Re: Diyer at its best!!!

Jorge,

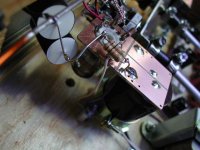

The photos were taken at the end of the construction proccess

and since I have made some changes.

The screws of the band brace were to big and had some interference with the att bracket so change them with some nice steel couplings, custom made.

I should take some new photos.

Tube_Dude said:Nice work...i really apreciated the union betwen the prolongament

shaft and the comutator...

Realy handcraft ...

Bravo!!!

jorge

Jorge,

The photos were taken at the end of the construction proccess

and since I have made some changes.

The screws of the band brace were to big and had some interference with the att bracket so change them with some nice steel couplings, custom made.

I should take some new photos.

Re: 417A

There is a RS Components around this small City but they carry very few parts and have not restock since at least a year!!! Little interest in electronics arround town, only students. Monterrey and Mexico City is another thing.

Sound?. Well still tweeking, What I can say is that is has a much more control over the 10K load than with the 6922 previously used. Note also that it is more neutral on overall character, and better high freq.

Have change the plate load resistor which were carbon film (and magnetic) with a couple 1/2 W carbon comp. (the only ones I had at hand) the sonic improvement was like night/day but unfortunatelly the power dissipation was way bellow what I needed (at least 2W) and so after a couple of hours they began to get noisy.

At this point I'm stuck with what to use as Plate load R since I can't get others than carbon or metal films around town, all magnetic. So in the mean while will install some 2W X2 wire wounds (sandy non magnetic) and see what happens.

Other tweeks I've made are on the HT regulators, bypassed the zeners and series output devices with good quality 0.01u polyprops and in some cases adding also a 0.47u. This addition smoothed the sound but still have some gritiness at high feq, not much.

Suggestions to gritiness other than tube series regs?

fdegrove said:

I don't know whether RS Components have an outlet in Mexico, but they do have shaftcouplers.

That should save you the time to make your own.

Happy with the sound of the pre?

Cheers,

There is a RS Components around this small City but they carry very few parts and have not restock since at least a year!!! Little interest in electronics arround town, only students. Monterrey and Mexico City is another thing.

Sound?. Well still tweeking, What I can say is that is has a much more control over the 10K load than with the 6922 previously used. Note also that it is more neutral on overall character, and better high freq.

Have change the plate load resistor which were carbon film (and magnetic) with a couple 1/2 W carbon comp. (the only ones I had at hand) the sonic improvement was like night/day but unfortunatelly the power dissipation was way bellow what I needed (at least 2W) and so after a couple of hours they began to get noisy.

At this point I'm stuck with what to use as Plate load R since I can't get others than carbon or metal films around town, all magnetic. So in the mean while will install some 2W X2 wire wounds (sandy non magnetic) and see what happens.

Other tweeks I've made are on the HT regulators, bypassed the zeners and series output devices with good quality 0.01u polyprops and in some cases adding also a 0.47u. This addition smoothed the sound but still have some gritiness at high feq, not much.

Suggestions to gritiness other than tube series regs?

417A.

Hi,

Your results do not come as a surprise, the 417A is a fine sounding tube.

But inductive?

I doubt the tubes are at fault here, maybe the zeners though.

Hard to tell really,

Hi,

Your results do not come as a surprise, the 417A is a fine sounding tube.

So in the mean while will install some 2W X2 wire wounds (sandy non magnetic) and see what happens.

But inductive?

This addition smoothed the sound but still have some gritiness at high feq, not much.

I doubt the tubes are at fault here, maybe the zeners though.

Hard to tell really,

Re: 417A.

fdegrove said:Hi,

>But inductive?<

Yes, inductive, no other type at hand.

What are the consequences of using inductive R on that position?

>I doubt the tubes are at fault here, maybe the zeners though.

Hard to tell really<

I agee with you, I will try bypassing each zener indivitually - six in total.

417A.

Hi,

A changing frequency response with regard to input.

Best to avoid inductive resistors.

Hi,

Yes, inductive, no other type at hand.

A changing frequency response with regard to input.

Best to avoid inductive resistors.

Zeners

are the zeners in series??'

I agee with you, I will try bypassing each zener indivitually - six in total

are the zeners in series??'

Re: Zeners

Yes Jorge zeners are in series, 30 V each to get 180V +B

Tube_Dude said:

are the zeners in series??'

Yes Jorge zeners are in series, 30 V each to get 180V +B

zener in series...

Then do not do:

Put only a capacitor betwen the extremes of the string ...if you put as you have said the parasitic inductance of the caps will add and the decoupling of the HF noise will be much worse..

Que lo passes bien!

Jorge

Then do not do:

I will try bypassing each zener indivitually - six in total.

Put only a capacitor betwen the extremes of the string ...if you put as you have said the parasitic inductance of the caps will add and the decoupling of the HF noise will be much worse..

Que lo passes bien!

Jorge

Frank,

I did test those inductive R as plate load, using 4W, double the minimum needed, did not check the freq. response on the scope though, to see what was happening.

Sonicwise they seem to be OK, even more inner details and transparent than the Carbon composition. But after a brief hearing I shut it down since rhe resistors started to make some noises, heat related I asume similar to the noises I got from the carbon comp.

To the touch they are quite hot!!!

I did test those inductive R as plate load, using 4W, double the minimum needed, did not check the freq. response on the scope though, to see what was happening.

Sonicwise they seem to be OK, even more inner details and transparent than the Carbon composition. But after a brief hearing I shut it down since rhe resistors started to make some noises, heat related I asume similar to the noises I got from the carbon comp.

To the touch they are quite hot!!!

Jorge,

The zener's work as a voltage reference and the regulators are series using IRF840LC mosfet's (very low capacitance).

What would be your suggestion for plate load R's (type)?

Have you experianced wire wounds on this position?

The tubes are biased for 18+ mA and I'm using 5K at the plates

Buenas noches amigo!!!

The zener's work as a voltage reference and the regulators are series using IRF840LC mosfet's (very low capacitance).

What would be your suggestion for plate load R's (type)?

Have you experianced wire wounds on this position?

The tubes are biased for 18+ mA and I'm using 5K at the plates

Buenas noches amigo!!!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- 417A Line Amp