Toddincabo.

I'm afraid that looks like a very badly designed exciter.

The problem is the double suspension at the back which connects to the coil.

This is very messy, if you remove the foot you will have no suspension.

You could try removing the coil and gluing to the panel, but you would have to arrange a mounting that would allow you to line up the magnet gap to the panel.

I have in the past thought of doing this with my exciters to remove the spider.

Too many projects, not enough time.

Steve.

I'm afraid that looks like a very badly designed exciter.

The problem is the double suspension at the back which connects to the coil.

This is very messy, if you remove the foot you will have no suspension.

You could try removing the coil and gluing to the panel, but you would have to arrange a mounting that would allow you to line up the magnet gap to the panel.

I have in the past thought of doing this with my exciters to remove the spider.

Too many projects, not enough time.

Steve.

The coil doesn't have to be round, does it? Or, even the magnet?You could try removing the coil and gluing to the panel, but you would have to arrange a mounting that would allow you to line up the magnet gap to the panel.

I have in the past thought of doing this with my exciters to remove the spider.

Like below, for example? Suspension is just an elastic string.

I've noticed this site only lets you edit and delete for around 10 minutes after that its like ones message is permanent.

Yawl remember the time when Ziggy was being attacked by a lot of people and he got fed up and deleted a huge amount of his post on a forum and left? LOL

Yawl remember the time when Ziggy was being attacked by a lot of people and he got fed up and deleted a huge amount of his post on a forum and left? LOL

Do you agree with my solution or have you found another?Yes, the legs have to cut off, as they add distortion. Also, anything other than the voice coil bobbin and suspension, if there's one. Even the little magnet hinders, so it has to be fixed a support, and that support shouldn't touch the panel, that is, if you are using a flat panel. The panel itself becomes a weight for the voice coil bobbin and that too hinders the sound propagating activity. The problem is how to touch the flat panel (in this case) without adding extra weight to the bobbin, pulling it down, distorting its to and fro movement. Then comes the question how to support the panel, so it won't pass its weight to the voice coil bobbin. Should it be fixed hard or soft? Whether the support is hard or soft, the frame also becomes a part of the panel, which in turn adds distortion.

Have we found a solution for this?

What's your solution?Do you agree with my solution or have you found another?

Audiofrenzy.

I do actually like the sound of your recordings.

But number 4 is much louder than number 5.

For that reason I probably prefer number 4.

It is difficult to make comparisons as I have to switch back to different pages and change volumes.

I still do not use edge damping or edge mounting unless a panel has problems or I want to use the panel down to lower frequencies than usual ( filling in dips in the response).

But for this I usually use weights not mounting or damping.

But only if I have to.

Steve.

I do actually like the sound of your recordings.

But number 4 is much louder than number 5.

For that reason I probably prefer number 4.

It is difficult to make comparisons as I have to switch back to different pages and change volumes.

I still do not use edge damping or edge mounting unless a panel has problems or I want to use the panel down to lower frequencies than usual ( filling in dips in the response).

But for this I usually use weights not mounting or damping.

But only if I have to.

Steve.

That's not a solution. What exactly is your solution?I told you in post 7857

That is my solution you build/design it like a BMR driver.That's not a solution. What exactly is your solution?

I stated on the youtube vid that vid 4 is louder then vid 5 so you would have to adjust the volume control on the youtube vid. Once its set it does not change so you can go back and forth to compare them. Both vids sound good its just a matter of personal preference.Audiofrenzy.

I do actually like the sound of your recordings.

But number 4 is much louder than number 5.

For that reason I probably prefer number 4.

It is difficult to make comparisons as I have to switch back to different pages and change volumes.

I still do not use edge damping or edge mounting unless a panel has problems or I want to use the panel down to lower frequencies than usual ( filling in dips in the response).

But for this I usually use weights not mounting or damping.

But only if I have to.

Steve.

Maybe if I have time I will let you hear a panel with edge dampening and one without edge dampening and see if you can tell the difference and see which one you prefer better.

Edge damping does restrict volume (spl) level because it reduces the out put from the sides.

Thanks, yep, removing the plastic parts are a no go as the springs are as you say suspending the coil and keeping it in alignment. "You could try removing the coil and gluing to the panel, but you would have to arrange a mounting that would allow you to line up the magnet gap to the panel." This is what I had to do when I first started and made my DIY exciters out of small speakers, the spider wasn't stiff enough to keep the coil self aligned from the weight of the panel and a spine was a necessity along with a hell of a lot of fiddling with super glue and shims.Toddincabo.

I'm afraid that looks like a very badly designed exciter.

The problem is the double suspension at the back which connects to the coil.

This is very messy, if you remove the foot you will have no suspension.

You could try removing the coil and gluing to the panel, but you would have to arrange a mounting that would allow you to line up the magnet gap to the panel.

I have in the past thought of doing this with my exciters to remove the spider.

Too many projects, not enough time.

Steve.

As far as cutting off the rubber boot I was worried about major distortion or whatever from the coil but thinking about the design of the FHE25's pictured below, and others like my next purchase, the 30HESF's, they have purposely incorporated holes in the rear for sound from the coil area. (Dayton Audio have the FHE25's now with their IMS plastic Interchangeable mount. I hope they leave the original as an option.)

The boot can be removed with an exacto knife fairly easily and seems to be a one way ticket, but they are toast to me as is anyway. I'm gonna' do it.

Attachments

Last edited:

Thanks, yep, removing the plastic parts are a no go as the springs are as you say suspending the coil and keeping it in alignment. "You could try removing the coil and gluing to the panel, but you would have to arrange a mounting that would allow you to line up the magnet gap to the panel." This is what I had to do when I first started and made my DIY exciters out of small speakers, the spider wasn't stiff enough to keep the coil self aligned from the weight of the panel and a spine was a necessity along with a hell of a lot of fiddling with super glue and shims.

As far as cutting off the rubber boot I was worried about major distortion or whatever from the coil but thinking about the design of the FHE25's pictured below, and others like my next purchase, the 30HESF's, they have purposely incorporated holes in the rear for sound from the coil area. (Dayton Audio have the FHE25's now with their IMS plastic Interchangeable mount. I hope they leave the original as an option.)

The boot can be removed with an exacto knife fairly easily and seems to be a one way ticket, but they are toast to me as is anyway. I'm gonna' do it.

I usually stay away from exciters with holes aka vents in the rear as sound does come out of those vents. DML's radiate sound equally from the front and back in phase. Sound radiating from the exciters vents combined with the sound radiating from the rear of the panel where the exciter resides can cause out of phase issues.

Last edited:

We are talking about a solution as related to a large panel DML, not a 3in or 5in BMR driver unit. Dude, you need to relax and chill - we all can do without the aggressive tone of a condescending expert. We are all here to have fun and learn through sharing and good natured posts. Please try be civil if not for the sake of peace over the holidays.Who's we? lol Yes we have and its been around forever. Its called a Loudspeaker DRIVER. Or in DML terms its a BMR driver or Sony likes to call them APM, others like techniques call it flat honeycomb? Yamaha has done it , Bertagni has done it. etc etc.

The Basket (aka. Frame)– the physical structure that holds the entire driver together holding the magnet in place like a brace/spine.

The Suspension (surround) usually made of cloth, foam or butyl rubber holds the diaphragms weight in place.

For those seeking a more peaceful thread.

1. Click on the offending profiles logo

2. On the bottom right of the profile page you will see a button “other options’

3. On the bottom of the menu that drops down you will find the block button.

This is a reversible action so does no harm

Burnt

1. Click on the offending profiles logo

2. On the bottom right of the profile page you will see a button “other options’

3. On the bottom of the menu that drops down you will find the block button.

This is a reversible action so does no harm

Burnt

Shame ..but Peace on Earth ... 🌍👍For those seeking a more peaceful thread.

1. Click on the offending profiles logo

2. On the bottom right of the profile page you will see a button “other options’

3. On the bottom of the menu that drops down you will find the block button.

This is a reversible action so does no harm

Burnt

Eucy

We are talking about a solution as related to a large panel DML, not a 3in or 5in BMR driver unit. Dude, you need to relax and chill - we all can do without the aggressive tone of a condescending expert. We are all here to have fun and learn through sharing and good natured posts. Please try be civil if not for the sake of peace over the holidays.

Dude you need to relax and chill I am not the one with the problem its yawl. SMDH Sorry if you feel the way I talk is aggressive I will try to tone it down a bit but calling me names in not appropriate either as its not civil. Plus you barely contribute to this thread anymore.

First off how large is considered a "large panel DML"? Second I never said anything about the size of a BMR driver I said you would design the frame and suspension like it I never said build it the size of a 3 or 5inch BMR. I thought it was common sense but I guess not. You can build it to ANY SIZE you want as there are 21inch conventional cone drivers, not sure if it meets your specifications of large?

Last edited:

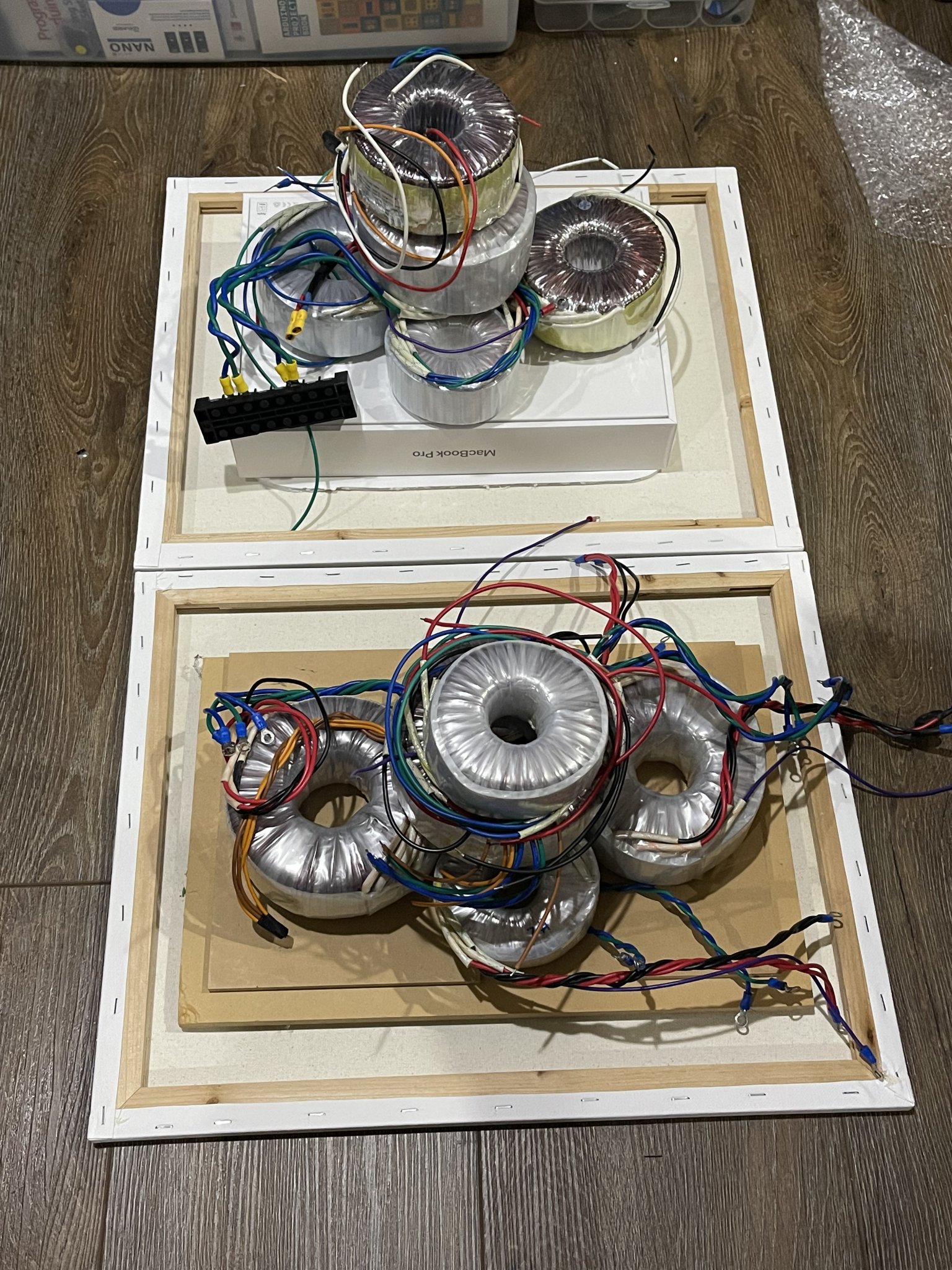

I can’t remember who had the suggestion to mount a driver to a flat board glued to the back of a mounted canvas frame. I bought these frames years ago and finally having some time to make this DML. I applied Titebond glue to an Elmers brand foam board cut about 2in smaller than the frame. I’m using a flat hard object and a bunch of weights (trafos in this case) to clamp the board to the canvas while it dries. I tested a Tectonics TEAX32C30-4/B driver by resting it on the board (no glue) and it sounded promising. So waiting for the glue to dry now before installing the driver. I recall someone used a cross brace on the back of the driver magnet to get more bass. These are 20in x 16in frames.

I think you've gone a little overboard with the panel weights 🤣😂I can’t remember who had the suggestion to mount a driver to a flat board glued to the back of a mounted canvas frame. I bought these frames years ago and finally having some time to make this DML. I applied Titebond glue to an Elmers brand foam board cut about 2in smaller than the frame. I’m using a flat hard object and a bunch of weights (trafos in this case) to clamp the board to the canvas while it dries. I tested a Tectonics TEAX32C30-4/B driver by resting it on the board (no glue) and it sounded promising. So waiting for the glue to dry now before installing the driver. I recall someone used a cross brace on the back of the driver magnet to get more bass. These are 20in x 16in frames.

View attachment 1122715

It was offgrid who first posted the art panel idea ,I believe.

This is probably the one I will build for my friend.

What board material are you using, I will probably use the crate ply for my friends panels.

Crate ply has a more lively sound than the standard ply.

I'm going to have to buy a few more panels first, hopefully I can get them as cheaply as before 😬

Steve.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker