I have a Transrotor table that uses a 4-wire, 2-phase motor with a controller that’s rated for 18V, 0.2A. I wonder if battery powered controller could be a possible upgrade?

Hello,

Would you share the files for the motor cover please? I've recently acquired a Systemdek and want to sell my Rega, but can not find the motor cover :- (

Thanks,

JG

Hi,

Beside an audio amp, do you guys use any dedicated design amplifier (instead of an audio amp) ?

I've tested different audio amps, now use LM3886 modules, but I do not think is it ideal. The smaller problem is that it is designed for higher power, but on the other hand when I've tested different audio amps, I found some are prone to "ringing" when driving the relative high impedance, very inductive 24V sync motor.

Can you suggest a dedicated drive for 24V motors? ( or 110V with or without transformer output).

Thanks,

JG

Beside an audio amp, do you guys use any dedicated design amplifier (instead of an audio amp) ?

I've tested different audio amps, now use LM3886 modules, but I do not think is it ideal. The smaller problem is that it is designed for higher power, but on the other hand when I've tested different audio amps, I found some are prone to "ringing" when driving the relative high impedance, very inductive 24V sync motor.

Can you suggest a dedicated drive for 24V motors? ( or 110V with or without transformer output).

Thanks,

JG

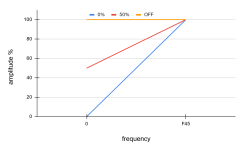

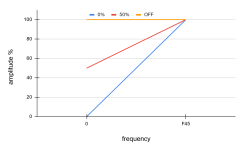

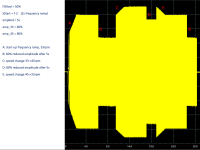

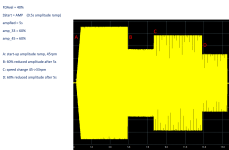

Further to the recent addition of frequency ramping (from start and between 33/45rpm frequencies), and following on from some very useful input from Bill (of SG4 fame) and other users, a new Frequency-Dependant-Amplitude (FDA) feature has been added to the firmware.

This is a global setting that scales the output amplitude with the frequency during all modes of operation, primarily intended to allow the current and hence torque to be equalised between the 33 and 45 rpm settings, and during start-up when a frequency ramp is used (for example for permanent-magnet synchronous or BLDC motors).

A new setting 'FDAval' in the 'amplitude' menu page has been added to set the zero-frequency amplitude as a percentage of the maximum amplitude (at 45rpm). The build guide in the first post has been updated with the new menu feature and description. Please request the updated firmware via PM.

FDAval setting (only 3 cases shown for clarity):

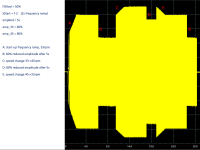

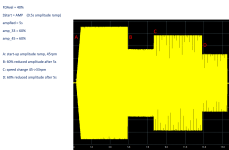

Some examples:

This is a global setting that scales the output amplitude with the frequency during all modes of operation, primarily intended to allow the current and hence torque to be equalised between the 33 and 45 rpm settings, and during start-up when a frequency ramp is used (for example for permanent-magnet synchronous or BLDC motors).

A new setting 'FDAval' in the 'amplitude' menu page has been added to set the zero-frequency amplitude as a percentage of the maximum amplitude (at 45rpm). The build guide in the first post has been updated with the new menu feature and description. Please request the updated firmware via PM.

FDAval setting (only 3 cases shown for clarity):

Some examples:

I've got a three phase BLDC VCR video head motor I used to replace the motor in an RCA 45 player that uses a drive wheel.

Would your circuit work for that motor?

Would your circuit work for that motor?

Hi, just to follow up now I'm back, I see you've joined the discussion in the limestone turntable motor drive thread, where there is a good discussion of using BLDC and other motor types

ever thought of using a renesas greenpak HV SLG47105 ? a hardware only solution to generate 2ch PWM sinewaves, dedicated to motor control. all greenpaks are fun to play with. originally named silego, silicon lego: integrate 15 components in 15 minutes for 15 cents

just fixed my crappy itho silent bathroom fan, that died after 3 years of no run heat dissipation, using a silego greenpak 2x2mm chip as delay timer and triac control

Hi all, I am busy buying the parts for the Supaspin motor control PCB. I see on the BOM that there are separate entries for 100nF (C2, C3, C7, C8) and 0.1 uF (C6) capacitors. In the end they all have the same value: 100nF = 0.1 uF. I see on the picture in the build guide that the 0.1uF are tantalum/ceramic and the 100nF are foil capacitors. The supplier I am buying the capacitors has an MOQ for capacitors, making it more economical to use the same capacitor for both types mentioned in the BOM. An advice on whether I can place the same component for C2, C3, C7, C8 & C6 is highly appreciated.

Last edited:

Hi, C6 is for supply decoupling and would typically be MLCC type, the others are a generic polyester box foil. You can use the latter type for C6 too without issues.

Hi, if of interest, I used njm4580 instead of Opa2134, think as long as they work with 5V PS most opams will do.Hi all, I am busy buying the parts for the Supaspin

Signal caps : any film or lytic that's right value and size,

Same for decouplers, just ceramic.

Signal with such components from drawer has 0.04% thd, complete overkill for motor drive 😊

Thanks for the suggestion. I chose the OPA2134 despite the high price because I did not want to spend time on finding a cheaper compatible part. I already ordered when I read your post. Maybe for the next one 🙂

Hi all, I finally assembled the PCB. I managed to get it working with the original motor from the Music Hall MMF 2.2. I have one issue I cannot resolve. The settings for phase adjustment are default at 30. I can change them to 0, but after a powerdown the phase settings are back at 30. Is there any way I can save the adjusted phase values so they stay at 0 after powering down the PCB?

It is indeed a bug! Just checked it on my testbed and I see the same thing, looks like I haven't properly handled the signed/unsigned conversion for the storage of negative phase values to the Flash - sorry!

I'm on (non-audio) DIY duties today, I'll get an update out as soon as I can.

I'm on (non-audio) DIY duties today, I'll get an update out as soon as I can.

Last edited:

Thanks to @Remco22 for some quick testing, the negative phase storage issue has been resolved, and new firmware for all supported RP2040 modules is now available at:

https://drive.google.com/drive/folders/1zttD3h1yLh_rkOKi_ILMN6ePMEPL9Dlp?usp=drive_link

As this fix will potentially affect everyone using phase trimming, it is recommended to update to this latest build, and for those who took firmware a while ago, it will also upgrade you with all the latest features described here and in the build guide.

https://drive.google.com/drive/folders/1zttD3h1yLh_rkOKi_ILMN6ePMEPL9Dlp?usp=drive_link

As this fix will potentially affect everyone using phase trimming, it is recommended to update to this latest build, and for those who took firmware a while ago, it will also upgrade you with all the latest features described here and in the build guide.

Last edited:

- Home

- Source & Line

- Analogue Source

- 2 phase synthesised sinewave generator for synchronous motor drive