It is just curiosity nothing I need to know. Just trying to understand the basics better. Thought this would be an appropriate side question in this thread. If the velocity and Surface area are given it should be straight forward to calaculate the rms volume velocity and the average rms pressure for the throat area. So I try to understand why they choose a rather complicated method to obtain the results.With the velocity fixed the program solves for pressure. What else would you need to know?

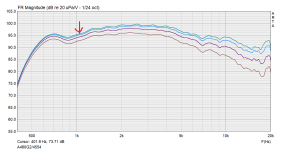

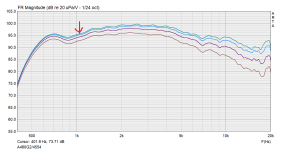

I see that now, probably was a little too tired. Just trying to discuss what the differences could be, not trying to critizise your work!:To me, smooth means simple. The less is going on regarding the radiation, the better. We're talking differences on the order of 1dB here (or even less), but it's obvious that there's something more going on in the case of 460 at least between 1 - 4 kHz; it's more complex, less smooth.

The polars shown were not taken at the exact same places, I just don't bother at this point. Actually, the radiation patterns of both should be virtually identical (i.e. including SPDI) down to 600 Hz or so.

The aspect ratio of the screenshots is a little different, the A460G2 being taller, that will not change a lot but will make small difference, the ripple will seem bigger in comparision.

I have found that a little different microphone positions and/or different windowsizes can have quiet an influence on smoothness. I do not know your process of measuring the DUTs but that might have intoduced the ripple.

I am not sure maybe it is due to the different aspect ratio or different mic positions but the A460 seems to be a little wider...

Did "we" ever establish the need for a perfect surface in real world measurements? I mean, there should be relation between an obstacles size and what frequency it cab have an impact on... Some polish their horns and think it is necessary for the best SQ.It's still without any surface finishing,

How is it really?

//

What I think: the wiggles start after a depression of the response compared to the 520 at just above 1 kHz. This extra energy causes the ripples. Whatever causes the depression of the frequency response, it kind of 'squeezes' this energy up into the midrange. Maybe it is just diffraction hitting there, idk.

Epoxy coating anyway. Since I measured a big increase of nonlinear distortion of a non-sealed printed adapter, I don't trust anything.

I will try some "additive" / non-destructive techniques first, to see if I can trace the effect somewhere around the mouth.

I will try some "additive" / non-destructive techniques first, to see if I can trace the effect somewhere around the mouth.

Hi

alex6679 and me had some discussions. Basically we have an idea how to let a adapter start in the DCX464 closely after the HF diaphragm without mechanically destroying anythin in the dcx (just an insert in the end). As first fit we tool the s140 BMS4552 profile adapter mabat posted. However the initial surface area is even less than at this adapter.

@mabat : is it possible to get a even more extended version of the bms4552 adapter drawing? Initial surface area is around 200mm^2.

alex6679 and me had some discussions. Basically we have an idea how to let a adapter start in the DCX464 closely after the HF diaphragm without mechanically destroying anythin in the dcx (just an insert in the end). As first fit we tool the s140 BMS4552 profile adapter mabat posted. However the initial surface area is even less than at this adapter.

@mabat : is it possible to get a even more extended version of the bms4552 adapter drawing? Initial surface area is around 200mm^2.

I'm not sure about polishing but I rather wouldn't have holes there, even if much smaller than the wavelengths. 🙂Some polish their horns and think it is necessary for the best SQ.

It's not so easy for me to change it. The current extension is already ~208 mm^2. Should it make a difference?@mabat : is it possible to get a even more extended version of the bms4552 adapter drawing? Initial surface area is around 200mm^2.

Last edited:

Opps... guilty as charged... I will see if I can fill the many small holes on my 52's...I rather wouldn't have holes there, even if much smaller than the wavelengths. 🙂

//

Forget my request. I misunderstood something. Maybe next week a custom adapter in print. Will share details asap

I'm curious about this as well - given that the exit angle of the DCX464 is essentially 0 degrees, how are you planning on making a smooth adaption inside the throat?

Hi

alex6679 and me had some discussions. Basically we have an idea how to let a adapter start in the DCX464 closely after the HF diaphragm without mechanically destroying anythin in the dcx (just an insert in the end). As first fit we tool the s140 BMS4552 profile adapter mabat posted. However the initial surface area is even less than at this adapter.

@mabat : is it possible to get a even more extended version of the bms4552 adapter drawing? Initial surface area is around 200mm^2.

Basically it is inside just a solid tube which contacts the outer surface of the wave-forming tube. So we keep the thorn and shape the cross section surface right after the HF diaphragm according to marcels adapter parameters. In front of the DCX we will make some connection for the rest of the adapter.

I will use.your 3D model from.my.scans then. Right now I want to get home from holiday 🤣. So need some.patience now

Pics as soon as.I get to CAD at home!

I will use.your 3D model from.my.scans then. Right now I want to get home from holiday 🤣. So need some.patience now

Pics as soon as.I get to CAD at home!

The adapter+driver covered with a blanket:

It's also possible that the bigger horn simply shields better from the sounds reflected from the things at the back.

This was not included in the BEM models.

It's also possible that the bigger horn simply shields better from the sounds reflected from the things at the back.

This was not included in the BEM models.

Last edited:

I suppose it is not only the surface texture that becomes more smooth after an epoxy layer but also the whole structure changes it mechanical properties moving low Q / level resonances around... perhaps?

//

//

So the rough version is a bit more directional?A460G2

Epoxy coating (a single layer, no sanding yet):

View attachment 1401225

Raw surfaces as printed/assembled:

View attachment 1401226

If that would be a general rule I think it is very interesting. And surprising. But I read it as you do....

//

//

Genuine question: with the right CD and one of Marcel’s G2 horns you can cover from c. 500hz up to more Khz than most of us can hear. With say a 2 way MEH you can probably get down to say 300hz. For the sake of another 200hz lower reach, is the MEH option really worth it, especially given the additional complexity / challenges posed by a MEH ?Hi mabat

my 4554s waited for them ;-)

But this week busy and then on vacation 😨. So have to wait a bit.

Still I think about best LF extension for a ATH project. What about adding some 4-5" LF drivers as MEH with XO @700Hz to the 4554 in a 460 or 520? 1/4 Distance with that XO frequeny seems pretty easy...

...and much more simple than my thoughts on modding a dcx464...

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)