With a thermal conductivity 7.5 times that of copper and a density 0.15 times that of copper, carbon nanotubes could be just the right stuff to incorporate into speaker absorbent! https://www.aliexpress.com/item/400...ubes&msclkid=e9d587d42f0018aa56abe0e7982999e8

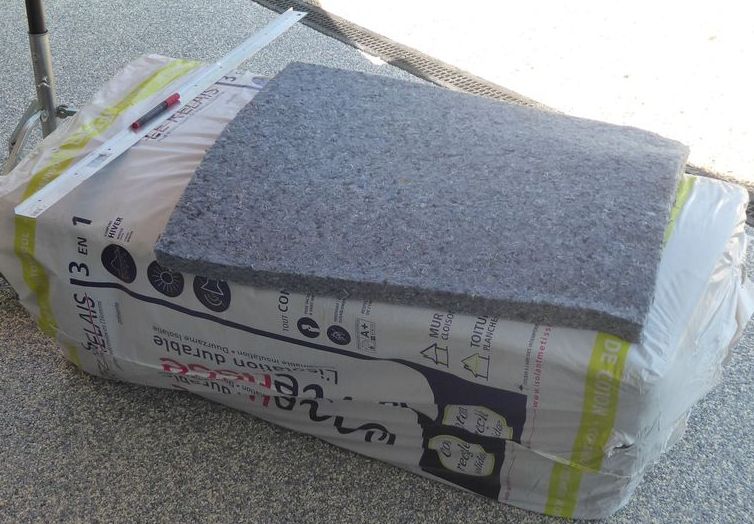

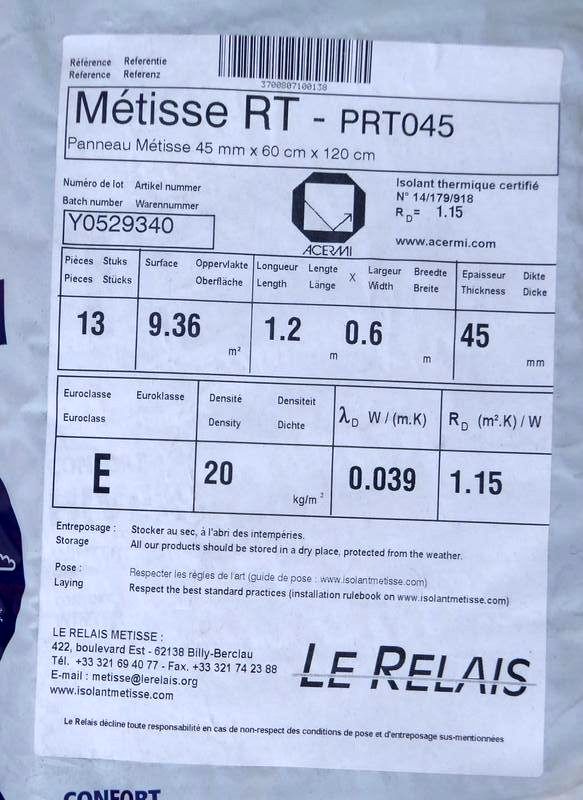

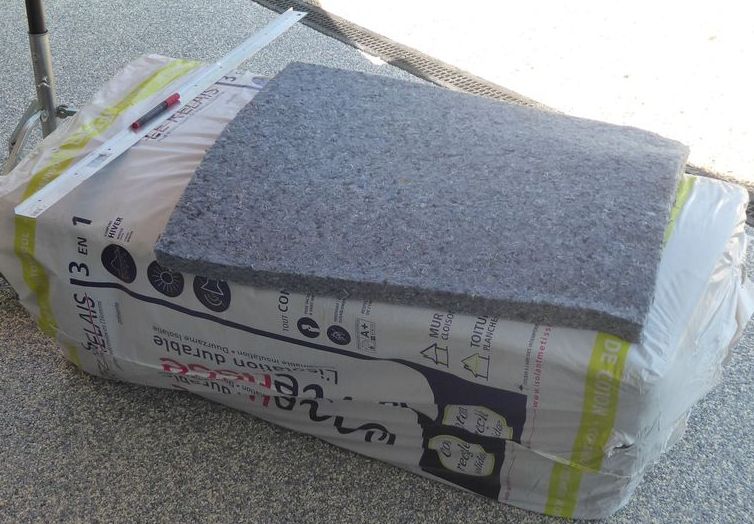

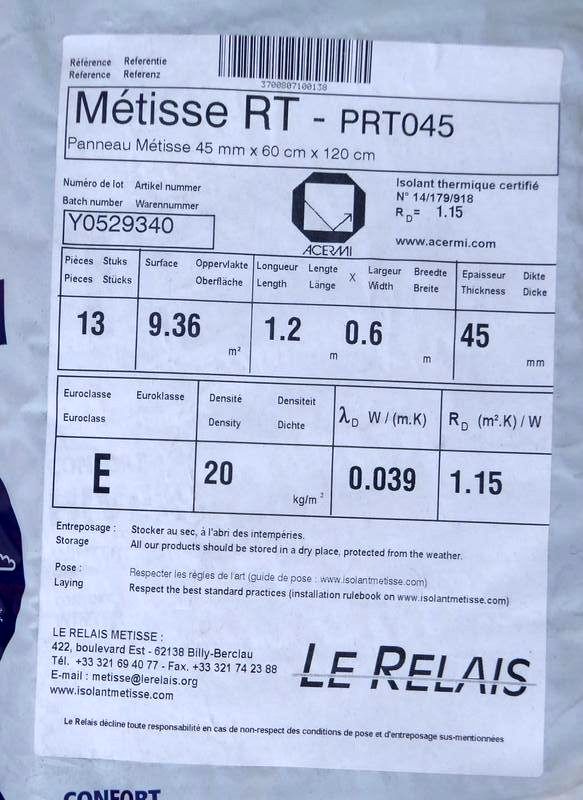

For me, It's mainly the Cotton Wool : harmless, easy to work, consisitent, affordable (insulation material - I think I paid 50 Euros for the package below in a local DIY supermarket) and offering fine, efficient damping results :

T

T

For me, It's mainly the Cotton Wool

It's the unique structure of its fibres that makes cotton such a good sound absorbent material.

Just look at how smooth a polyester fibre is in comparison to a cotton fibre!

Thanks for the input @Galu ! Interesting comparison 😎 😎 😎

Sometimes yes, I use Coarse or Fine Wool mixed with Cotton Wool, notably for Midrange speaker cavities (as shown in my last post, lower right pic. Since these do not have the same density, I figure that, for the mid to treble range, it's a probably a more efficient, "spreaded" solution. For Bass, I stay with Cotton Wool, which is more consistent (panels) and densier than Coarse / Fine Wool.

T

Sometimes yes, I use Coarse or Fine Wool mixed with Cotton Wool, notably for Midrange speaker cavities (as shown in my last post, lower right pic. Since these do not have the same density, I figure that, for the mid to treble range, it's a probably a more efficient, "spreaded" solution. For Bass, I stay with Cotton Wool, which is more consistent (panels) and densier than Coarse / Fine Wool.

T

C'mon now, it only looks like that if you wash it in warm and dry it on high.It's the unique structure of its fibres that makes cotton such a good sound absorbent material.

Has anybody tried the felt pad type material used in cars (under the carpet) in speakers?

Those seem to be synthetic fibers stuck or heated together.

And of course polyurethane foam, again used in firewalls in cars, among other things. There is a type of mattress slab with a flat side and a side with tapered blind hole, that might be useful, or has been tried earlier.

In a damp tropical climate, I would prefer a synthetic material, less chance of damp induced rotting, or fungal / mould growth.

Steel wool as a speaker stuffing material....what were you smoking or mainlining, dude?

Those seem to be synthetic fibers stuck or heated together.

And of course polyurethane foam, again used in firewalls in cars, among other things. There is a type of mattress slab with a flat side and a side with tapered blind hole, that might be useful, or has been tried earlier.

In a damp tropical climate, I would prefer a synthetic material, less chance of damp induced rotting, or fungal / mould growth.

Steel wool as a speaker stuffing material....what were you smoking or mainlining, dude?

It may be a combination of this and that, but I wouldn't know where and when. Experimentation, yup, just like Edison, will get you there sometime before you dye. Hint denim material is better than Tie dyed T shirt material. Has anyone tried stuffing a teddy bear into a cabinet?

But as crazy as it gets, stick to some of the more common solutions. I like the idea of a material that can be teased out to different degrees according to its position in the cabinet.

But as crazy as it gets, stick to some of the more common solutions. I like the idea of a material that can be teased out to different degrees according to its position in the cabinet.

And bless your scotch soaked ones Galu. I welcome your invitation my friend. I am near retirement.Well, bless your cotton socks, Cal!

I have been called things worse than a sock sucker but I’m pretty sure you don’t want to see pictures of that guy. They wouldn’t even let me in the hospital to apologize. I was hurt.

Last edited:

I had once moved a speaker near my old CRT screen TV, and the magnetic field made the colors go funny, had to degauss it.

Similar effect might occur if you use a magnetic material as stuffing inside a speaker, distorted magnetic fields meaning coil and cone not getting same force all around the periphery of the motor.

The chance of getting stray bits in the gap is pretty high, meaning rebuilding the speaker, a pain in wrong place.

Even copper wool is magnetic to some extent, and now the price is quite high. As a magnetic and radiation shield in medical equipment, yes, but in a speaker, not recommended.

Similar effect might occur if you use a magnetic material as stuffing inside a speaker, distorted magnetic fields meaning coil and cone not getting same force all around the periphery of the motor.

The chance of getting stray bits in the gap is pretty high, meaning rebuilding the speaker, a pain in wrong place.

Even copper wool is magnetic to some extent, and now the price is quite high. As a magnetic and radiation shield in medical equipment, yes, but in a speaker, not recommended.

I welcome your invitation my friend. I am near retirement.

I hope you don't think I'm suggesting you're suffering from swollen feet or ankles due to your advancing years!

"Bless your cotton socks" is an expression of appreciation for another person.

And I always appreciate your jokes!

Does it have to be a wool type material?

In the context of this thread, any absorbent material that is a better conductor of heat than air is a candidate.

In the context of this thread, any absorbent material that is a better conductor of heat than air is a candidate.

It is not so much about heat conduction as it is about Specific Heat and fiber surface area per pound. lower density materials fill more space and have greater surface area. A pound of fine fluffy fiber stuffing will adsorb and return many more BTU's than a pound of steel shavings or copper chips at the speaker's resonate frequency.

At a given frequency there is only so much time for the stuffing to adsorb and return heat. The finer the fiber the faster and greater the number of BTU's transferred in the time determined by the frequency.

Thanks DT

Only a piece of information at a time. People will only read only a limited number of words at a time.

lower density materials fill more space and have greater surface area.

That's another plus for carbon nanofibres with a density 0.15 times that of copper!

It is not so much about heat conduction as it is about Specific Heat and fiber surface area per pound.

Indeed, any factor that encourages an efficient transfer of heat from the air to the absorbent will help keep the air in the enclosure at constant temperature and provide an approximation of isothermal (equal temperature) loading.

- Home

- Loudspeakers

- Multi-Way

- using 'steel wool' as box stuffing