As the test horn (https://www.diyaudio.com/community/threads/3-way-meh-with-1-4-cd-3d-print-and-cnc.383396/) progresses forward, I am slowly starting to think about the successor of it.

Here is some first Hornresp simulation, using 4x 3FE22 as mids and 2x Fane Sovereign Pro 12-300, sealed with a little EQ and a basic crossover:

The Hornresp records are attached. Depending on how the measurements on the first prototype will finish, this one will be built using 12 mm chipboard, since the final one will be most probably from 12 mm birch plywood.

It is meant to be 85 x 65 degrees, 40 cm length, mouth dimensions ca 78 x 57 cm, with the option of external secondary flare. I am still not decided on the bass drivers, but the Fanes look pretty fine. I was also thinking about using car audio subwoofer drivers for lower SPL and lower LF cutoff.

Here is some first Hornresp simulation, using 4x 3FE22 as mids and 2x Fane Sovereign Pro 12-300, sealed with a little EQ and a basic crossover:

The Hornresp records are attached. Depending on how the measurements on the first prototype will finish, this one will be built using 12 mm chipboard, since the final one will be most probably from 12 mm birch plywood.

It is meant to be 85 x 65 degrees, 40 cm length, mouth dimensions ca 78 x 57 cm, with the option of external secondary flare. I am still not decided on the bass drivers, but the Fanes look pretty fine. I was also thinking about using car audio subwoofer drivers for lower SPL and lower LF cutoff.

Attachments

It seems all the Sovereigns 12s would work pretty fine. This is Sovereign 12-300/2 just dropped in. Not much difference, it could be tuned by EQ adjustment.

And here is the even cheaper the.box 12-280/8-A, with cast frame.

And here is the even cheaper the.box 12-280/8-A, with cast frame.

Some renderings from the OpenSCAD model. It still needs some work, especially the ports and their placement.

I really like the (open baffle) bass of the single 18" in my first test horn. I also had some good experience with SLOB 2x12 (I do not care for the slot, but I dig the force cancelling), therefore I am considering to use a folded 2x18 SLOB of matching size for the lowest band. Or two PPD style OBs.

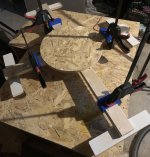

Improved (adjustable) fixture using 3D printed sliders and one hand clamps. This time I played around with the adjustments for a while and the result seems to be more square than the first one. Still not perfect, but good enough.

Attachments

Not unlike a Chinese meal - it’s all prep. and very little cooking-time. 😉 (..well, a stir-fry meal.)

CAD time + a bit of machine setup and the machines do the rest. (..though you typically have to check-in on the CNC and particularly the 3D print.) Of course like the meal there is also time spent on “cleanup”/quality-control.

CAD time + a bit of machine setup and the machines do the rest. (..though you typically have to check-in on the CNC and particularly the 3D print.) Of course like the meal there is also time spent on “cleanup”/quality-control.

In the other thread, someone suggested to use two (or even three) long planars. I think this horn will be the next prototype to compare with the green one:

This was just a quick modification of the OpenSCAD file, it will most probably use a round central entry port for the 12" woofers. It takes only one "project board" of 16 mm chipboard (1400 * 1050 mm), which is dirt cheap. I need to solve the mounting of the large Heil AMT for the third prototype and then decide, which one is actually the best🙂 It will be a touch choice, since I am now really happy with the Trynity prototype with the small PT2522.

This was just a quick modification of the OpenSCAD file, it will most probably use a round central entry port for the 12" woofers. It takes only one "project board" of 16 mm chipboard (1400 * 1050 mm), which is dirt cheap. I need to solve the mounting of the large Heil AMT for the third prototype and then decide, which one is actually the best🙂 It will be a touch choice, since I am now really happy with the Trynity prototype with the small PT2522.

Reducing the old AMT-1 adapter design to only square box insert seems to be an option. This will be printed either as two halves (one shown in the picture) or as one piece - that will be decided after some test prints. If this proves to be a viable mounting option, the third prototype will definitely be built as well. Most probably as two way, but that will depend on how the first green prototype will measure and how close will I be able to fit the 12" woofers.

Thomann woofers are ordered...finally🙂 I have some leftover 40x40 Al profiles - these will be used for the advanced glue up rig.

- Home

- Loudspeakers

- Multi-Way

- 3 way MEH with a planar tweeter (GRS PT2522 tweeter, FaitalPro 3FE22 mids)