Hi @Pano,

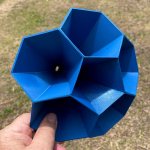

indeed there are many ways to skin a cat. I fact, I first contemplated a pentagon in the center, just like our horn, but my OCD id not allow me to implement something not symmetrical.

Also, I was not aiming for the least restriction, thinking that more load on the diaphragm can improve the damping.

These ideas were unsupported by any rigorous analysis.

Kindest regards,

M

indeed there are many ways to skin a cat. I fact, I first contemplated a pentagon in the center, just like our horn, but my OCD id not allow me to implement something not symmetrical.

Also, I was not aiming for the least restriction, thinking that more load on the diaphragm can improve the damping.

These ideas were unsupported by any rigorous analysis.

Kindest regards,

M

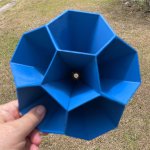

Fullerene for sure. And yes, the flare certainly needs a more elegant termination, perhaps on the form of a mounting flange. Although the Altec multi-cell horns don’t have them and do well without.

BEM simulation would be a good next step, but I have never done it. AKABAK?

BEM simulation would be a good next step, but I have never done it. AKABAK?

Buckminster-Fullerene

A geodesic dome usually makes the Pentagons and Hexagones with triangles — improving the resolution wrt mimiking a sphere.

A subset of this shape is the mouth of Michael’s Fuller Muti-cel Horn. A version with triangles coud be made, all trianguar Cels. If the purpose of the cels is to reduce the potential resonances across the horn width, these triangles would push those frequencies up, even if anything forms given no parallel surfaces.

dave

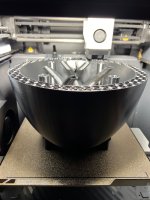

I've done some printing and am very happy with the results. They are truly cool objects IRL. These need a little sanding and filing to achieve a good fit and finish, typical of printed PLA. These should make a very happy horn! 😛

For reference, each horn/cell is 82mm (~3.22") wide outside - wall to wall.

For reference, each horn/cell is 82mm (~3.22") wide outside - wall to wall.

I wanted a nice mounting flange for this thing, but it proved to be devilishly difficult to draw in 3D. This is what it will look like. This version of the horn is 215mm in diameter, or about 8.5". It should mate well with a 10 or even 12" woofer. I have printed a section of the flange and it fits "OK" but the fit isn't easy to do. I'd love to print the whole thing as a piece but its shape makes that impractical and long, it would take about 48 hours. 😱 I'm thinking about the best way to print this in sections.

Ways to print can be a rabbit-hole, when I saw this I thought: throat, mouth, six individual cells….glueing up might be uh difficult and require filling etc so a refined look would take work but it does split it up into 8 prints so less all or nothing and might offer greater range on the horn length? More experienced 3d printers could have a better suggestion?

My personal preference was the free standing shape when the mount is at the driver flange.I wanted a nice mounting flange for this thing, but it proved to be devilishly difficult to draw in 3D. This is what it will look like. This version of the horn is 215mm in diameter, or about 8.5". It should mate well with a 10 or even 12" woofer. I have printed a section of the flange and it fits "OK" but the fit isn't easy to do. I'd love to print the whole thing as a piece but its shape makes that impractical and long, it would take about 48 hours. 😱 I'm thinking about the best way to print this in sections.

View attachment 1441494

Me too for the big horns. But it would be nice to have a small horn like this that can be flush mounted in a box with a woofer below it.

No flange is way easier, though.

No flange is way easier, though.

That’s for sure - and I am new to 3D printing and have not learned all the tricks.Ways to print can be a rabbit-hole

What I have looked at for this is making the flange 6mm thick and slicing it into two parts. One part would be the front flange with the cell mouths, the second part would be the back of the flange and the cell bodies going back to the throat. That gives each half a flat plane to print from and simulates well.

Of course one would have to glue together the front and back halves.

I think my Sidewinder can do it, but in one piece it needs sooo much support material. Maybe that is the trade off.A Bambu Lab printer would probably have a 99% success rate

I love the look of that silver filament. 👍

It exists! Unique au monde, not another like it.

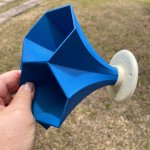

Just a crude prototype, but still a good start for a project I have wanted to do for over 10 years. This could be a type of horn for those who like this sort of thing.

Just a crude prototype, but still a good start for a project I have wanted to do for over 10 years. This could be a type of horn for those who like this sort of thing.

Attachments

It’s small so I imagine 1.5-2 kHz or above.

This prototype was just to see if I could draw it and print it. It wasn’t easy. The size was a bit random.

My printer can do 300x300x400, maybe I should figure out what that could be. It would be nice to have one that could work down to 700-800 Hz.

This prototype was just to see if I could draw it and print it. It wasn’t easy. The size was a bit random.

My printer can do 300x300x400, maybe I should figure out what that could be. It would be nice to have one that could work down to 700-800 Hz.

Talk about an understatement.This could be a type of horn for those who like this sort of thing.

It would be nice to have one that could work down to 700-800 Hz.

After hearing the 1505B I couldn't understand the criticism of multi-cells. Seamless across the width of the room (. . .and what honk?) Beautiful.

A living room sized version would be very cool. Maybe with 12" underneath ?

- Home

- Loudspeakers

- Multi-Way

- A different sort of Multi-Cell horn. 3D printing.