I made some really nice sounding panels from rigid EPS, thinness is the key. Where the exciter mounts is 1" and tapers pretty quick to 1/2" all the way to the edges. I used this same process of sanding the panel down thin on my Poly panels as they are even more rigid than the EPS, which you could park a truck on. (Came from a cooler I found on the side of a highway, had a sticker for something medical being shipped inside). 16" x 12" panels used with 8" sub.Also I only use lower grades of eps not the rigidly higher grades.

Last edited:

Toddincabo.

Have you compared the sound of a 10mm low density panel coated in a 50x50 mix of pva to the same size HD grade of EPS and poly panels?

Steve.

Have you compared the sound of a 10mm low density panel coated in a 50x50 mix of pva to the same size HD grade of EPS and poly panels?

Steve.

This was a picture I posted of an exciter that was accidentally ripped off of one of your identical types of panels.On the last point, see the latest post from JoskaNZ in the PA thread, combining a bass exciter with a smaller exciter for top end which would make a for a more cost-efficient high power plate. https://www.diyaudio.com/community/threads/dml-pa-systems.390363/post-7954377

While I think the Xcite performs very well, there are various models from manufacturers like Billionsound that could be used to make a similar design but keep the cost down further.

Regarding the DML sound for PA use, I had so much feedback from people on the panels, and at least for the kind of application I use them for, playing electronic music with a dancefloor setup with speakers in all corners, the benefits are very obvious.

1) Distortion remains very low even at extreme SPL. This means that you can have conversations even if volume is very high, don't get ringing ears and sensitive people does not feel they need earplugs.

2) Coverage is great and difference between right in front of speakers and middle of dancefloor seems smaller.

3) Transient response seems much clearer, resulting in excellent directivity, with a huge sweetspot and ability to hear stereo imaging even if positioned right in front on one stack.

4) Extremely punch low mid that is easy to cross over with subs.

5) A much more open natural sound making even good PA mid-tops sound boxy. Sound more like listening on a good hifi system or headphones than a PA.

6) Extremely cost efficient and light weight compared to regular speakers.

There are some issues as well of course:

1) So far I have not made a really reliable construction. There are quite different challenges than with a regular speaker, and a lot of trial and error. But at least I feel confident now that the exciters can hold up for PA use. I have pushed them very hard for long durations, and have a pair of plates in my studio now, and those exciters are still fine. But will plates and exciters last many years of intense use?

2) The dipolar response can be an issue, indoors because of increased reflections and outdoors because of sound pollution.

3) They do need DSP to adjust the response. I'm sure you can make something good enough by tweaking the design, but DML responds well to EQ and it is an easy way to improve the sound a lot even with a good design.

4) While they give good SPL per kg, they do need a bit of surface area, which makes them a bit more complicated to rig compared to regular mid tops.

5) When using EPS plates at least, dismounting exciters from the plater is not possible without ruining the plate, which makes them not very serviceable. Plates are cheap to replace, but it is a bit of work to pry off the exciters and clean them, and if an exciter fails it is not something you would fix in the field.

The beads are like a jigsaw puzzle.

So you do not have to remove the eps from the exciter and throw away your panel, you can just glue the beads back together

I coated the exciter beads and the exposed beads on the panel with 50x50 mix of pva.

This panel has been working perfectly ever since.

It is a perfect fit and no joins can be seen.

A hair dryer can be used to speed up the drying process of evaporating the water.

Once the water has evaporated there is very little weight as the very thin coat of pva left , is miniscule, but is stronger than the EPS.

If this is not quick enough, I am sure there must be other types of glue that could do the same job , but quicker 🤔

I have done this repair quite a few times over the years as it is easy to accidentally rip off an exciter or drop a panel on its side accidentally shearing off the exciter.

Steve.

Attachments

Leob.

Unless, if you had an exciter with a removable foot.

This would be easy to swop over.

Steve.

Unless, if you had an exciter with a removable foot.

This would be easy to swop over.

Steve.

Hi Leon5) When using EPS plates at least, dismounting exciters from the plater is not possible without ruining the plate, which makes them not very serviceable. Plates are cheap to replace, but it is a bit of work to pry off the exciters and clean them, and if an exciter fails it is not something you would fix in the field.

Have you tried to 3d print a screw mount. I managed to replicate the Dayton thread and used it for various types of printed concentrators. They all worked without any loosening or other issues.. Worth a try.

Eucy

No, not side by side. I tried some low density 1" thick with 50/50 before I acquired the high density stuff or the poly. The sound was pretty good but had a hollowness to them. I moved on to thin plywood. You can tell with just a thump test between the low density 1" and the thin denser stuff or poly that the sound would be "tighter". No left over hollow ringing. I bought an RV that has taken up all my time upgrading, but I slacked off experimenting with building DML's a bit before that because I just cant top these hybrid wood/poly panels, the sound they put out is all I need to be happy. I am going to try some of those new exciters everyone is trying out though.. It'll be a while. I do plan on trying a couple of boxed panels under the tv in my rig and see how that goes, so I'll test some low grade side by side then. I always do 50/50 pva on my panels.Toddincabo.

Have you compared the sound of a 10mm low density panel coated in a 50x50 mix of pva to the same size HD grade of EPS and poly panels?

Steve.

Last edited:

Toddincabo.

Have you made any recordings or videos of your panels playing music?

It would be interesting to hear.

Have you listened to my audio recordings and videos on you tube.

What are your impressions.

Do you know the 1inch low grade EPS density or grade you used.

Low grade can vary from very soft and spongy to fairly hard.

1inch thick very low grade is probably a little too thick for a panel.

You say you also use thin ply, how thin ?

Sorry for all the questions, I'm just trying to get an idea of your setup.

Steve.

Have you made any recordings or videos of your panels playing music?

It would be interesting to hear.

Have you listened to my audio recordings and videos on you tube.

What are your impressions.

Do you know the 1inch low grade EPS density or grade you used.

Low grade can vary from very soft and spongy to fairly hard.

1inch thick very low grade is probably a little too thick for a panel.

You say you also use thin ply, how thin ?

Sorry for all the questions, I'm just trying to get an idea of your setup.

Steve.

Steve

I've watched all your videos to see the technique and panels used but as far as listening to others or recording my own panels, I feel that what you hear is only as good as what you are listening with or recorded with, taking away what can be heard live, equivalent to watching a black and white TV and a commercial is trying to sell me a TV by showing how wonderful their colors are. No offense intended. Your panels could sound better than mine and I wouldn't even know it. If someone could explain how that's not true, I'm all ears. I guess I could do a comparison of clarity with original recordings of the same songs but it still holds true.

The 1 inch EPS i have is not spongy, I'd say it's medium. The ply that I have available and use is just bought from the big box store The Home Depot and is very thin @ 1/8", 3 ply - middle ply alternated.

Here are some photos from an earlier post of the hybrid panels I'm satisfied with, they started out with a 3" circular piece of the 1/8" ply glued to the rear with accompanying hole cut through the Poly and ended up with the larger flower shaped wood and larger hole. The highs come through while staying warm enough for my liking, especially after stretching some thin black material over the face and perimeter attached with super glue on the rear. The poly "cone" (from your posts) that is placed in the middle of the wood turned out to act as a "tent pole", if you will, holding the material away from the panel, have no idea if that matters. Subwoofer a must.

I've watched all your videos to see the technique and panels used but as far as listening to others or recording my own panels, I feel that what you hear is only as good as what you are listening with or recorded with, taking away what can be heard live, equivalent to watching a black and white TV and a commercial is trying to sell me a TV by showing how wonderful their colors are. No offense intended. Your panels could sound better than mine and I wouldn't even know it. If someone could explain how that's not true, I'm all ears. I guess I could do a comparison of clarity with original recordings of the same songs but it still holds true.

The 1 inch EPS i have is not spongy, I'd say it's medium. The ply that I have available and use is just bought from the big box store The Home Depot and is very thin @ 1/8", 3 ply - middle ply alternated.

Here are some photos from an earlier post of the hybrid panels I'm satisfied with, they started out with a 3" circular piece of the 1/8" ply glued to the rear with accompanying hole cut through the Poly and ended up with the larger flower shaped wood and larger hole. The highs come through while staying warm enough for my liking, especially after stretching some thin black material over the face and perimeter attached with super glue on the rear. The poly "cone" (from your posts) that is placed in the middle of the wood turned out to act as a "tent pole", if you will, holding the material away from the panel, have no idea if that matters. Subwoofer a must.

Attachments

Last edited:

Toddincabo,

Are these the high density polyurethane from the cooler? Tapered to 1/2" thick at the edges? Poly spacers between the wood brace and panel?

Is the exciter screwed to the wood brace? Thanks, Bruce.

Are these the high density polyurethane from the cooler? Tapered to 1/2" thick at the edges? Poly spacers between the wood brace and panel?

Is the exciter screwed to the wood brace? Thanks, Bruce.

These are the high density polyurethane closed cell from the large fish cooler a buddy gave me. Yes they are sanded down to 1/2" completely with more of a slight concave going on toward the middle until reaching the wood. The wood is super glued directly to the poly all around. The exciters were attached to the wooden spines with Frost King door/window foam strip. The foam was attached to the exciter with epoxy which in turn was epoxied to the spine/brace. It was the first time trying this as you can see all the mounting holes in that wood where I had rigidly attached the exciter before with bolts pulling the exciter tight to the wood. The entire thing is "foam floating" as the only other attachment points are the 4 arms with the same foam attached to the panel. So far so good.Are these the high density polyurethane from the cooler? Tapered to 1/2" thick at the edges? Poly spacers between the wood brace and panel?

Is the exciter screwed to the wood brace? Thanks, Bruce.

I've posted this on the DML PA thread but thought there may be interest here too.

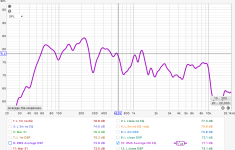

If anyone is interested in the new Xcite XTB40 exciters I've made a couple of panels now with the XTB40 and XT25 combo, high pass 1st order capacitor around 4khz. They are 600/400mm 20mm thick HD EPS with dilute hide glue and shellac coating. Suspension surrounds are 40/3mm adhesive foam tape all around, will see how the adhesive stands up to use but it is an easy suspension with damping and allows piston motion for the bass to some extent. I'm not sure if it is as good as the clamping in places with EPDM foam I was using for other panels but a lot simpler.

Un Eq'd they sound pretty good and definitely listenable, much stronger in the below 300Hz than others I have made, they fall off pretty steep at 10khz so I need to tweak the XT25, maybe different coating or thin the mounting area more as I have had better HF results on the EPS before with other exciters so know it is possible. I haven't tried to physically Eq these with weights or changing the damping yet.

With DSP I smoothed and boosted the highs plus put a high pass at 80Hz to save the panel as I thought the XTB40 may rip out the poly beads as it has quite a bit more force and weight than other exciters.

Did some quick tests, first is no EQ, second DSP. Both are an average of close, 1m and 2m measurements in room.

3rd image is comparison moving mic 1m no eq vs DSP.

They have a lot more punch than other panels I've made and solid output to 60Hz they play loud too but haven't pushed them too much without a high pass. Moderate high volume they sound good even without a sub.

These will be my party panels probably, with a sub. I have a little BRU5 amp that has inbuilt DSP so makes it fairly portable.

If anyone is interested in the new Xcite XTB40 exciters I've made a couple of panels now with the XTB40 and XT25 combo, high pass 1st order capacitor around 4khz. They are 600/400mm 20mm thick HD EPS with dilute hide glue and shellac coating. Suspension surrounds are 40/3mm adhesive foam tape all around, will see how the adhesive stands up to use but it is an easy suspension with damping and allows piston motion for the bass to some extent. I'm not sure if it is as good as the clamping in places with EPDM foam I was using for other panels but a lot simpler.

Un Eq'd they sound pretty good and definitely listenable, much stronger in the below 300Hz than others I have made, they fall off pretty steep at 10khz so I need to tweak the XT25, maybe different coating or thin the mounting area more as I have had better HF results on the EPS before with other exciters so know it is possible. I haven't tried to physically Eq these with weights or changing the damping yet.

With DSP I smoothed and boosted the highs plus put a high pass at 80Hz to save the panel as I thought the XTB40 may rip out the poly beads as it has quite a bit more force and weight than other exciters.

Did some quick tests, first is no EQ, second DSP. Both are an average of close, 1m and 2m measurements in room.

3rd image is comparison moving mic 1m no eq vs DSP.

They have a lot more punch than other panels I've made and solid output to 60Hz they play loud too but haven't pushed them too much without a high pass. Moderate high volume they sound good even without a sub.

These will be my party panels probably, with a sub. I have a little BRU5 amp that has inbuilt DSP so makes it fairly portable.

Attachments

I finished prepping my other 1/4" birch plywood panel for evaluation as a DML. I didn't make a frame for it, just hung it from a support using some "bulldog" clips attached to the top left and right side of the panel. Definitely not a long-term mounting scheme, the panel slowly drops out of the clips due to the panel vibration. There also are some nasty buzzing sounds that erupt at specific frequencies, also related to the clips.

Listening to it showed that it has the same issues with vocals, relative to my frame-mounted panel. Very recessed/muted relative to instruments. So that particular issue doesn't change much w/regard to how the panel is supported/mounted.

It's interesting that instruments, for the most part, sound pretty decent. Nice sound stage, too.

It may be possible to address the issues I have with the panels using some equalization. It may not take much.

Listening to it showed that it has the same issues with vocals, relative to my frame-mounted panel. Very recessed/muted relative to instruments. So that particular issue doesn't change much w/regard to how the panel is supported/mounted.

It's interesting that instruments, for the most part, sound pretty decent. Nice sound stage, too.

It may be possible to address the issues I have with the panels using some equalization. It may not take much.

Vibrations can be terrible in a DML. Some months ago I was surprised how a simple kitchen string used to hang the panel can be noisy!Definitely not a long-term mounting scheme, the panel slowly drops out of the clips due to the panel vibration. There also are some nasty buzzing sounds that erupt at specific frequencies, also related to the clips.

I don't remember Mark if you you have the possibility of measurements. If not, you could nevertheless played band limited pink noise (1/3 of octave or less) to detect the noisy parts or the frequency range involved in vocals that seems to be to low. REW offers such generators. No need of a mic.Listening to it showed that it has the same issues with vocals, relative to my frame-mounted panel. Very recessed/muted relative to instruments.

Christian

@Mark'51finished prepping my other 1/4" birch plywood panel for evaluation as a DML. I

My thoughts are as follows (fwiw):

1/ Birch is a bit too heavy for general use...a lighter timber like poplar will be more efficient/responsive.

2/ Combined with 1/ above, 1/4" thick (6.25 mm) is too thick. Try 1/8".

3/ A hollow vocal output can be caused by resonance... Try selective damping on the rear of the panel... Play some news reports or similar, run your fingers over the panel and locate the main source areas, then apply some thin self adhesive felt patches to those areas.

Cheers

Eucy

Unfortunately the big-box hardware stores don't carry 1/8" plywood. I did find some online sources for thinner plywood (they cater to airplane-builders). I've avoided that approach because I'm concerned about the possibility of damage occurring during shipping. Before I do that I probably would try some 1/2" EPS, it's available at my local Lowe's so I can select un-damaged panels.

I don't have a decent-enough mike for performing FR measurements. But, in terms of detecting resonance problems, it wouldn't be too difficult for me to generate impedane vs. frequency plots. That also might exhibit fewer interactions with the room, which is pretty "live" -- no wall to wall carpet.

I don't have a decent-enough mike for performing FR measurements. But, in terms of detecting resonance problems, it wouldn't be too difficult for me to generate impedane vs. frequency plots. That also might exhibit fewer interactions with the room, which is pretty "live" -- no wall to wall carpet.

Locally (Aus) specialty plywoods are shipped sandwiched between 2 sheets of thin customwood and bubble wrapped - Works well- Maybe ask suppliers how they pack for transportI've avoided that approach because I'm concerned about the possibility of damage occurring during shipping

Eucy

In Australia, I used an insulation product that is 6mm EPS bonded with aluminum foil with very good results > however still requiring a Super Tweeter.from my experience with sandwich cones of classic loudspeaker drivers alu foil - paper - alu foil I would go for that

or

3mm polystyrene sandwiched between metal foils

(household alu foil)

This material would be considered to be quite rigid & light weight.

The 'debate' between flexible and rigid is QUITE INTERESTING 🙂

PS.

I don't quite understand people using thick & heavy ply wood (?)

3mm poplar is quite light, and there's a tonal issue with EPS/XPS which has been noticed by most who have compared them with ply or other tone woods such as cedarI don't quite understand people using thick & heavy ply wood (?)

Was that laminated with aluminum foil on both sides? Also you mentioned that it had poor top end response, could you comment on the thickness (weight) of the foil please? Thanks you.I used an insulation product that is 6mm EPS bonded with aluminum foil with very good results

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker