Hi Giuseppe,

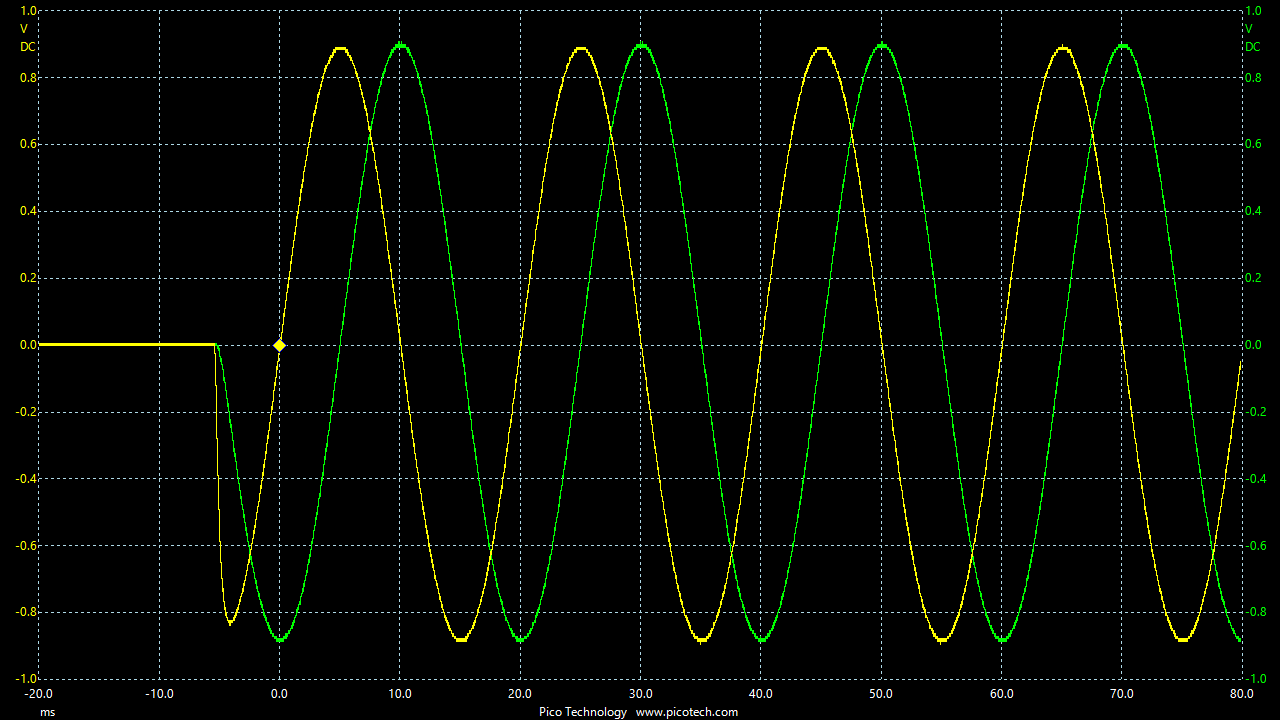

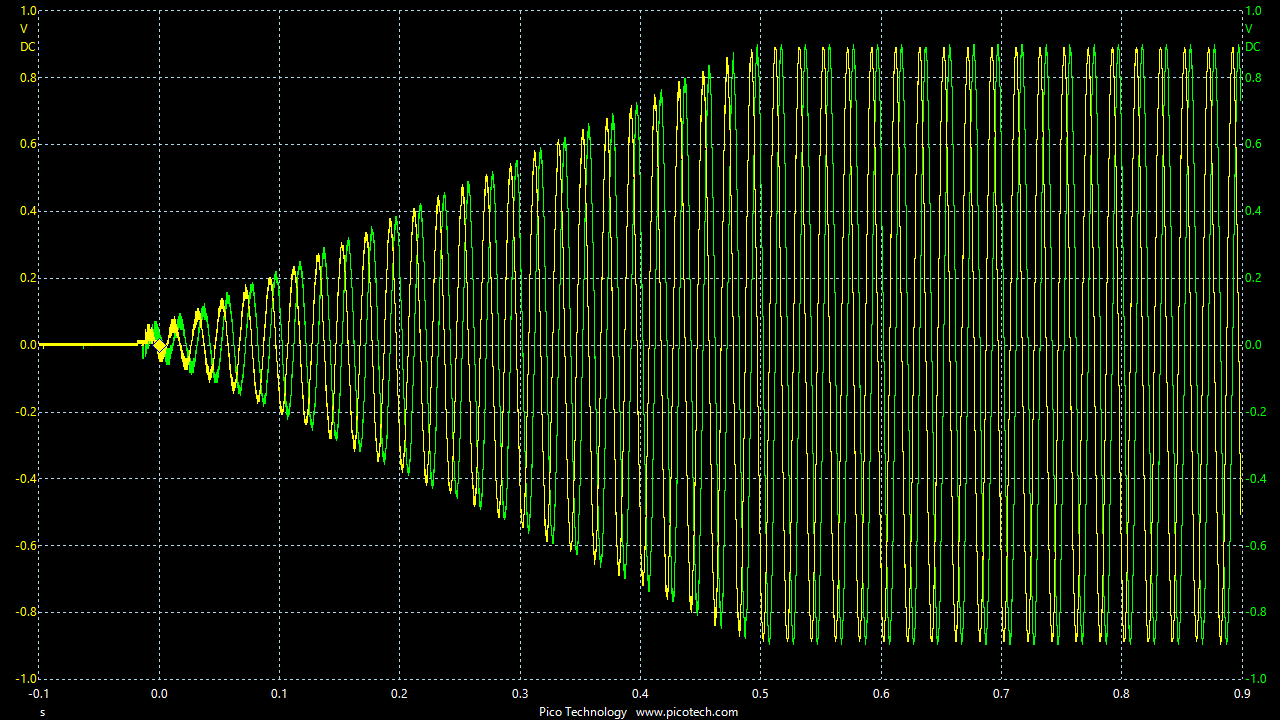

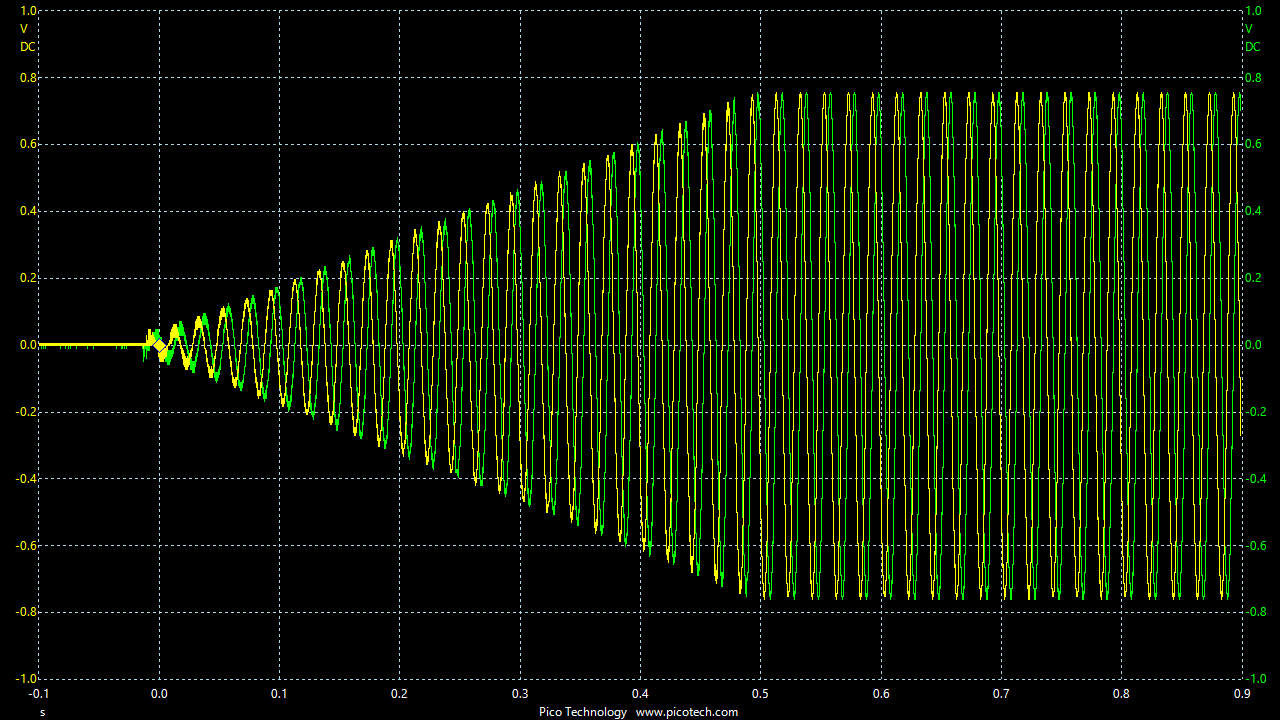

That's an interesting situation. As a first step, I've checked the startup behaviour of the supaspin only, for the Nano and RP2040 versions, both with and without 0.5s soft-start:

Nano:

RP2040:

These look identical, so I don't think it's down to the processor/firmware choice.

The obvious thing to do, if you have an oscilloscope, is to look at the amplifier output to the motor and see if there are any differences betweem the two setups you have. I'll try and get some waveforms for the supaspin + spinamp combination that you use in one of your setups, to see if there are any startup issues there.

That's an interesting situation. As a first step, I've checked the startup behaviour of the supaspin only, for the Nano and RP2040 versions, both with and without 0.5s soft-start:

Nano:

RP2040:

These look identical, so I don't think it's down to the processor/firmware choice.

The obvious thing to do, if you have an oscilloscope, is to look at the amplifier output to the motor and see if there are any differences betweem the two setups you have. I'll try and get some waveforms for the supaspin + spinamp combination that you use in one of your setups, to see if there are any startup issues there.

Hi,

solved the problem of random rotation at start for the supaspin_rb2040/supamp, the return wire of phase B was interrupted inside the insulating sheath!

Coming soon to friends who are fond of Thorens: a couple of tips and tricks derived from my experience to use this phase generator in quadrature with the legendary and widespread Thorens turntables series TD166, TD160, TD145, TD147 with 16Vac synchronous motor, it is absolutely possible to match and perhaps surpass the performance of an original TD125 MKII.

Cheers, Giuseppe.

solved the problem of random rotation at start for the supaspin_rb2040/supamp, the return wire of phase B was interrupted inside the insulating sheath!

Coming soon to friends who are fond of Thorens: a couple of tips and tricks derived from my experience to use this phase generator in quadrature with the legendary and widespread Thorens turntables series TD166, TD160, TD145, TD147 with 16Vac synchronous motor, it is absolutely possible to match and perhaps surpass the performance of an original TD125 MKII.

Cheers, Giuseppe.

Advanced dual sine wave power supply for thorens td166 160 147 etc, using Richb Supaspin generator and Supamp amp.

The 16 volt Thorens motor, a 16 pole, does not tolerate frequencies higher than 50Hz well, perhaps it loses too much torque, so you have to use the same technique as the td125, you have to exclude the mechanical speed change and only use the larger diameter pulley, 18.5mm, feeding with frequency 37.68 Hz you get 33.3 rpm, feeding at 50 Hz you get 45rpm. I set the initial voltage to 16Vrms, then after 10" I drop to 12Vrms (75%), the old Thorens motor will run silently and without vibrations.

The wow & flutter, measured with an app, imprecise in absolute value, also improves by 30%, stability obviously too.

We therefore hope in new developments from Richb, perhaps for a 1.2" display, two-button speed change, LED for 33.3 and LED for 45, to replace the Thorens mechanical control with an electric switch with three fixed positions.

Greetings everyone, Giuseppe.

The 16 volt Thorens motor, a 16 pole, does not tolerate frequencies higher than 50Hz well, perhaps it loses too much torque, so you have to use the same technique as the td125, you have to exclude the mechanical speed change and only use the larger diameter pulley, 18.5mm, feeding with frequency 37.68 Hz you get 33.3 rpm, feeding at 50 Hz you get 45rpm. I set the initial voltage to 16Vrms, then after 10" I drop to 12Vrms (75%), the old Thorens motor will run silently and without vibrations.

The wow & flutter, measured with an app, imprecise in absolute value, also improves by 30%, stability obviously too.

We therefore hope in new developments from Richb, perhaps for a 1.2" display, two-button speed change, LED for 33.3 and LED for 45, to replace the Thorens mechanical control with an electric switch with three fixed positions.

Greetings everyone, Giuseppe.

Dear Richmond,

I am very interested and would like to buy the complete turntable drive. Or just the PCB and wiring drawings, BOM list.

I am building 2 turntables completely with my own machining.

One DD drive is a Papst AC motor and the other is a 24 V BLCD motor with internal drive.

Controllers are a problem. I need help with this.

Best Regards

Andrew

Hungary

I am very interested and would like to buy the complete turntable drive. Or just the PCB and wiring drawings, BOM list.

I am building 2 turntables completely with my own machining.

One DD drive is a Papst AC motor and the other is a 24 V BLCD motor with internal drive.

Controllers are a problem. I need help with this.

Best Regards

Andrew

Hungary

Attachments

Andrew, that looks like an interesting project. The first post of this thread has the PCB Gerber files which you can use to get the PCB made at your chosen PCB fab (I've used JLCPCB successfully for this). The build guide has the BOM and some further useful information.

I'm definitely not an expert on the motors you have, but searching in this thread and also others for sinewave generation should give you some good examples of builds with various motors and the parts used to complete the system.

If you need any further information feel free to contact me or post here.

I'm definitely not an expert on the motors you have, but searching in this thread and also others for sinewave generation should give you some good examples of builds with various motors and the parts used to complete the system.

If you need any further information feel free to contact me or post here.

Dear Richmond,

The first post of this topic is perfect for BLCD engine.

I would like to buy a PCB or a kit. There is a PSU.

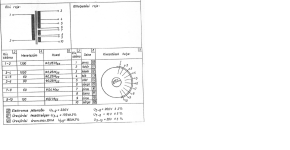

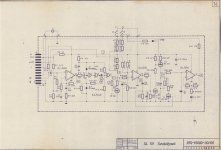

What I really want to finish is the replica of the record player in the picture. The DD AC in this picture was installed. I am attaching the controller drawing from that time. I would like to provide this with a modern frequency variable digital display controller. The motor rotates silently, sintering the replaced ball bearings.

I would like to buy a PCB or a kit. There is a AC 120 V PSU. Example LM3886 PSU

Thank you for trying to help from a distance like this

Andrew

The first post of this topic is perfect for BLCD engine.

I would like to buy a PCB or a kit. There is a PSU.

What I really want to finish is the replica of the record player in the picture. The DD AC in this picture was installed. I am attaching the controller drawing from that time. I would like to provide this with a modern frequency variable digital display controller. The motor rotates silently, sintering the replaced ball bearings.

I would like to buy a PCB or a kit. There is a AC 120 V PSU. Example LM3886 PSU

Thank you for trying to help from a distance like this

Andrew

Attachments

Dear Rich,

Unfortunately, the originally planned drive does not work. Pictured is 334-450 Rpm. By connecting the 7440 IC, I was able to reduce the speed to 66.

Torque is gone. The engine is the original studio turntable engine!

It's not the engine that's the problem, it's the control.

I would like to request your feedback on how I can buy your development?

Andrew

Unfortunately, the originally planned drive does not work. Pictured is 334-450 Rpm. By connecting the 7440 IC, I was able to reduce the speed to 66.

Torque is gone. The engine is the original studio turntable engine!

It's not the engine that's the problem, it's the control.

I would like to request your feedback on how I can buy your development?

Andrew

Attachments

Zincho

It works

What is not on the drawing is a Z=250 toothed tachograph.

This must be connected to the "on" side.

There will be a new PCB for it soon.

What is important is the C7 52nf capacitor 0.5% max 1%.

With a 1.1 kg plate, it reaches the speed in less than a quarter. Its torque is huge.

It works

What is not on the drawing is a Z=250 toothed tachograph.

This must be connected to the "on" side.

There will be a new PCB for it soon.

What is important is the C7 52nf capacitor 0.5% max 1%.

With a 1.1 kg plate, it reaches the speed in less than a quarter. Its torque is huge.

Attachments

A few spare v3.1 PCBs have recently been sent out, just a few minor footprint and silkscreen updates, plus separated the tacho test jumper from the tacho header, but identical functionality and processor/firmware. PCB Gerber files in the first post have now been replaced with this version

It's easy for my system to be in a permanent state of flux, but after a few recent updates it's back together again.

I'd bought a vintage Rotel amp from Ebay, I liked the look and it had just the right supply rails for the 24v AC motor, plus a nice LED bar graph power meter!

Originally I used it 'as is' for both driving the turntable motor with the external sinewave generator, and as a phono preamp using the tape monitor outputs, but it was quite power hungry for the turntable motor, so later moved to replacing the innards with the sinewave generator + companion low-power amplifier (and moving to a separate phono preamp):

(Currently using a v3.0(NANO) supaspin board + RP2040 module, and a recently revised full-wave version of the spinamp)

The OLED fitted nicely behind the clear display panel, the rotary encoder replaces the original volume pot, and the LED bargraph was tweaked with a regulated supply and recalibrated to usefully show the output amplitude:

The turntable is connected via an ethernet cable for both the 2 phase motor drive and tacho sensor:

And (briefly) in use:

I'd bought a vintage Rotel amp from Ebay, I liked the look and it had just the right supply rails for the 24v AC motor, plus a nice LED bar graph power meter!

Originally I used it 'as is' for both driving the turntable motor with the external sinewave generator, and as a phono preamp using the tape monitor outputs, but it was quite power hungry for the turntable motor, so later moved to replacing the innards with the sinewave generator + companion low-power amplifier (and moving to a separate phono preamp):

(Currently using a v3.0(NANO) supaspin board + RP2040 module, and a recently revised full-wave version of the spinamp)

The OLED fitted nicely behind the clear display panel, the rotary encoder replaces the original volume pot, and the LED bargraph was tweaked with a regulated supply and recalibrated to usefully show the output amplitude:

The turntable is connected via an ethernet cable for both the 2 phase motor drive and tacho sensor:

And (briefly) in use:

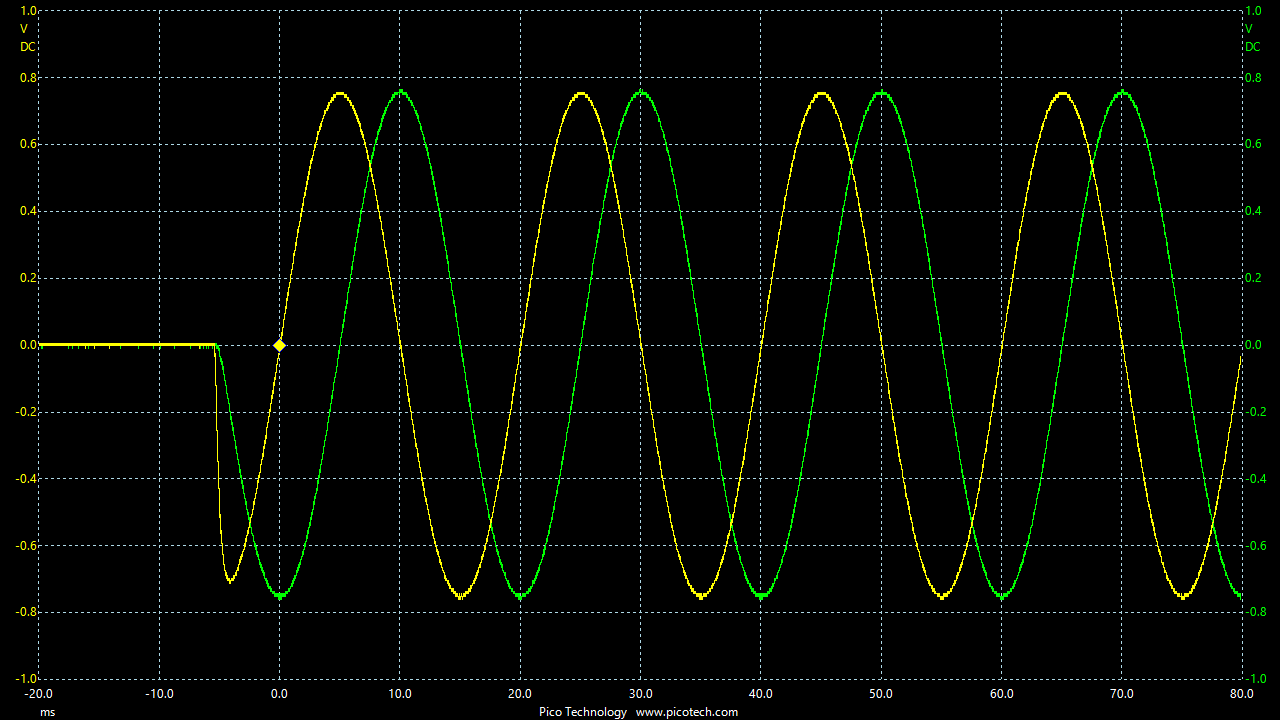

Something I haven't previously detailed - as there is AC-coupling at the output, for optimum settling behaviousr whilst maintaining a suitable HP cut-on frequency. the total parallel resistance of the supaspin output shunt resistance (R9/10/17) + the amplifier input shunt resistances should be around 30-50kΩ, so the supaspin output shunt resistance can be changed from the value in the BOM in order to achieve this.

The build guide in the first post has been updated to include a note in the BOM.

The build guide in the first post has been updated to include a note in the BOM.

New frequency ramp feature to support permanent-magnet synchronous motors

Recently I've been working with Drbulj to support some of the motors he's trialling on his TT in this thread, and after some testing an updated firmware is now ready with a frequency ramp option. This smoothly changes the drive frequency both at startup and at a speed chage, over a chosed time period (2, 4, 8, 16 seconds), and is accessed in the 'amplitude' menu under the 'SStart' item:

The amplitude reduction feature is maintained when using the frequency ramp, happening the chosen time after the completion of the frequency ramp.

Other smaller changes include reverting to full amplitude on speed change, with the amplitude reducing again the chosen time after the completion of the speed change.

The build guide in the first post has been updated to include the new menu options. For the latest firmware including these changes, please PM me.

Recently I've been working with Drbulj to support some of the motors he's trialling on his TT in this thread, and after some testing an updated firmware is now ready with a frequency ramp option. This smoothly changes the drive frequency both at startup and at a speed chage, over a chosed time period (2, 4, 8, 16 seconds), and is accessed in the 'amplitude' menu under the 'SStart' item:

The amplitude reduction feature is maintained when using the frequency ramp, happening the chosen time after the completion of the frequency ramp.

Other smaller changes include reverting to full amplitude on speed change, with the amplitude reducing again the chosen time after the completion of the speed change.

The build guide in the first post has been updated to include the new menu options. For the latest firmware including these changes, please PM me.

More great work Richard. As I dig deeper into implementing this into a turntable, at the moment using the Premotec 24V motor, I find myself wondering about small 3-phase BLDC motors. The thread linked above is interesting and there are a couple of dead VCRs here that might donate some motors for testing. However it would be great to find an affordable, quiet motor that can be purchased easily and used with a project like this to achieve a nominal 250 or 300RPM that could be used in new designs or fitted as a replacement for older broken motors. I saw an article some time ago in which the author used a 7.5-degree stepper motor driven by a twin-phase power supply, as it was similar in construction to the Premotec et al but a lot cheaper. I'm curious to know what you personally consider is the best motor that one can currently use?

- Home

- Source & Line

- Analogue Source

- 2 phase synthesised sinewave generator for synchronous motor drive