Kevin, how do you wire 1544 balanced to unbalanced: R4B/L4U? (as input)

Yes, that's correct.

Good news. <snip>

I'm sorry, but my old head is not taking in the "two per channel - one with minimal gain... etc." Can you restate this requirement differently for for me, like what are you referring to in "two per channel"? Thanks....

Plywood is a great medium for advancing designs. Metal is somehow inhibitory...

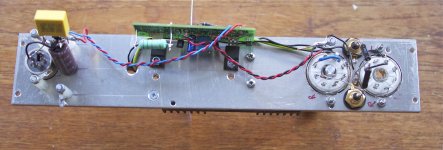

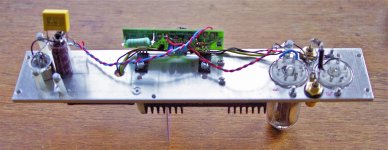

Au contraire, mon pote...... I love my metalwork. Made this today - my "line stage on a module". It fits into my modular amp, made of 19" subrack 2U parts. The module is 50mm by 275mm.

Attachments

Au contraire, mon pote...... I love my metalwork. Made this today - my "line stage on a module". It fits into my modular amp, made of 19" subrack 2U parts. The module is 50mm by 275mm.

I admire that metalwork that you made, too, but I was thinking of that 6 sided box monster, rather than a single. elegant piece of aluminum. 🙂

Two per channel - one for low pass which requires an additional 6 db of gain and the other for the high pass. Don't want to pad down the above 500 hz horns.

I worried this might have been obtuse.

I worried this might have been obtuse.

Think of it as a line stage/crossover.

Don't want to pad down the above 500 hz horns, would rather boost the below 500 hz ones.

Don't want to pad down the above 500 hz horns, would rather boost the below 500 hz ones.

Think of it as a line stage/crossover.

Don't want to pad down the above 500 hz horns, would rather boost the below 500 hz ones.

Don't want to pad down the above 500 hz horns, would rather boost the below 500 hz ones.

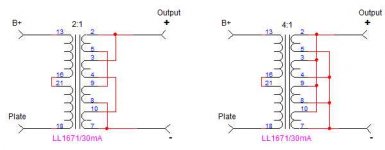

OK, thanks for clarifying that. I understand. The LL1671 output transformer can be connected 4:1 or 2:1, so there is a "natural" way to provide a 6dB gain difference.

What's the "best" operating point for 4P1L, for line stage purpose? I was thinking about 175V 20mA, -15V fixed bias, 3:1 transformer output.

Good question - I'd welcome some views. I have been using a 0D3 glow tube which sets the HT at 150v, but may free myself from this and use a solid stage reg like the Morgan Jones Statistical Regulator for instance.

On the other hand, I use filament bias and for the sake of standardising the filament power supplies at the same voltage I've been using a 15 ohm cathode resistor which gives me about 9,5v bias. So add 2v for the tube and I need to supply 11.5v through the Rod Coleman regs, so needs something like 16-18v going into the reg.

It's all a question of juggling voltages with filament bis, but it's worth it.

On the other hand, I use filament bias and for the sake of standardising the filament power supplies at the same voltage I've been using a 15 ohm cathode resistor which gives me about 9,5v bias. So add 2v for the tube and I need to supply 11.5v through the Rod Coleman regs, so needs something like 16-18v going into the reg.

It's all a question of juggling voltages with filament bis, but it's worth it.

OK, thanks for clarifying that. I understand. The LL1671 output transformer can be connected 4:1 or 2:1, so there is a "natural" way to provide a 6dB gain difference.

Hi Kevin,

will you show, please, how to wire 2:1? (A+B and B+A in parallel?)

Good question - I'd welcome some views.<snip>

I don't want to use filament bias. 4P1L has centar tap in filament and it doesn't have it for no purpose. I think I said enough about that 😉

I use 4P1L in driver stage for GM-70 and it's excellent, no problems whatsoever, but in line stage (low signal levels), it tends to be microphonics etc.

Hi Kevin,

will you show, please, how to wire 2:1? (A+B and B+A in parallel?)

Attachments

Re. microphonics..... Have you read all the stuff about starving the filaments? And either using dead weight mass in the chassis or some kind of rubberised suspension? Should be plenty of posts on all that. I went the chassis dead weight route - 4mm aluminium top plates, wood ends to chassis etc. I also wrapped teflon plumbers tape round the tubes several times and then secured it with a ring of ordinary electrician's tape. Seemed to quieten it down. I don't know if the operating point is relevant to the microphonics.

I have 4P1L in driver stage in GM-70 and I've used Dead weight mass in the chassis and that Works excellent.

I have no comment about starving the filaments. I don't agree with that method, but if you are happy with that, I won't try to change your mind.

I will make some testing and report back.

I have no comment about starving the filaments. I don't agree with that method, but if you are happy with that, I won't try to change your mind.

I will make some testing and report back.

I had a very interesting day today with Ale Moglia and a friend of ours, Tony. We auditioned 4 line stages. Amp was a PSE 4P1L, with 4P1L input (plate choke and FT-3 coupling cap). Speakers were Mark Audio Alpair 10s. Full range, 23 litre infinite baffles. We placed them in this rank order:

1. Ale's 01A

2. 26 into LL1692A stepdown

3. Ale's 4P1L

4. 30sp

All DHTs and all sounded good - quite alike in having that DHT sound. I think they were all filament bias. Ale's 4P1L line stage might have suffered from going into two more stages of 4P1L so may be better into a different amp. In that sense it may not be a definitive test, so the jury is out on that. We have known from past experiments that 3 4P1L stages in a row just don't sound that good.

The 26 preamp was predictably nice, sweet and detailed. Audibly better than 30sp. Just a bit better in this context than Ale's 4P1L but not far away.

The star without any doubt was Ale's 01A preamp. It was just stunning. Quite magical. So if it's a question of building a line stage, this to my ears supercedes the 4P1L. I never expected this - I've built 01A preamps in the past, but this is a very clever circuit. you can find it here:

01a Preamp (Gen2) | Bartola Valves

I do urge you to look seriously at this design. It's a bit special. It was the only one of the 4 we auditioned that actually sounded better in the system than without it. There is enough gain with just the 2 4P1L stages in the amplifier, which I usually drive straight out of a ES9023 DAC. But adding this stage was a better sound. I never expect 3 stages to sound better than 2, but this did.

1. Ale's 01A

2. 26 into LL1692A stepdown

3. Ale's 4P1L

4. 30sp

All DHTs and all sounded good - quite alike in having that DHT sound. I think they were all filament bias. Ale's 4P1L line stage might have suffered from going into two more stages of 4P1L so may be better into a different amp. In that sense it may not be a definitive test, so the jury is out on that. We have known from past experiments that 3 4P1L stages in a row just don't sound that good.

The 26 preamp was predictably nice, sweet and detailed. Audibly better than 30sp. Just a bit better in this context than Ale's 4P1L but not far away.

The star without any doubt was Ale's 01A preamp. It was just stunning. Quite magical. So if it's a question of building a line stage, this to my ears supercedes the 4P1L. I never expected this - I've built 01A preamps in the past, but this is a very clever circuit. you can find it here:

01a Preamp (Gen2) | Bartola Valves

I do urge you to look seriously at this design. It's a bit special. It was the only one of the 4 we auditioned that actually sounded better in the system than without it. There is enough gain with just the 2 4P1L stages in the amplifier, which I usually drive straight out of a ES9023 DAC. But adding this stage was a better sound. I never expect 3 stages to sound better than 2, but this did.

Last edited:

Hi Andy, Ale,

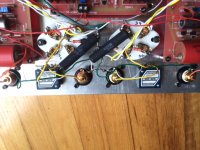

I had the same experience regarding the 4P1L, 26 and respectively 01A line stages. I love them all. However, I can't agree more that my favorite is Ale's 01A Gen2. 01A has the glamorous sound of the Thoriated Tungsten filament. My optimized implementation of the 01A line stage/gain stage is build on a 12"x12" brushed Alum 1/8" plate at $28 from McMaster Carr. I kept the PSU very close to the back side and the tubes very close to the front side...this way there are 8" between them and there is no audible interference.

Best,

Radu

I had the same experience regarding the 4P1L, 26 and respectively 01A line stages. I love them all. However, I can't agree more that my favorite is Ale's 01A Gen2. 01A has the glamorous sound of the Thoriated Tungsten filament. My optimized implementation of the 01A line stage/gain stage is build on a 12"x12" brushed Alum 1/8" plate at $28 from McMaster Carr. I kept the PSU very close to the back side and the tubes very close to the front side...this way there are 8" between them and there is no audible interference.

Best,

Radu

Attachments

Nice work, Radu! Ale says you took the preamp to some audio meets in NY and got a lot of new fans.

I'm starting my build already! Can't wait.

I'm starting my build already! Can't wait.

Nice work, Radu! Ale says you took the preamp to some audio meets in NY and got a lot of new fans.

I'm starting my build already! Can't wait.

Andy,

I have few friends that listened to it and loved it.

I have built one for a friend in NYC that was switchable between 26 and 01A and also switchable between gyrator load or LL2745. It was very easy to compare.

I've also built a PSE 300B where the first state is Ale's 2nd Gen 01A.

all very good sounding stages.

The only thing is that I had to buy many 01As in order to select few good ones.

Radu

PCB for a 4P1L gain stage

Now back to 4P1L:

4P1L gain stage (about 19dB) compact for use with First Watt F4, and not only

In this era of miniaturization, I always tried to make a tube amp reasonable compact. After long hours of experimentation, I came up with this compact 4P1L gain stage. There is room for improvements and modifications depending on what it will be used for.

Almost everything is on the PCB: transformers PSU, Coleman regulators, tubes and ancillaries.

The power supply uses 3 transformers ( one of the 187D20 for each filament, and one Antek 50VA 160V for the HT.). Ht supply is filtered by a CLC (470uF-15H-470uF). The raw supply for the filaments uses 1n5822 and CRC 10mF-0.47R-10mF. The Coleman regulators need to be preassembled except the power transistors who are mounted on 2" Wakefield heatsinks. The 4P1L is biased at about 115V Uak, 35mA and 560mA starved filament. The load for the 4P1L is a cascoded DN2540 CCS.

The PCB measures 266mmx274mm. It was much cheaper to order it on 1.6mm thickness and I provided many holes for support. One can use Aluminum stand-offs to make sure that the board stays rigid.

The only thing of concern is how the 4P1L's socket is attached to the board. I would use neoprene damper sandwich mount, rubber rings and even a dead weight.

I made few extra PCBs. Whoever is interested, I am selling 3 boards.

I have a BOM for this PCB.

Best,

Radu

Now back to 4P1L:

4P1L gain stage (about 19dB) compact for use with First Watt F4, and not only

In this era of miniaturization, I always tried to make a tube amp reasonable compact. After long hours of experimentation, I came up with this compact 4P1L gain stage. There is room for improvements and modifications depending on what it will be used for.

Almost everything is on the PCB: transformers PSU, Coleman regulators, tubes and ancillaries.

The power supply uses 3 transformers ( one of the 187D20 for each filament, and one Antek 50VA 160V for the HT.). Ht supply is filtered by a CLC (470uF-15H-470uF). The raw supply for the filaments uses 1n5822 and CRC 10mF-0.47R-10mF. The Coleman regulators need to be preassembled except the power transistors who are mounted on 2" Wakefield heatsinks. The 4P1L is biased at about 115V Uak, 35mA and 560mA starved filament. The load for the 4P1L is a cascoded DN2540 CCS.

The PCB measures 266mmx274mm. It was much cheaper to order it on 1.6mm thickness and I provided many holes for support. One can use Aluminum stand-offs to make sure that the board stays rigid.

The only thing of concern is how the 4P1L's socket is attached to the board. I would use neoprene damper sandwich mount, rubber rings and even a dead weight.

I made few extra PCBs. Whoever is interested, I am selling 3 boards.

I have a BOM for this PCB.

Best,

Radu

Attachments

-

overall.JPG141.4 KB · Views: 279

overall.JPG141.4 KB · Views: 279 -

front viw.JPG139.9 KB · Views: 226

front viw.JPG139.9 KB · Views: 226 -

delay timer.JPG129.7 KB · Views: 237

delay timer.JPG129.7 KB · Views: 237 -

top view rear.JPG130.5 KB · Views: 262

top view rear.JPG130.5 KB · Views: 262 -

top view.JPG139.5 KB · Views: 268

top view.JPG139.5 KB · Views: 268 -

coleman regs closeup.JPG129.1 KB · Views: 292

coleman regs closeup.JPG129.1 KB · Views: 292 -

front closeup.JPG115 KB · Views: 383

front closeup.JPG115 KB · Views: 383 -

overall top.JPG138.5 KB · Views: 334

overall top.JPG138.5 KB · Views: 334

- Home

- Amplifiers

- Tubes / Valves

- 4P1L DHT Line Stage