The internal chamber dimensions are 75 mm top width, 100 mm bottom width and 150 mm length.

I am not sure what would work better or how the angle affects the response. I only have a feeling that the single axis of symmetry k-slot will behave differently than the JBL style with two symmetry axes.

I will try to compare the k-slot with the JBL on the 8PE21. At least with some rough in-room measurements🙂

I am not sure what would work better or how the angle affects the response. I only have a feeling that the single axis of symmetry k-slot will behave differently than the JBL style with two symmetry axes.

I will try to compare the k-slot with the JBL on the 8PE21. At least with some rough in-room measurements🙂

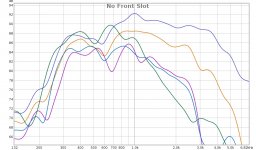

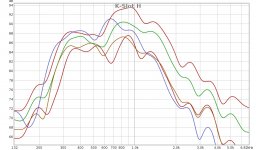

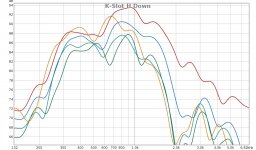

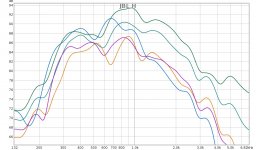

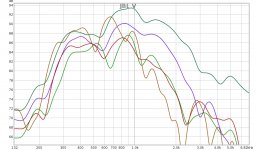

Some quick and dirty polar measurements. Again, the 3D printed back cover was used. The microphone was left in a certain position and the front covers were put on and rotated. I am sure there were some leaks around the edge.

I have vague feeling that a symmetrical star shaped opening should work fine, too. And it seems that this thing works with more or less any shape - and that great results could be obtained by optimizing the shape.

The angles are on axis, and roughly 15, 30, 45 and 90.

I have vague feeling that a symmetrical star shaped opening should work fine, too. And it seems that this thing works with more or less any shape - and that great results could be obtained by optimizing the shape.

The angles are on axis, and roughly 15, 30, 45 and 90.

Attachments

Last edited:

I have discovered the benefits of PETG. The prints are looking very nice and it was almost no effort to get the printer setup right. The material also feels better mechanically and I get zero warping. The only downside is that it is more expensive than PLA. I will still use PLA for development and prototypes, but for the final prints, I think I will start using PETG.

Nice work on K aperture!

JBL = Figure 8

RJ = Lemon shape

K = Triangle w. curved sides

As a control, try a circle - all should have same CSA

JBL = Figure 8

RJ = Lemon shape

K = Triangle w. curved sides

As a control, try a circle - all should have same CSA

Hey Pelang - my printer guy says the little K lens file seems corrupted - will not print right - - here's what he gets

https://i.imgur.com/s0jYPiv.jpg

https://i.imgur.com/s0jYPiv.jpg

Freddi, my printer is currently offline. I only tried to slice it - it must be printed on its side and easiest would be in two halves. I will do a test print when I have a chance again.

If printed on the side, less support material would be needed. I will maybe try to print a scaled down model on my smaller printer.

Edit: I will also try some little tricks - it will need a bit of work with a sharp knife after printing.

If printed on the side, less support material would be needed. I will maybe try to print a scaled down model on my smaller printer.

Edit: I will also try some little tricks - it will need a bit of work with a sharp knife after printing.

thanks for the explanation - - did you try to make the B&O style lens or variant yet to go with a compression driver or dome tweeter ?

what do you think the mini klam would do different if anything if its curved aperture were a bit wider at the end? I have prints of it but am not yet back at home where I can play stuff.

https://i.imgur.com/kFWnR68.jpg

https://i.imgur.com/kFWnR68.jpg

Hi Freddi, I would say it would not matter much if at all. I tried to print a scaled down model on its side - I stopped the print by a stupid mistake, but it seems that a half would print perfectly when on a side and with some supports at the beginning of the K-Slot, it would be actually possible to print it in one piece. That would need some advanced slicer setup for the print. I also discovered there was a problem in the model - an edge, that would actually open, so I added some material and made another one - I added a thin layer into the speaker opening and screw holes and it is meant to be printed with the K-Slot laying flat on the bed. A well tuned printer should be able to print it like this in one piece and without any supports. I will most probably try that in full scale when I have my large printer ready.

Attachments

hi pelanj - -that guy is still having printing issues - he wants to know:

- what is the layer height? what is the infill percent? - oh - never mind - he gave up. If you see any BeoLab style lens files, let me know.

- what is the layer height? what is the infill percent? - oh - never mind - he gave up. If you see any BeoLab style lens files, let me know.

Last edited:

This sample was printed with 0.3 mm nozzle and 0.2 mm layer height. On my larger printer, I have a 0.4 mm nozzle and 0.3 mm layer height. 3 perimeters, 3 bottom, 3 top layers and 20 % infill. I tried most of the infill patterns but the difference was mostly in printing time. And all my prints used PLA and I am trying my first spool of PETG with good results. Both printers are cheap Prusa i3 style clones with 20 x 20 x 18 cm and 30 x 30 x 42 cm build volume. After 4 months of 3D printing, I begin to see the weaknesses in construction and I am improving the large one with my own and Thingiverse 3D printed parts🙂

I could share my SAW model, but as I said, it is nothing special and it is not very high on my "to print" list. I plan to make a small one at some time in future.

I am pretty sure there were some here on the forum and I found this one on Thingiverse: Waveguide - Vifa XT25 by Shankenstein - Thingiverse

I could share my SAW model, but as I said, it is nothing special and it is not very high on my "to print" list. I plan to make a small one at some time in future.

I am pretty sure there were some here on the forum and I found this one on Thingiverse: Waveguide - Vifa XT25 by Shankenstein - Thingiverse

Thanks for the information. Do you think with a decent stock printer one could create finish worthy parts? I see you were talking about up grading your printer.

If you apply some filler and sanding, almost any printer would do. My upgrades are mostly stiftening the frame and making it as square as possible. I printed Joseph Crowe's ES800 horns on the printer before the upgrades and it turned out really well. I do not mind the layered look, so on the better one I just used a little filler for the gap (it was made from two parts glued together) very little sanding to rough off the layer edges with 200 grit sandpaper and two layers of black spray paint. As a secret tip, car threshold protective paint can create some interesting textures as well.

My PETG Unitized Image Control Waveguides by Patrick Bateman (printed on a Prusa mk3 by a friend had an absolutely stunning shiny finish by appliyng Revell Plasto and some sanding + two layers of spray paint. Polyester wood filler should work as well, I have not tried it yet.

My PETG Unitized Image Control Waveguides by Patrick Bateman (printed on a Prusa mk3 by a friend had an absolutely stunning shiny finish by appliyng Revell Plasto and some sanding + two layers of spray paint. Polyester wood filler should work as well, I have not tried it yet.

I don't know the difficulty that guy who prints for me is having but one double slot K-tube and a mini klam came out rough - I had to remove several layers on the base of the mini-klam, same with a double K-tube and that tube has some rough stuff inside. Two other mini-klam prints and double-slot K-tube prints came out pretty nice (if not matching color)

hopefully that XT25 lens is something he can print cleanly. Can you think of other speakers which might work with that lens? I wonder how much EQ if any is needed on the top octave of those ring radiators with such a lens?

Waveguide - Vifa XT25 by Shankenstein - Thingiverse

hopefully that XT25 lens is something he can print cleanly. Can you think of other speakers which might work with that lens? I wonder how much EQ if any is needed on the top octave of those ring radiators with such a lens?

Waveguide - Vifa XT25 by Shankenstein - Thingiverse

Last edited:

I have not tried a SAW lens yet. It looks like it would print best if positioned with the slant back on the bed. The original design may be modified in 3D software to fit another flange and scaled.

- Home

- Loudspeakers

- Multi-Way

- 3D printed audio stuff (with STL files)