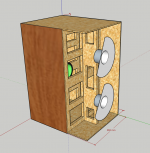

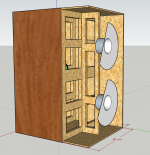

Getting there. The vertical brace, should, if possible also reach up to and support thr baffle. This, i believe would be a development of your first drawing (only the little divot for the magnet?). possible depends on how much baffle is above or below the driver.

Do note that getting the speacing “perfect” on the brace is not always the easiest task.

dave

Do note that getting the speacing “perfect” on the brace is not always the easiest task.

dave

What Dave said plus please note this brace goes all the way to the back.Maybe better?

"brace/mass load the driver to the baffle"

So now I'm curious about above quote and concept/complete meaning/philosophy.

We do hear about designers/builders mechanically isolating the driver(s) from the baffle/box. The above appears to be the polar opposite?

So now I'm curious about above quote and concept/complete meaning/philosophy.

We do hear about designers/builders mechanically isolating the driver(s) from the baffle/box. The above appears to be the polar opposite?

"brace/mass load the driver to the baffle"

So now I'm curious about above quote and concept/complete meaning/philosophy

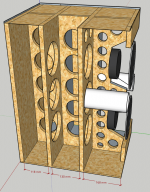

If one can spread the energy across more panels, the amount of energy per volume unit of box material goes down, greatly reducing the potential to get the baffle, thee weakest part of the box. The brute force fix is a REALLY thick baffle. Bracing the driver in an effective manner creates an I/T bream and makes for the whole (more of) the box gets used. An i.T beam is also stiffer than a flat panel.

dave

Last edited:

That said, the pioneers originally designed technically ideal prototypes as a baseline for when the 'bean counters' became the dominant 'designers'. As such, the 'driver' was mounted to either a massive frame cum floor-stand or proper framework rigidly attached to the floor and the floor mounted baffle gapped close to the driver with basically just a flap of leather or a bike's inner tube.

Later, the cost solution was a driver with an appropriately rigid/massive steel frame with the mounting perimeter consisting of four to eight mounting holes and a second rim that stood proud of the outer rim so that the typical (un) skilled laborer couldn't (accidentally) over tighten it, just screw it down till the outer rim sealed it. This also negated any need for box bracing beyond what was required for shipping/handling.

The rigid/massive box framework 'squeezing' the driver against the baffle is an acceptable alternative, what with a modern speaker's standard gasketing and why proper torquing of the hardware is required for max benefit.

Later, the cost solution was a driver with an appropriately rigid/massive steel frame with the mounting perimeter consisting of four to eight mounting holes and a second rim that stood proud of the outer rim so that the typical (un) skilled laborer couldn't (accidentally) over tighten it, just screw it down till the outer rim sealed it. This also negated any need for box bracing beyond what was required for shipping/handling.

The rigid/massive box framework 'squeezing' the driver against the baffle is an acceptable alternative, what with a modern speaker's standard gasketing and why proper torquing of the hardware is required for max benefit.

- Home

- Loudspeakers

- Multi-Way

- 1/2 inch Baltic Birch for Bass Cabinets?