My first post so a little background is in order. I design and build synthesizers and occasionally some furniture, the technical aspects of speaker DIY should be no issue given I commit the time and resources to learning and fabricating. That said, I have a rather mediocre system. I monitor in Berdynamic DT770s and my stereo is a set of the Pioneer FS52s, Onkyo 8050 integrated amp, Denon 300PF and my PC.

I have been itching to upgrade my loudspeakers and experience a fuller sound. I like the FS52s, they are a relaxed speaker but lack excitement. For me the biggest issue is anemic mid bass. Songs that absolutely punch (i.e. Vapor Trail - The Crystal Method) just don't do it in this system. I will probably build a Hypex or IcePower Amp and look at source later.

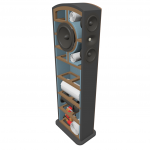

So I want to go for a large floorstander. My current conception is a 2x8"+5"+1" with about 85-90L in the base cabinet. The room it will be used in is on the edge of small, 13"x18", with a typical asymmetric opening to the dining and kitchen. Speakers would be on the short wall and about 18" from the front wall (already started building a diffuser for the back wall). The driver complement would be the ceramic range by SB Acoustics. The tweeter and midrange seem to be well regarded in what I am seeing on forums, particularly the midrange (SB26CDC, SB15CAC30, SB23CACS45). The woofer seems a bit spendy, but the matched aesthetic is nice. As an alternate I am considering the RS225, more on that later.

Gonna try to find some good baltic birch, shouldn't be a problem here in LA. If not I will use MDF. I am going to use buytl deadner, 1/2" felt and polyfill where appropriate for backwaves and standing waves.

I want to try a waveguide for the tweeter. It is an edit of the Soma Sonus 5"x0.75" waveguide. They have test results already for the SB26CDC. I would have one 3d printed in nylon and then resin cast from that so I can make some extras if I get motivation to build surrounds.

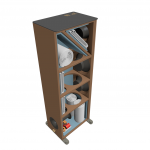

I have attached a rough of the measurements of the cabinet, 47x17x11.5" w/o plinth. Basically as big as it gets to cut each from a 4x8' sheet. ~10L for the midrange and ~90L for the base cabinet. Port would be a 3".

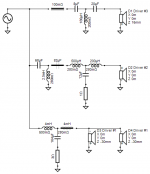

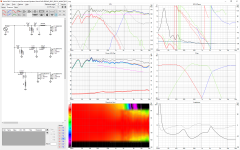

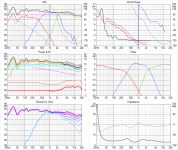

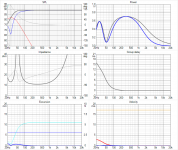

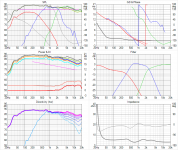

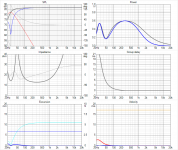

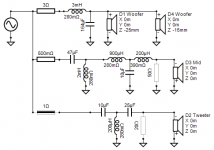

I have also attached some cross over and box responses comparing the SB23 woofer to the RS225. Generated from VituixCAD and traced curves. Cross over points at about 350Hz and 2200Hz, subject to change when I measure. Targeting about a 5dB slope from 100 to 10k. Only a resistor change on the woofer between the two. From what I am seeing the RS225 seems to win out on base extension (30Hz f3 vs. 35Hz f3) and price (saves $250 on the pair of speakers). Is there likely to be a benefit of using the SB23 other than aesthetics? I know the RS225 is well regarded and sees use with some seriously high end mid/tweeter combos so who am I to push against that.

Wouldn't mind some general feedback if I am on the wrong course. I have spent a two months now absorbing as much as I could from DIY sources, so no need to refer me to the basics and I should understand the jargon.

TLDR; RS225 vs. SB23CACS45?

I have been itching to upgrade my loudspeakers and experience a fuller sound. I like the FS52s, they are a relaxed speaker but lack excitement. For me the biggest issue is anemic mid bass. Songs that absolutely punch (i.e. Vapor Trail - The Crystal Method) just don't do it in this system. I will probably build a Hypex or IcePower Amp and look at source later.

So I want to go for a large floorstander. My current conception is a 2x8"+5"+1" with about 85-90L in the base cabinet. The room it will be used in is on the edge of small, 13"x18", with a typical asymmetric opening to the dining and kitchen. Speakers would be on the short wall and about 18" from the front wall (already started building a diffuser for the back wall). The driver complement would be the ceramic range by SB Acoustics. The tweeter and midrange seem to be well regarded in what I am seeing on forums, particularly the midrange (SB26CDC, SB15CAC30, SB23CACS45). The woofer seems a bit spendy, but the matched aesthetic is nice. As an alternate I am considering the RS225, more on that later.

Gonna try to find some good baltic birch, shouldn't be a problem here in LA. If not I will use MDF. I am going to use buytl deadner, 1/2" felt and polyfill where appropriate for backwaves and standing waves.

I want to try a waveguide for the tweeter. It is an edit of the Soma Sonus 5"x0.75" waveguide. They have test results already for the SB26CDC. I would have one 3d printed in nylon and then resin cast from that so I can make some extras if I get motivation to build surrounds.

I have attached a rough of the measurements of the cabinet, 47x17x11.5" w/o plinth. Basically as big as it gets to cut each from a 4x8' sheet. ~10L for the midrange and ~90L for the base cabinet. Port would be a 3".

I have also attached some cross over and box responses comparing the SB23 woofer to the RS225. Generated from VituixCAD and traced curves. Cross over points at about 350Hz and 2200Hz, subject to change when I measure. Targeting about a 5dB slope from 100 to 10k. Only a resistor change on the woofer between the two. From what I am seeing the RS225 seems to win out on base extension (30Hz f3 vs. 35Hz f3) and price (saves $250 on the pair of speakers). Is there likely to be a benefit of using the SB23 other than aesthetics? I know the RS225 is well regarded and sees use with some seriously high end mid/tweeter combos so who am I to push against that.

Wouldn't mind some general feedback if I am on the wrong course. I have spent a two months now absorbing as much as I could from DIY sources, so no need to refer me to the basics and I should understand the jargon.

TLDR; RS225 vs. SB23CACS45?

Attachments

-

Zhangqi_015.png180.2 KB · Views: 1,762

Zhangqi_015.png180.2 KB · Views: 1,762 -

WWTM_SB23_SB15_SB26WG.png109.1 KB · Views: 655

WWTM_SB23_SB15_SB26WG.png109.1 KB · Views: 655 -

WWTM_SB23_SB15_SB26WG_box.png54.5 KB · Views: 640

WWTM_SB23_SB15_SB26WG_box.png54.5 KB · Views: 640 -

WWTM_RS225_SB15_SB26WG.png100.1 KB · Views: 1,531

WWTM_RS225_SB15_SB26WG.png100.1 KB · Views: 1,531 -

WWTM_RS225_SB15_SB26WG_box.png52.9 KB · Views: 1,696

WWTM_RS225_SB15_SB26WG_box.png52.9 KB · Views: 1,696 -

WWTM_RS225_SB15_SB26WG_crossover.png18 KB · Views: 1,883

WWTM_RS225_SB15_SB26WG_crossover.png18 KB · Views: 1,883 -

Zhangqi_016.png331.2 KB · Views: 2,060

Zhangqi_016.png331.2 KB · Views: 2,060 -

Zhangqi_017.png352.4 KB · Views: 950

Zhangqi_017.png352.4 KB · Views: 950

Last edited:

worth having a look at Javad Shadzi's Ceramico's on the DIY facebook page.

The "Ceramicos" are a wrap and they are... - Midwest Audio Club | Facebook

easier info to follow here -

SB Acoustics Ceramicos Speaker Project by Javad Shadzi & Jeff bagby | Diyaudioparts

Looks like this is exactly what you are looking for 8" and 5" sb ceramic driver.

The "Ceramicos" are a wrap and they are... - Midwest Audio Club | Facebook

easier info to follow here -

SB Acoustics Ceramicos Speaker Project by Javad Shadzi & Jeff bagby | Diyaudioparts

Looks like this is exactly what you are looking for 8" and 5" sb ceramic driver.

Last edited:

There are no standing waves inside a speaker box. SW might take place in a room, yesI am going to use buytl deadner, 1/2" felt and polyfill where appropriate for backwaves and standing waves.

I see the pictures, now, after log-in: what about putting the crossover out of the box ?! Still it's about box environment...

Now let's see the Xxx-over...what's that 3 Ω resistor in front of the woofer??

Maybe better to take a look at Jshadzi's design!

Maybe better to take a look at Jshadzi's design!

Last edited:

Take that 3 ohm resistor out! If bass efficiency is too high, then get a pair of 4 ohm drivers and put them in series - that will be 3db less than parallel 8's. And the RS225 is a very good driver. Otherwise I am impressed with your plan. But it is just a plan, and will require fine tuning once it is built.

In a larger cabinet volume, a pair of ported Aluminum SB23NACS45-8 woofers can produce -F3 = 30Hz - 35Hz bass. Good value.

For low edge distortion, low cabinet vibration, and HIGH style, side-side bottom woofers in a "Kronos style" cabinet might catch your interest.

P.S. If you use a horn loaded dome tweeter, a 6.5" midrange typically produces a smoother directivity response because the polar changes in mid-cone directivity at the crossover frequency are a close match to the tweet-horn polar response. A 6.5" midrange can carry a wider vocal range and allows a lower bass crossover frequency.

Want powerful deep bass in a modest volume cabinet? Bi-amp the two woofers in a sealed volume with a Linkwitz equalization circuit, plus modest room equalization.

For low edge distortion, low cabinet vibration, and HIGH style, side-side bottom woofers in a "Kronos style" cabinet might catch your interest.

P.S. If you use a horn loaded dome tweeter, a 6.5" midrange typically produces a smoother directivity response because the polar changes in mid-cone directivity at the crossover frequency are a close match to the tweet-horn polar response. A 6.5" midrange can carry a wider vocal range and allows a lower bass crossover frequency.

Want powerful deep bass in a modest volume cabinet? Bi-amp the two woofers in a sealed volume with a Linkwitz equalization circuit, plus modest room equalization.

Attachments

I can't give you an answer about your woofer choices but I can recommend the mid. I built towers with these mids and I am still overwhelmed by the clarity of these mids. My towers are a little smaller than youre, I used dual Anarchy 6.5 inch woofers. I am currently modeling a 3 way clone of my Infinity RS8b with the 8 inch SB you are looking at, I spotted its FR in your SIMs. Two things I will mention is your HF XO seems a little low to me, I crossed mine at 3Khz and I'm satisfied. You mention Baltic Birch and 4x8 sheets, I could only source 5x5 sheets, I was told the 4x8 are hard to find. Here is a link to another forum with my towers, not a build thread, but it might help.

3 Way Tower Baffle Step Compensation Question - AVS Forum | Home Theater Discussions And Reviews

3 Way Tower Baffle Step Compensation Question - AVS Forum | Home Theater Discussions And Reviews

Thanks all for the replies. Did my homework on the resistor with the woofer, won't be using that. I suspect it won't be needed given BSC, but still need to check with a 4 ohm.

I did a quick sim of the Ceramico's crossover and it looked a mess, so going to have to give it a second closer look. Maybe I got my curve traces wrong. I have seen those names around on some great speakers. Will use that as a basis moving forward, just want to cross the tweeter lower in the waveguide

I have seen the opposed woofers and actually did consider a design using them, though with the idea of an apparent point source thrown in. They received a strong negative response from the girlfriend as too skinny and the woofers on the side looking weird. Tilted baffles also a no for some reason. See the attached image. Thought it would be a fun build, but a bit low on cabinet volume.

As to the 6.5". I have seen a fair bit saying 4-5" being preferable even with a crossover near 2k. Not sure I would see much benefit pushing lower than 350 on the single mid. The waveguide thread shows good directivity matches with the 15cm or 17cm drivers, so keeping an open mind there. Will do some simulated crossovers. Surrounds with the wave guide tweeter and the 17 are a possibility.

Not looking to biamp or build and active speaker. Staying passive for this one.

I did a quick sim of the Ceramico's crossover and it looked a mess, so going to have to give it a second closer look. Maybe I got my curve traces wrong. I have seen those names around on some great speakers. Will use that as a basis moving forward, just want to cross the tweeter lower in the waveguide

I have seen the opposed woofers and actually did consider a design using them, though with the idea of an apparent point source thrown in. They received a strong negative response from the girlfriend as too skinny and the woofers on the side looking weird. Tilted baffles also a no for some reason. See the attached image. Thought it would be a fun build, but a bit low on cabinet volume.

As to the 6.5". I have seen a fair bit saying 4-5" being preferable even with a crossover near 2k. Not sure I would see much benefit pushing lower than 350 on the single mid. The waveguide thread shows good directivity matches with the 15cm or 17cm drivers, so keeping an open mind there. Will do some simulated crossovers. Surrounds with the wave guide tweeter and the 17 are a possibility.

Not looking to biamp or build and active speaker. Staying passive for this one.

Attachments

The aesthetics aren't as nice as the aluminum drivers, but the SB23MFCL-4 models really well in smaller boxes. 2 in 40-50L is pretty solid. Rick at Selah has them in an unnamed WWMT design with the MR13p and SB29BAC here New 3-way floorstander which if nothing else might serve as inspiration.

I personally think the WO24 is the most interesting SB woofer, but a single 9.5 is probably harder to work into a design than 2x8 - the dual woofers are a pretty classic look. Dual WO24's unfortunately need a pretty big box.

I personally think the WO24 is the most interesting SB woofer, but a single 9.5 is probably harder to work into a design than 2x8 - the dual woofers are a pretty classic look. Dual WO24's unfortunately need a pretty big box.

Add ~ 1 Ohms to your shunt devices (esp. second component in woofer and mid) to bring up the minimum impedance.

Why not swap out the pair of 8" woofers if the Ceramicos and use Jeff Bagby's woofer module? You'll need to mod the crossover a bit, assuming that you'll be taking measurements, if you're making an all in one the baffle width would change for the midland tweeter, so worth measuring too incase you need to make changes.

I've simulated this, looks very nice though if I do build this I'll be taking measurements rather than winging it.

I've simulated this, looks very nice though if I do build this I'll be taking measurements rather than winging it.

I had just switched from XSim and didn't know about VituixCADs other features and have poked about the diffraction module and come up with some more plausible crossovers. playing with both a wave guide and standard faceplate on the tweeter. Looks like I will be fine with the 8ohm woofers and no series resistor. Incorporated what I saw in the designs and feedback you all gave me (thanks a ton, always need a bit of a sanity check and confidence boost to take on a big DIY project).

The waveguide data I have is probably not normalized to the same sensitivity as the SB direct data, so gave it +3dB. Will have to measure in a test baffle myself to know where that stands. Attached what I found working with the standard faceplate. Crossover at 300Hz and 2.8kHz.

Probably enough simulating until I get the drivers in a cabinet, don't see any reason they won't perform well.

The waveguide data I have is probably not normalized to the same sensitivity as the SB direct data, so gave it +3dB. Will have to measure in a test baffle myself to know where that stands. Attached what I found working with the standard faceplate. Crossover at 300Hz and 2.8kHz.

Probably enough simulating until I get the drivers in a cabinet, don't see any reason they won't perform well.

Attachments

Been a lot of planning and second guessing over the last year and I am ready to start my build. The drivers are here and they look great! (one 5" does have a stray spot of glue on the cone, shame)

Done some more work on my crossover plan, will build cabinets and measure first. Directivity looks really nice, will have see how the frequency response turns out. Please let me know if I am missing anything obviously wrong.

Sill have some work to do on my planned waveguide with the phase shield. Might make the phase shield removable so I can try out some different geometries.

Practicing my woodworking, still need to experiment with some veneer and finishes. If I can make it work I will do rosewood with a satin finish. Realizing the finished cabinet will be 120+lbs, considering some leveling casters instead of furniture levelers.

Also made some significant upgrades to my front end with a miniDSP SHD (Dirac and all that for 4 channels) and Purifi amp to match what I hope to achieve with my speakers. Will eventually integrate with a pair of Rythmik subs.

Done some more work on my crossover plan, will build cabinets and measure first. Directivity looks really nice, will have see how the frequency response turns out. Please let me know if I am missing anything obviously wrong.

Sill have some work to do on my planned waveguide with the phase shield. Might make the phase shield removable so I can try out some different geometries.

Practicing my woodworking, still need to experiment with some veneer and finishes. If I can make it work I will do rosewood with a satin finish. Realizing the finished cabinet will be 120+lbs, considering some leveling casters instead of furniture levelers.

Also made some significant upgrades to my front end with a miniDSP SHD (Dirac and all that for 4 channels) and Purifi amp to match what I hope to achieve with my speakers. Will eventually integrate with a pair of Rythmik subs.

Attachments

You are on the right track by measuring your drivers in the cabinet, and then finalizing your crossover design based on those measurements.

It is a classic design (8+8+5+1) which we see everywhere. The reason is because it works well, and it is easy to get a great result from this architecture.

It is a classic design (8+8+5+1) which we see everywhere. The reason is because it works well, and it is easy to get a great result from this architecture.

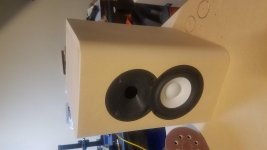

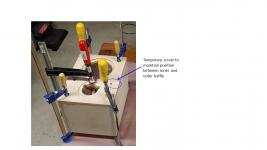

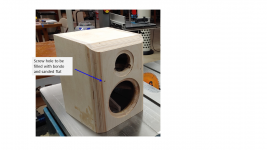

Decided to build a smaller test box to make sure I could get everything done with something easier to handle. Knew I needed more clamps going in, but really underestimated so basically doubled what I was going to get. Only issue I had was when I glued the inner to the outer front baffle it slid a bit. The waveguide and mid went together really great. Things are at an interference fit right now, not sure if I should open things up a bit more. 1.5 inch round overs look great, should make veneering easier and have a diffraction mitigating bonus.

Time to move on to the full sized cabinet!

Time to move on to the full sized cabinet!

Attachments

... Only issue I had was when I glued the inner to the outer front baffle it slid a bit. ...

A common problem. Some builders will machine a dado and matching groove so that the outer baffle indexes to the inner. Another technique is to use small dowels as alignment pins.

A more simple approach that has worked for me is to clamp the pieces together without glue, and then drill and install several screws. Then I unclamp the pieces, and unscrew the screws until the pieces come apart. When it is time to glue, I rotate the screws until they protrude slightly from the first piece. This allows the screws to "find their hole" even in the presence of slippery glue.

I apply glue, press the pieces together and let the screws find their holes. Then I screw them down tight. Then I apply clamps to ensure even pressure and good glue up.

Later the screws are removed and the holes filled. Since everything is getting veneered, those small filled holes are insignificant.

Attachments

Watching this build with interest. Building something similar with 2x RS225, 1x SB15MFC30 and some D2905/9900's I got in a really cheap second hand speaker set.

I have a great deal of enthusiasm about the SB CAC drivers and the SB26CDC tweeter. I think they have a very high performance considering their cost.

It was smart to construct a test box to work out any fabrication issues. Do you plan to do any acoustic testing with this box?

It was smart to construct a test box to work out any fabrication issues. Do you plan to do any acoustic testing with this box?

I dont plan on going as far as buying a crossover for it, but in the evenings when I dont have daylight to run power tools I am going to practice my measurement and simulation techniques. The box would be a fine speaker, hole for a 2in port and generous volume for a 5in that would even suit the 6.5in. I may make a set of standmounts for my brother or another room based on this cabinet.

- Home

- Loudspeakers

- Multi-Way

- 3 Way w/SB Acoustics Ceramics (woofer choice?)