Do you know anyone with a bench punch? This is very doable if you do.

A hand punch would be more difficult, and have less access to areas farther from the edges.

Otherwise, a laser cutting service for the entire fabrication would be easier.

https://sendcutsend.com/services/laser-cutting/

A hand punch would be more difficult, and have less access to areas farther from the edges.

Otherwise, a laser cutting service for the entire fabrication would be easier.

https://sendcutsend.com/services/laser-cutting/

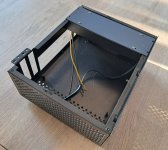

Mounting the box for any of these is the problem, as the a09m steel box is 18x22x9 cm. and can not be disassembled.

Post some photos.

Why do you need all the ventilation holes?

Using a hand drill would be difficult, even with a center punch.

Why do you need all the ventilation holes?

Using a hand drill would be difficult, even with a center punch.

With a sharp drill bit, little by little. I'd start with a 2-2.5 mm pilot hole. Then probably 3.5 mm and 4.0 mm. Use cutting oil. The hole won't be 200% free of burrs, but it should be possible to get a relatively clean hole that way. The outside is easily de-burred. You can choose not to care about the inside.

Without a punch that's probably your best bet.

A piece of perforated sheet can serve as a drill guide if you need to drill many holes for ventilation.

Tom

Without a punch that's probably your best bet.

A piece of perforated sheet can serve as a drill guide if you need to drill many holes for ventilation.

Tom

Ventilation for the graphics card (I hope this is ok, even in this Audio forum ?).

The top could be removed and used as an accurate drilling template, but removing the steel grates on the inside was a nightmare.

PS. Hej Tom. Rart at høre fra dig igen. Mvh Ole

The top could be removed and used as an accurate drilling template, but removing the steel grates on the inside was a nightmare.

PS. Hej Tom. Rart at høre fra dig igen. Mvh Ole

Attachments

Last edited:

Oh, so the issue isn't that you can't poke holes in the chassis. The issue is that you get burrs when you do so?

An easy way to remove burrs is to use a countersink mounted in a drill press. Run the drill at the lowest speed and touch the inside of the holes to the counter sink. I show that trick here:

Tom

An easy way to remove burrs is to use a countersink mounted in a drill press. Run the drill at the lowest speed and touch the inside of the holes to the counter sink. I show that trick here:

Tom

That's the second thing I learned about drilling.

The first thing was not to drill your thumb.

A deburring tool can also be useful, especially in aluminum.

https://www.amazon.com/AFA-Tooling-Deburring-High-Speed-Removal/dp/B07RM1D6WD/ref=asc_df_B07RM1D6WD/

The first thing was not to drill your thumb.

A deburring tool can also be useful, especially in aluminum.

https://www.amazon.com/AFA-Tooling-Deburring-High-Speed-Removal/dp/B07RM1D6WD/ref=asc_df_B07RM1D6WD/

Yes, Thanks, I hate burrs/grates. I also worry if they loosen and cause shorts.Oh, so the issue isn't that you can't poke holes in the chassis. The issue is that you get burrs when you do so?

An easy way to remove burrs is to use a countersink mounted in a drill press. Run the drill at the lowest speed and touch the inside of the holes to the counter sink. I show that trick here:

Tom

Do you have a trick to drill a C6 Power connector (Mickey Mouse) hole ? The 2 first are easy, but the mid 3rd hole is a pain.

Last edited:

Why not just buy a dedicated ventilated case for whatever this is for. Computer?

If you have to drill a bunch of holes, just deburr them. Get a Shaviv deburring tool like the center one in the attached pic.

jeff

If you have to drill a bunch of holes, just deburr them. Get a Shaviv deburring tool like the center one in the attached pic.

jeff

I found the single flute type a better choice for me. Works smoothly in a hand held drill or drill press.

Single Flute Countersink

Single Flute Countersink

Fair question, but no case I like.Why not just buy a dedicated ventilated case for whatever this is for. Computer?

If you have to drill a bunch of holes, just deburr them. Get a Shaviv deburring tool like the center one in the attached pic.

jeff

I did use a deburring tool like the one to the right, and it was terribly bad. Countersink sounds better, but access inside is difficult.

Last edited:

That one's meant for large holes or long flat edges.I did use a deburring tool like the one to the right, and it was terribly bad.

jeff

Convert it to a C14... 🙂Do you have a trick to drill a C6 Power connector (Mickey Mouse) hole ? The 2 first are easy, but the mid 3rd hole is a pain.

Tom

If you're gonna drill: start with a 3mm (1/8") bit. Use cutting oil, 3-in-1, something. After making the first hole with a twist bit, get a Step Bit to make the larger holes. A twist bit will bend thin sheet metal as it goes in, don't use big twist bits on thin sheet metal. There are many deburring tools out there, for sheet metal I like to use a Countersink Bit, but not one with flutes, they chatter. Use one with a hole through it, like this:

This will give you the smoothest edge.

Try to practice a couple cuts on similar material, if possible. Go slow. Have fun!

w

This will give you the smoothest edge.

Try to practice a couple cuts on similar material, if possible. Go slow. Have fun!

w

Stepped drills are definitely nice if you can find one that has a small enough diameter. Thanks to the transitions between steps you basically get drill and de-burr in one operation.

Tom

Tom

yes, I like to use the step bit to deburr both sides, if I can get the drill in there. If not, I have a 3/4" countersink with the 1/4" hex shaft, and I use that with a 1/4" ratchet. ya just gotta push real hard against the hole while cranking. heh.

+1 for step drill bit.

I imagine the local big box hardware store should have step drill bits. I bought fairly cheap one a few years back.

4mm-11mm. It has been worth its weight in gold. Several thousand holes through 1-2mm steel sheet and it still cuts like butter.

Cannot recommend the investment enough.

P & N was the brand of mine. Cost about $20usd

I imagine the local big box hardware store should have step drill bits. I bought fairly cheap one a few years back.

4mm-11mm. It has been worth its weight in gold. Several thousand holes through 1-2mm steel sheet and it still cuts like butter.

Cannot recommend the investment enough.

P & N was the brand of mine. Cost about $20usd

Tom,

Where did you get the volume knob you showed in the video on deburring above? Movishop? Novishop?

Where did you get the volume knob you showed in the video on deburring above? Movishop? Novishop?

- Home

- Design & Build

- Construction Tips

- How to drill 4 mm holes in 1 mm. Steel and avoid grates?