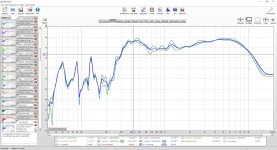

Today I took again some measurements of my different dml speakers, both left and right speaker as they differentiate quite substantially from each other. I measured at 1 meter distance and mic at panel center height.

Actually I took all measurements twice. First normal positioning and then diagonally in the room (which helps in my case against some resonances). I know already that my room does have some room modes, but as I cannot measure anything outside right now this is all I have.

The poplar and birch ply are 1200x600mm. The small XPS panel is 750x600mm and the big XPS is 1250x600mm. I also used different exciters as you can see in the plots.

How do you guys actually reuse an exciter/panel? Because it would have been much better of course if I would use the same exciters on all materials but I didn't want to risk to damage anything because all stores are closed right now... On plywood I can image that you can get the exciter off but on XPS I doubt that (without damaging the panel).

One thing that immediately jumped into my eye when I first measured my panels was, that I have a big jump at about 250Hz - on all materials/exciters. Below that it's pretty wild (to a certain degree also due to my room) and above quite ok. Compared to measurements from many other people that I've seen I don't have any problems with the high end, except from the big XPS panels. Overall I like the poplar the most as it provides the flattest response but it tends to rattle as it's quite soft.

Do you guys also have this wild peaks and troughs below 200Hz? I've tried different forms of frames, splines, panel attachements / dampening but still, I cannot really overcome that problem.

Actually I took all measurements twice. First normal positioning and then diagonally in the room (which helps in my case against some resonances). I know already that my room does have some room modes, but as I cannot measure anything outside right now this is all I have.

The poplar and birch ply are 1200x600mm. The small XPS panel is 750x600mm and the big XPS is 1250x600mm. I also used different exciters as you can see in the plots.

How do you guys actually reuse an exciter/panel? Because it would have been much better of course if I would use the same exciters on all materials but I didn't want to risk to damage anything because all stores are closed right now... On plywood I can image that you can get the exciter off but on XPS I doubt that (without damaging the panel).

One thing that immediately jumped into my eye when I first measured my panels was, that I have a big jump at about 250Hz - on all materials/exciters. Below that it's pretty wild (to a certain degree also due to my room) and above quite ok. Compared to measurements from many other people that I've seen I don't have any problems with the high end, except from the big XPS panels. Overall I like the poplar the most as it provides the flattest response but it tends to rattle as it's quite soft.

Do you guys also have this wild peaks and troughs below 200Hz? I've tried different forms of frames, splines, panel attachements / dampening but still, I cannot really overcome that problem.

Attachments

I stumbled over this video today:

YouTube

The guy uses a 2mm thin polypropylene protection board. I guess it's that one: Antinox Temporary Protection Black - 2mm | Homebase

Based on the structure it should be really stiff and with ~250g/m^2 is very light too! Did anyone already try that material?

YouTube

The guy uses a 2mm thin polypropylene protection board. I guess it's that one: Antinox Temporary Protection Black - 2mm | Homebase

Based on the structure it should be really stiff and with ~250g/m^2 is very light too! Did anyone already try that material?

Do you guys also have this wild peaks and troughs below 200Hz? I've tried different forms of frames, splines, panel attachements / dampening but still, I cannot really overcome that problem.

Yes. Everyone does. You're running into small room low frequency modal behavior. You can't solve for it by making adjustments to your DMLs.

There are different strategies for dealing with low frequencies depending on what you want to do.

So I made a start.

I hope you find it useful

DML Patents....

If you find any you think should be included let me know.

Burnt,

Good list.

Here's another Azima/NXT patent. And it speaks directly to the question of damping that we have been discussing. Curiously, on Google patents the title of this patent is shown as:

RECOVERY OF METALS BY INCINERATION OF METAL CONTAINING BASIC ION EXCHANGE RESIN, now that's an odd typo!

Bending wave loudspeaker

Abstract

A loudspeaker comprising a panel which is sufficiently stiff to support bending waves, the panel having a boundary, a transducer mounted to the panel to apply bending wave energy in the form of dispensive travelling waves thereto at a first location in response to an electrical signal applied to the transducer to cause the panel to vibrate and radiate an acoustic output, the loudspeaker having a frequency range extending from a lower frequency to a higher frequency and the panel having a stiffness giving a coincidence frequency above the lower frequency, and comprising means on or associated with the panel at a second location to attenuate travelling bending waves in the panel to prevent or at least substantially to moderate panel resonance.

https://patentimages.storage.googleapis.com/0c/3a/a0/d6d5134f14ae29/WO2002013575A1.pdf

An interesting quote from the patent:

It is the intention of the present invention to achieve a more effective use of bending waves for reproduction of sound especially in the lower operating range of the loudspeaker. It is an objective of this invention to avoid altogether or at least reduce the modal behaviour of the panel, either throughout the operating range or at least in the lower frequency range of operation. Ideally, the panel should behave as if it were infinite in size - that is no energy is reflected from the boundaries, despite its finite physical size. The core idea of the present invention is that the imposition of an acoustic aperture onto a conceptually infinite panel results in a net acoustic power available in the far field of the panel at below the coincidence frequency, and also above it .

It is well documented that an infinitely large panel operating in bending plane wave radiates little or no acoustic energy below its coincidence frequency (frequency at which speed of sound in the panel reaches that of its surrounding air (fluid) . To overcome this limitation, a distributed-mode loudspeaker in effect imposes a fini te mechanical aperture onto an infinite panel (by its finite size and boundary conditions) , thus creating a modal object to achieve this effect. The effect of this aperture is to either present a zero (clamped edge) or infinite (free edge) mechanical impedance to the panel and therefore instigate reflections in order to build up natural resonant behaviour in the panel.

In contrast, the present invention stipulates substantially terminating the panel structure at the panel boundaries, ideally to absorb incident bending wave energy. This is tantamount to an infinite panel with a finite acoustic aperture imposed on it. This is a significant departure from the prior art and in fact an antithesis to a modal object.

Exactly what you've been talking about, right?

Funny, I recall reading this patent some time ago but apparently forgot about it. I found it again only because I was going through my bookmarks trying to find things to add to your list. Keep trying your damping ideas.

Eric

The guy uses a 2mm thin polypropylene protection board. I guess it's that one: Antinox Temporary Protection Black - 2mm | Homebase

Based on the structure it should be really stiff and with ~250g/m^2 is very light too! Did anyone already try that material?

I don't recognize that as something we have here in the US. Anybody know if there is an equivalent here?

Eric

Thank you for that one Eric, much appreciated! I dimly remember it from a search a while back and It must have influenced my thinking. what a bizarre title!

I am going to measure and document the experiment using REW which I am more familiar with now, such a great tool, so you can observe my failure in detail. ��

Just need the shops to open

Burnt

I am going to measure and document the experiment using REW which I am more familiar with now, such a great tool, so you can observe my failure in detail. ��

Just need the shops to open

Burnt

Here's another Azima/NXT patent. And it speaks directly to the question of damping that we have been discussing. Curiously, on Google patents the title of this patent is shown as:

RECOVERY OF METALS BY INCINERATION OF METAL CONTAINING BASIC ION EXCHANGE RESIN, now that's an odd typo!

Eric

That cleared up the difference between a bending wave speaker and a DML for me. I used to think they were both the same thing.

However, it sounds like bending wave/infinite panel is a strategy to achieve improved low frequency behavior. So it seems like it would be a specialized application of panel speakers.

IOW, you'd build bending wave panels as separate low frequency sources in addition to your DML mains.

Do you guys also have this wild peaks and troughs below 200Hz? I've tried different forms of frames, splines, panel attachements / dampening but still, I cannot really overcome that problem.

How are your panels supported? To me those all look like panels without a frame and foam surround. I generally find that a rigid frame and some thick window insulation foam around the perimeter with adhesive on both sides to attach the panel to the frame, helps provide better low frequency output. Not miracles, but better than what yours look like.

Also, how thick are your wood panels? Any more than 6 mm may be too thick.

Eric

IOW, you'd build bending wave panels as separate low frequency sources in addition to your DML mains.

Why do you say that? I don't mean I think that you are wrong. Just that I didn't understand that improving the low frequency this way necessarily compromised the high frequency. But maybe I missed something, as I have not read the patent in detail recently.

Eric

And two more for the patent database. Both these are cited by the NXT/Azima patents:

Panel-form loudspeaker

Abstract

A panel-form loudspeaker has a resonant multi-mode radiator panel which is excited at frequencies above the fundamental frequency and the coincidence frequency of the panel to provide high radiation efficiency through multi-medal motions within the panel, in contrast to the pistonic motions required of conventional loudspeakers. The radiator panel is a skinned composite with a honeycomb or similar core and must be such that it has a ratio of bending stiffness to the third power of panel mass per unit area (in mks units) of at least 10 and preferably at least 100. An aluminium skinned, aluminium honeycomb cored composite can meet this more severe criterion easily. <IMAGE>

https://patentimages.storage.googleapis.com/9a/43/32/b09245ff903cac/WO1992003024A1.pdf

And

Loudspeaker

https://patentimages.storage.googleapis.com/d7/c4/c9/cbd405fcdd75ae/US3247925.pdf

Panel-form loudspeaker

Abstract

A panel-form loudspeaker has a resonant multi-mode radiator panel which is excited at frequencies above the fundamental frequency and the coincidence frequency of the panel to provide high radiation efficiency through multi-medal motions within the panel, in contrast to the pistonic motions required of conventional loudspeakers. The radiator panel is a skinned composite with a honeycomb or similar core and must be such that it has a ratio of bending stiffness to the third power of panel mass per unit area (in mks units) of at least 10 and preferably at least 100. An aluminium skinned, aluminium honeycomb cored composite can meet this more severe criterion easily. <IMAGE>

https://patentimages.storage.googleapis.com/9a/43/32/b09245ff903cac/WO1992003024A1.pdf

And

Loudspeaker

https://patentimages.storage.googleapis.com/d7/c4/c9/cbd405fcdd75ae/US3247925.pdf

Thanks Eric.I will add them to the database and any others people find. Once we have all the relevant ones I'll repost the complete list.

That cleared up the difference between a bending wave speaker and a DML for me. I used to think they were both the same thing.

However, it sounds like bending wave/infinite panel is a strategy to achieve improved low frequency behavior. So it seems like it would be a specialized application of panel speakers.

IOW, you'd build bending wave panels as separate low frequency sources in addition to your DML mains.

Its the same concept just different designs. Like I said before its all in ones design.

Today I took again some measurements of my different dml speakers, both left and right speaker as they differentiate quite substantially from each other. I measured at 1 meter distance and mic at panel center height.

Actually I took all measurements twice. First normal positioning and then diagonally in the room (which helps in my case against some resonances). I know already that my room does have some room modes, but as I cannot measure anything outside right now this is all I have.

The poplar and birch ply are 1200x600mm. The small XPS panel is 750x600mm and the big XPS is 1250x600mm. I also used different exciters as you can see in the plots.

How do you guys actually reuse an exciter/panel? Because it would have been much better of course if I would use the same exciters on all materials but I didn't want to risk to damage anything because all stores are closed right now... On plywood I can image that you can get the exciter off but on XPS I doubt that (without damaging the panel).

One thing that immediately jumped into my eye when I first measured my panels was, that I have a big jump at about 250Hz - on all materials/exciters. Below that it's pretty wild (to a certain degree also due to my room) and above quite ok. Compared to measurements from many other people that I've seen I don't have any problems with the high end, except from the big XPS panels. Overall I like the poplar the most as it provides the flattest response but it tends to rattle as it's quite soft.

Do you guys also have this wild peaks and troughs below 200Hz? I've tried different forms of frames, splines, panel attachements / dampening but still, I cannot really overcome that problem.

If you use different exciters it will sound different so you wont be able to do a accurate comparison.

Today I took again some measurements of my different dml speakers, both left and right speaker as they differentiate quite substantially from each other. I measured at 1 meter distance and mic at panel center height.

Actually I took all measurements twice. First normal positioning and then diagonally in the room (which helps in my case against some resonances). I know already that my room does have some room modes, but as I cannot measure anything outside right now this is all I have.

The poplar and birch ply are 1200x600mm. The small XPS panel is 750x600mm and the big XPS is 1250x600mm. I also used different exciters as you can see in the plots.

How do you guys actually reuse an exciter/panel? Because it would have been much better of course if I would use the same exciters on all materials but I didn't want to risk to damage anything because all stores are closed right now... On plywood I can image that you can get the exciter off but on XPS I doubt that (without damaging the panel).

One thing that immediately jumped into my eye when I first measured my panels was, that I have a big jump at about 250Hz - on all materials/exciters. Below that it's pretty wild (to a certain degree also due to my room) and above quite ok. Compared to measurements from many other people that I've seen I don't have any problems with the high end, except from the big XPS panels. Overall I like the poplar the most as it provides the flattest response but it tends to rattle as it's quite soft.

Do you guys also have this wild peaks and troughs below 200Hz? I've tried different forms of frames, splines, panel attachements / dampening but still, I cannot really overcome that problem.

Urpgor,

I just realized that part of the reason your responses look odd to me is because you are using VAR (variable) smoothing, a smoothing mode that I never use. This type of smoothing applies less smoothing at low frequencies and more smoothing at high frequencies. This will naturally make the low freq end look bumpier than the high frequency end, regardless of whether it actually is or not.

According to the REW instructions, VAR should be used for "responses that are to be equalized". I can't say that makes sense to me.

I tend to use Psyhcoacoustic smoothing since it (at least supposedly) corresponds to what our ears/brains perceive.

I don't think there's really a right or wrong smoothing to choose. But I do think that using VAR smoothing is making it look like your response is wilder below 200 Hz and pretty flat above. But I bet it will look a lot less like that if you switch to a more consistent smoothing.

Eric

I stumbled over this video today:

YouTube

The guy uses a 2mm thin polypropylene protection board. I guess it's that one: Antinox Temporary Protection Black - 2mm | Homebase

Based on the structure it should be really stiff and with ~250g/m^2 is very light too! Did anyone already try that material?

Looks very similar in construction to the 4mm thick polycarbonate glazing sheet I've been using.

Why do you say that? I don't mean I think that you are wrong. Just that I didn't understand that improving the low frequency this way necessarily compromised the high frequency. But maybe I missed something, as I have not read the patent in detail recently.

Eric

IMO, the comparative advantage DML offers is a wide diffuse soundfield in the higher frequencies. You get good intelligibility regardless of room reflections.

The patent said bending wave/infinite panel was the opposite of "a modal object." Instead, the bending waves go out like throwing a pebble into a very large lake. The reason they did it was to improve low frequency performance. But there's no comparative advantage in that over a traditional cone speaker. You get a design advantage because it is flat and you can hang it on a wall, but it doesn't sound any better than a cone in a small room.

To obtain the comparative advantage of a DML over a cone I'd want it to be modal. The more modal the better.

Another reason is that if you are pursuing the goal of improving low frequencies in a small room then you are probably going to use a small room low frequency room strategy. All those strategies separate the low frequency sources from the mains. Toole/Welti use four sub located in corners. Earl Geddes uses three or more in an uneven room placement. That's why you'd want your low frequency bending wave panels separated from your high frequency DML panels.

I accidentally built low frequency performance into my DMLs but it doesn't do me any good. All it does is excite uneven low frequency room modes. I have no way equalizing that from my mains.

You can see the modal high frequencies collapse in the graph as you move toward the lower frequency spectrum.

Attachments

Today I took again some measurements of my different dml speakers, both left and right speaker as they differentiate quite substantially from each other. I measured at 1 meter distance and mic at panel center height.

Actually I took all measurements twice. First normal positioning and then diagonally in the room (which helps in my case against some resonances). I know already that my room does have some room modes, but as I cannot measure anything outside right now this is all I have.

The poplar and birch ply are 1200x600mm. The small XPS panel is 750x600mm and the big XPS is 1250x600mm. I also used different exciters as you can see in the plots.

How do you guys actually reuse an exciter/panel? Because it would have been much better of course if I would use the same exciters on all materials but I didn't want to risk to damage anything because all stores are closed right now... On plywood I can image that you can get the exciter off but on XPS I doubt that (without damaging the panel).

One thing that immediately jumped into my eye when I first measured my panels was, that I have a big jump at about 250Hz - on all materials/exciters. Below that it's pretty wild (to a certain degree also due to my room) and above quite ok. Compared to measurements from many other people that I've seen I don't have any problems with the high end, except from the big XPS panels. Overall I like the poplar the most as it provides the flattest response but it tends to rattle as it's quite soft.

Do you guys also have this wild peaks and troughs below 200Hz? I've tried different forms of frames, splines, panel attachements / dampening but still, I cannot really overcome that problem.

If you look at your response of the poplar and birch,you will see a dip around the 10k Mark and a peak around the 15k area,it's lower on the birch ,this is a classic response and shows the what I call the tin can effect.

The xps shows roll off in the 10k region ,so HF is damped by the panel material,similar to eps but more so.

Hopefully I will get in my room today to do some measurements on various panels to show this in more detail

Steve

... But there's no comparative advantage in that over a traditional cone speaker. You get a design advantage because it is flat and you can hang it on a wall, but it doesn't sound any better than a cone in a small room...

Thanks bradleypnw,

Eric

Thanks bradleypnw,

Eric

This is exactly what I have been trying to say, manipulating a panel to increase LF or any other reason will have a knock on effect to the overall sound of the panel, usually a negative effect I'm afraid .

Steve

Urpgor,

I just realized that part of the reason your responses look odd to me is because you are using VAR (variable) smoothing, a smoothing mode that I never use. This type of smoothing applies less smoothing at low frequencies and more smoothing at high frequencies. This will naturally make the low freq end look bumpier than the high frequency end, regardless of whether it actually is or not.

According to the REW instructions, VAR should be used for "responses that are to be equalized". I can't say that makes sense to me.

I tend to use Psyhcoacoustic smoothing since it (at least supposedly) corresponds to what our ears/brains perceive.

I don't think there's really a right or wrong smoothing to choose. But I do think that using VAR smoothing is making it look like your response is wilder below 200 Hz and pretty flat above. But I bet it will look a lot less like that if you switch to a more consistent smoothing.

Eric

I've used VAR smoothing because it's recommended quite often. Actually it doesn't really matter how we smooth and show the data as long as we use similar settings.

In order to make comparisons easier it would be nice if we would all have the same baseline in terms of how our plots look like. If we would agree that we measure at 75dB then graph limits could be from 40Hz to 20.000Hz and 45dB to 95dB with e.g. 1/6, 1/12, 1/24 etc smoothing. What do you guys think of that?

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker