If you used those 3 woofers in the same box keep in mind that in the instance with 1 woofer out of phase you now effectively only have 1 woofer loading the enclosure instead of 3 so any comparisons tell you little to nothing.

Scott & i were working on “wiring” three drivers, and it is currently sitting in a folder called multi-driver mess, as some strange things start to happen when they aren’t all in apralll or series (and in acoustic phase).

dave

Scott & i were working on “wiring” three drivers, and it is currently sitting in a folder called multi-driver mess, as some strange things start to happen when they aren’t all in apralll or series (and in acoustic phase).

dave

Another cool way to think about it is? Calm your tits.

🙂

Tune it! You want vibrations of the good sounding kind. It is not as simple as mounting a fine bass woofer in a five inch thick walled, completely dead, all concrete box.

It simply has to sing! Tune it! It takes time.

A full range speaker is a musical instrument. So is, for sure, a low bass speaker. It is not supposed to be stone dead. It is supposed to rock, blues and funk your entire soul.🙂🎸

Build it, tune it, according to your taste and room. 🙂👍

Add/remove that last brace? Add/remove that last piece of internal damping material? Goto Closed box, or a little longer bass reflex port?

🙂

Tune it! You want vibrations of the good sounding kind. It is not as simple as mounting a fine bass woofer in a five inch thick walled, completely dead, all concrete box.

It simply has to sing! Tune it! It takes time.

A full range speaker is a musical instrument. So is, for sure, a low bass speaker. It is not supposed to be stone dead. It is supposed to rock, blues and funk your entire soul.🙂🎸

Build it, tune it, according to your taste and room. 🙂👍

Add/remove that last brace? Add/remove that last piece of internal damping material? Goto Closed box, or a little longer bass reflex port?

Thank you Dave!

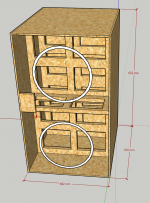

I have some 78L boxes to repurpose made of 1" BB. Maybe this could work in my drawing. I chose a random 10 inch driver for dimensions. I would need to find proper woofers for volume of 70L. The mid box will take up 6-10L.

The woofers would have magnets 2.2 inches apart.

Is the woofer configuration acceptable for push push?

I have some 78L boxes to repurpose made of 1" BB. Maybe this could work in my drawing. I chose a random 10 inch driver for dimensions. I would need to find proper woofers for volume of 70L. The mid box will take up 6-10L.

The woofers would have magnets 2.2 inches apart.

Is the woofer configuration acceptable for push push?

Attachments

Last edited:

No, they're not.A full range speaker is a musical instrument. So is, for sure, a low bass speaker.

I found this. Also, I see ported is not an issue. ported if my preference for the these particular boxes.

edit; just realized that is Dave's drawing🙂

edit; just realized that is Dave's drawing🙂

Attachments

Last edited:

I was remebering our build of that. Scott built it out of scraps (some recycled from old consoles)m painted black. A tiny little thing that was/is a really nice woofer.

Push-push means material choice was not as critical.

dave

Push-push means material choice was not as critical.

dave

Better than bracing: plywood and silicone and plywood sandwich. For this, 1/2 inch is perfect size.

Have you done this and tested this?Better than bracing: plywood and silicone and plywood sandwich. For this, 1/2 inch is perfect size.

Silcone meaning regular silicone sealant?

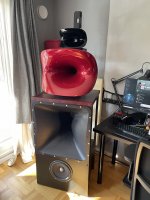

I did it on the front of my newest speaker. Two 12mm Oak sandwiched with silicon. It is so strong but dead when I tap on it. No ringing at all. No need to use oak, but it turned out to be cheaper than plywood because of covid.Have you done this and tested this?

Silcone meaning regular silicone sealant?

Attachments

Probably functions similar to Green Glue used in home theater soundproofing applications?Silicon in between sounds like a mess.

dave

No, make it some acoustic or golden ratio and brace/tie all six sides together with risers on edge offset at some acoustic or golden ratio to make an inert box to well above the driver's pass band and yes, done this way you don't need very rigid and/or heavy riser boards, though most folks will make 'window panes' assuming they will inherently be better overall.The plan is for midbass Cabs of 100-120L and subwoofer Cabs of 220L

I'm going for the lowest weight as possible so I'd like to use 1/2" BB. With good bracing do you see any issues with my plan? Noise, panel resonance etc?

Frankly, I have, and would build, using 1/4" BB since it's comparable spec-wise to the marine grades I used way back when with up to 8.5 ft^3 cabs loaded with (heavy) 12 -15" AlNiCo woofers with soft wood plank/board bracing to further reduce weight. The big problem then becomes one of needing to add weight on top to keep it firmly in place if a long throw driver (never my problem) and while the horn(s) were heavy enough for my apps, will a lightweight mids/high box be enough?

No, make it some acoustic or golden ratio and brace/tie all six sides together with risers on edge offset at some acoustic or golden ratio to make an inert box to well above the driver's pass band and yes, done this way you don't need very rigid and/or heavy riser boards, though most folks will make 'window panes' assuming they will inherently be better overall.

Frankly, I have, and would build, using 1/4" BB since it's comparable spec-wise to the marine grades I used way back when with up to 8.5 ft^3 cabs loaded with (heavy) 12 -15" AlNiCo woofers with soft wood plank/board bracing to further reduce weight. The big problem then becomes one of needing to add weight on top to keep it firmly in place if a long throw driver (never my problem) and while the horn(s) were heavy enough for my apps, will a lightweight mids/high box be enough?

1/4" BB panels - Great idea, light weight, thanks!

1/2 or 3/4 ply window pane risers - panels glued and screwed to risers

3/4 ply horizontal mid windos pane connections front to back

12mm BB front and back panel - holds screws very well

Box has 1/8 - 1/4 spalted maple thin boards glued and pressed

Many Thanks!

Attachments

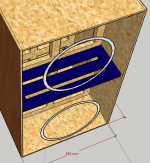

I would rotate the brace that runs just between the drivers 90° to a/ provide a better brace, b/ provides the opportunity to shar the driver reaction energy more evenly thruout all the box panels.

General bracing rule: the subpanels created by a brace should have a higher aspect ratio than the panel being braced.

dave

General bracing rule: the subpanels created by a brace should have a higher aspect ratio than the panel being braced.

dave

Last edited:

No, all bracing is along it longest axis, so viewed from above it will look like an 'X', 'cross' depending on offset with the offset predicated on both proper offset from a bracing POV and usually to brace/mass load the driver to the baffle.

Dave, please post an example of one of your bracing schemes.

Dave, please post an example of one of your bracing schemes.

You want to push (potential) resonancces up in frequency, ideally high enuff that i never gets excited.

And not in the exact centre to avoid this:

Here is a top view of what is meant.

dave

And not in the exact centre to avoid this:

Here is a top view of what is meant.

dave

- Home

- Loudspeakers

- Multi-Way

- 1/2 inch Baltic Birch for Bass Cabinets?