Help Please

This is the material I have been referring to as high density EPS, came from a very large cooler. I know that EPS is made from beads of foam within a mold so am really not sure. It sounds way more natural than the really hard Pink Panther material that I have which is for sure XPS. Regardless, this is the best sounding material I have tried so far. I'm still going to revisit the canvas panels later but for now am happy.

Any thoughts from the photos would be appreciated:

This is the material I have been referring to as high density EPS, came from a very large cooler. I know that EPS is made from beads of foam within a mold so am really not sure. It sounds way more natural than the really hard Pink Panther material that I have which is for sure XPS. Regardless, this is the best sounding material I have tried so far. I'm still going to revisit the canvas panels later but for now am happy.

Any thoughts from the photos would be appreciated:

Attachments

I went with 3.2 mm since that seems like what Tectonic is using for their plates. I figured I can't really go wrong using same dimensions and thickness as they do, since they have put a bit of effort into coming up with those numbers I assume.

Both with the printed plates and the EPS plates I'm actually quite surprised that size and thickness of the plate doesn't matter more than it does. I could spend a lot of time iterating and improving but in the end it seems like the differences will be pretty small, and I'm quite happy with the results of EPS without doing a lot of tweaking and even without EQ apart from an HPF.

Both with the printed plates and the EPS plates I'm actually quite surprised that size and thickness of the plate doesn't matter more than it does. I could spend a lot of time iterating and improving but in the end it seems like the differences will be pretty small, and I'm quite happy with the results of EPS without doing a lot of tweaking and even without EQ apart from an HPF.

Toddincabo.

this material looks like the expanding foam used by builders to fill in gaps between piping and walls ?

As well as insulting fridges and freezers.

not EPS.

Steve.

this material looks like the expanding foam used by builders to fill in gaps between piping and walls ?

As well as insulting fridges and freezers.

not EPS.

Steve.

JohnnoG.

I was thinking of trying the 2 mm protex material for one of my small panels ?

I also noticed that they make a 3mm panel.

I can get the 2mm from wickes down the road, but probably won't bother getting the 3mm + postage.

the two types of panel you sent me have a pretty good sound, with very little build time.

you just have to cut them to the size you want.

I'm going to try my thin strip of paper and see if this improves things a little ?

I'm sure most people would be happy and surprised at the very good full range sound quality produced but these 2ft panels.

Heavy panels do seem to have a problem with low level detail though, (not so much the old veg crate?) Similar to heavy cone drivers.

Steve.

I was thinking of trying the 2 mm protex material for one of my small panels ?

I also noticed that they make a 3mm panel.

I can get the 2mm from wickes down the road, but probably won't bother getting the 3mm + postage.

the two types of panel you sent me have a pretty good sound, with very little build time.

you just have to cut them to the size you want.

I'm going to try my thin strip of paper and see if this improves things a little ?

I'm sure most people would be happy and surprised at the very good full range sound quality produced but these 2ft panels.

Heavy panels do seem to have a problem with low level detail though, (not so much the old veg crate?) Similar to heavy cone drivers.

Steve.

Steve, this was my exact thought upon first seeing and holding it, the color and everything. I have used can spray foam many times. "Spray foam insulation is made by combining isocyanate and polyol resin into a foam. Polyurethane, a polymer made of organic units, is the most commonly used material for spray foam."Toddincabo.

this material looks like the expanding foam used by builders to fill in gaps between piping and walls ?

As well as insulting fridges and freezers.

not EPS.

Steve.

This stuff is way more dense than what I've seen from the can. Below photo shows the pink stuff and I guess a medium EPS panel. I use the "rope saw" strung taught technique from one of my earlier posts to thin my material and this stuff was dry to the bone and extruded a very fine powder dust. The EPS and the XPS pictured had more of a faint "rubbery", thick dust.

I'll call this material "Poly"? I mounted the exact exciters to the Poly and the EPS pictured with the Poly panel being 16"x10"x1/2" and the EPS being 18"x12"x1/2" and did an extensive A-B comparison. The medium grade EPS was more efficient/louder but did not sound as natural as the Poly. These Poly panels are amazing at wood instruments and vocals as well.

"Polyurethane, a polymer made of organic units". These panels are for sure the most organic sounding panels I've yet tried, which is my preferred taste. We just may have a contender here.

I guess a thin form could be built and lined with whatever skin desired and spray some high density can foam into it, remove the form, cut to size and Voila! Man, that's all I need is a new project, but will keep this in the back of my mind.

Attachments

Hi Steve

If you can hold off, I will send you samples of what I will refer to as the lightest ribbed material I can get access to.

It will most likely be 3mm, but it will be noticeably much less rigid that the samples you have at present.

As said in a earlier post the lighter weight materials are easy to form a shape from without scribing it, the material is about as resistant as a light weight corrugated cardboard.

Maybe a few rods threaded internally inside the flutes will help, but I'm sure with your experiences there will be a method that can produce a improved rigidity if wanted.

From my end, I'm glad the thread caught my attention, and has led to having a curiosity for a material that has now proved to be one that is to be placed on the usable list.

If you can hold off, I will send you samples of what I will refer to as the lightest ribbed material I can get access to.

It will most likely be 3mm, but it will be noticeably much less rigid that the samples you have at present.

As said in a earlier post the lighter weight materials are easy to form a shape from without scribing it, the material is about as resistant as a light weight corrugated cardboard.

Maybe a few rods threaded internally inside the flutes will help, but I'm sure with your experiences there will be a method that can produce a improved rigidity if wanted.

From my end, I'm glad the thread caught my attention, and has led to having a curiosity for a material that has now proved to be one that is to be placed on the usable list.

JohnnoG.

OK I will wait and see what you send me.

If the panel is too floppy , I will just make the panel smaller.

I did have my eye on the 3mm anyway.

Personally I avoid panels that are too rigid.

Its not just that the panels you sent me are usable, it is the fact that they are easy to make.

I just stuck the exciter on the 2ft panels you sent me and that was it 😀

I did find today that my strips of paper , does help the sound, in my opinion ,that is.

but the sound from get go was good.

good enough for me to keep listening, and playing more CDs.

I had no problem with the performance of the corrugated cardboard I first started with , it was just the sound of the cardboard .

The panels you sent me have quite a neutral sound , with low coloration.

although they have a good flat response to 20k ,the hf is a little subdued, similar to the podiums.

I have mainly been listening to jazz, using the panels full range, listening to close mic recordings of the double bass.

So far no problems, in my room anyway ?

steve.

OK I will wait and see what you send me.

If the panel is too floppy , I will just make the panel smaller.

I did have my eye on the 3mm anyway.

Personally I avoid panels that are too rigid.

Its not just that the panels you sent me are usable, it is the fact that they are easy to make.

I just stuck the exciter on the 2ft panels you sent me and that was it 😀

I did find today that my strips of paper , does help the sound, in my opinion ,that is.

but the sound from get go was good.

good enough for me to keep listening, and playing more CDs.

I had no problem with the performance of the corrugated cardboard I first started with , it was just the sound of the cardboard .

The panels you sent me have quite a neutral sound , with low coloration.

although they have a good flat response to 20k ,the hf is a little subdued, similar to the podiums.

I have mainly been listening to jazz, using the panels full range, listening to close mic recordings of the double bass.

So far no problems, in my room anyway ?

steve.

Jaxboy.

If I remember correctly, the 901s were supposed to have a clear uncluttered rear wall to reflect the sound off of.

With a good bit of space behind .

I doubt most people had the room for this, and you shouldn't really toe them in,in my opinion, as this would make one side of the 901s fire directly at the wall .

Similar to the problem of having the dml panel too close and parallel to the wall , the sound would bounce straight back to the drivers.

It was a good idea to fire the sound across the wall , not directly at it, and the same for DML.

I think a lot of people used to turn them around for a more direct sound, similar to the ones used for PA use on vocals ?

Steve.

If I remember correctly, the 901s were supposed to have a clear uncluttered rear wall to reflect the sound off of.

With a good bit of space behind .

I doubt most people had the room for this, and you shouldn't really toe them in,in my opinion, as this would make one side of the 901s fire directly at the wall .

Similar to the problem of having the dml panel too close and parallel to the wall , the sound would bounce straight back to the drivers.

It was a good idea to fire the sound across the wall , not directly at it, and the same for DML.

I think a lot of people used to turn them around for a more direct sound, similar to the ones used for PA use on vocals ?

Steve.

Steve,

I bought my first set of 901s in Germany at the audio center for the GIs. When I got the set home and set them up, they just didn't sound right, so I went back to the center. As it turned out, the Bose representative was there demonstrating them. I told him of the problem. He had a date with a smoking hot girl but told her he needed to help me. He took his computer and followed me to my house. He spent about an hour setting up my system. (So my system followed what the factory rep said was the best way to set them up. After that I always used a tape measure to set them up.) It turns out my wires were too small. He gave me his. He was so nice during the whole process. I wrote Bose telling them of his service. At a later base I went to their audio center, and another representative was there. I asked about him. He said the first guy was now vice president in charge of sales! I'd like to think that my letter had at least a little to do with that.

I bought my first set of 901s in Germany at the audio center for the GIs. When I got the set home and set them up, they just didn't sound right, so I went back to the center. As it turned out, the Bose representative was there demonstrating them. I told him of the problem. He had a date with a smoking hot girl but told her he needed to help me. He took his computer and followed me to my house. He spent about an hour setting up my system. (So my system followed what the factory rep said was the best way to set them up. After that I always used a tape measure to set them up.) It turns out my wires were too small. He gave me his. He was so nice during the whole process. I wrote Bose telling them of his service. At a later base I went to their audio center, and another representative was there. I asked about him. He said the first guy was now vice president in charge of sales! I'd like to think that my letter had at least a little to do with that.

johnnoG.

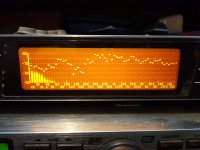

i was half way through this recording when the wire from the left exciter broke.

that is another reason its a good idea to brace the exciter, to stop the wires flexing and eventually snapping from the terminals .

but the recording shows the low end performance before terminating .

i was playing the music quite loud and the AVC kept cutting in, which was annoying .

i did try recording at a lower volume but the same happened.

my 10watt exciters were starting to get warm using them full range, so a more powerful exciter is needed for that.

but it shows good output to about 30hz with a little roll off from 40hz in my room.

nice and solid.

as you can hear in the recording.

the mic was at about 1m and the panels were pointing straight down the room ,with no toe in.

steve.

i was half way through this recording when the wire from the left exciter broke.

that is another reason its a good idea to brace the exciter, to stop the wires flexing and eventually snapping from the terminals .

but the recording shows the low end performance before terminating .

i was playing the music quite loud and the AVC kept cutting in, which was annoying .

i did try recording at a lower volume but the same happened.

my 10watt exciters were starting to get warm using them full range, so a more powerful exciter is needed for that.

but it shows good output to about 30hz with a little roll off from 40hz in my room.

nice and solid.

as you can hear in the recording.

the mic was at about 1m and the panels were pointing straight down the room ,with no toe in.

steve.

Attachments

Out of curiosity, has anyone tried with an old satellite dish ? Could be interesting, also, it might needs some coating to remove the metallic sound....

Hi Steve

I have sent all of your made available music files using the ribbed panels to friends from my local HiFi Group who use Headphones, they can benefit from these productions as well.

On the subject of Materials to be tried, there are also numerous High Tensile Lightweight Fabrics in use today, one such material seen regularly, but would not be suspected for being a materials that is a Fabric, is a Stadium Roof, these used materials are designed to evaporate at a certain temperature of heat exposure.

The Link will show a few structures covered in a High Tensile Fabric, the weight per m2 and a method to apply a surface tensioning will need a little more investigation.

A very basic and quite affordable material would be the mesh reinforced Plastic Sheeting known as Monarflex that is found at a range of weights between 140-180g per m2.

https://streetspacegroup.co.uk/tensile-fabric-structures/#

http://www.monarflex.com/Product Guide/Weather protection/Scaffold sheeting.aspx

I have sent all of your made available music files using the ribbed panels to friends from my local HiFi Group who use Headphones, they can benefit from these productions as well.

On the subject of Materials to be tried, there are also numerous High Tensile Lightweight Fabrics in use today, one such material seen regularly, but would not be suspected for being a materials that is a Fabric, is a Stadium Roof, these used materials are designed to evaporate at a certain temperature of heat exposure.

The Link will show a few structures covered in a High Tensile Fabric, the weight per m2 and a method to apply a surface tensioning will need a little more investigation.

A very basic and quite affordable material would be the mesh reinforced Plastic Sheeting known as Monarflex that is found at a range of weights between 140-180g per m2.

https://streetspacegroup.co.uk/tensile-fabric-structures/#

http://www.monarflex.com/Product Guide/Weather protection/Scaffold sheeting.aspx

JohnnoG.

OH NO 😱 you have sent my poorly recorded music files to the, GOLDEN EAR BRIGADE !

I hope there will not be too much coughing and spluttering going on.

I might try 2 or 4 of my 10watt exciters and see what happens with the low frequencies, I could Even try the tectonic mounting method ?

I'll have to think about how to implement this ?

But there is no rush.

I did a quick test with some small weights to see if I could fill the usual dip in the response in the 100hz to 200hz .

I had some success, but the low frequencies suffered a little.

Maybe the extra exciters would sort this ?

So with a more powerful exciter or with more low powered exciters , this could be a good full range panel ?

It would be interesting to know how powerful an output in the LF this 2ft panel could do ?

My single exciter is at its limits , let's face it , they were never designed to go this low, let alone at this power rating !

Steve.

OH NO 😱 you have sent my poorly recorded music files to the, GOLDEN EAR BRIGADE !

I hope there will not be too much coughing and spluttering going on.

I might try 2 or 4 of my 10watt exciters and see what happens with the low frequencies, I could Even try the tectonic mounting method ?

I'll have to think about how to implement this ?

But there is no rush.

I did a quick test with some small weights to see if I could fill the usual dip in the response in the 100hz to 200hz .

I had some success, but the low frequencies suffered a little.

Maybe the extra exciters would sort this ?

So with a more powerful exciter or with more low powered exciters , this could be a good full range panel ?

It would be interesting to know how powerful an output in the LF this 2ft panel could do ?

My single exciter is at its limits , let's face it , they were never designed to go this low, let alone at this power rating !

Steve.

Hi Steve

There is an experiment or two in waiting for the Ribbed Sheet. I await with anticipation for the reports to be returned.

There are a couple of reports returned on the Listening of the Files, and both are very kind and complimentary in the evaluation with one additional inquiry.

Is the efficiency of the DML Panels being produced known?

I am assuming one listener, is wondering, would these Panels work with a 3 Watt SE Valve Amp they use in a Second System, that is set up in a room with a limited space for equipment, as they referred to them being an alternative to building a Karlsonator Speaker

There is an experiment or two in waiting for the Ribbed Sheet. I await with anticipation for the reports to be returned.

There are a couple of reports returned on the Listening of the Files, and both are very kind and complimentary in the evaluation with one additional inquiry.

Is the efficiency of the DML Panels being produced known?

I am assuming one listener, is wondering, would these Panels work with a 3 Watt SE Valve Amp they use in a Second System, that is set up in a room with a limited space for equipment, as they referred to them being an alternative to building a Karlsonator Speaker

JohnnoG.

No sooner than I mentioned these exciters were not built to go this low, then one of the exciters spider came away from the exciter body !

I will put the 2ft EPS panel back up while I repair the exciter, and do some comparisons.

EPS is the most efficient material I have used, I did use a 3watt digital chip amp on my large EPS panels some years ago, but felt I needed a bit more oomph for the levels that I was listen to Them at.

A 3watt valve amp will probably give a little more on short peaks because of the soft clipping ? they do not have the brick wall affect , if I remember correctly ?

It would depend on the type of music and the volume listened at ? XO of the low end frequencies would improve this.

Let's face it ,it is not that hard or expensive ,if you send one of your panels to him 😁

I remember, at one audio show I attended, I walked into a room that was playing small horns using a 2 or 3watt valve set .

I asked if they could turn the volume up a little as I could not hear the music properly (similar to lift misic).

I received a very stern NO ! I had obviously breached some sort of , low wattage code , so had to leave the room , with my head bowed in shame 😱

Steve.

No sooner than I mentioned these exciters were not built to go this low, then one of the exciters spider came away from the exciter body !

I will put the 2ft EPS panel back up while I repair the exciter, and do some comparisons.

EPS is the most efficient material I have used, I did use a 3watt digital chip amp on my large EPS panels some years ago, but felt I needed a bit more oomph for the levels that I was listen to Them at.

A 3watt valve amp will probably give a little more on short peaks because of the soft clipping ? they do not have the brick wall affect , if I remember correctly ?

It would depend on the type of music and the volume listened at ? XO of the low end frequencies would improve this.

Let's face it ,it is not that hard or expensive ,if you send one of your panels to him 😁

I remember, at one audio show I attended, I walked into a room that was playing small horns using a 2 or 3watt valve set .

I asked if they could turn the volume up a little as I could not hear the music properly (similar to lift misic).

I received a very stern NO ! I had obviously breached some sort of , low wattage code , so had to leave the room , with my head bowed in shame 😱

Steve.

Hi Steve

Another discovery made, Ribbed Panels can give an Exciter a tough time, when experimenting to discover its max' potential.

I am picking away presenting the idea of these Panels, I feel confident I will not be the only person from the Group using a version.

As for the Volume Levels that are selected by individuals, I grew up owning on 70's Rock, Blues and Folk, so I just crave volume when listening to this type of music, I have been known to stress the odd speaker out, the 57's have taken my assault well ' i think ? '.

I have a broader interest in music types now, and many are listened to at much lesser volumes.

When in the listening room, it is best for me to go from lower volumes to high, I can't tolerate the opposite, so the early in life enjoyed music, usually finds in place at the later part of a session.

I have found over the years there are Output Tranx's used on certain equipment that are unobtanium, and not possible to replace without a struggle. I have friends with Spare Vintage Amp's on the Sub's Bench for these reasons, there will be a vigilant concern for looking after such components.

The only other reason I could imagine is that a Break Up occurs and a distortion becomes quite noticeable, not good when demonstrating to the Public, they will 'av' ya', the Mob at a HiFi Gathering don't do mercy.

You were probably seen to be plant trying to initiate a Public Stoning 🤾♂️ 🙂

Another discovery made, Ribbed Panels can give an Exciter a tough time, when experimenting to discover its max' potential.

I am picking away presenting the idea of these Panels, I feel confident I will not be the only person from the Group using a version.

As for the Volume Levels that are selected by individuals, I grew up owning on 70's Rock, Blues and Folk, so I just crave volume when listening to this type of music, I have been known to stress the odd speaker out, the 57's have taken my assault well ' i think ? '.

I have a broader interest in music types now, and many are listened to at much lesser volumes.

When in the listening room, it is best for me to go from lower volumes to high, I can't tolerate the opposite, so the early in life enjoyed music, usually finds in place at the later part of a session.

I have found over the years there are Output Tranx's used on certain equipment that are unobtanium, and not possible to replace without a struggle. I have friends with Spare Vintage Amp's on the Sub's Bench for these reasons, there will be a vigilant concern for looking after such components.

The only other reason I could imagine is that a Break Up occurs and a distortion becomes quite noticeable, not good when demonstrating to the Public, they will 'av' ya', the Mob at a HiFi Gathering don't do mercy.

You were probably seen to be plant trying to initiate a Public Stoning 🤾♂️ 🙂

JohnnoG.

I know we talk about the good sound quality of the dml panels, but it is also about the performance !

You can stand or sit (or even lie on the floor !) anywhere in the room and still feel you are hearing the full performance, (no trying to clamp your head in the minute sweet spot !)

If you move to the left of the left panel , the soundstage moves with you, you can hear both panels perfectly.

Listening to ordinary speakers at an audio show becomes more of a trial, because it you are not sitting in the middle you will loose one of the speakers.

or the speakers are pointing down the room with no soundstage in the middle ?

DMLs are a new experience .

This is why I could never go back to ordinary speakers , and why I strive to get the best sound possible from them.

Steve.

I know we talk about the good sound quality of the dml panels, but it is also about the performance !

You can stand or sit (or even lie on the floor !) anywhere in the room and still feel you are hearing the full performance, (no trying to clamp your head in the minute sweet spot !)

If you move to the left of the left panel , the soundstage moves with you, you can hear both panels perfectly.

Listening to ordinary speakers at an audio show becomes more of a trial, because it you are not sitting in the middle you will loose one of the speakers.

or the speakers are pointing down the room with no soundstage in the middle ?

DMLs are a new experience .

This is why I could never go back to ordinary speakers , and why I strive to get the best sound possible from them.

Steve.

Look what I found on my way back from London ,late last night .

Three new dml panels 😁

I can now do some proper testing of this material.

this material is very bendy and springy.

not like other plys, which are more rigid.

Is this the magic of this material ?

Steve

Three new dml panels 😁

I can now do some proper testing of this material.

this material is very bendy and springy.

not like other plys, which are more rigid.

Is this the magic of this material ?

Steve

Attachments

JohnnoG.

Some very quick measurements from my seating position ,showing the room dip at about 160hz .

I just quickly moved some weights about the panel to try to fill in the gap, with some success.

The first pic is without the weights, the second is with the weights.

With a little more time (and a computer program 😁) I could do better.

The third pic is with two strips of paper 😱 which I have never done before, heaven knows why ? But it has overdone it a bit above 10k? But still sounds good to me.

Dml panels are very flexible (pun intended) and are very easy to mould into the sound you want.

You just have to know what you are doing 😁

Steve.

Some very quick measurements from my seating position ,showing the room dip at about 160hz .

I just quickly moved some weights about the panel to try to fill in the gap, with some success.

The first pic is without the weights, the second is with the weights.

With a little more time (and a computer program 😁) I could do better.

The third pic is with two strips of paper 😱 which I have never done before, heaven knows why ? But it has overdone it a bit above 10k? But still sounds good to me.

Dml panels are very flexible (pun intended) and are very easy to mould into the sound you want.

You just have to know what you are doing 😁

Steve.

Attachments

As I have to remove the exciter to fix the spider, I thought I would test how strong the glue was holding.

I did try prising off the exciter with a Stanley knife but thought I might damage something or me.

So I decided to use an old tried method of just dropping the panel on its edge .

This has worked in the past when I have accidentally dropped a panel 🙄

And yes it worked perfectly.

On the panel in the pic you can see the area I applied a neat coating of pva before gluing on the exciter.

As you can see, There is still a ring of glue on the exciter foot

You can also see the strip of wood showing where the spider was coming away from the exciter.

I shall probably apply some pva to this area.

Problem solved.

I also noticed that the screw I was using to mount the panel was slowly sagging as the surface is not strong enough to hold weight of the panel and exciter.

So now have inserted an elastic band through the hole, which seems to be fine for now.

Steve.

I did try prising off the exciter with a Stanley knife but thought I might damage something or me.

So I decided to use an old tried method of just dropping the panel on its edge .

This has worked in the past when I have accidentally dropped a panel 🙄

And yes it worked perfectly.

On the panel in the pic you can see the area I applied a neat coating of pva before gluing on the exciter.

As you can see, There is still a ring of glue on the exciter foot

You can also see the strip of wood showing where the spider was coming away from the exciter.

I shall probably apply some pva to this area.

Problem solved.

I also noticed that the screw I was using to mount the panel was slowly sagging as the surface is not strong enough to hold weight of the panel and exciter.

So now have inserted an elastic band through the hole, which seems to be fine for now.

Steve.

Attachments

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker