I'm working on a portable, cart-based PA system for outdoor events.

Covering crowds of thousands is a huge challenge, and it is crucial to get speakers high into the air so the acoustic energy is not absorbed by the crowd. I have found line of sight between audience members and the PA is critical for intelligibility. I am mostly concerned with speeches, so bass response is not important.

In the pro audio world, they use line array towers hoisted high into the air to cover large events, with similar "delay towers" deeper into the audience to reinforce the sound with appropriate delay.

I am hoping to emulate this somewhat with a low cost, lower quality system that can be easily set up and taken down.

I am happy with my current version, but excited to make a few improvements to the horn design and the DSP programming.

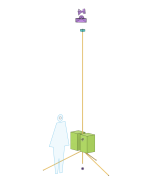

The system uses a two-way speaker design where the mid/high horn is mounted as much as 5 meters(15'ft) above the woofer. I am using very strong telescoping carbon fiber cleaning poles as the masts.

Here’s the current signal chain and driver setup:

In my tests it sounds good as long as one is standing in the coverage zone of both the woofer and the horns. It is very intelligible, though far from "full" sounding as the lows are pretty underpowered.

By using two of the horns I can point to 180° for large crowds. I have access to a printer with 350*320*325 mm³ Print Volume, so ideally it fits in this space.

Making the horns sound better and weigh less would help even more, and let me raise them higher safely. The horns are connected with all-metal hardware and each has backup safety tethers to reduce head injury risk.

I’m currently using an injection-molded Goldwood GM-450PB (90° x 40°), but it’s far more rugged than I need. They also rely on an adapter which I imagine harms the sound somewhat.

To keep things manageable, I’m trying to make the horns as light as physically possible, I'd love to print them in PETG.

The horn geometry stuff is frankly terrifyingly complex to me, and I wonder if I could get help creating a single-surface STEP file of a horn with similar or better frequency performance, which I can thicken in Fusion to to be printed in one piece.

Also would love to hear thoughts on the project!

Thanks!

Covering crowds of thousands is a huge challenge, and it is crucial to get speakers high into the air so the acoustic energy is not absorbed by the crowd. I have found line of sight between audience members and the PA is critical for intelligibility. I am mostly concerned with speeches, so bass response is not important.

In the pro audio world, they use line array towers hoisted high into the air to cover large events, with similar "delay towers" deeper into the audience to reinforce the sound with appropriate delay.

I am hoping to emulate this somewhat with a low cost, lower quality system that can be easily set up and taken down.

I am happy with my current version, but excited to make a few improvements to the horn design and the DSP programming.

The system uses a two-way speaker design where the mid/high horn is mounted as much as 5 meters(15'ft) above the woofer. I am using very strong telescoping carbon fiber cleaning poles as the masts.

Here’s the current signal chain and driver setup:

- 2x JBL Selenium D250-X GW 1" phenolic compression driver (1-3/8"-18 TPI)

- 2x PRV Audio ADM25-50 adapter (to 4-bolt 2″ horn mount)

- 2x Goldwood GM-450PB horn

- 12" woofer (Behringer b112d, removed old(broken) amp, not using tweeter) near ground level to fill in 50hz-400hz

- DSP via Dayton Audio KABD-4100, handling crossover, delay, and EQ (using REW for auto eq)

In my tests it sounds good as long as one is standing in the coverage zone of both the woofer and the horns. It is very intelligible, though far from "full" sounding as the lows are pretty underpowered.

By using two of the horns I can point to 180° for large crowds. I have access to a printer with 350*320*325 mm³ Print Volume, so ideally it fits in this space.

Making the horns sound better and weigh less would help even more, and let me raise them higher safely. The horns are connected with all-metal hardware and each has backup safety tethers to reduce head injury risk.

I’m currently using an injection-molded Goldwood GM-450PB (90° x 40°), but it’s far more rugged than I need. They also rely on an adapter which I imagine harms the sound somewhat.

To keep things manageable, I’m trying to make the horns as light as physically possible, I'd love to print them in PETG.

The horn geometry stuff is frankly terrifyingly complex to me, and I wonder if I could get help creating a single-surface STEP file of a horn with similar or better frequency performance, which I can thicken in Fusion to to be printed in one piece.

Also would love to hear thoughts on the project!

Thanks!

Attachments

Ah ah! You mimic that situation in your little spaceIn the pro audio world, they use line array towers hoisted high into the air to cover large events, with similar "delay towers" deeper into the audience to reinforce the sound with appropriate delay.

I mean...you should overcome the distribution of sound in say- a 20x 20 m area - with enough power and even covering the audience with full spectrum radiating sources that can be subdivided into units with specific drivers for the given function.

I don't see the typical subwoofer (array- coz' it's never enough) and head system, just a too stretched in height dismantled system.

The idea is good - sound from a 45° source above the head.

Experiment can be done with the existing speaker. The problem is how to suspend a mass.

I fear some problems below the Schroeder's frequency (?!) may arise. Some speculation about WHY in the Altec's VOTT the HF horn is near the woofer horn, and what's that woofer horn?!

I fear some problems below the Schroeder's frequency (?!) may arise. Some speculation about WHY in the Altec's VOTT the HF horn is near the woofer horn, and what's that woofer horn?!

👍I'm working on a portable, cart-based PA system for outdoor events.

Absorbing acoustic energy by the crowd is not a problem, with correct aiming. High mounting is a good choice because you are using simple point source speaker to fill large area with more-or-less uniform SPL. What is the expected distance form your pole to the nearest crowd? Line arrays have multiple modules in high (long) segmented column, where lower module or two (or three) can be pointed downward to the nearby crowd without overpowering them with high SPL, while upper multitude of line-array modules are pointing to the crowd farther in distance, providing the same SPL far away.Covering crowds of thousands is a huge challenge, and it is crucial to get speakers high into the air so the acoustic energy is not absorbed by the crowd.

It is not clear to me - are you also intending to use several your pole-mounted systems to cover larger area farther in the crowd, with appropriate delay?In the pro audio world, they use line array towers hoisted high into the air to cover large events, with similar "delay towers" deeper into the audience to reinforce the sound with appropriate delay.

Although woofers are attached low enough to ensure low center of mass, everything is looking flimsy and dangerous for use in the crowd. What is the safe carrying weight of that tripod? What about powerful wind gusts?The system uses a two-way speaker design where the mid/high horn is mounted as much as 5 meters(15'ft) above the woofer. I am using very strong telescoping carbon fiber cleaning poles as the masts.

With woofers mounted that low (from the ground), all frequencies in the 300-400Hz range will be absorbed by the crowd, reducing intelligibility. There is a reason why line array modules have low frequency extension to at least 100 Hz. What is the expected distance form your pole to the nearest crowd?I’d like the horn to preserve the 90° x 40° pattern, and be able to cross over around 400 Hz.

Last edited:

Those poles are not designed or rated for overhead weight support, and show considerable deflection in your photo.The system uses a two-way speaker design where the mid/high horn is mounted as much as 5 meters(15'ft) above the woofer. I am using very strong telescoping carbon fiber cleaning poles as the masts.

They will wave in a slight breeze, and are unsafe.

If you plan to suspend speakers in the air above a crowd, your rigging should be certified, and you should carry liability insurance.

To preserve a 40 degree vertical pattern to ~400Hz, the horn's height would need to be around 1meter tall.I’d like the horn to preserve the 90° x 40° pattern, and be able to cross over around 400 Hz.

To be non-resonant, it will be heavy.

Thanks for all the thoughts!

Safety is the number one priority, and is being taken seriously. The image is not current. Each 3 kg horn (7lbs) in the current version is on its own extension pole. Each pole us rated for 6+ kg, and the poles are only being used ay 75% extension, which cuts the torque moment in half. Additionally, I hope to cut a lot of weight from the horns by printing them. The photo is both not the current poles, and some of the curve is an artifact of "panorama" mode on my phone. The area under the tower is kept clear and the operator is careful to raise less high in winds. Also the current version has 20+kg (50+lbs) of ballast in the base not including the woofer. I have done extensive tipping simulation and real-wold tests and the tower self-rights when tipped to 15° from vertical, which is one standard for tipping safety for equipment stands in industry. Overhead weight is no joke, and I assure you precautions are being taken.

In an recent actual use example, furthest audience member is 100 meters (300ft) away from the main sound system, which is 4 12" full range active PA units on a 2m (6') stage platform with 2m (6') tripod stands.

This system is the delay tower, it was set up by ear once the main system could no longer be heard clearly, about 50m 150'ft away from the stage. The delay was set to ~150ms to account for speed of sound.

The crossover point was picked to be as low as could practically be emitted in the vocal range by a extremely loud speaker without it weighing too much to safely be hoisted to these heights. The goal is to ensure everyone can understand the speeches, not to win any sound quality awards.

It sounds fuller than I expected, though definitely a bit shrill. I have the DSP set up so the woofer is redlining even when the horns are not to make up for the imbalance somewhat.

Is there a ideal place in the forum to ask for CAD horn geometry help to lighten the horns, and perhaps improve the low end?

Safety is the number one priority, and is being taken seriously. The image is not current. Each 3 kg horn (7lbs) in the current version is on its own extension pole. Each pole us rated for 6+ kg, and the poles are only being used ay 75% extension, which cuts the torque moment in half. Additionally, I hope to cut a lot of weight from the horns by printing them. The photo is both not the current poles, and some of the curve is an artifact of "panorama" mode on my phone. The area under the tower is kept clear and the operator is careful to raise less high in winds. Also the current version has 20+kg (50+lbs) of ballast in the base not including the woofer. I have done extensive tipping simulation and real-wold tests and the tower self-rights when tipped to 15° from vertical, which is one standard for tipping safety for equipment stands in industry. Overhead weight is no joke, and I assure you precautions are being taken.

In an recent actual use example, furthest audience member is 100 meters (300ft) away from the main sound system, which is 4 12" full range active PA units on a 2m (6') stage platform with 2m (6') tripod stands.

This system is the delay tower, it was set up by ear once the main system could no longer be heard clearly, about 50m 150'ft away from the stage. The delay was set to ~150ms to account for speed of sound.

The crossover point was picked to be as low as could practically be emitted in the vocal range by a extremely loud speaker without it weighing too much to safely be hoisted to these heights. The goal is to ensure everyone can understand the speeches, not to win any sound quality awards.

It sounds fuller than I expected, though definitely a bit shrill. I have the DSP set up so the woofer is redlining even when the horns are not to make up for the imbalance somewhat.

Is there a ideal place in the forum to ask for CAD horn geometry help to lighten the horns, and perhaps improve the low end?

So, just a delay filling, farther in the crowd. OK.This system is the delay tower

Because this pole is in the middle of the crowd, woofer output between 300 and 400 Hz will be absorbed by a nearby crowd - that position of the woofer is not good. I would suggest to build new, smaller enclosures fitted with the same woofers (or preferably with lightweight neodymium magnet versions), attached at the same height next to the midrange horn. Bass enclosure should be very small (just to enclose the woofer), because you don't really need any output below 200 Hz. And of course you need a proper rigging system to put those loudspeakers high enough. Fiberglass pole and simple loudspeaker tripod are not serious nor professional.

Last edited:

I agree with Sonce and others that this pole and tripod solution is not safe enough, whether you have tested it or not, sorry to say. When dealing with crowds, you can expect the unexpected and Murphy's Law is waiting for something to happen. Is it possible to use a multitude of distributed smaller speakers, that are placed much closer to the ground, instead of one high up? Or use a trailer or heavy cart to attach a strong enough pole?

I truly am taking the safety of this system seriously.

The original tests(photo) were done with a commercial fiberglass antenna mast that is rated for over 3x the load being used, when the mast is also not even at 75% height. Compared to the fiberglass mast (pictured) the carbon fiber pole is more rigid, stronger, and being used with half the load of one light horn each. Everything overhead has a safety cable to account for hardware failure. I am wearing a hardhat in all of my tests. The rig is being used only in constant attendance and with no audience members near by. In my view as a mechanical engineer, the rig is safer in its current configuration than an average 15" PA on a normal 2m (7'ft) speaker stand, which will not self-right if tipped 15°. Having said all that, you are right the current poles do not have ratings and I will explore stronger poles with appropriate TÜV ratings such as the Manfrotto 269.

I posted here with the hope of getting all kinds of feedback, and I am grateful for it!

I am especially interested in making the horns even lighter to allow for a greater safety factor. The drivers are only 1.2 kg (2.7lbs) and I bet a printed horn could be less than 500g.

In terms of improving the bass response, my thinking is that only a compression driver can produce the SPL I need while not weighing a lot. Anything I can do to help the exisitng drivers reach lower frequencies would be really helpful.

The original tests(photo) were done with a commercial fiberglass antenna mast that is rated for over 3x the load being used, when the mast is also not even at 75% height. Compared to the fiberglass mast (pictured) the carbon fiber pole is more rigid, stronger, and being used with half the load of one light horn each. Everything overhead has a safety cable to account for hardware failure. I am wearing a hardhat in all of my tests. The rig is being used only in constant attendance and with no audience members near by. In my view as a mechanical engineer, the rig is safer in its current configuration than an average 15" PA on a normal 2m (7'ft) speaker stand, which will not self-right if tipped 15°. Having said all that, you are right the current poles do not have ratings and I will explore stronger poles with appropriate TÜV ratings such as the Manfrotto 269.

I posted here with the hope of getting all kinds of feedback, and I am grateful for it!

I am especially interested in making the horns even lighter to allow for a greater safety factor. The drivers are only 1.2 kg (2.7lbs) and I bet a printed horn could be less than 500g.

In terms of improving the bass response, my thinking is that only a compression driver can produce the SPL I need while not weighing a lot. Anything I can do to help the exisitng drivers reach lower frequencies would be really helpful.

No, it is not.the rig is safer in its current configuration than an average 15" PA on a normal 2m (7'ft) speaker stand,

Proper rigging will not allow 15 degrees tipping.which will not self-right if tipped 15°.

Maximum load for Manfrotto 269 is only 10 kg, in still air. Wind is not taken into account.I will explore stronger poles with appropriate TÜV ratings such as the Manfrotto 269.

The main problem is wind, not weight.I am especially interested in making the horns even lighter to allow for a greater safety factor. The drivers are only 1.2 kg (2.7lbs) and I bet a printed horn could be less than 500g.

You can't cross D250-X below 400 Hz. Even 400 Hz is a big stretch - 500 Hz is the minimum crossover per manufacturer recommendation.In terms of improving the bass response, my thinking is that only a compression driver can produce the SPL I need while not weighing a lot. Anything I can do to help the exisitng drivers reach lower frequencies would be really helpful.

The only way to produce bass below 400 Hz is by conventional cone woofers.

Actually, there are/were many good old PA horn drivers that can go well below 400Hz, and get loud enough to cover 1000 feet or more with no additional delay speakers, as was the case in the 1963 March on Washington using manifolded drivers on RCA straight horns:The only way to produce bass below 400 Hz is by conventional cone woofers.

The RCA MI6341 was 4.5 feet long, the MI6442 was 6 foot, 250Hz Fc.

More current offerings like the TOA TH660 re-entrant (folded) horn has a usable range from 250Hz-6kHz:

For speech only applications, re-entrant PA horns with proper equalization still are often the lightest, loudest and most cost-effective solutions available.

Art

I did wind load calculations before ever setting it up, even in 50kph (30mph) winds the small 0.1m^2 surface area (~1sqft) means the side load is only about 1kg (2.3lbs). In high wind conditions, this project will stay home.Wind is not taken into account.

I wondered what the limits of this diver/horn is. I would have to look at the DSP file, but I think I have it set to 500hz or so with a 12dB curve.

So cool Art! thanks for sharing. I have often wondered about this very event and how sound was covered. I wonder if people could really hear all the way in the back. The speeches are so inspiring, and based on the recording we have all heard, very intelligible, although not so strong in the bass region. 🙂as was the case in the 1963 March on Washington using manifolded drivers on RCA straight horns:

I used Pyle folded horns a lot for events years ago and they always sounded bad, though the efficiency and throw was amazing!

TOA seems to make some very relevant stuff! here is a $55 driver that goes down to 150hz. I saw a non-folded very large TOA horn somewhere online that I thought about. It is exciting that it goes down to 200hz! But I think keeping things small and light is my current priority.

Is the basic geometry of the Goldwood GM-450PB as good as it gets for my application?

I chose the D250-X because it was small and light and had the lowest frequency I saw of anything in its size.

I even saw some heavy and expensive 2" drivers with not-as-low performance. But there are also even more expensive and heavy drivers with low-freq support.

I picked it after calling PartsExpress and explaining the project. It had the lowest frequency of anything the tech knew of.

Based on what I have seen about HornRESP it seems potentially best to generate geometry to suit an application to reduce distortion and maximize response. if it weighs less, and looks cool, thats event better.

Yes, of course, but not in this case where the weight and bulk are limiting factors.Actually, there are/were many good old PA horn drivers that can go well below 400Hz, ...

- Home

- Loudspeakers

- Multi-Way

- DIY Lightweight 5-meter tall Delay Tower PA System