Hello everyone,

I just mounted the Vifa/Peerless XT25TG30-04 on a Visaton 148 R waveguide and thought that I'd post some pics of how I did it in case someone is interested.

First here is the couple:

Due to the slightly curved front plate of the XT25 a small ~2 mm gap remains between the tweeter and the wg which I thought might not do any good to the sound:

A cheap solution was found from blutack or what ever this sticky stuff is called in English. I made a thin donut and placed it to the very edge of the opening in the waveguide:

I also put three small blobs of blutack on the tweeter face while I aligned the wg to make sure that it stays in place while I mark the holes.

I don't have any pics of the alignment process itself, but it's of course very straightforward. I used a 4 mm wood drill bit to push small marks on the wg wg back plate as the bit fit the holes nicely and was thus centered well enough automatically.

Some of the holes go close to the original mounting holes with thread inserts on the wg, but the original holes are not at the same distance from the center point as the XT25 mounting holes so they can't be used.

I first put some white paint around the mark to make the mark more visible for drilling and used a normal 2,5 mm metal drill bit for the hole.

3,5x13 DIN 7981 screws and washers were used to mounting:

And here is the result from the front:

I think they came out quite nice.

No idea how the sound is yet, though.😱

I just mounted the Vifa/Peerless XT25TG30-04 on a Visaton 148 R waveguide and thought that I'd post some pics of how I did it in case someone is interested.

First here is the couple:

Due to the slightly curved front plate of the XT25 a small ~2 mm gap remains between the tweeter and the wg which I thought might not do any good to the sound:

A cheap solution was found from blutack or what ever this sticky stuff is called in English. I made a thin donut and placed it to the very edge of the opening in the waveguide:

I also put three small blobs of blutack on the tweeter face while I aligned the wg to make sure that it stays in place while I mark the holes.

I don't have any pics of the alignment process itself, but it's of course very straightforward. I used a 4 mm wood drill bit to push small marks on the wg wg back plate as the bit fit the holes nicely and was thus centered well enough automatically.

Some of the holes go close to the original mounting holes with thread inserts on the wg, but the original holes are not at the same distance from the center point as the XT25 mounting holes so they can't be used.

I first put some white paint around the mark to make the mark more visible for drilling and used a normal 2,5 mm metal drill bit for the hole.

3,5x13 DIN 7981 screws and washers were used to mounting:

And here is the result from the front:

I think they came out quite nice.

No idea how the sound is yet, though.😱

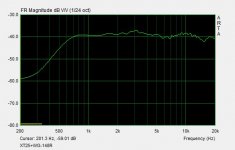

Measurements?

Here is another option: https://www.madisoundspeakerstore.com/acoustic-damping/dampers-felt-defraction-ring-for-tweeters/

Here is another option: https://www.madisoundspeakerstore.com/acoustic-damping/dampers-felt-defraction-ring-for-tweeters/

Hmm. You could use some wood putty or clay instead of the bluetak in the gap.

I think it would come off the plastics easily later and allow you to sculpt the face between the wg and xt.

Exactly like you have now but it won't pill and pull like the bluetak and will give you a super smooth transition.

I get the feeling that any discontinueity that close to the membrane will cause response Wierdness.

Just a thought and thanks for sharing.

I think it would come off the plastics easily later and allow you to sculpt the face between the wg and xt.

Exactly like you have now but it won't pill and pull like the bluetak and will give you a super smooth transition.

I get the feeling that any discontinueity that close to the membrane will cause response Wierdness.

Just a thought and thanks for sharing.

Measurements?

Here is another option: https://www.madisoundspeakerstore.com/acoustic-damping/dampers-felt-defraction-ring-for-tweeters/

Or you could get felt from anywhere and purchase a craft felt circle cutter. When you are done you can go hot glue some rhinestones on your subwoofers. 🙂

Best,

Erik

Smooth transition from membrane to throat is a key for good results.I get the feeling that any discontinuity that close to the membrane will cause response Wierdness.

I think that this Visaton WG should be used with a tweeter with a flat faceplate like some Seas. For the XT25 the best commercial WG should be the Monacor WG300 as can be seen here: 7100-waveguide

Ralf

I'm sorry guys, but for the measurements I have only REW and UMIK and can't do any measurements outside. If I measure anything in my echoing livingroom it's probably meaningless.

Since taking the pics I smoothed out the bluetack. It's pretty much seamless now with the wg.

Since taking the pics I smoothed out the bluetack. It's pretty much seamless now with the wg.

Last edited:

You don't have to measure outside, just do a gated measure. At the frequencies involved for the tweeter it has small effect on the precision.

Ralf

Ralf

You don't have to measure outside, just do a gated measure. At the frequencies involved for the tweeter it has small effect on the precision.

Ralf

Measure your woofer a foot away, unless sealed. 🙂

+1.You don't have to measure outside, just do a gated measure. At the frequencies involved for the tweeter it has small effect on the precision.

Ralf

I took the faceplate off a Vifa XT25 - it's quite annoying the way they've designed the bit of plastic that holds the diaphragm 🙁

Sure would be nice if they'd made the front flat instead!

Sure would be nice if they'd made the front flat instead!

This ring radiator may work with this guide without modifications:

https://www.madisoundspeakerstore.c...04/6020-10-1-tweeter-soft-dome-ring-radiator/

https://www.madisoundspeakerstore.c...04/6020-10-1-tweeter-soft-dome-ring-radiator/

Seas 27TFD, Noferro900 (@Intertechnik), 27TFF, 27TAF+ seem to work work fine in the WG148R.

Seas 27TFD in WG148R

Alexander Heissmann has tested the NoFerro900 with the Viaston WG and soon will be testing the Scan Speak D2604/833000.

NoFerro900 with WG148R

An externally hosted image should be here but it was not working when we last tested it.

Seas 27TFD in WG148R

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Alexander Heissmann has tested the NoFerro900 with the Viaston WG and soon will be testing the Scan Speak D2604/833000.

NoFerro900 with WG148R

You don't have to measure outside, just do a gated measure. At the frequencies involved for the tweeter it has small effect on the precision.

Ralf

Oh yeah true, I did not think of gated measurements. I'll try to get it done someday in the near future.

Seas 27TFD, Noferro900 (@Intertechnik), 27TFF, 27TAF+ seem to work work fine in the WG148R.

An externally hosted image should be here but it was not working when we last tested it.

Seas 27TFD in WG148R

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Alexander Heissmann has tested the NoFerro900 with the Viaston WG and soon will be testing the Scan Speak D2604/833000.

NoFerro900 with WG148R

Yep I know of Alexanders measurements. From there I found the WG 148 R in the first place.

I first thought about buying the Noferro's for the WG, but decided to see if I can mount the XT25's instead which I wanted to use for my next project.

Some measurements?

Please? Even something quick - ~ 1/2 meter away, a few sweeps? We're very curious.

Oh yeah true, I did not think of gated measurements. I'll try to get it done someday in the near future.

Please? Even something quick - ~ 1/2 meter away, a few sweeps? We're very curious.

Hello

I did, and with very nice results!

kind regards

Alexander

...and soon will be testing the Scan Speak D2604/833000.

I did, and with very nice results!

kind regards

Alexander

Just to update this older thread, in case others are thinking about doing this.

It's possible to take the face plate off the XT25 first.

This lets the waveguide fit a few mm back, closer to the tweeter body and reducing the gap to fill.

I filled the gap with some kind of modelling clay, which I think is starting to dry out a bit now - I did these a couple of years ago.

It's possible to take the face plate off the XT25 first.

This lets the waveguide fit a few mm back, closer to the tweeter body and reducing the gap to fill.

I filled the gap with some kind of modelling clay, which I think is starting to dry out a bit now - I did these a couple of years ago.

Just to update this older thread, in case others are thinking about doing this.

It's possible to take the face plate off the XT25 first.

This lets the waveguide fit a few mm back, closer to the tweeter body and reducing the gap to fill.

View attachment 789826

I filled the gap with some kind of modelling clay, which I think is starting to dry out a bit now - I did these a couple of years ago.

So how do they sound and perform?

I happen to have a handful XT25s here for my next build (3 way though). I would really like to use them, but wide dispersion is not really their best thing.

BR,

Steen

Hi Kimmi,

I got the waveguide and I am considering the XT25. HAve you aver finished your project?

I got the waveguide and I am considering the XT25. HAve you aver finished your project?

- Home

- Loudspeakers

- Multi-Way

- XT25 + Visaton WG 148 R with pictures