Update, shield was grounded to rca ground and fatigue has disappeared for the most part if not completely. Still an aggressive sounding dac IMO, but a good improvement.

One last question, I’ve been using the stock cabling you sent me back late 2021. The wire appears to be aluminum colored, but I’m not sure if it is aluminum. Should I be replacing it all with copper cable since I’m shortening and redoing the cables anyway?

One last question, I’ve been using the stock cabling you sent me back late 2021. The wire appears to be aluminum colored, but I’m not sure if it is aluminum. Should I be replacing it all with copper cable since I’m shortening and redoing the cables anyway?

I've not met aluminium wires in this context, the colour you notice might just be the tinning on the outside of copper. If the wires were really aluminium, normal solder wouldn't flow on them but those I have here from the same supplier are able to be tinned in the normal way. It can't do any harm to replace the cables with thicker wires than the ones we sent (which might be 26AWG, I can't recall). However if you go any thicker than 24AWG I suspect the wires will be incompatible with the crimps.

Thank you Richard! You’ve been a great help!I've not met aluminium wires in this context, the colour you notice might just be the tinning on the outside of copper. If the wires were really aluminium, normal solder wouldn't flow on them but those I have here from the same supplier are able to be tinned in the normal way. It can't do any harm to replace the cables with thicker wires than the ones we sent (which might be 26AWG, I can't recall). However if you go any thicker than 24AWG I suspect the wires will be incompatible with the crimps.

Correct, should I instead be grounding the shield to one of the RCA grounds instead?

I have used this technique with CAT-5 where the drain wire is clipped at the RCA end and the other connected to chassis ground. The shield in the W2534 cable should be fine for this purpose since it short. Here is some further diyaudio reading on chassis grounding.A good point on the tonality. Thanks for picking out the model.

The Mogami cables has 4 conductors and an additional shield as pictured below.

View attachment 1131952

I was reading on audio circle that you could ground only one end of the shield to provide some EMI protection. I’m hoping it will do so, but I’m very open to your recommendations.

Do you have any isolation between your power transformer and the chassis? Just wondering if maybe your picking hum transference.

A note of caution: I noticed in your picture you appear to have the IEC earth soldered to the chassis. This is not electrically safe. You should be using a set of star washers, lug/screw, bolt, and a solder tab. Here is a reference picture. At least partially implementing this would make me feel better that you will blow up the fuse and not yourself! Hey, you may even get closer to resolving your noise issue to boot.

Thank you for the help! I’m not sure what you mean by isolation on the transformer.I have used this technique with CAT-5 where the drain wire is clipped at the RCA end and the other connected to chassis ground. The shield in the W2534 cable should be fine for this purpose since it short. Here is some further diyaudio reading on chassis grounding.

Do you have any isolation between your power transformer and the chassis? Just wondering if maybe your picking hum transference.

A note of caution: I noticed in your picture you appear to have the IEC earth soldered to the chassis. This is not electrically safe. You should be using a set of star washers, lug/screw, bolt, and a solder tab. Here is a reference picture. At least partially implementing this would make me feel better that you will blow up the fuse and not yourself! Hey, you may even get closer to resolving your noise issue to boot.

I could fairly easy implement the star washer and lug screws, I’ll look in to that. I did wrap ground wire through two holes and tightly twisted it to make sure there was good contact though.

I don’t believe there is currently a fuse in this set up. Should I rush out and implement one?

You’re welcome… Didn’t want to come across as condescending since I am new around these parts!Thank you for the help! I’m not sure what you mean by isolation on the transformer.

I could fairly easy implement the star washer and lug screws, I’ll look in to that. I did wrap ground wire through two holes and tightly twisted it to make sure there was good contact though.

I don’t believe there is currently a fuse in this set up. Should I rush out and implement one?

On the transformer isolation, I was just asking if perhaps you had rubber or nylon insulators between the transformer and the chassis. Having multiple common ground sources can create a ground loop in the chassis or caused by components inter-connected into your DAC. Check that you have a good common reference ground(s) for all your boards. A screw, nut and solder lug always ensures your ground stable if you have a couple of these setup in the chassis.

As for the fuse, that's up to you really. 1A jolt from a short is less damaging-painful then the full 15A! A circuit protected power bar will do the job but replacing the IEC with a fused one is the better option. Sort of a set and forget. Something like this as an example.

Let us know how you get on.

You’re welcome… Didn’t want to come across as condescending since I am new around these parts!

On the transformer isolation, I was just asking if perhaps you had rubber or nylon insulators between the transformer and the chassis. Having multiple common ground sources can create a ground loop in the chassis or caused by components inter-connected into your DAC. Check that you have a good common reference ground(s) for all your boards. A screw, nut and solder lug always ensures your ground stable if you have a couple of these setup in the chassis.

As for the fuse, that's up to you really. 1A jolt from a short is less damaging-painful then the full 15A! A circuit protected power bar will do the job but replacing the IEC with a fused one is the better option. Sort of a set and forget. Something like this as an example.

Let us know how you get on.

No isolation on the transformer, it's grounded to the chassis. The procedure you described, I remember doing something like that when I built my Akitika amp. Currently, I've grounded the chassis to earth ground, and only the transformer is grounded.

I run all my electronics off of good quality surge protectors, so I guess I'm good for now?

Thank you! Not enjoying the music quite yet, but I’ll do a few upgrades only my crack lol. I also found out my schiit sys adds a little fatigue on my speaker system as well :/ What a rabbit hole!

I have got an oldish dac based on ak4399, from 2013, I think it is called weiliang dac 9. Looks like this dac can be a nice diy option. Kits still sold I hope?

I'm pretty sure I do, I will look and check.

<later> Yes we do have at least one complete kit in stock.

<later> Yes we do have at least one complete kit in stock.

Last edited:

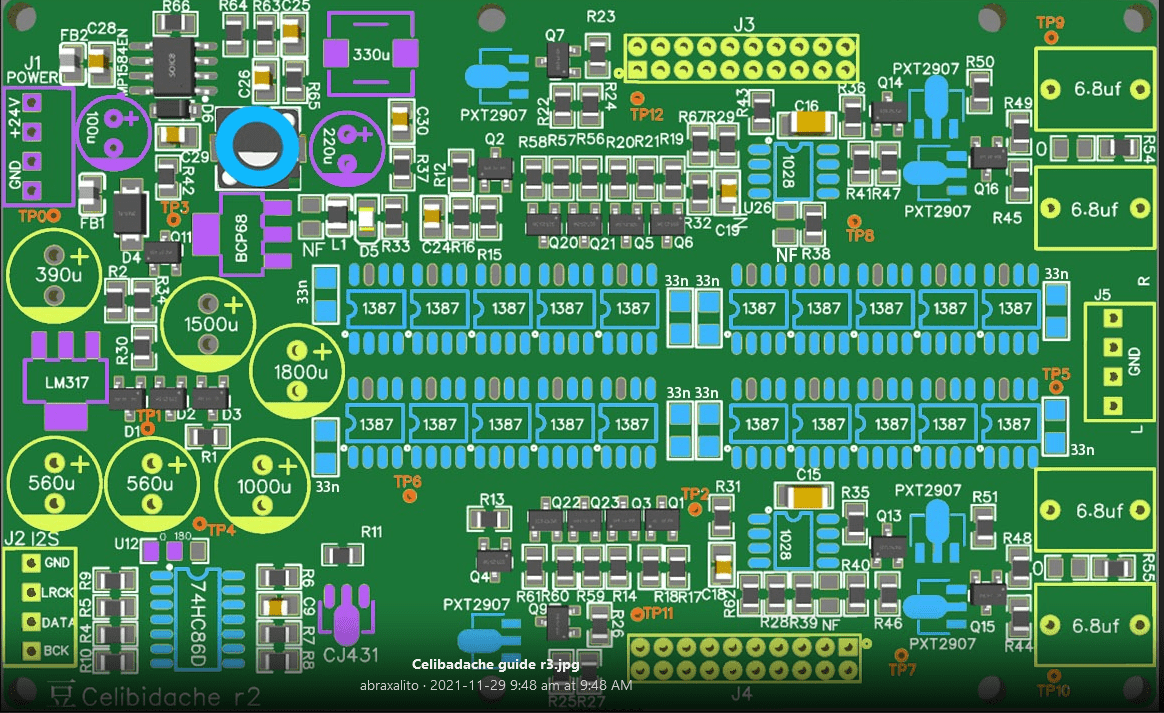

Hi @abraxalito Can you let me know which capacitors are in the analog side? When the kit arrives, I want to play around with some different caps but I am not sure what area of the board is affected by which capacitor. How precise are the values? Can the 390 uf be replaced by a 470? What value and grade is C15 and C16? Why are there 2 Wima's per channel? As you can tell, I am looking forward to playing around with this one.

@nautibuoy that is true but the values on the schematic are not the same as on the guide. Additionally, I know which end of the soldering iron is hot but if I were an electrical engineer and that schematic were actually meaningful to me, I would not ask the question. But, alas I dabble because it is fun and I leave the creating to those who can. Nonetheless, I am not afraid to ask.

@pelopidas, that's fine, I was just trying to be helpful rather than critical. FWIW I'm not an electrical engineer either, but I have learned my way around schematics, even if I'm not competent to actually design something.

From a very quick look at the schematic, the only capacitors in the analogue signal path, which I think is what you're asking, are the 6.8uF ones on the output of each channel. For each channel there are a pair of them in parallel so together are just equivalent to a single 13.6uF capacitor. Some improvement in sound quality might accrue from experimenting with different types but you'll likely need to accommodate physically larger capacitors, possibly off board.

My experience from building several of Richard's (Abraxalito) kits is that you'll not be disappointed with the results 'out of the box', his designs are very well considered and are great value.

From a very quick look at the schematic, the only capacitors in the analogue signal path, which I think is what you're asking, are the 6.8uF ones on the output of each channel. For each channel there are a pair of them in parallel so together are just equivalent to a single 13.6uF capacitor. Some improvement in sound quality might accrue from experimenting with different types but you'll likely need to accommodate physically larger capacitors, possibly off board.

My experience from building several of Richard's (Abraxalito) kits is that you'll not be disappointed with the results 'out of the box', his designs are very well considered and are great value.

Last edited:

Hi @abraxalito Can you let me know which capacitors are in the analog side? When the kit arrives, I want to play around with some different caps but I am not sure what area of the board is affected by which capacitor. How precise are the values? Can the 390 uf be replaced by a 470? What value and grade is C15 and C16? Why are there 2 Wima's per channel? As you can tell, I am looking forward to playing around with this one.

Hi Hans,

It would be easier to say which capacitors aren't on the analog side as most are decoupling analog power supplies and/or analog voltage references. The ones which aren't are generally small ceramics - that's C9,C24,C25,C26,C28,C29 and C30. The decoupling caps don't need to be the precise values I've used, there's plenty of flexibility with them. So yes, 390uF can be replaced with a 470uF or almost anything above 220uF which will still fit in the space. C15 and C16 are 10uF 35V X7R There are two Wimas per channel because a single 15uF isn't available with a conveniently small footprint so I put two 6.8uFs in parallel.

From listening to Celibidache against my current reference (an 8*PCM58) the key shortfall is that its background is noisier, this is the result of limited SNR out of the DAC chips, even with 20 in parallel. So the most obvious way to improve it would be by adding more DAC chips through piggy-backing on top of the existing ones. But this route of enhancement has considerable challenges because ideally the LC filter would need to be redesigned to work with a lower impedance - more chips makes more current and to maintain the same output voltage the I/V resistor needs to be reduced in value. The I/V resistor is also the termination resistor of the filter which is why the filter would need a complete redesign, so that route isn't practical unless the power supply voltage were also increased to accommodate the extra voltage swing that would occur if the filter and I/V resistor were left as they are. 28V is the maximum supply voltage for the buck regulator used to supply the DAC chips, probably at 28V supply to Celi the number of DAC chips could be doubled and hence the background noise would drop by 3dB. If the buck reg chip were changed to a higher voltage type (XL7005 would be my choice if I were designing Celi today) then the supply could go higher still for even more chips but then the increased dissipation of various transistors would become the next bottleneck. Until the maximum supply for the LT1028 opamps is reached that is.

Enough pontification, I hope you have fun with it once it arrives.

@abraxalito I have a question that I can't find a good answer to. What exactly is the noise that paralleling the chips is trying to reduce? I was looking at various forums and documents such as https://www.ti.com/lit/an/slyt751/slyt751.pdf?ts=1701963076991 TI explains noise as the jitter from the clock. The TDA 1387 receives its clock from I2s, doesn't it? Does the quality of the I2s affect the noise of the TDA1387 or is the noise we are looking to reduce something else?

The TDA1387 datasheet mentions signal to noise. So I guess my question is where is the noise coming from? Is the chip design itself noisy like a cheap carbon resistor? Is it the chips ability to suppress noise from the power supply? Is the noise even audible or is the noise a type of limitation on the performance?

The TDA1387 datasheet mentions signal to noise. So I guess my question is where is the noise coming from? Is the chip design itself noisy like a cheap carbon resistor? Is it the chips ability to suppress noise from the power supply? Is the noise even audible or is the noise a type of limitation on the performance?

The noise that gets reduced through paralleling isn't what's being talked about at your TI link. That kind of noise is related to what signal is coming out of the DAC and often isn't called 'noise' as its a function of the DAC's output signal. The clock jitter modulates the DAC output signal hence the bigger the output signal, the greater the 'noise'. The quality of the I2S is going to have some effect on the 'noise' when signal's playing but that isn't improved through paralleling chips.

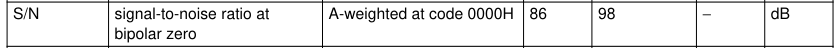

Paralleling is lowering the 'analog' noise unrelated to whatever signal the DAC's putting out. Its this line in the datasheet that gets improved through using more chips :

Notice that its 'at bipolar zero' so its the noise when the DAC outputs zeroes continuously. This noise comes from noise in reference voltages and currents, FET gate noise, thermal noise in resistors, that kind of thing. What's mysterious to me is why this noise matters so much in a DAC - the noise coming through from the (16bit) recording is always going to be bigger than this so why does it make such a difference subjectively? The chip's ability to suppress noise from the power supply is an important aspect which is why I've paid attention to the DAC chip's supply through using discrete transistors rather than cooking grade regulators (like LM317) which are significantly noisier. The noise isn't audible as noise rather it shows up by veiling the acoustic picture painted by the system, its only really noticeable in comparison with a lower noise DAC which gives a clearer picture. The lower noise DAC presents more saturated tonal colours - the analogy with video is that the lower noise DAC is more akin to an OLED screen (vs LCD for a higher noise DAC), with blacker blacks.

Paralleling is lowering the 'analog' noise unrelated to whatever signal the DAC's putting out. Its this line in the datasheet that gets improved through using more chips :

Notice that its 'at bipolar zero' so its the noise when the DAC outputs zeroes continuously. This noise comes from noise in reference voltages and currents, FET gate noise, thermal noise in resistors, that kind of thing. What's mysterious to me is why this noise matters so much in a DAC - the noise coming through from the (16bit) recording is always going to be bigger than this so why does it make such a difference subjectively? The chip's ability to suppress noise from the power supply is an important aspect which is why I've paid attention to the DAC chip's supply through using discrete transistors rather than cooking grade regulators (like LM317) which are significantly noisier. The noise isn't audible as noise rather it shows up by veiling the acoustic picture painted by the system, its only really noticeable in comparison with a lower noise DAC which gives a clearer picture. The lower noise DAC presents more saturated tonal colours - the analogy with video is that the lower noise DAC is more akin to an OLED screen (vs LCD for a higher noise DAC), with blacker blacks.

- Home

- Vendor's Bazaar

- Celibidache NOS DAC