Its working now, 8 days start to finish. they replaced Acoustic Research S-50's for

HT and music. Over all it seems like they work fine, A bit smoother not as sibilant,

much more coherent image Need more time to judge....... and adjust polyfill.

I think the DMA90 driver works good but:

How much better would an approved / tested driver be?

Maybe its time to buy a better microphone

I do have a pair of the 3 1/2" TC9 drivers from 5 yrs ago whatever was recommended in the spiral horn thread so those could be swapped if that helps?

I have a lot of amp building parts but nothing for crossovers so that is why I used what I had. With measurements maybe they could be adjusted...

Or leave it as is and buy some foam board/ look for something else to build?

HT and music. Over all it seems like they work fine, A bit smoother not as sibilant,

much more coherent image Need more time to judge....... and adjust polyfill.

I think the DMA90 driver works good but:

How much better would an approved / tested driver be?

Maybe its time to buy a better microphone

I do have a pair of the 3 1/2" TC9 drivers from 5 yrs ago whatever was recommended in the spiral horn thread so those could be swapped if that helps?

I have a lot of amp building parts but nothing for crossovers so that is why I used what I had. With measurements maybe they could be adjusted...

Or leave it as is and buy some foam board/ look for something else to build?

Hi Congo,

Nice work! I have not tried the the DMA90 so don’t know how they compare. I’m sure they are fine. They are aluminum cones though so might have some ringing in the higher octaves. But I don’t know for sure until I see measurements. TC9 may have less “air” compared to aluminum drivers.

Nice work! I have not tried the the DMA90 so don’t know how they compare. I’m sure they are fine. They are aluminum cones though so might have some ringing in the higher octaves. But I don’t know for sure until I see measurements. TC9 may have less “air” compared to aluminum drivers.

X

Thanks, I hoped not to offend you by my cobbled together crossover or DMA driver choice......

I find the TC9 lacking... as in needs a tweeter

this build does work and I am happy ...

I do sometimes miss the heil amt type sound but those can also be piercing with some music

So what to build?

corno's are fun, this I knew could be very good. And worth the effort.

want to try some foam....

Thanks, I hoped not to offend you by my cobbled together crossover or DMA driver choice......

I find the TC9 lacking... as in needs a tweeter

this build does work and I am happy ...

I do sometimes miss the heil amt type sound but those can also be piercing with some music

So what to build?

corno's are fun, this I knew could be very good. And worth the effort.

want to try some foam....

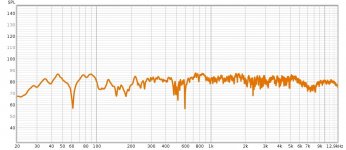

its been a few years since I used REW and that was on HPhones.

so muddling a bit in the dark.........

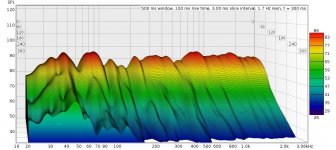

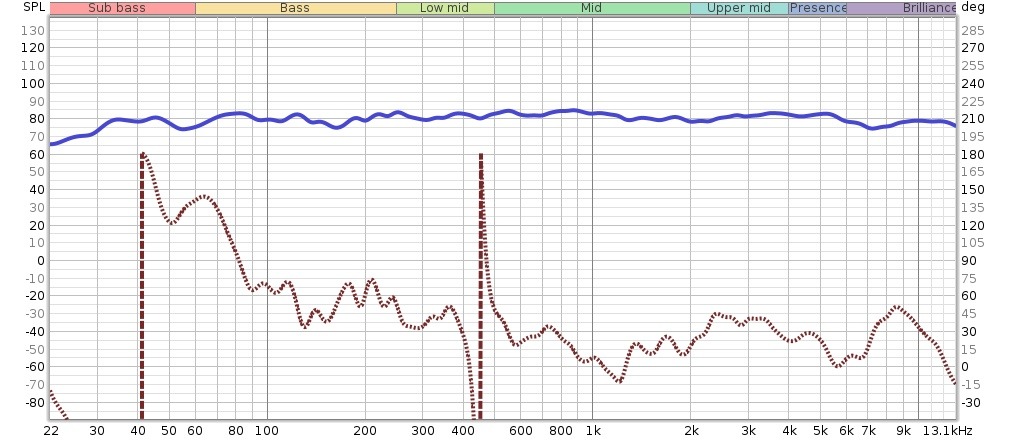

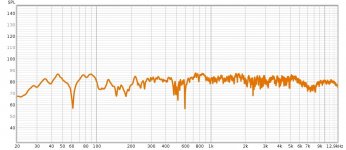

First run - no smoothing

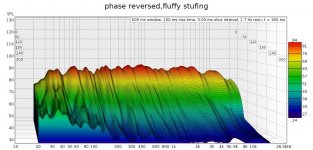

looked like some suck-out and phase reversal so reversed RS225 polarity and lightened stuffing a tiny bit

and added 1/6 smoothing

one way I judge a speaker is how temped I am to turn it up to get it to sound better

These sound good from 75db to 105db

Thanks

so muddling a bit in the dark.........

First run - no smoothing

looked like some suck-out and phase reversal so reversed RS225 polarity and lightened stuffing a tiny bit

and added 1/6 smoothing

one way I judge a speaker is how temped I am to turn it up to get it to sound better

These sound good from 75db to 105db

Thanks

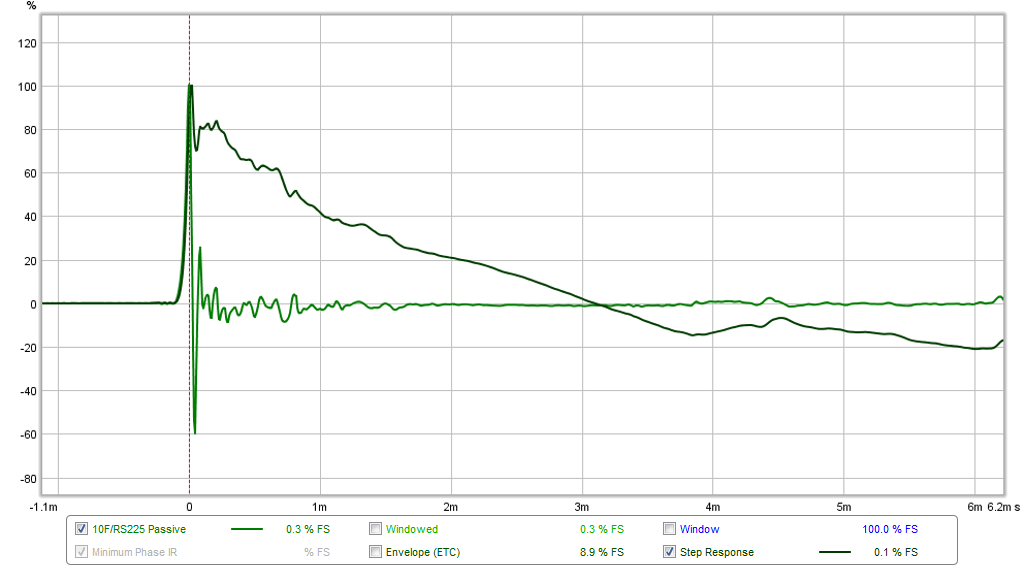

Look at the step response and make sure you have a right triangle. Inverting the woofer polarity (unless it was accidentally reversed) may not be good. Your measurement shows a phase glitch at 400Hz which is odd. Measure on a stand at least 1m above the floor. Set the mic at 0.5m height on fullrange axis. Look at frequency dependent window 6 cycles. The phase should be flat from 100Hz to 15kHz.

Hi Congo,

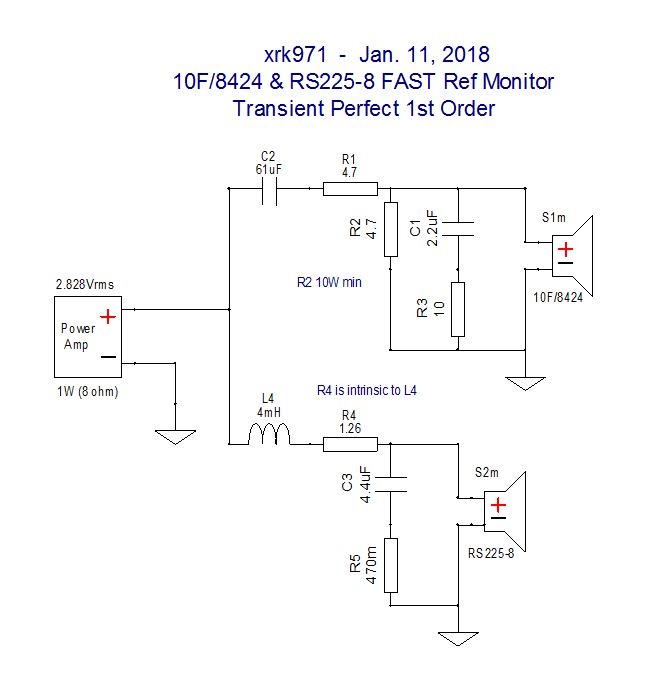

Can you please remind me what drivers you are using and if you are implementing the XO as described in the schematic?

Under the “Impulse Response” tab, click the “Step Response” check box. You should see something like this:

The whole thing may be upside down if your mic is inverted (or amp is inverted output). But the important thing is the tweeter and woofer are if they same polarity. This is what gives the the realism to the percussion.

10F schematic:

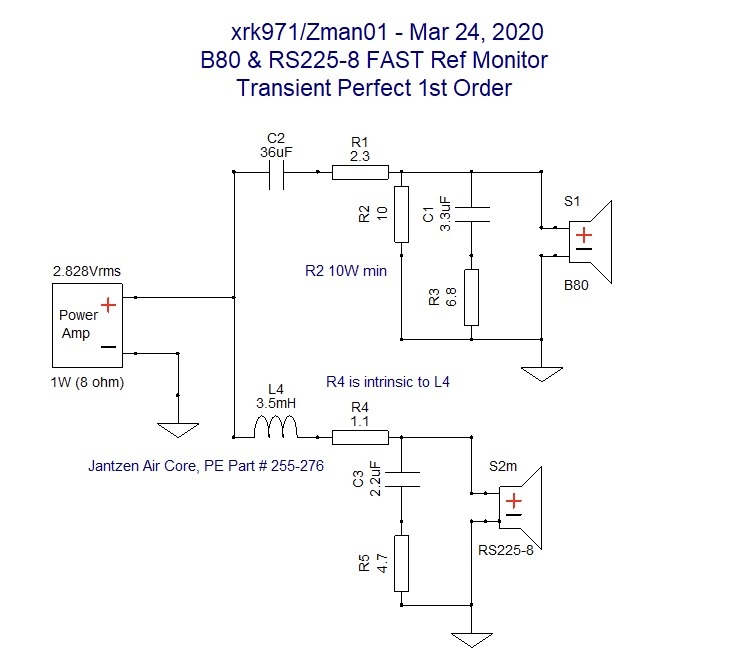

B80 schematic:

Note that both tweeter(wideband) and woofer are same absolute polarity.

Can you please remind me what drivers you are using and if you are implementing the XO as described in the schematic?

Under the “Impulse Response” tab, click the “Step Response” check box. You should see something like this:

The whole thing may be upside down if your mic is inverted (or amp is inverted output). But the important thing is the tweeter and woofer are if they same polarity. This is what gives the the realism to the percussion.

10F schematic:

B80 schematic:

Note that both tweeter(wideband) and woofer are same absolute polarity.

Drivers are:Can you please remind me what drivers you are using and if you are implementing the XO as described in the schematic?

RS225-8 https://www.parts-express.com/Dayton-Audio-RS225-8-8-Reference-Woofer-295-356

DMA90-8 https://www.parts-express.com/Dayto...Aluminum-Cone-Full-Range-Driver-8-Ohm-295-589

The Good:

The box IS built to your 3/4 BB plans

the Dagger is 5 sided sealed & stuffed 1/4 plywood

I used some butyl rubber in center of spans

the foam is done to spec's

this DMA90 is an undocumented fullrange driver

studied your schematics and made one with parts on hand to closet values I had.

and I have not made an order for crossover parts yet

Yesnote that both tweeter(wideband) and woofer are same absolute polarity.

None of this is a Design fault

its my work in progress

Nothing is permanently compromised Yet

I like this driver fine but a new one can be ordered

its already better that what I had

need learn to simulate the

xo;s

Last edited:

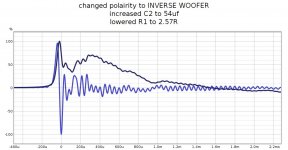

You have your woofer inverted polarity and that can be seen in the step response. It may have better integration because the inductor and capacitor values are so far off. Inductor should closer to 4mH and cap closer to 60uF. As you have it, the crossover frequency might be up a bit higher and causes phase misalignment of 180deg requiring polarity flip. But it’s probably not bad sounding at all - just not transient perfect.

thanks for sharing.

thanks for sharing.

Congo,

Nice use of repurposed wood 👍

Just a question about your cabinet construction, in addition to glue, did you seal all the baffle panels in the transmission line and side panel walls?

Nice use of repurposed wood 👍

Just a question about your cabinet construction, in addition to glue, did you seal all the baffle panels in the transmission line and side panel walls?

OK thanks a lot ...............

I can add an 18uf and a 6uf film in parallel = 60uf

also have a 1mh inductor add that in series for 3.5mh??

I can order better parts but wasn't sure about values

I can add an 18uf and a 6uf film in parallel = 60uf

also have a 1mh inductor add that in series for 3.5mh??

I can order better parts but wasn't sure about values

Yes I think so, Used liquid nails Extreme heavy duty LN-907. So on the first side I glued and caulked it 100%, second side I used a generous amount then still finger sealed what I could see / reachJust a question about your cabinet construction, in addition to glue, did you seal all the baffle panels in the transmission line and side panel walls?

no cross contamination of pressure waves allowed!

the plywood was installed in a restaurant bar and then changed out so it had some screw holes and light damage, and no straight edges as it was all curved. still good wood for something.

Now place your microphone on the woofer axis 0.5m away and that should provide the time delay to get the wideband time aligned with the woofer. That’s why the woofer is on top. That’s about 10cm delay to get 350usec shift.

- Home

- Loudspeakers

- Full Range

- 10F/8424 & RS225-8 FAST / WAW Ref Monitor