This is probably a very elementary question but I was unable to find a definitive answer so here goes......

Does the lining of the enclosure count against the enclosure space?

I know polyfill "expands" the enclosure space by making the "air denser"

One more elementary question since I probably already sound stupid......

Would it be ideal to keep any sort of lining away from the woofer port entrance on the inside of the enclosure?

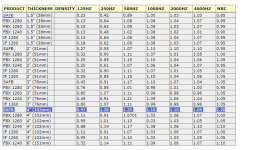

I plan to use this SAFB material and it seems from the charts that the thicker, the better. I am pondering why anyone doesn't just go with the thickest material they can find. That is, unless it counts against the enclosure air space.

Does the lining of the enclosure count against the enclosure space?

I know polyfill "expands" the enclosure space by making the "air denser"

One more elementary question since I probably already sound stupid......

Would it be ideal to keep any sort of lining away from the woofer port entrance on the inside of the enclosure?

I plan to use this SAFB material and it seems from the charts that the thicker, the better. I am pondering why anyone doesn't just go with the thickest material they can find. That is, unless it counts against the enclosure air space.

Attachments

Lining, no, stuffing, your call. All acoustic openings have a pipe end correction based on its (effective) diameter (d) and any surrounding baffling, i.e. it's acoustically larger, so using the basic vent pipe k = 0.732d is good enough for a sufficient gap.

Attachments

Acoustic Wool dampens the waves in the enclosure. To do so it has to be placed where the velocity is highest. And that is close to the driver.

Most useless is to place wool close to the wall! over 90% of all speakers i have seen has wool placed close to the wall where it is totally useless. Pressure maximum is close to the enclosure wall and velocity is zero. Damping maaterial works as a friction brake for the air molecules while moving. No movement = no friction. There is actually papers written about this in the 70ties. And there is some loudspeaker engineers/researcher who tied wool around the magnet covering the holes in the cage behind the mambrane, acting as a friction brake and as an early damping of the wave behind the membrane very efficient.

Most useless is to place wool close to the wall! over 90% of all speakers i have seen has wool placed close to the wall where it is totally useless. Pressure maximum is close to the enclosure wall and velocity is zero. Damping maaterial works as a friction brake for the air molecules while moving. No movement = no friction. There is actually papers written about this in the 70ties. And there is some loudspeaker engineers/researcher who tied wool around the magnet covering the holes in the cage behind the mambrane, acting as a friction brake and as an early damping of the wave behind the membrane very efficient.

The Loudspeaker Design Cookbook has a pretty good table with various combinations of lining and stuffing.I was unable to find a definitive answer

In this case we're only interested in damping spurious reflections, so you're saying wool is reflective if used as a lining for these higher frequencies and reduces net volume (Vb)?

Understood, thanks.Lining, no, stuffing, your call. All acoustic openings have a pipe end correction based on its (effective) diameter (d) and any surrounding baffling, i.e. it's acoustically larger, so using the basic vent pipe k = 0.732d is good enough for a sufficient gap.

I find that hard to believe looking at this data here:Acoustic Wool dampens the waves in the enclosure. To do so it has to be placed where the velocity is highest. And that is close to the driver.

Most useless is to place wool close to the wall! over 90% of all speakers i have seen has wool placed close to the wall where it is totally useless. Pressure maximum is close to the enclosure wall and velocity is zero. Damping maaterial works as a friction brake for the air molecules while moving. No movement = no friction. There is actually papers written about this in the 70ties. And there is some loudspeaker engineers/researcher who tied wool around the magnet covering the holes in the cage behind the mambrane, acting as a friction brake and as an early damping of the wave behind the membrane very efficient.

https://www.bobgolds.com/AbsorptionCoefficients.htm

Attachments

You don't want damping material near the back of the woofer or port. It can add mass and change the Q. Stick with lining the walls of ported enclosures.

Both WinISD and Hornresp free software have inputs for box stuffing. It is very useful to just enter a design and adjust the stuffing amount and watch the response change. In Hornresp you actually see it damp out the internal acoustic box modes, which is why you put it in there. WinISD just shows the reduction in the output of the woofer as the Q goes down. Use the wizard in Hornresp to create a closed box design and go from there. On sealed designs I just fill the space with damping leaving room for the driver. On a ported design it needs more open space for the port to breath.

thank you This is my first build other than a kit.

I would like to line the walls and back top and bottom with the 705 soundproofing sheets but I do not want to end up losing 10 liters of volume.

I would like to line the walls and back top and bottom with the 705 soundproofing sheets but I do not want to end up losing 10 liters of volume.

I hate to admit this but I have spent literally days trying to figure out Hornresp and I respect the program and all the work that was done but I am not smart enough to figure it out. I even wrote to Martin and reading the material he sent I came to the conclusion that I should not build a TL. I am concerned that I am going to screw up and create a unintentional mltl and hit the wrong quarterwave and end up with a speaker with missing bass. I am building a narrow MTM floor stander using seas w18nx001 and tc25002 millenium tweeters with a modified thor crossover. I got the combination to work very well in a small thor cabinet but need to go smaller and have a better built cabinet.

Unfortunately the user interface for Hornresp is not very intuitive. I can't find a youtube video that shows how to do the sealed box design with it. As an approximation, adding more damping causes the response to look like that of a larger box. Adding stuffing will making a sharp low frequency roll off into a more gentle rounded roll off. It will always lower the response curve, but it can push the roll off frequency a bit lower. It's hard to go wrong as you can always just remove some of it.

I think it is not knowing what the abbreviations mean I am going to build one pair of speakers. I spent more time on hornresp and with Martin Kings writing then I did making sawdust. I will most likey keep them until the end if I like them . if I do not like them I will burn the boxes and sell the drivers. I bought a used set of drivers and the crossover for a pair of thors and uiqckly built the boxes and really liked them the drivers corroded so I bought the nextels to replace them not quite as good but still really good so I want to build better boxes but small enough to move into the living room. and here we are I built the cabinets and just need to brace line and put the port in and finish them. I not sure what to line them with and I have owens 705 panels on hand. I did not line the small thors as they were mltl and just had a little polyfill in them. because these,are br I think they should be lined.

Just pick up some rockwool from the hardware store. The thicker the better. R14 rockwool. Stable it to the inside

D

Deleted member 375592

The lining is good for preventing backside reflections and the accompanying spike in distortions, especially for 2-way cabinets. Usually around 1.5kHz. Often, a good enough approach is cheap 2" acoustic foam.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Lining and Enclosure Size