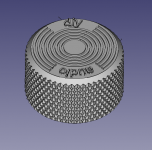

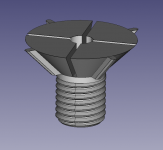

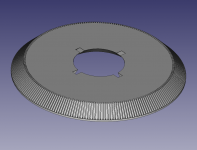

Attached are PNG's of the components of a 3D printed record clamp, and a photo of a completed unit. If there is any interest I will be happy to post the the Freecad files (better, because then it is easy to make your own modifications) and the .STL files. I am making these available under the CC-BY-SA license (that is the sharing license). The design was inspired by several designs that I have seen on thingiverse (for example Ghostly Record Clamp by Feroto - Thingiverse ). None that I saw included the knurling (which helps to twist the knob), the locking wings (which helps with tightening the knob) or the strobe pattern (yes that's a strobe pattern that really works with a 60 hz light).

I made this on an inexpensive DaVinci Pro 1.0 Jr. printer) using 3D Fuel Pro PLA. It seems to work well on my ancient, but still serviceable Thorens TD-160 with home made record mat.

Thanks for looking.

I made this on an inexpensive DaVinci Pro 1.0 Jr. printer) using 3D Fuel Pro PLA. It seems to work well on my ancient, but still serviceable Thorens TD-160 with home made record mat.

Thanks for looking.

Attachments

That’s really nice looking

Now if I only had a 3D printer. Lol

If anyone would print one up for me please message me

Anyway. Nice work

Now if I only had a 3D printer. Lol

If anyone would print one up for me please message me

Anyway. Nice work

Looks like a worthwhile 3D printer project. Ì for one would be interested in the CAD files. Even if just to convert the strobe markings for 50 Hz operation.

Herewith the .STL files. The Freecad files, even zipped, are larger than what diyaudio permits (about 6 mb for two of the three). I'll have to figure out a better

way to distribute them-or I can just e-mail them..

By the way, you can see the formula to calculate the number of bars here:Howmany lines on a strobe disc?- Vinyl Engine

but for Europe, the formula yields 180 bars for 33 1/3. (in the US and Japan it is 216).

way to distribute them-or I can just e-mail them..

By the way, you can see the formula to calculate the number of bars here:Howmany lines on a strobe disc?- Vinyl Engine

but for Europe, the formula yields 180 bars for 33 1/3. (in the US and Japan it is 216).

Attachments

Could you email me the files for all 3 of the record clamp system?

I’ll have to get someone here in Florida to print it up for me

What’s the best material and has the most weight for these?

My email is carlthess@yahoo.com

Thanks

I’ll have to get someone here in Florida to print it up for me

What’s the best material and has the most weight for these?

My email is carlthess@yahoo.com

Thanks

Files are on the way. I can't really tell you what the best filament to use is. I decided that I like, for my printer, 3D-Fuel, Pro PLA. As far as I can tell, this is what is also known as a "Tough" PLA. I find the 3D-Fuel Pro PLA filament to be reasonably priced compared to other tough PLA's, easy to work with and pretty, well, tough. In an earlier version I was making the collets out of PETG because the cheaper PLA I was using kept cracking when I tightened down the knob. But I couldn't (on my machine) get a good finish using PETG (I couldn't eliminate the stringing). I also ended up tweaking the collet design to add a little strength. It seems to work with fine with the Pro PLA.

I have been playing with Cura to do my printing, and still have a lot to learn as to how best to optimize it. I can tell you that I mostly use the default settings for PLA (except temperature) and I am printing at a density of 60%. But this is really going to vary quite a bit depending on your machine.

I have been playing with Cura to do my printing, and still have a lot to learn as to how best to optimize it. I can tell you that I mostly use the default settings for PLA (except temperature) and I am printing at a density of 60%. But this is really going to vary quite a bit depending on your machine.

- Home

- Source & Line

- Analogue Source

- A Small Contribution-3D Printed Record Clamp