@Moor,

Again, I have a question, this time about the resistors.

Your design comes with two different coil options. Therefore, R2, R3, R4, and R8 can be chosen as 680K or 330K, depending on whether Tr.1 has 7.5mH or 33mH. Do you know the reason why the resistance was reduced?

Maybe I am completely wrong, but to me, these resistors seem to be bleeder resistors. So I would expect much higher values than those in the layout. However, maybe I am missing something, and there is a specific dependency?

And how much power do the resistors need to handle?

Again, I have a question, this time about the resistors.

Your design comes with two different coil options. Therefore, R2, R3, R4, and R8 can be chosen as 680K or 330K, depending on whether Tr.1 has 7.5mH or 33mH. Do you know the reason why the resistance was reduced?

Maybe I am completely wrong, but to me, these resistors seem to be bleeder resistors. So I would expect much higher values than those in the layout. However, maybe I am missing something, and there is a specific dependency?

And how much power do the resistors need to handle?

The rezistors values are not critical at all ... any value between 220k and 680k can be chosen, because their only role is to protect the user while testing the module, because some capacitors might remained charged for a few seconds after power off. The resistors discharge the capacitors in fractions of a second, so you can't be electrocuted - it is just protection, no role in filtering ... But when you increase the amount of electric charges the circuit is capable, normally for the protection only, you should lower a little the discharge resistors. But you can safely choose 330k no matter the power output.

Hi,

since I am considering making an EMI filter, I was quite interested in this article.

Can anyone explain me the function of the schottky diode SBL3045PT and the two 4700uF/25V capacitors?

This diode has a maximum reverse voltage of 45V so it is not suitable for 230V. Or I'm wrong.

Thank you for the answer.

since I am considering making an EMI filter, I was quite interested in this article.

Can anyone explain me the function of the schottky diode SBL3045PT and the two 4700uF/25V capacitors?

This diode has a maximum reverse voltage of 45V so it is not suitable for 230V. Or I'm wrong.

Thank you for the answer.

the function of the schottky diode SBL3045PT and the two 4700uF/25V capacitors?

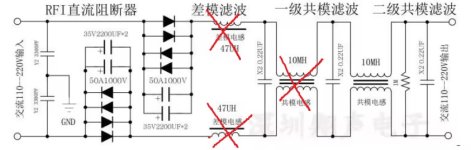

That's the DC blocker mentioned at the top of the figure. See Elliott Sound Products' article for more info.

Good evening, very nice circuit. I was wondering if I am allowed to make the Gerber as someone asked for it, and post it here.In my city there is a private manager which can create the PCB directly from a jpg photo ,,.. I am sorry I can't help you... buy the filter directly from that website...

I am halfway done but there are a few things that I can't see very well from the pictures

In particular I was wondering where is the full bridge rectifier located (P2 - 1A), and the issue with the two resistors on the top left, which do not seem to be connected anywhere, but i might be wrong. Also I suppose the SBL3045 diode + capacitors have been omitted from the circuit and placed externally?

No onboard input fuse(s)? That is pretty bad.

Certainly with onboard GDTs and MOVs an onboard fuse is mandatory as that is also onboard where the overcurrents will take place when overvoltage occurs (and this by design).

Best solution probably is an onboard PCB mount IEC inlet with a fuse holder both in L and N and no wiring. Whatever the audiophile reasoning may be, it all should start with a fuse. Always.

Certainly with onboard GDTs and MOVs an onboard fuse is mandatory as that is also onboard where the overcurrents will take place when overvoltage occurs (and this by design).

Best solution probably is an onboard PCB mount IEC inlet with a fuse holder both in L and N and no wiring. Whatever the audiophile reasoning may be, it all should start with a fuse. Always.

Last edited:

It can be that dual input fuse is in the IEC plug, but you are right, there are some issues I also want to fix within the build.

Also the DC Blocker seems to be an add on but there are better DIY designs available. But I want to give the Filter itself a trial

Cheers

Also the DC Blocker seems to be an add on but there are better DIY designs available. But I want to give the Filter itself a trial

Cheers

Pretty valid comments, but I just took the original jpg file provided by the OP, converted into a bitmap and used it for the bottom layer. Then manually made the holes and the silk screen on top. It's not actually possible to edit the bottom layer, unless you edit the original picture with photoshop.

I just need permission from the OP to share the files, since from what I understood he is selling the circuit himself? What do you think?

I just need permission from the OP to share the files, since from what I understood he is selling the circuit himself? What do you think?

Selling?! Without fusing? Depending on the clouded opinions of audiophiles that notice blacker than black backgrounds but at the same time probably not even notice there are no fuses?

Boy oh boy.

Boy oh boy.

Well, the website is down and I have no way to check honestly if the version sold has the fuse or not.

The approach you all suggest would require to completely redo the layout of the components and integrate it with the solutions suggested, which is more time consuming. I just wanted to simply give this circuit a try as it is considering the enthusiasm of the person that posted it.

The approach you all suggest would require to completely redo the layout of the components and integrate it with the solutions suggested, which is more time consuming. I just wanted to simply give this circuit a try as it is considering the enthusiasm of the person that posted it.

Enthusiam is good but electrical safety always comes first. Please think what will happen when the mains voltage reaches MOV/GDT triggering level.

Always use (technical) common sense. You did without this device, now you decide to insert this device then also make it safe. It was safe without it.

Always use (technical) common sense. You did without this device, now you decide to insert this device then also make it safe. It was safe without it.

Last edited:

Sure thing. In this case, as Korniman suggested, I was also going to add some fuses outside the board, but having them inside the board would make things easier, complete and organized, and prevent accidents in case people forget about them.

You have no idea how many "audiophile grade" emi filter pcbs i've seen sold online that do not have fuses at all.

In some cases, some users reported the main inductors melting or traces burning up, if a short is present.

You have no idea how many "audiophile grade" emi filter pcbs i've seen sold online that do not have fuses at all.

In some cases, some users reported the main inductors melting or traces burning up, if a short is present.

Enthusiam is good but electrical safety always comes first. Please think what will happen when the mains voltage reaches MOV/GDT triggering level.

Always use (technical) common sense. You did without this device, now you decide to insert this device then also make it safe. It was safe without it.

Best left to user to use fuse IEC or not to. Makes it way simpler and targets both camps equally 🙂

No. Make it safe for everyone or don’t publish/sell it at all.

Omit simple & effective safety by thinking everyone implement it externally and you’ll see that most make the wrong choice (the one that costs least time and effort). Make it safe by design and not by voluntary choice. Add a fuse holder and publish the right value and you’ll see that there will at least be a fuse in the holder.

As it was only seen in the 30th post that proves a point. Stuff that is not safe should be banned. Showing other dubious stuff without safety (and also without GDT/MOV!) is not a strong point either.

Omit simple & effective safety by thinking everyone implement it externally and you’ll see that most make the wrong choice (the one that costs least time and effort). Make it safe by design and not by voluntary choice. Add a fuse holder and publish the right value and you’ll see that there will at least be a fuse in the holder.

As it was only seen in the 30th post that proves a point. Stuff that is not safe should be banned. Showing other dubious stuff without safety (and also without GDT/MOV!) is not a strong point either.

Last edited:

- Home

- Amplifiers

- Power Supplies

- DIY EMI filter for power supply