I've been away from the thread for a while, but the Subject and the Hybrid Designs appearing certainly have kept my interest when browsing.

My interest in materials to be used that can offer improvements when used in conjunction with Audio Equipment lead me into investigating organic composites.

My main aim was to discover organic origin resins that could be substitutes for Phenolic and other Petro Chemical Industry origin resins, as a result, my investigations lead me to discovering Soy Based Resins 😎.

I soon learnt that Soy Resin was being used with organic fibres to produce pure organic origin composites, which then lead on to learning Formula 1 Motor Sport has adopted versions of organic origin composite materials.

Additional learning has suggested that the methods to create such materials are very difficult to patent and are not backed by the Petro Chemical Industries, hence their not exploding in to the mainstream, as had Carbon and Kevlar composites had when first produced.

The next discovery and one I thought might be off interest in this thread, especially one for the experimentalists to ponder, is that Fungi (Mycelium) is being used to produce organic origin foam boards.

Mycelium Foam Boards are broad in their densities and applications where they are selected to be used.

Certain densities are becoming a replacement for XPS Foam.

Mycelium is also being impregnated with Soy Resin to produce composites as well.

Mycelium Foam Boards also have Acoustic Properties that are being shown as advantageous, I would not know if this transfers to being a wanted property for a DML Panel.

The Link will give a much better picture.

I look forward to the first report on a Fungi DML 👍.

https://www.sciencedirect.com/science/article/pii/S0264127519308354

My interest in materials to be used that can offer improvements when used in conjunction with Audio Equipment lead me into investigating organic composites.

My main aim was to discover organic origin resins that could be substitutes for Phenolic and other Petro Chemical Industry origin resins, as a result, my investigations lead me to discovering Soy Based Resins 😎.

I soon learnt that Soy Resin was being used with organic fibres to produce pure organic origin composites, which then lead on to learning Formula 1 Motor Sport has adopted versions of organic origin composite materials.

Additional learning has suggested that the methods to create such materials are very difficult to patent and are not backed by the Petro Chemical Industries, hence their not exploding in to the mainstream, as had Carbon and Kevlar composites had when first produced.

The next discovery and one I thought might be off interest in this thread, especially one for the experimentalists to ponder, is that Fungi (Mycelium) is being used to produce organic origin foam boards.

Mycelium Foam Boards are broad in their densities and applications where they are selected to be used.

Certain densities are becoming a replacement for XPS Foam.

Mycelium is also being impregnated with Soy Resin to produce composites as well.

Mycelium Foam Boards also have Acoustic Properties that are being shown as advantageous, I would not know if this transfers to being a wanted property for a DML Panel.

The Link will give a much better picture.

I look forward to the first report on a Fungi DML 👍.

https://www.sciencedirect.com/science/article/pii/S0264127519308354

jmproject,You can see the three layers with the side view. This was the only board available where you could tell it had 3 layers.

I suppose my plan is to cut it in half, but, before I do anything, curious what the birch-ply veterans have to say. Cut in half? buy a second? are these better with a frame?

I think you will like the sound of your new panel. I know these panels well, if they are what I think they are. Are they labelled as "1/4" 2'x4' BIRCH"?

If so, take a very close look at the edges. You might be surprised to find that it is actually 5 plies, rather than 3! Yes, I saw your pictures and it sure looks like 3 ply, and the ones I have look the same, but actually have a very thin veneer on the two faces that is much thinner than the 3 obvious layers in the core. The face layers are on the order of about 10-15 mils thick, compared to the core layers which are each about 50 mils thick, so they are easy to miss when you look at the edge.

I suspect that the only Birch in these panels is actually those two skin layers, while the core layers are something cheaper. But that's not a bad thing, because whatever they use in the core is lighter than birch, so they have better efficiency than Baltic/Finnish/Russian birch plywood in which all the plies are Birch (and roughly equal thickness).

As you noted, they vary considerably in quality and appearance, so you really have to examine them closely. But if you can find a second nice one, you should buy it too. Then you can make a pair like I will describe in my next post.

Eric

jmproject,

I have made several prototypes using the Home Depot 1/4" Birch plywood (or similar plywood) that you bought yourself for Christmas. All were slight variations on the same basic design, which I highly recommend. I still have two of those prototypes assembled in my "lab" which are shown in the following pictures, and I use them frequently for testing and/or listening.

The panels are 14" x 48". So unfortunately you need two sheets to make a pair. You could try 12" wide (to get both panels from the same sheet), and it would probably sound good too, but you would lose some range at the bass end. Yes, they are on the large side, I know, but they sound great.

The frames are made of sturdy lumber. The two speakers pictured are made from 1"x6" and 1-1/4"x4" lumber, respectively, (actual dimensions, not nominal). For this design to work as intended, the frame needs to be rigid. I wouldn't use anything smaller than a nominal 1x4 (3/4 x 3-1/2). Also, as you can see, there is a brace across the back of the frame in the middle, which is also needed to keep the frame sufficiently rigid.

The third picture shows some cleats attached to the inside of the frame that are used to attach the brace for the exciter. The pictures also show a bunch of white squares on the back of the panels, which are actually just pieces of double sided tape that I used to attach exciters at various places for testing.

The panel is attached to the frame using a foam material with good damping properties. I have used several different materials, and am still frankly undecided as to which is the best. But a great choice that is easily available is the 3M Extreme double sided exterior mounting tape. And the nice thing is that you can get it from Home Depot when you go back to get the second panel!

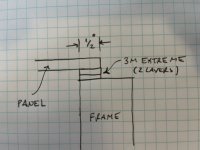

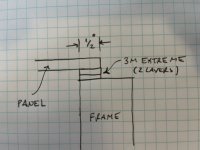

While there are more elegant ways to mount the panel to the frame, perhaps the most simple way is as shown in the sketch below. The 3M Tape comes 1" wide, but using the full width is too much constraint (almost like clamping) on the panel edge. Two stacked layers, each 1/2" wide, works great, providing minimal constraint but effective control of frequency spikes and "ringing" that otherwise occur from insufficient damping. For this arrangement, the inside dimensions of the frame should be 1" smaller than the panel's overall dimensions. The foam tape should go virtually around the entire perimeter of the panel. I like to stop the tape around 2" from each of the panel corners, but the only reason for that is to allow the possibility of removing the panel from the frame at some point. However, be aware that the 3M tape is really sticky and it's very difficult to remove without delaminating the layers of the plywood panel in the process.

Attach your favorite exciter to the panel and brace as necessary. The exciter location that typically works best for this design is to offset the exciter about 5" from center in the long direction and 1-1/2" to 2" across the short direction. I especially like the DAEX25FHE-4 or DAEX25VT-4, but probably others will work well too.

I hope you find this useful,

Eric

I have made several prototypes using the Home Depot 1/4" Birch plywood (or similar plywood) that you bought yourself for Christmas. All were slight variations on the same basic design, which I highly recommend. I still have two of those prototypes assembled in my "lab" which are shown in the following pictures, and I use them frequently for testing and/or listening.

The panels are 14" x 48". So unfortunately you need two sheets to make a pair. You could try 12" wide (to get both panels from the same sheet), and it would probably sound good too, but you would lose some range at the bass end. Yes, they are on the large side, I know, but they sound great.

The frames are made of sturdy lumber. The two speakers pictured are made from 1"x6" and 1-1/4"x4" lumber, respectively, (actual dimensions, not nominal). For this design to work as intended, the frame needs to be rigid. I wouldn't use anything smaller than a nominal 1x4 (3/4 x 3-1/2). Also, as you can see, there is a brace across the back of the frame in the middle, which is also needed to keep the frame sufficiently rigid.

The third picture shows some cleats attached to the inside of the frame that are used to attach the brace for the exciter. The pictures also show a bunch of white squares on the back of the panels, which are actually just pieces of double sided tape that I used to attach exciters at various places for testing.

The panel is attached to the frame using a foam material with good damping properties. I have used several different materials, and am still frankly undecided as to which is the best. But a great choice that is easily available is the 3M Extreme double sided exterior mounting tape. And the nice thing is that you can get it from Home Depot when you go back to get the second panel!

While there are more elegant ways to mount the panel to the frame, perhaps the most simple way is as shown in the sketch below. The 3M Tape comes 1" wide, but using the full width is too much constraint (almost like clamping) on the panel edge. Two stacked layers, each 1/2" wide, works great, providing minimal constraint but effective control of frequency spikes and "ringing" that otherwise occur from insufficient damping. For this arrangement, the inside dimensions of the frame should be 1" smaller than the panel's overall dimensions. The foam tape should go virtually around the entire perimeter of the panel. I like to stop the tape around 2" from each of the panel corners, but the only reason for that is to allow the possibility of removing the panel from the frame at some point. However, be aware that the 3M tape is really sticky and it's very difficult to remove without delaminating the layers of the plywood panel in the process.

Attach your favorite exciter to the panel and brace as necessary. The exciter location that typically works best for this design is to offset the exciter about 5" from center in the long direction and 1-1/2" to 2" across the short direction. I especially like the DAEX25FHE-4 or DAEX25VT-4, but probably others will work well too.

I hope you find this useful,

Eric

I've been slowly making my way through this thread. Has anyone tried making cutouts between drivers to reduce the negative interaction between them?

I thought of this mostly as a means to make a line array out of them. Have the line of exciters up the center with long thin slits between each.

I thought of this mostly as a means to make a line array out of them. Have the line of exciters up the center with long thin slits between each.

Take a look here ... This seems to have faded away but it was intriguing

https://www.diyaudio.com/community/...s-as-a-full-range-speaker.272576/post-7343598

Eucy

https://www.diyaudio.com/community/...s-as-a-full-range-speaker.272576/post-7343598

Eucy

Now that we're 566 posts into this, how is the sound in comparison to other speaker design concepts (conventional, planar, line arrays, open baffle, rubenoide, etc)?

Sorry Nvphotos, I couldn't resist. Currently on holiday at the coast with extreme foul weather and I am bored to death and there is nothing new or exciting happening on the forum.

I cannot offer a descriptive comparison between different kinds of speakers, but DML sound reminds me of the day when I heard electrostatics for the first time. I was a student at the time (early 80's) and popped into a high end hifi shop (like I often did) drooling over the gear. Then they played a Little Feet record on these newly imported electrostatic speakers as large as doors. The music filled the whole shop. My jaws dropped at this amazing sound experience. I felt like walking up to the band members and shake their hands. I was blown away and will never forget that day.

Unfortunately DML speakers do not attract much audiophile attention, possibly because of the extremely low cost of entry. How on earth can you get hifi sound from a $20 exciter and a piece of XPS foam or plywood plank? The (in)famous Tech Ingredients "World's best speakers" video also did not help give DML implementations a credible reputation.

You would not know what DML sounds like, until you've heard it yourself.

PS: 566 pages, only 11,318 posts, and now I've added 2 more

I cannot offer a descriptive comparison between different kinds of speakers, but DML sound reminds me of the day when I heard electrostatics for the first time. I was a student at the time (early 80's) and popped into a high end hifi shop (like I often did) drooling over the gear. Then they played a Little Feet record on these newly imported electrostatic speakers as large as doors. The music filled the whole shop. My jaws dropped at this amazing sound experience. I felt like walking up to the band members and shake their hands. I was blown away and will never forget that day.

Unfortunately DML speakers do not attract much audiophile attention, possibly because of the extremely low cost of entry. How on earth can you get hifi sound from a $20 exciter and a piece of XPS foam or plywood plank? The (in)famous Tech Ingredients "World's best speakers" video also did not help give DML implementations a credible reputation.

You would not know what DML sounds like, until you've heard it yourself.

PS: 566 pages, only 11,318 posts, and now I've added 2 more

I think there is no concensus that the interactions between drivers are necessarily negative. Have you tried such a line array and observed an issue?I've been slowly making my way through this thread. Has anyone tried making cutouts between drivers to reduce the negative interaction between them?

I thought of this mostly as a means to make a line array out of them. Have the line of exciters up the center with long thin slits between each.

Eric

Thanks for the information on the panels, Eric. I'll check for another panel this weekend. I was actually assuming I'd be using the full 24 x 48 board for each speaker, is there a sonic benefit to cutting it down to 14"?

Using 2x6s is going to be a bit on the heavy side, I was hoping to be able to hang these up (easily!) when not in use, 1x4 should be okay. Any problem you can see just using wood glue? My xps panels are glued with wood glue to their frames and sound great to me.

Speaking of those, they are modular and light, and have feet. If the full 24 x 48 is okay, I could on occasion mount them on top of the birch speakers. (ceiling is 11 foot).

I wish they made a 100w exciter. (well, honestly, I don't think I've had my xps panels anywhere near full volume yet so 40w is probably okay, but I like having overhead).

Using 2x6s is going to be a bit on the heavy side, I was hoping to be able to hang these up (easily!) when not in use, 1x4 should be okay. Any problem you can see just using wood glue? My xps panels are glued with wood glue to their frames and sound great to me.

Speaking of those, they are modular and light, and have feet. If the full 24 x 48 is okay, I could on occasion mount them on top of the birch speakers. (ceiling is 11 foot).

I wish they made a 100w exciter. (well, honestly, I don't think I've had my xps panels anywhere near full volume yet so 40w is probably okay, but I like having overhead).

I built a pair of IDS-25 line arrays and am toying with different ways to make a open baffle/bipolar version.I think there is no concensus that the interactions between drivers are necessarily negative. Have you tried such a line array and observed an issue?

Eric

I have only seen some speculations, but no measurements that would indicate if there is an issue using multiple exciters and how that issue would appear.I think there is no concensus that the interactions between drivers are necessarily negative. Have you tried such a line array and observed an issue?

Eric

Multi Exciter Panels have been researched and used for Wave Field Synthesis applications and is used by Tectonic for their commercial PA panels.

This paper on WFS mentions issue with "cross-talk" if panel material is not dampening enough, but for WFS you would have different signal for each exciter, which means cross-talk can be an issue. It is more like having stereo on a single plate which of course can cause interference.

I do think that multi-exciter in a cluster can have benefits by enlarging the central emission area, which results in stronger transients and directivity, but mainly it comes down to if you need the power. If you don't, multi exciter is most likely a waste of money, and if you do it makes a lot more sense than having lots of plates instead. And it is very doubtful that the interference of multiple plates is less significant than multiple exciters on the same plate anyway.

Have any of you tried this yet (the video at the bottom)?

I could see this with either a parlor guitar with an easily removable bridge or a cello with it's bridge removed.

In theory, an instrument like this fits the same concept of a dml panel but has already been developed. The vibration goes from the strings, through the bridge, into the soundboard made of tone wood (like a dml panel), resonates in the body, and out the sound hole.

If nothing else, tone wood could make a good material for a panel.

I know that in conventional speakers, we don't want resonance in the speaker cabinet. With DML's the whole panel minus the supports are meant to resonate.

I believe the sound exciter shout be positioned in the same spot the dridge originally was as that is where the sound was designed to originate from. Then some kind of support for the back of the exciter would need to be made.

Any thoughts?

I could see this with either a parlor guitar with an easily removable bridge or a cello with it's bridge removed.

In theory, an instrument like this fits the same concept of a dml panel but has already been developed. The vibration goes from the strings, through the bridge, into the soundboard made of tone wood (like a dml panel), resonates in the body, and out the sound hole.

If nothing else, tone wood could make a good material for a panel.

I know that in conventional speakers, we don't want resonance in the speaker cabinet. With DML's the whole panel minus the supports are meant to resonate.

I believe the sound exciter shout be positioned in the same spot the dridge originally was as that is where the sound was designed to originate from. Then some kind of support for the back of the exciter would need to be made.

Any thoughts?

Problem is that larger exciters will have larger coil, increasing inductance and reducing HF reproduction. Hence currently if you want more than 40w there is only bass thrusters.I wish they made a 100w exciter. (well, honestly, I don't think I've had my xps panels anywhere near full volume yet so 40w is probably okay, but I like having overhead).

Xite should have another model coming that I guess will be larger than their current 40w model, hopefully while maintaining HF reproduction.

Forgive me for discussing multiple topics at the same time.

Theoretically, are there are real differences between a dml panel and a planar driver? Obviously in a planar, the membrane should never touch the magnets. Does that lack of contact create any clearer of a presentation? A planar also has a push pull effect across it's entirely surface. Theoretically, that could also be done with a dml panel, just expensive and tedious.

Theoretically, are there are real differences between a dml panel and a planar driver? Obviously in a planar, the membrane should never touch the magnets. Does that lack of contact create any clearer of a presentation? A planar also has a push pull effect across it's entirely surface. Theoretically, that could also be done with a dml panel, just expensive and tedious.

jmproject,Thanks for the information on the panels, Eric. I'll check for another panel this weekend. I was actually assuming I'd be using the full 24 x 48 board for each speaker, is there a sonic benefit to cutting it down to 14"?

Using 2x6s is going to be a bit on the heavy side, I was hoping to be able to hang these up (easily!) when not in use, 1x4 should be okay. Any problem you can see just using wood glue? My xps panels are glued with wood glue to their frames and sound great to me.

Speaking of those, they are modular and light, and have feet. If the full 24 x 48 is okay, I could on occasion mount them on top of the birch speakers. (ceiling is 11 foot).

I wish they made a 100w exciter. (well, honestly, I don't think I've had my xps panels anywhere near full volume yet so 40w is probably okay, but I like having overhead).

Yes, there is a sonic benefit to cutting it down to 14". The reason is that at the full 24" width, the most effective natural frequencies will be too spread out at the lowest end of the frequency range (leaving gaps in the SPL) and then too bunched up at slightly higher frequencies (causing peaks). I actually did a series of experiments with one of these exact panels where I measured the frequency response at the full 24" x 48" size, then cut down the 24" width in small steps and re-measured the frequency response at each size. At every size I modified the frame so that the panel was supported around the entire perimeter (except the corners) on the 3M mounting tape. I found the flattest response at the 14" width.

I have never tried simply gluing a panel to a frame. Depending on the width of the glued area, it may act more like a clamped edge than a hinged edge, and hence limit your frequency range (at the low end) unnecessarily. But further, I suspect it will provide no significant damping, resulting prolonged ringing at some of the natural frequencies. I think the 3M Extreme (black) tape I mentioned will give a better result than gluing the panel directly to the frame.

Regarding the exciter power: One thing is for sure, the plywood panel will not be even close to the volume you get from the XPS panels. But for me, a single 20 or 24 Watt exciter on each panel is loud enough (combined with a powered sub). I can't say if it will be loud enough for you, however.

Eric

Hello all,

some of the above posts now make me wonder if there is actually a 'Life span' of exciters.

Apart from over-loading & heating, I wonder if some brands and models are most resilient (?)

Because they are a 'relatively new' product, there is probably no real information regarding this.

From a simple visual inspection of the Dayton EX32's I'm about to use, the suspension system

appears to be made of Spring Steel, so I doubt it would sag or fail > without heat.

This makes me mention that there are a lot of low-power exciters out there and people must

take this into consideration when building. So many amplifiers today have a lot of power.

This is why I will be using twin exciters (80W RMS) and also filtering-out very low bass frequencies.

CHEERS 🙂

DAEX32Q-8 Dual Steel Spring Balanced 32mm Exciter 20W 8 Ohm I hope these are not the ones you're referring to, I would have returned the pair I bought if possible. Terrible sound. Audio Frenzy didn't like them as well.

Thanks for that info. >

My exciters are labeled - EX32EP2-4 (4ohm / 40W)

so I'm glad about that !

Cheers 🙂

My exciters are labeled - EX32EP2-4 (4ohm / 40W)

so I'm glad about that !

Cheers 🙂

Exactly.... Not to be an ***, but, common sense along with the slightest bit of knowledge about the tolerances between the voice coil and pole elements in speakers, especially on "speakers" this small, should trigger the need to do whatever is needed to avoid sag. It's just so obvious what the end result will be without support, especially pushing them.Leob.

As far as I can remember, discussion about exciter mounting has been going on for about one and a half decades.

The fact that you were warned of this problem, but decided to go your own way is why you have damaged exciters.

Agreed that the manufacturers should make it clear how to mount them.

But it has been mentioned many many times ,by me, and also on this forum.

You can't blame the exciter.

It also seems clear to me why one out of four exciters on the single panel has problems.

I made a post and video of this probable cause.

Steve.

If they have the same spring setup instead of a spider then they are probably gonna' be a disappointment, sorry.Thanks for that info. >

My exciters are labeled - EX32EP2-4 (4ohm / 40W)

so I'm glad about that !

Cheers 🙂

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker