the custom manufacturer so I can't see the specifications on offer.

Nor do we have we any information about your loudspeaker and its crossover circuit.

@Tubenstein:The DC resistance of the Chinese custom made air core coil should be as low as that of the iron core coil (typically around 0.2 ohm) in order not to alter the crossover function.

Would that be obtainable? You haven't given a link to the custom manufacturer so I can't see the specifications on offer.

Nor do we have we any information about your loudspeaker and its crossover circuit.

Last edited:

The Q of the air cored one will be different from that of the iron cored one. Benefit of the iron core is less DCR due to less wire required. It's a toss-up. An iron cored inductor can saturate when the iron is completely magnetized; the air core one will not saturate. Burn it out? Maybe. Saturate it? No.

The OP is seeking to upgrade his 1 mH iron cored coil with an air cored one.

I know, thank you. Just compare 3.3mH / 0.13R vs. 0.33mH / 0.15R you see on my picture posted above : DCR is similar, but L value is simply X10 for the Iron-Core... A 1mH Iron-Core inductance of " typically around 0.2 ohm" as you wrote is a poor one, as this is nearly what DCR you can expect from an Air-Core one of fair quality.

Assuming the Iron-Core is used for the Woofer, changing for an Air-Core that have nearly the same DCR will show no "upgrade". Only a lower DCR Iron-Core would bring a significant improvement on damping and transients.

T

The Q of the air cored one will be different from that of the iron cored one. Benefit of the iron core is less DCR due to less wire required. It's a toss-up.

Yes. And if it is for a Bass speaker, which usually requires higher L values, the advantage turns to the Iron-Core : the lower DCR is then the "upgrade" for a Woofer section, not switching to Air-Core... Unless you accept to put inside your speaker cabinet a flower pot-sized coil !

T

How about these two?You probably don't want to use those caps for that purpose...they are physically small, and probably can't handle the power they will need to, the ripple current rating probably isn't high enough, and there is a high probability in my opinion of damage or failure...and some caps fail to short circuit, and that would be bad. Something like this is way more appropriate:

Film and Foil Crossover Capacitors

Mike

https://partsconnexion.com/collecti...ucts/auricap-capacitor-2-7uf-200vdc-xo-series

https://partsconnexion.com/collecti...lized-polypropylene-film-capacitor-axial-lead

I know, thank you.

I wasn't actually referring to your post, but was summarising the OP's requirements since they were not fully stated in his opening post.

Thanks for your "0.2 ohm" correction.

It may be helpful to know that the OP would appear to have undertaken an unspecified 'upgrade' of the 2 mH iron core in the bass section of a 3-way speaker. In that case, the 1 mH iron core he now appears to want to 'upgrade' could belong elsewhere in the crossover

P.S. I wonder why he hasn't supplied any further information about his loudspeaker and its crossover in order that members have something concrete to work on?

The inductor Q, yes but to the filter Q it's more of a secondary concern. You'll notice this more if creating a deep notch, but who needs to do that with a speaker? We already take into account the resistance of coils and can effect adjustments.I wonder if there is a difference in the Q factor of the air core versus the iron core? This could hold some relevance at the knee/transition frequency.

The point is that we don't know what is the DCR of the actual 1mH cored coil. Many mfg use a cored coil instead of an air core one simply for cost saving purpose. Sometimes they choose wisely, sometimes not (the chosen coil will saturate or distort easily). If for peace of mind the OP wants to remove this possibility, my advice is to replace the actual cored coil with one that has a similar DCR (*), and with a 1mH coil this should be pretty easy.A 1mH Iron-Core inductance of " typically around 0.2 ohm" as you wrote is a poor one, as this is nearly what DCR you can expect from an Air-Core one of fair quality.

Just as an example compare 1mH air core and iron core coils from Jantzen Audio:

a 0.7mm wire cored has a DCR of around 0.4 Ohm, replace with 1.2mm wire air core (60g vs 250g)

a 1mm wire cored has a DCR of around 0.25 Ohm, replace with 1.6mm wire air core (100g vs 500g)

(*) The point is that changing significantly the DCR of a woofer coil will change the SPL of the whole woofer section, and this can be perceived easily.

Ralf

Dear Michael,You probably don't want to use those caps for that purpose...they are physically small, and probably can't handle the power they will need to, the ripple current rating probably isn't high enough, and there is a high probability in my opinion of damage or failure...and some caps fail to short circuit, and that would be bad. Something like this is way more appropriate:

Film and Foil Crossover Capacitors

Mike

When you say MKT1822 cannot handle the power, here is the circuit of the crossover I'm working on. You'll see 2.7uf and 4.7uf there.

https://www.diyaudio.com/community/attachments/1718276719004-png.1321475/

Any thoughts?

Thanks!

- Home

- Loudspeakers

- Multi-Way

- Air Coil Inductor replacing iron coil type