I use a Doot desolder pump to remove solder, very effective. In Australia, its at Jaycar.

I was searching google and came across Farnell/Element14 pdf from Multicore Solder on Solder types.

Soldering silver-plated surfaces: The presence

of the 2% silver in Sn62 alloys suppresses

absorption of silver from silver-plated surfaces into

the solder. A good joint is thus obtained. If an

ordinary tin/lead alloy is used on silver-plated

surfaces, the silver can be lifted from the surface

and dissolved into the solder so that a good joint is

unlikely. The attachment of terminations in the

manufacture of silver ceramic capacitors is a

typical application.

I think, regardless both are good and from my test, i think the 63/37 seemed the better joint

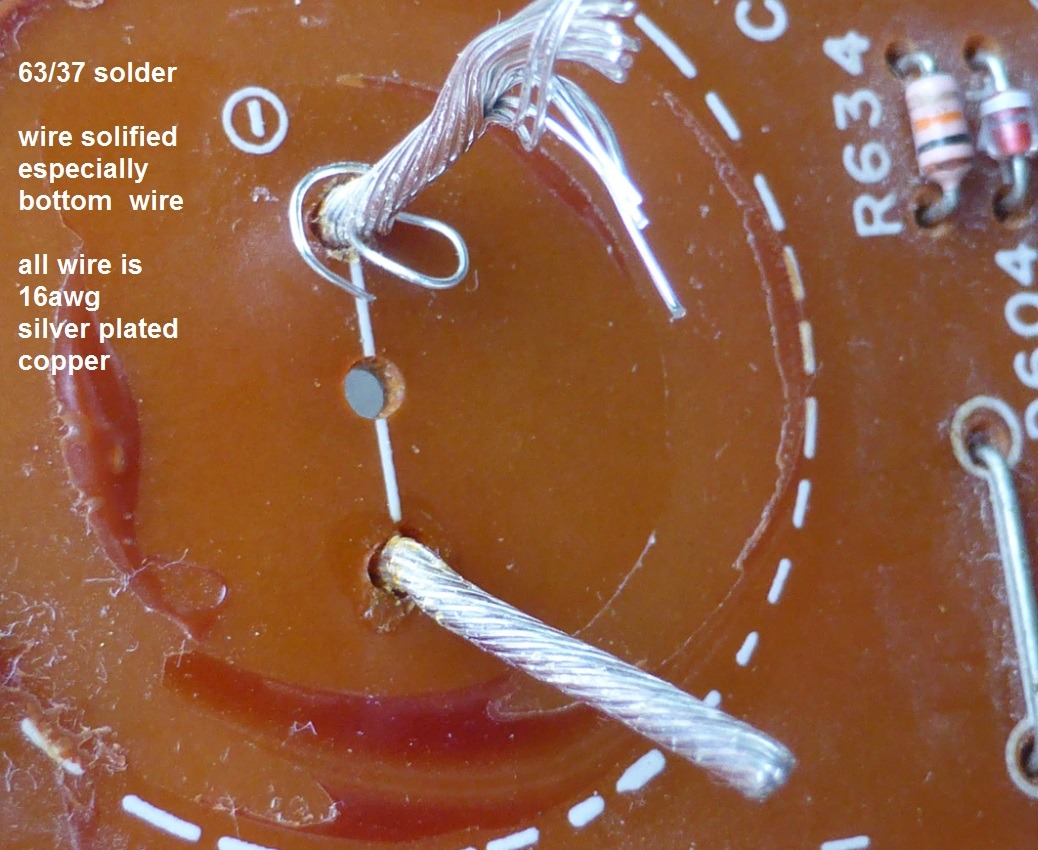

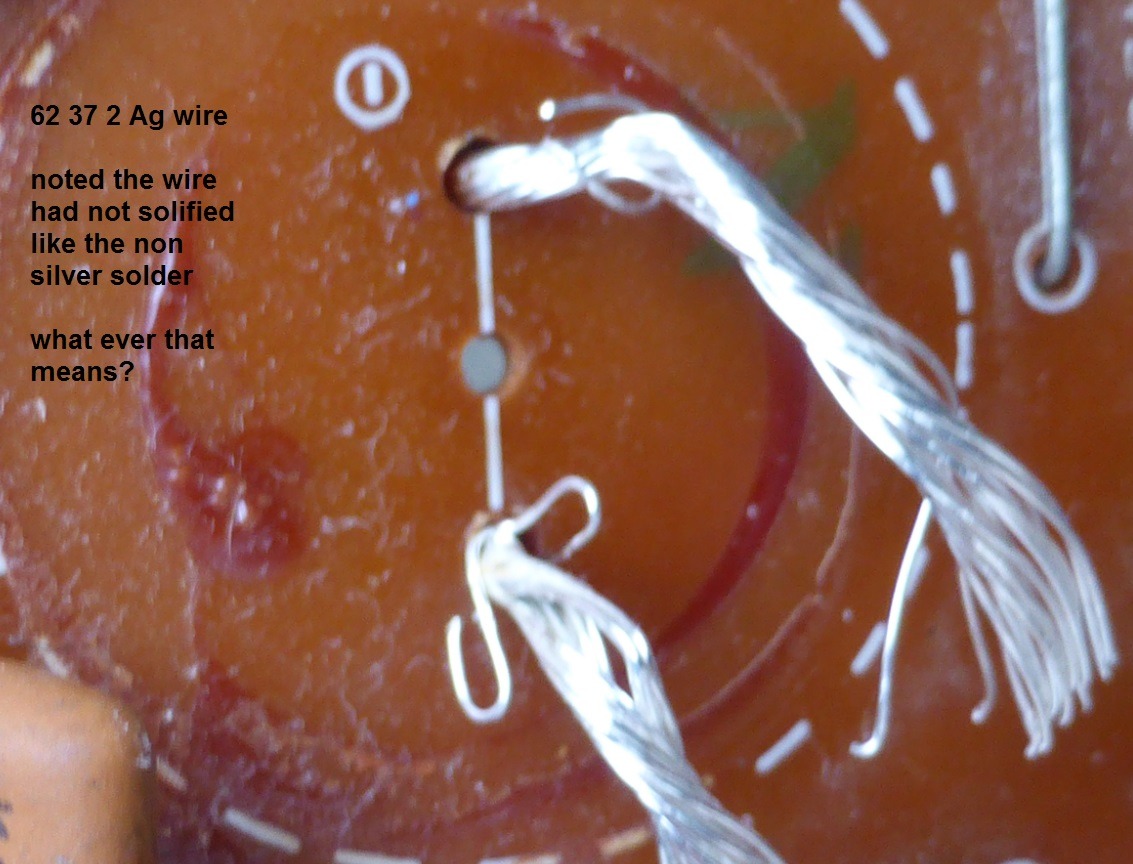

I decided to test for myself, and with images, I got some old spare amp board around and scraped back to bare copper on the traces. I got 16 silver plated copper same length.

I swapped which solder went first.

1. Duratool 63/37, really like it and have been using it

3. Chip Quik 62 37 2 AG, very nice flow also, hard to pick.

Detailed images

Side by side

6337 close up, my fav is the right, looks nice and solid

Silver content 62

The no sliver based solder, the silver plalted copper wire had solidfied

Silver version wire, not solidfied

multifcore link i found

https://www.farnell.com/datasheets/315929.pdf

I was searching google and came across Farnell/Element14 pdf from Multicore Solder on Solder types.

Soldering silver-plated surfaces: The presence

of the 2% silver in Sn62 alloys suppresses

absorption of silver from silver-plated surfaces into

the solder. A good joint is thus obtained. If an

ordinary tin/lead alloy is used on silver-plated

surfaces, the silver can be lifted from the surface

and dissolved into the solder so that a good joint is

unlikely. The attachment of terminations in the

manufacture of silver ceramic capacitors is a

typical application.

I think, regardless both are good and from my test, i think the 63/37 seemed the better joint

I decided to test for myself, and with images, I got some old spare amp board around and scraped back to bare copper on the traces. I got 16 silver plated copper same length.

I swapped which solder went first.

1. Duratool 63/37, really like it and have been using it

3. Chip Quik 62 37 2 AG, very nice flow also, hard to pick.

Detailed images

Side by side

6337 close up, my fav is the right, looks nice and solid

Silver content 62

The no sliver based solder, the silver plalted copper wire had solidfied

Silver version wire, not solidfied

multifcore link i found

https://www.farnell.com/datasheets/315929.pdf

Exactly Stuey. 20 years is a long time. Back then most of the stuff was of decent quality.I have a roll of Jaycar 60/40 Duratech branded solder from about 20 years ago and I find it pretty good.

@Stanislav , Stuey, if can recall they actually sold Supra Ply there at Jaycar once, the blue monitor cable speaker cable wasnt bad and todays Jumbo, i got a some to test, it oxidises quickly, They had the Goot solder there once also, well the store at Mermaid Beach did back then, not sure if it was non lead or lead,

Like above, but get all three together, less shipping, insurance against future bans.

60-40 for regular work.

63-37 for chassis etc.

70-30 for electrical work like lamp bases, if you do that.

Get the flux as well, who knows what some 'woke' brat will decide in future, it seems removing the tag from a mattress is a big offense in the USA.

60-40 for regular work.

63-37 for chassis etc.

70-30 for electrical work like lamp bases, if you do that.

Get the flux as well, who knows what some 'woke' brat will decide in future, it seems removing the tag from a mattress is a big offense in the USA.

@Stanislav , Stuey, if can recall they actually sold Supra Ply there at Jaycar once, the blue monitor cable speaker cable wasnt bad and todays Jumbo, i got a some to test, it oxidises quickly, They had the Goot solder there once also, well the store at Mermaid Beach did back then, not sure if it was non lead or lead,

Yep, I remember the Supra cable. I got some Goot desoldering braid there, and they did sell a Goot iron as well...the one with temperature adjustment on the handle.

Exactly Stuey. 20 years is a long time. Back then most of the stuff was of decent quality.

What's wrong with it now?

Fortunately I have 2kg of 0.71mm and 250g of 1mm so should be ok for a while.

Nothing is as good as the Goot desolder braid, tried others, not as good in my opinon, it just instantly removes the solder, i am surprised the big electronic places like Element14 etc dont stock it. Goot is good stuff, and i have Supra Ply 3.4S, as much as i go for high end cables. The blue monitor cable they used to sell i liked it alsoYep, I remember the Supra cable. I got some Goot desoldering braid there, and they did sell a Goot iron as well...the one with temperature adjustment on the handle.

Jaycar solder is nice, how it flows, forms joints etc. A friend used it in his repair shop. If I was out and needed solder quickly, i would go and get some.

Last edited:

Learn something every day, here's a second opinion.

From this, it appears as: strands: finer is better; weaving: denser is better; temperature: higher is better.

That leaves the flux: I just dip my braids in a soldering paste before use, and that works.

Re. solder, I use the AIM 62/36/2; this has the certificate of approval from Pass Labs

From this, it appears as: strands: finer is better; weaving: denser is better; temperature: higher is better.

That leaves the flux: I just dip my braids in a soldering paste before use, and that works.

Re. solder, I use the AIM 62/36/2; this has the certificate of approval from Pass Labs

Hello,

Several years ago I bought a few rolls of surplus Multicore CRYSTAL 400 63-37 Solder, much the same as recommended by Mark Johnson above. Turns out this is very good solder, if everything is clean it flows nice and the the zero Halide flux is non-corrosive.

It is a absolute must to wash off the Kester 44 flux as it is more than a little corrosive.

Thanks DT

The data sheet states clearly that it doesn't need cleaning and that it's not corrosive.

RA = must clean, quite corrosive, RMA = you can leave on. Special formulations for no clean can be left on. But in all cases, it is hydroscopic even for a no clean and it attracts mousture over time. And it's just good practice to clean everything 😉 The sooner you start making that a habit, the easier it gets, more happy you become 😊

Here is (Kester's datasheet for their Kester 44 flux core) ; the final paragraph of page 2 addresses the issues of cleaning and corrosion.

They've nicely fenced themselves by saying under normal usage, but haven't specified which ones. Whats normal for a spider is a complete state of chaos for a fly. 7 days test (yes it's part od the compliance certificate they have) ain't gonna cut it for when we are building amps to last us half a lifetime and more due to diminishing quality transistor manufacturing (not to mention rest of the chain that can go out in case of hazard). It really is easy to clean, doesn't take much time, and you have a picture perfect board that will keep your components safe a long time.

If someone is adamant about not cleaning boards after soldering, you should use some with milspec compliance.

If someone is adamant about not cleaning boards after soldering, you should use some with milspec compliance.

So, they're lying?

They are minimizing the truth.

Thee 44 flux residue is a sponge, it adsorbs humidity given the opportunity. It's mildly active (acidic) and will corrode the copper traces on a PCB given the right set of conditions.

Chemistry happens. I have seen it happen.

Thanks DT

In that case, anyone has experience with the Kester 282 series? Or even better with the 285 series as the 282 is way too expensive?

Or any good no-clean/ RMA eutectic solder for that matter? 🙂

I know I will raise some eyebrows but I really don't want to clean the PCBs.

Or any good no-clean/ RMA eutectic solder for that matter? 🙂

I know I will raise some eyebrows but I really don't want to clean the PCBs.

Last edited:

Sorry, I'm really confused after reading this thread & had a question:

IF i'm using Kester 44 no-clean flux solder, do I clean or NOT clean after soldering? If I do clean, what do I clean with? There seems to be varying opinions on whether no-clean means no-clean. I have less experience with soldering and want to choose a solder that is accessible, affordable and easy to work with - Kester seems to fit the bill for my future work.....please help me understand!

IF i'm using Kester 44 no-clean flux solder, do I clean or NOT clean after soldering? If I do clean, what do I clean with? There seems to be varying opinions on whether no-clean means no-clean. I have less experience with soldering and want to choose a solder that is accessible, affordable and easy to work with - Kester seems to fit the bill for my future work.....please help me understand!

Do as you please. Nobody else needs to approve except you.

Myself, personally, I always scrub the board with a toothbrush and 99% isopropyl alcohol that I buy from amazon. Flood board with IPA, scrub. Flood a second time, scrub. Flood a third time, scrub. Go fetch a pistol style hair dryer and plug it in. Flood PCB with 99% isopropyl a fourth time, scrub. Flood a fifth time and immediately blow dry with hair dryer. Inspect. If haze remains, or if faint shadowy streaks of flux remain, soak kitchen paper towel in IPA and scrub PCB like crazy. Flood again and blow dry again.

If you're feeling posh, invest in a (battery powered electric toothbrush for kids) and scrub with that. Woo baby.

Myself, personally, I always scrub the board with a toothbrush and 99% isopropyl alcohol that I buy from amazon. Flood board with IPA, scrub. Flood a second time, scrub. Flood a third time, scrub. Go fetch a pistol style hair dryer and plug it in. Flood PCB with 99% isopropyl a fourth time, scrub. Flood a fifth time and immediately blow dry with hair dryer. Inspect. If haze remains, or if faint shadowy streaks of flux remain, soak kitchen paper towel in IPA and scrub PCB like crazy. Flood again and blow dry again.

If you're feeling posh, invest in a (battery powered electric toothbrush for kids) and scrub with that. Woo baby.

- Home

- Design & Build

- Construction Tips

- Solder for hand soldering