Plywood is not a good material because its layers of wood with glue between each layer so it becomes stronger but it also becomes heavy and over damped.

I was actually wondering if the damping provided by the glue layers isn't actually the reason "Sureply" plywood sounds better (to me anyway) than XPS or foamcore (xps with paper skin) or gatorfoam (xps with fiberboard skins).

I was very surprised, I must admit, that the plywood sounded better than gatorfoam. Conventional wisdom would say that the lighter, stiffer gatorfoam would make a better DML panel. I was really eager to get some and hear it. Well the gatorfoam is certainly louder. But the plywood sound seems more realisitic (to both me and my wife) than gatorfoam.

I sure hope I find something better than the plywood, but so far it's the best I've heard.

Interesting that the wood sounds better. There is another (very similar) product called Lite Ply, but probably better quality. It is a plywood made from Poplar - primarily used in model aircraft. Probably not as lightweight but much stronger than Balsa wood."Sureply" plywood sounds better (to me anyway) than XPS or foamcore (xps with paper skin) or gatorfoam (xps with fiberboard skins).

I sure hope I find something better than the plywood, but so far it's the best I've heard.

LITE PLY PLYWOOD | Aircraft Spruce

Did anyone use EPS?

The YT video comparing materials did not include EPS because he was not able to stick a exciter to it.

In the second video he comes up with good sounding 'acoustic ceiling tiles' which have paper on both sides but are brittle and heavy.

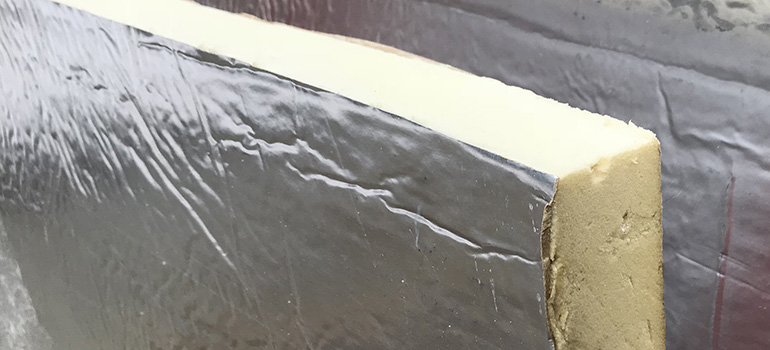

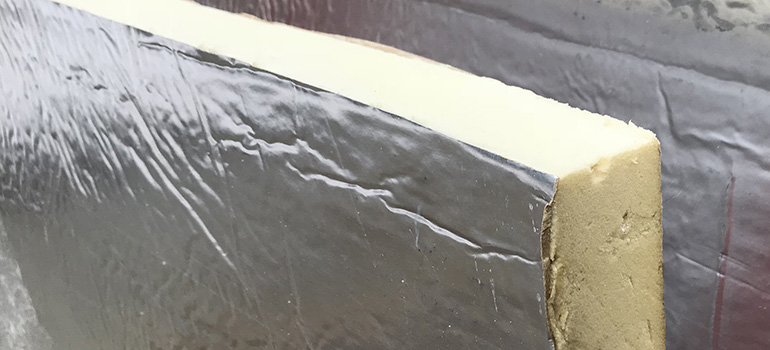

Did anyone test PIR/polyiso/polyisocyanurate foam panels?

They are often sold with aluminum foil on both sides:

I have a few left over pieces of similar panels and these are very stiff but are quite a bit heavier then the EPS panels that I have.

The foil does not stretch (much?), it is the foam that compresses when I bend it.

EPS/XPS with paper (spray) glued on it will be lighter and behave similar.

The EPS 60 panels that I have are 100x50cm and 3cm thick. The 60 seems to be an indication for compressive strength or density. I can also find EPS 100 but only in 200x100x10cm which is probably way to thick. 🙁

I also found EPS with black dots in it, is that recycled?

Over here EPS is sold for €8 a package while XPS costs about €40. You get a bit bigger and more sheets of XPS but it is still about 2.5 times as expensive. And I don't need 20 speakers...... (yet) 😉

I will use the $20 tpa3116 2.1 amp with high pass and a €30 2nd hand passive sub; €90 for a complete system. 🙂

I'm looking forward to my exciters to be delivered so I can finally hear DML's for the first time.

some DML links I found:

Carbon fiber panels YT

aluminium honeycomb panels YT

Analysis of Flat Panel Speakers.pdf

http://www.vxm.com/NXT.html

How a wide diffuse DML can perform so well in reverberant spaces. YT

Tectonic Intelligibility Demo YT looks like they have closed backs

DML line array; 2 panels with 400W each + ribbon tweeter

Roll-up DML line array anyone?

These Tectonic panels have a metallic look, does anyone know what material they are made off?

Alu foil might be worth a try instead of paper.

The YT video comparing materials did not include EPS because he was not able to stick a exciter to it.

In the second video he comes up with good sounding 'acoustic ceiling tiles' which have paper on both sides but are brittle and heavy.

Did anyone test PIR/polyiso/polyisocyanurate foam panels?

They are often sold with aluminum foil on both sides:

I have a few left over pieces of similar panels and these are very stiff but are quite a bit heavier then the EPS panels that I have.

The foil does not stretch (much?), it is the foam that compresses when I bend it.

EPS/XPS with paper (spray) glued on it will be lighter and behave similar.

The EPS 60 panels that I have are 100x50cm and 3cm thick. The 60 seems to be an indication for compressive strength or density. I can also find EPS 100 but only in 200x100x10cm which is probably way to thick. 🙁

I also found EPS with black dots in it, is that recycled?

Over here EPS is sold for €8 a package while XPS costs about €40. You get a bit bigger and more sheets of XPS but it is still about 2.5 times as expensive. And I don't need 20 speakers...... (yet) 😉

I will use the $20 tpa3116 2.1 amp with high pass and a €30 2nd hand passive sub; €90 for a complete system. 🙂

I'm looking forward to my exciters to be delivered so I can finally hear DML's for the first time.

some DML links I found:

Carbon fiber panels YT

aluminium honeycomb panels YT

Analysis of Flat Panel Speakers.pdf

http://www.vxm.com/NXT.html

How a wide diffuse DML can perform so well in reverberant spaces. YT

Tectonic Intelligibility Demo YT looks like they have closed backs

DML line array; 2 panels with 400W each + ribbon tweeter

Roll-up DML line array anyone?

These Tectonic panels have a metallic look, does anyone know what material they are made off?

Alu foil might be worth a try instead of paper.

Interesting that the wood sounds better. There is another (very similar) product called Lite Ply, but probably better quality. It is a plywood made from Poplar - primarily used in model aircraft. Probably not as lightweight but much stronger than Balsa wood.

LITE PLY PLYWOOD | Aircraft Spruce

Yeah, I was thinking the same thing. I was looking for a source of smaller pieces as 4x8 sheets are pretty expensive to ship, I expect. The model airplane suppliers sell it but theirs is too narrow (12"), I fear.

I did order some of this:

https://www.homedepot.com/p/Columbi...VB56fCh2qrAzAEAQYASABEgIfvfD_BwE&gclsrc=aw.ds

I should have it in a day or two. But I'm not sure it's the same. It says it's Poplar, but I wonder if it's just the veneer that's Poplar? Anyway it was cheap enough to take a risk.

I'd still be interested to try Balsa, or Balsa plywood, if I could find sheets about 16"x24" or larger at reasonable cost.

Eric

TecCell anyone?

YouTube

Or honeycomb core plywood?

Wood panels

Lightweight Panels, Wall Panels, Wood Veneer Honeycomb core by Sing Homes

Lightweight Structural Marine Honeycomb Sandwich Plywood for Boat Builders - Non-warping patented wooden pivot door, sliding door, and Eco-friendly metal cores

Marine Honeycomb and Plascore Board™ for Boat Building

YouTube

Or honeycomb core plywood?

Wood panels

Lightweight Panels, Wall Panels, Wood Veneer Honeycomb core by Sing Homes

Lightweight Structural Marine Honeycomb Sandwich Plywood for Boat Builders - Non-warping patented wooden pivot door, sliding door, and Eco-friendly metal cores

Marine Honeycomb and Plascore Board™ for Boat Building

Last edited:

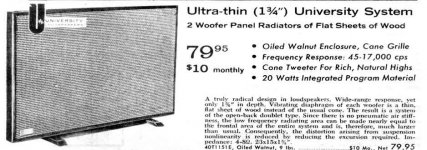

Never messed with any of this, but I remember seeing some not-so-distributed plywood designs from the 60's aimed at working more conventionally (the DM-stuff was maybe Ambience). Those guys just stuck tweeters in the boards.

Names escape me now but the advanced acoustics biphonic coupler has an interesting rear treatment.

Again memory fails but I think Abe Cohen had a hand in some of this stuff (???)

Names escape me now but the advanced acoustics biphonic coupler has an interesting rear treatment.

Again memory fails but I think Abe Cohen had a hand in some of this stuff (???)

Attachments

My interest in this topic relates to the possibility of using a DML panel as part of a FAST type setup over an OB woofer.

In particular, I'd be interested to get a feel for how a DML panel would perform in comparison to a normal cone mid or mid/tweeter with respect to the kinds of dipole peaks and troughs we typically see. Furthermore, is there any particular panel size which might seem optimal for say frequencies of 200hz upwards.

In particular, I'd be interested to get a feel for how a DML panel would perform in comparison to a normal cone mid or mid/tweeter with respect to the kinds of dipole peaks and troughs we typically see. Furthermore, is there any particular panel size which might seem optimal for say frequencies of 200hz upwards.

I may have found the answer further up in this thread re. dipole behaviour: basically DML seems less problematic than OB coned regarding front/back cancellations and reinforcements.

In terms of sizing, a golden ratio of something like 36x58cm with the exciter placed at a golden ratio point looks like it might work well for >200hz purposes. It would sit pretty well in a frame above my 45cm wide U frame bass unit.

In terms of sizing, a golden ratio of something like 36x58cm with the exciter placed at a golden ratio point looks like it might work well for >200hz purposes. It would sit pretty well in a frame above my 45cm wide U frame bass unit.

Yeah, I was thinking the same thing. I was looking for a source of smaller pieces as 4x8 sheets are pretty expensive to ship, I expect. The model airplane suppliers sell it but theirs is too narrow (12"), I fear.

I did order some of this:

https://www.homedepot.com/p/Columbi...VB56fCh2qrAzAEAQYASABEgIfvfD_BwE&gclsrc=aw.ds

I should have it in a day or two. But I'm not sure it's the same. It says it's Poplar, but I wonder if it's just the veneer that's Poplar? Anyway it was cheap enough to take a risk.

I'd still be interested to try Balsa, or Balsa plywood, if I could find sheets about 16"x24" or larger at reasonable cost.

Eric

End-grain Balsa in various sizes and thickness at a reasonable price: Amazon.com: end grain balsa wood

Since the plywood you are buying comes with free custom cutting, why not cut them down slightly to the NXT recommended "golden ratio" which is 1.134 times the shortest length or conversely 0.882 times the longest length. That would give you a panel size of ~21.2" x 24". According to NXT that's the best panel dimensions to create the most amount of and evenness of distribution of resonant nodes and thereby creating the flattest Freq Resp.

I may have found the answer further up in this thread re. dipole behaviour: basically DML seems less problematic than OB coned regarding front/back cancellations and reinforcements.

In terms of sizing, a golden ratio of something like 36x58cm with the exciter placed at a golden ratio point looks like it might work well for >200hz purposes. It would sit pretty well in a frame above my 45cm wide U frame bass unit.

DML's are more or less Bipoles, not Dipoles. I.e., there radiation pattern in back is in phase with the front. There is minimal cancellation from front to back. Just the opposite of bipoles. However, they are not quite omni-directional. The radiation pattern is more like a figure 8, where there is significantly less sound coming from the side edges of the panel. (Think of a balloon you pinch between your fingers in the middle of it). The radiation angle at the sides is fairly narrow. So if you walk between 2 DML's you will hear less sound directly between the panels for just a small angle. Its this wide dispersion sound field that gives the DML's its "magic". No point source here, no directionality per se. Just a seemingly endless sound field that surrounds you with no particular sweet spot. It really does make it feel like your in the audience of a live event, rather than just sitting in front of 2 directional piston-type speakers. But as others have said the sound presentation is just so different that it can take a few playings to get used it before you realize that its just so right...no beaming in your face, single spot for perfect listening that you get with piston/cone speakers...and no cabinet reflections/distortions...

Found a video that shows the tectonic panels @YT:

50cm x 40cm x 3,5-4,0mm (20" x 16" x a bit more then 1/8") so very thin.

Light, (extremely) stiff, sandwich, honeycomb inside with 2 skins, "aviation and F1 technology"

The core is just to separate the 2 skins. The skins have a very high compression and tensile strength. Something like carbon fiber with epoxy but it has a metallic look. Anyone?

Foam, wood and all the soft plastics look a lot less good to me now..... But I will make the EPS with paper panels anyway as they are very easy and cheap to make and my first chance to experience this kind of sound.

50cm x 40cm x 3,5-4,0mm (20" x 16" x a bit more then 1/8") so very thin.

Light, (extremely) stiff, sandwich, honeycomb inside with 2 skins, "aviation and F1 technology"

The core is just to separate the 2 skins. The skins have a very high compression and tensile strength. Something like carbon fiber with epoxy but it has a metallic look. Anyone?

Foam, wood and all the soft plastics look a lot less good to me now..... But I will make the EPS with paper panels anyway as they are very easy and cheap to make and my first chance to experience this kind of sound.

Last edited:

End-grain Balsa in various sizes and thickness at a reasonable price: Amazon.com: end grain balsa wood

Since the plywood you are buying comes with free custom cutting, why not cut them down slightly to the NXT recommended "golden ratio" which is 1.134 times the shortest length or conversely 0.882 times the longest length. That would give you a panel size of ~21.2" x 24". According to NXT that's the best panel dimensions to create the most amount of and evenness of distribution of resonant nodes and thereby creating the flattest Freq Resp.

geosand,

Thanks for the balsa link and your comments. I am thinking the end grain balsa isn't really what I want. With no grain in the plain of the sheet I suspect it won't be stiff enough. Of course I could be wrong about that.

I have not seen that NXT aspect ratio of 1.134 before. Do you have an source for that? I'd be interested to read about it. So far, for no particularly good reason, I'm copying the dimensions of the Tectonic DML-10, which is roughly 23"x16".

Eric

Here's another in the Tectonic series of You tube vids:

YouTube

One thing I find especially interesting is modelling result they show starting around 30 seconds in. It shows what appear to be elastic supports along each side that do not extend to the corners of the panel. They also show fixed supports at 4 points, located along the long edges, near (but not at) the corners.

It makes me wonder if the fixed supports help optimize the modal response? Or did they feel they needed fixed supports to have a robust construction, and those locations where chosen because they were the least damaging to the modal response?

You can see what appears to be the fixed support points here too:

YouTube

Eric

YouTube

One thing I find especially interesting is modelling result they show starting around 30 seconds in. It shows what appear to be elastic supports along each side that do not extend to the corners of the panel. They also show fixed supports at 4 points, located along the long edges, near (but not at) the corners.

It makes me wonder if the fixed supports help optimize the modal response? Or did they feel they needed fixed supports to have a robust construction, and those locations where chosen because they were the least damaging to the modal response?

You can see what appears to be the fixed support points here too:

YouTube

Eric

geosand,

Thanks for the balsa link and your comments. I am thinking the end grain balsa isn't really what I want. With no grain in the plain of the sheet I suspect it won't be stiff enough. Of course I could be wrong about that.

I have not seen that NXT aspect ratio of 1.134 before. Do you have an source for that? I'd be interested to read about it. So far, for no particularly good reason, I'm copying the dimensions of the Tectonic DML-10, which is roughly 23"x16".

Eric

The end grain Balsa is what Tech Ingredients says is best on low end and only bested by XPS overall. I'd never heard of end grain before but they did specifically state that type.

The NXT "Golden Ratios" are specified in one of the NXT patents that came out around 2005 I beleive. I don't have it at my fingertips now, but it has been mentioned before in some of the other DML threads. In that patent, they had golden ratios and silver ratios (somewhere around 1.3X and even one around 1.5x that was good). And that was for rectangles. They had other ratios for various oval/oblong type shapes as well. NXT was very prolific in their patents and they are a tremendous source of info and ideas.

There are certain places on the panel that will resonate greater than other areas. An easy way to dampen these resonate areas is through the use of clamping, weighting, removing panel area, adding felt and other materials as dampners also at these resonant points. This will also flatten the FR, but also will tend to move the resonant point to another area of the panel, though at a lower level. At some point it almost becomes a game of wack-a-mole. The idea is to dampen enough, but not too much, to control the resonant modal areas. Another interesting thing is to put exciters at the resonant points. That will increase their output greatly and control that modal point as well...the often suggested 2/5-3/5 points. NXT also has their recommended points that are close to 2/5-3/5 but slightly different. There is also a neat modal map that NXT made available that shows where these point are on a rectangle. I believe they identified 24 specific modal points that could be used for both exciter and dampners. But again using these modal points means that others will potentially show up in other areas...beyond a point your probably just wasting time and remember, adding and taking away from the panel in and of itself changes the panels properties as well...as they say...there is no perfection, just compromises.Here's another in the Tectonic series of You tube vids:

YouTube

One thing I find especially interesting is modelling result they show starting around 30 seconds in. It shows what appear to be elastic supports along each side that do not extend to the corners of the panel. They also show fixed supports at 4 points, located along the long edges, near (but not at) the corners.

It makes me wonder if the fixed supports help optimize the modal response? Or did they feel they needed fixed supports to have a robust construction, and those locations where chosen because they were the least damaging to the modal response?

You can see what appears to be the fixed support points here too:

YouTube

Eric

I really recommend that new comers go back and read the 11+ year long thread at Audio Circle and the other DML threads here and the years long thread at PE. All the links to studies, research papers, Patents, etc...can be found in those threads. They are very enlightening, though some are near impossible to understand without a PhD. I've read most if not everything I could find online and virtually every paper I read had some little nugget of info that could be put to use as another experimentation point. Thats the beauty of DML's for the DIYer and its curse...theres just so much to play with to crack this egg... and there are so many different ways to crack it. Take everything you read here with a grain of salt. I say that because much info here is poorly documented and pictures don't always tell the tale...never the less, this stuff is just pure fun.

Thanks geosand. That's the kind of info I was looking for. The non-cancellation aspect is potentially very useful. I've run with semi-omnis for a year or so (modified Allison 6) and am now playing with OBs. I much prefer the presentation of either to 'point & squirt' traditional box speakers.

DML over OB bass looks an interresting way forward. I use a miniDSP with a pair of TPA3116 amps, so have the facility to tailor the sound to my liking. I need to get the panel materials / construction / dimensions clearer in my head first.

DML over OB bass looks an interresting way forward. I use a miniDSP with a pair of TPA3116 amps, so have the facility to tailor the sound to my liking. I need to get the panel materials / construction / dimensions clearer in my head first.

There is also a neat modal map that NXT made available that shows where these point are on a rectangle. I believe they identified 24 specific modal points that could be used for both exciter and dampners.

I did not recall seeing the NXT modal map before so I did a quick seach and found this:

NXT.......rubbish??....THINK AGAIN!

see post 1791. It shows the modal map and identifies the patent from which the 3/7, 4/9 and 5/13 fractions come.

Thanks for mentioning it.

Concerning the end grain balsa, it may very well be good stuff. I'll have to review the Tech Ingredients Videos and see what exactly they say about it. Though they also liked XPS and ceiling tiles as panels, both of which seem ok to me but not great, and not as good as plywood, at least in my own experience.

Eric

From that post 1791:

" Another helpful tip that can be garnered from the NXT patents involves favorable panel dimensions. They list two ratios that are supposedly the best for rectangular panels. The gold ratio is 1.134:1, and the silver ratio is either 1.37:1 (patent) or 1.41:1 (technical notes) "

3/7 4/9(=2/3) 5/13 are all fractions made of prime numbers.

Natures golden ratio is 1😛hi or 1:1.618 or about 5/8 and is my best bet to use for panel size and exciter location.

Square root Phi = ~1.272 so I would give 1:1.272 also a try as it is close to the NXT numbers

third power root of Phi (?)

Square root 1.272 = 1.1278 = extremely close to the 1.134:1 NXT ratio.

" Another helpful tip that can be garnered from the NXT patents involves favorable panel dimensions. They list two ratios that are supposedly the best for rectangular panels. The gold ratio is 1.134:1, and the silver ratio is either 1.37:1 (patent) or 1.41:1 (technical notes) "

3/7 4/9(=2/3) 5/13 are all fractions made of prime numbers.

Natures golden ratio is 1😛hi or 1:1.618 or about 5/8 and is my best bet to use for panel size and exciter location.

Square root Phi = ~1.272 so I would give 1:1.272 also a try as it is close to the NXT numbers

third power root of Phi (?)

Square root 1.272 = 1.1278 = extremely close to the 1.134:1 NXT ratio.

Last edited:

Think: I was considering 1😛hi as a possibility and then read the NXT numbers (also the recommended exciter positioning). Here in the UK we seem to have to spend twice as much as our friends over the pond for the same products too.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker