Running out of my beloved solder :|

Have had a big spool of solder for many years. It has worked just perfect for all my soldering from wire to the smallest SMD components.

I'm not sure which brand it was as the label has come off, but I think it was Weller, and I'm sure it was containing a bit of Silver.

I'm now trying to get some now solder, but have not been successful yet, and hope someone can help me here

I have bought a small spool of Stannol Sn95,5,5Ag3,8Cu0,7 so that means lead free for SMD (2% flux), and a small spool of Stannol Sn60Pb40 (1% flux)

Both 0,5 mm as is my old solder.

The lead free is maybe a bit better than the leaded, but both is really not easy to apply .... like they do not want to stick on the pcb.

Maybe it is because the old solder has a higher amount of flux .... when using flus on the pcb it flows better, but still not at all like the old solder!!

There is small markings on the red spool, H .... something and the number 63/37-E .... might mean Sn63Pb37 maybe .....

Hope someone can help here with good advice

/Baldin

Have had a big spool of solder for many years. It has worked just perfect for all my soldering from wire to the smallest SMD components.

I'm not sure which brand it was as the label has come off, but I think it was Weller, and I'm sure it was containing a bit of Silver.

I'm now trying to get some now solder, but have not been successful yet, and hope someone can help me here

I have bought a small spool of Stannol Sn95,5,5Ag3,8Cu0,7 so that means lead free for SMD (2% flux), and a small spool of Stannol Sn60Pb40 (1% flux)

Both 0,5 mm as is my old solder.

The lead free is maybe a bit better than the leaded, but both is really not easy to apply .... like they do not want to stick on the pcb.

Maybe it is because the old solder has a higher amount of flux .... when using flus on the pcb it flows better, but still not at all like the old solder!!

There is small markings on the red spool, H .... something and the number 63/37-E .... might mean Sn63Pb37 maybe .....

Hope someone can help here with good advice

/Baldin

Attachments

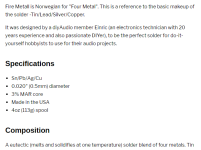

I bought this years ago and I'm happy with it.

https://be.farnell.com/multicore-lo...-r-250g/solder-wire-lmp-0-71mm-250g/dp/419540

It is leaded though, I'm sure a similar lead free variant will exist.

Hugo

https://be.farnell.com/multicore-lo...-r-250g/solder-wire-lmp-0-71mm-250g/dp/419540

It is leaded though, I'm sure a similar lead free variant will exist.

Hugo

Indeed, one can look for the ideal temperature in the datasheets.Have you tried higher temperature

Hugo

Hi Hugo

Thanks, yes it is what it says .... 183 - 190° for HF32 SMD and 227° for 2630 Ecoloy

Maybe I should have chosen the normal HF32 ... as it has 3.5% Flux ......

Thanks for the offer amplidude, but it seems to be very much the same as the 2630 ...

I'll try to put the temp a bit higher for the lead free

Thanks, yes it is what it says .... 183 - 190° for HF32 SMD and 227° for 2630 Ecoloy

Maybe I should have chosen the normal HF32 ... as it has 3.5% Flux ......

Thanks for the offer amplidude, but it seems to be very much the same as the 2630 ...

I'll try to put the temp a bit higher for the lead free

I am very happy with this setup

_

- Hakko FX-888

- Multicore solder / 63-37 / wire diameter .015" == 0.38 mm (sales link at DigiKey)

- Temperature 405C / 760F

_

Attachments

Last edited:

I use leaded solder although I am ready to use the new unleaded solders if they have very similar properties like leaded solder. I have read that modern solders are brittle and they tend to develop dry joints after some years. If this is not true I might consider using non-leaded solder.

- Home

- Design & Build

- Construction Tips

- Solder for hand soldering