I don't believe it works that way. I'd sooner choose good design with drivers that are simply 'good enough', provided one makes good choices.The better the drivers get, the more important do the details get.

Dr Geddes once put it this way..

Quote-

"As I have stated many times, I believe that the drivers themselves are mostly a commodity - one can make a very good system out of almost any "good" brand of drivers. While it is true that "no loudspeaker is perfect" as they get closer and closer to perfect the differences must vanish (that's only logical.) Over the years drivers have gotten significantly better (at least objectively) and as such the differences are becoming vanishingly small, perhaps even negligible. In non-blind test, of course people will always hear differences, but these are not necessarily real.

In an important test for me many years ago, we had four speaker systems. Two were of identical design but with different drivers (each system optimized for its driver set.) In a blind subjective test of 20 people the systems with just different drivers were not statistically different from each other but were from the other designs. This told me a lot and is the basis for my belief that it is the design that matters and not the drivers."

from here - https://www.diyaudio.com/community/threads/beyond-the-ariel.100392/post-4430216

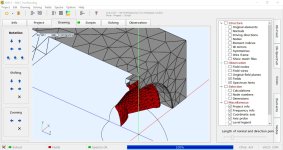

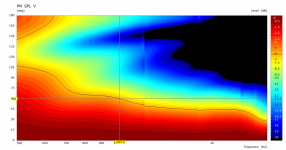

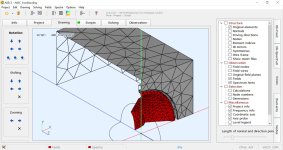

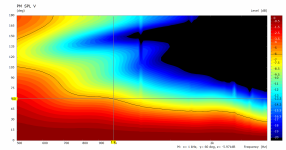

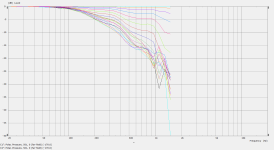

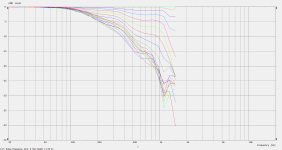

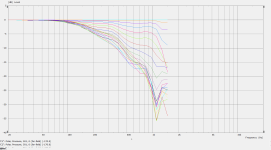

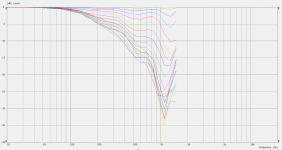

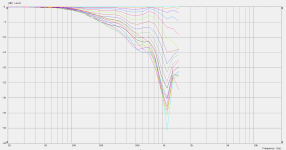

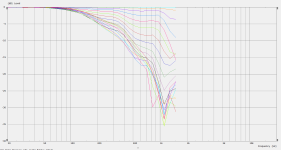

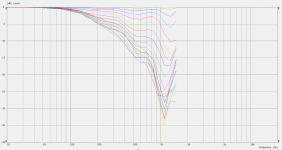

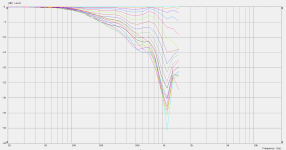

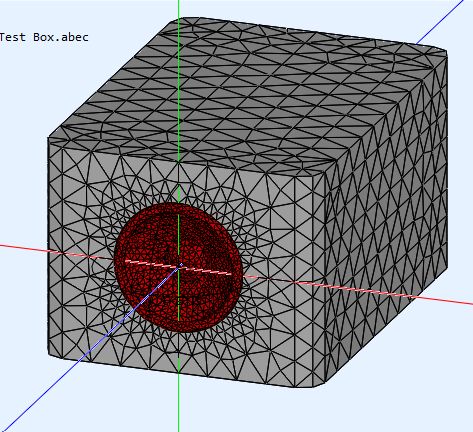

Here's an ATH/ABEC configuration file to compare flush, surface, and recessed mounting an 8 inch Dayton DC200-8 woofer. You can modify the Source.Contours in the configuration file to create different driver shapes, different enclosures, etc. In this case I simulated a H x W x D (234mm x 260mm x 260mm) box. It was supposed to be a 260mm cube but I forgot to change my box height. Recently, I used a surface mounted driver in a non-cube shaped enclosure because I wanted a slightly wider polar pattern at crossover to my waveguide. In addition, the radiation pattern over the controlled bandwidth of the driver was affected - slightly. Basically, it helped smooth my polars over the region I was trying to control. After I discovered that I remembered Neumann elevates their woofers and adds a slight bevel. So whether you surface, flush, or recess mount your driver just depends on what's going on at your crossover and your overall polar pattern goal. Would I mess with mounting variants if I couldn't use simulation first and had to physically build/measure a speaker to figure out my crossovers? Heeeeck no. But since simulation is so easy thanks to ATH software I wouldn't not do it now.

Surface mounted

Flush mounted

Recessed mounted

Surface mounted

Flush mounted

Recessed mounted

Attachments

Designing and building speakers is all about making rational choices. It is not necessary to recess drivers, but doing so will increase the potential performance. With surface mounted drivers, tweeters in particular, there will always be some added diffraction bumpiness to the response, both on and off axis. That does not mean the speaker will sound bad. It just means that the performance potential is limited by the presence of that diffraction.

We all work within the tools and skills that we have. If we don't have access to a router, table saw, band saw..., well, we have to do what we can. My first speaker was built with 3 tools... a jig saw, a drill, and a screw driver. it did not sound bad, in fact it sounded pretty good.

j.

We all work within the tools and skills that we have. If we don't have access to a router, table saw, band saw..., well, we have to do what we can. My first speaker was built with 3 tools... a jig saw, a drill, and a screw driver. it did not sound bad, in fact it sounded pretty good.

j.

Maybe Dr. Geddes is not right in anything, perhaps some things have changed.

What is right, there are very good drivers aviable for very limited money today. Also, there are very bad drivers out there, sold even not so cheap. Did I say China? In our part of the world, building a bad driver basically does not come cheaper than building a good one. Things are different where old tools exist and any material you use can be found a little cheaper, dirtyer, scrapier or older. As in the past, it is about picking the pearls and avoiding the pigs.

I may see things a bit different to people just building passive speakers all their life. Active is mercyless in showing the smallest differences in chassis.

Passive, you can not "hear" a tweeter without at least a capacitor crossover. Which performs depending on the impedance curve. So how will you tell me which one is better, if maybe only the capacitor is a better match? With active commercial speakers, the advantages are often used to get away with worse material. Look at BOSE, only using the cheapest stuff you can get, bending and shaping it electronically, fooling customers for decades now. So don't take the average active speaker as state of the art, most are crappy constructions, just made to be a tiny bit better than the next cheaper product in the line.

Today Klippel is the first tool that can show you the cause for good, better and not so good chassis. A pitty it is so expensive. Before Klippel chassis could measure identical and perform very different.

Here comes Mr. Geddes into play: Yes, good chassis at different price points may measure different and perform just as well as others, used right. But again, you can only judge a complete speaker, where cabinet, crossover and construction form a unity. Geddes knows he never used a final, perfect test, he constantly tried to improve them.

I have build active speakers for HIFI much longer than most here I suppose. After hearing an active Focal, Görlich, Dynaudio combination, in the 80th, I knew the potential compared to passive. To me it was shocking. I knew the tweeter, mid and woofer in many passive constructions, yes nice, but active they blew me away.

Analog active was limited and or complicated, good amps expensive, so only very linear drivers, build in baffles that did not spoil their linearity, was most important and a high budget. If you get the baffle right, you don't need to compensate in the (active) crossover. So drivers where more important than with a "bend me, shake me" passive crossover. Which prohibited them hitting the market in large number and at moderate prices. Phillips and Grundig had the electronics, but developers had wooden ears and used really cheap chassis. Better than BOSE, but cheap OEM they produced in house. Sorry fanboys!

Today the DSP has made things much simpler.

With PA stuff things where simpler, as you always had the eqalizer in the rack.

Today, which close to perfect D-chip-amps and DSP's for pocket money, passive is more or less dead from a pure performance point of view.

The problem is that with cheap, perfect speaker chassis, there has to be something to make money. That's why boutique crossover parts are agressively promoted and so ridiculously expensive. Mundorf being the leader of the pack, throwing boxes of his 1000% overpriced parts at magazines, developers and influencers for free and paying advertisments. Simple products made at lowest costs, but perfect marketing. Some may call it corrupting sources of information.

If you think it's an option to pay 90 $/€ for a small capacitor, maybe recessing your speakers is a very cheap improvement?

As we say in German: Keep the church in the village and never mind the bollock's!

What is right, there are very good drivers aviable for very limited money today. Also, there are very bad drivers out there, sold even not so cheap. Did I say China? In our part of the world, building a bad driver basically does not come cheaper than building a good one. Things are different where old tools exist and any material you use can be found a little cheaper, dirtyer, scrapier or older. As in the past, it is about picking the pearls and avoiding the pigs.

I may see things a bit different to people just building passive speakers all their life. Active is mercyless in showing the smallest differences in chassis.

Passive, you can not "hear" a tweeter without at least a capacitor crossover. Which performs depending on the impedance curve. So how will you tell me which one is better, if maybe only the capacitor is a better match? With active commercial speakers, the advantages are often used to get away with worse material. Look at BOSE, only using the cheapest stuff you can get, bending and shaping it electronically, fooling customers for decades now. So don't take the average active speaker as state of the art, most are crappy constructions, just made to be a tiny bit better than the next cheaper product in the line.

Today Klippel is the first tool that can show you the cause for good, better and not so good chassis. A pitty it is so expensive. Before Klippel chassis could measure identical and perform very different.

Here comes Mr. Geddes into play: Yes, good chassis at different price points may measure different and perform just as well as others, used right. But again, you can only judge a complete speaker, where cabinet, crossover and construction form a unity. Geddes knows he never used a final, perfect test, he constantly tried to improve them.

I have build active speakers for HIFI much longer than most here I suppose. After hearing an active Focal, Görlich, Dynaudio combination, in the 80th, I knew the potential compared to passive. To me it was shocking. I knew the tweeter, mid and woofer in many passive constructions, yes nice, but active they blew me away.

Analog active was limited and or complicated, good amps expensive, so only very linear drivers, build in baffles that did not spoil their linearity, was most important and a high budget. If you get the baffle right, you don't need to compensate in the (active) crossover. So drivers where more important than with a "bend me, shake me" passive crossover. Which prohibited them hitting the market in large number and at moderate prices. Phillips and Grundig had the electronics, but developers had wooden ears and used really cheap chassis. Better than BOSE, but cheap OEM they produced in house. Sorry fanboys!

Today the DSP has made things much simpler.

With PA stuff things where simpler, as you always had the eqalizer in the rack.

Today, which close to perfect D-chip-amps and DSP's for pocket money, passive is more or less dead from a pure performance point of view.

The problem is that with cheap, perfect speaker chassis, there has to be something to make money. That's why boutique crossover parts are agressively promoted and so ridiculously expensive. Mundorf being the leader of the pack, throwing boxes of his 1000% overpriced parts at magazines, developers and influencers for free and paying advertisments. Simple products made at lowest costs, but perfect marketing. Some may call it corrupting sources of information.

If you think it's an option to pay 90 $/€ for a small capacitor, maybe recessing your speakers is a very cheap improvement?

As we say in German: Keep the church in the village and never mind the bollock's!

Last edited:

That what I have done with all my builds. I make the baffle in layers, with the one or two layers at the front having a hole fitting the outer rim of the driver. Where I live, a router (a) is too noisy, and (b) makes far too much dust for my small working space.Years back I built some three ways and the instructions said recess the HF & mid. I made the baffle in two sections the second was slightly too thick. Cut the holes in the main bit, cut the profiles in the top layer then clamped and bonded the two with PVA. I Packed out the bottom layer cutouts with some veneer offcuts toalign the drive unit surfaces. Clamped & PVA'd the life out of those too.

Seemed to work ok once glue set, it was rock hard and as if it was one piece. I was young and couldn't afford a router etc. etc.

Alex

Methinks too many people frets over details that are insubstantial while the elephant is (in) the room...

Yeah the whole system, including room and positioning, have to work together for best results. That would also include the recess and all other features imaginable. No magic bullets, just bunch of details that align towards same goal.

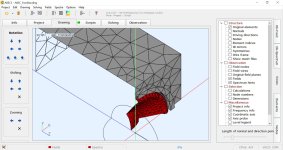

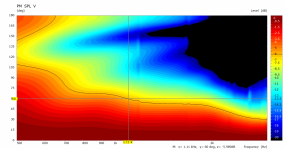

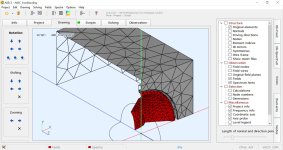

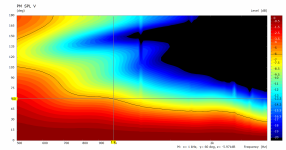

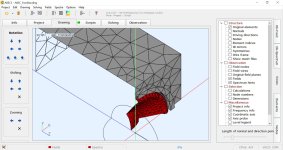

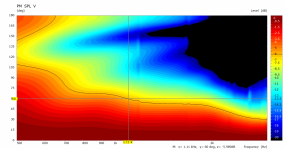

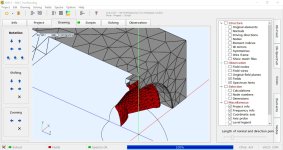

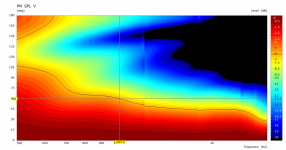

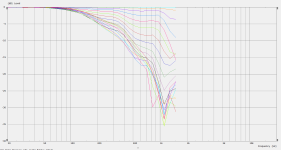

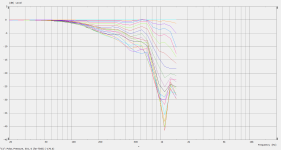

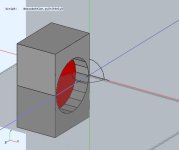

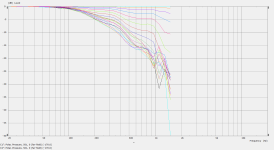

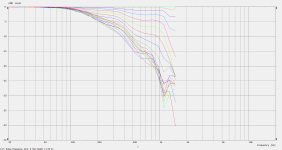

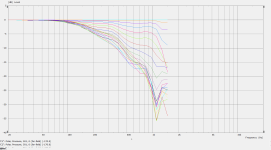

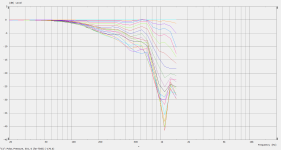

ps. here is similar sims to what cinnamonrolls posted. This is 15" driver with various (huge) recess. Sorry the images are not consistent through out, but I think it's enough to give hint of magnitude of things.

Here protruding

Illustrations what the models look like, extreme case of 100mm recess and protruding.

ps. This kind of simple boxes are easy to do with ABEC alone. There is Baffle and Diaphragm definitions along with few nodes that determine size and shape of the box, which makes things like "recess" just one parameter to adjust and simulation that is very fast to compute. This stuff can be adapted from example projects that come with ABEC, found from the Project -menu on the main program.

ps. here is similar sims to what cinnamonrolls posted. This is 15" driver with various (huge) recess. Sorry the images are not consistent through out, but I think it's enough to give hint of magnitude of things.

Here protruding

Illustrations what the models look like, extreme case of 100mm recess and protruding.

ps. This kind of simple boxes are easy to do with ABEC alone. There is Baffle and Diaphragm definitions along with few nodes that determine size and shape of the box, which makes things like "recess" just one parameter to adjust and simulation that is very fast to compute. This stuff can be adapted from example projects that come with ABEC, found from the Project -menu on the main program.

Last edited:

I'd agree with the statement that all details matter. Not only the flush mounting makes a difference (especially on the top end) but also details like enclosure shape determine the off-axis behavior. So in my humble opinion, all those little details do something. For each of us it's a choice if we are going to do something with that information.

From an earlier post of mine:

The shape of the cabinet determines a lot of what the off-axis energy looks like.

A while ago member @fluid ran sims for a driver in a flat baffle and the same driver with a rounded enclosure, the last example in

this row (with the set back or we could call it a short waveguide) is what I used, based on a hunch, but apparently a good one...

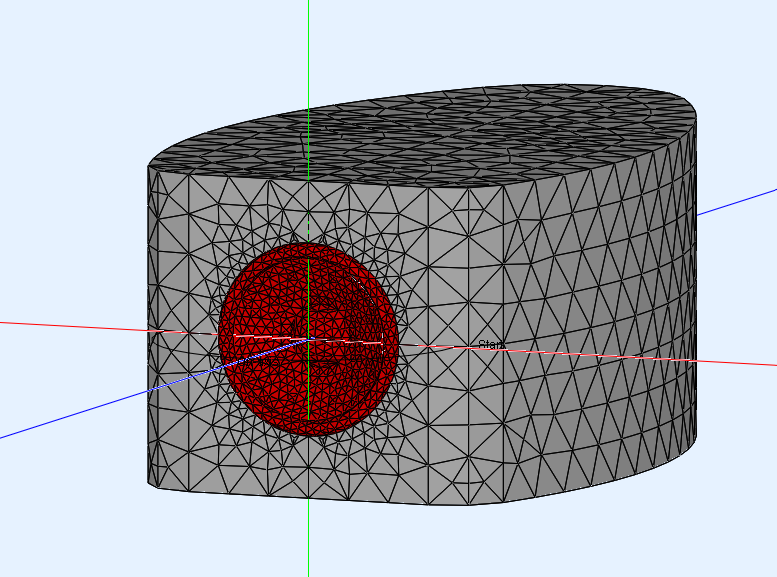

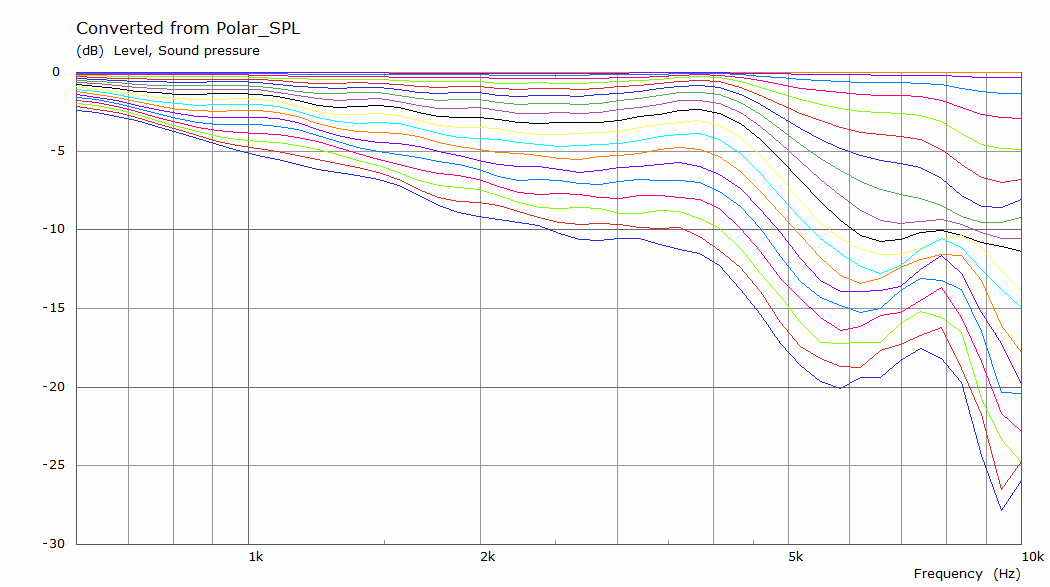

The relatively flat baffle with flush mounted driver simulation in ABEC:

Versus the rounded enclosure with flush mounted driver:

I'd say it is easy to spot differences. The first round-over used on that enclosure shape is only 25.5mm or about 1" radius. Yet the effect it has is quite obvious. A 2" round-over would get you enough of a noticeable effect i.m.h.o.

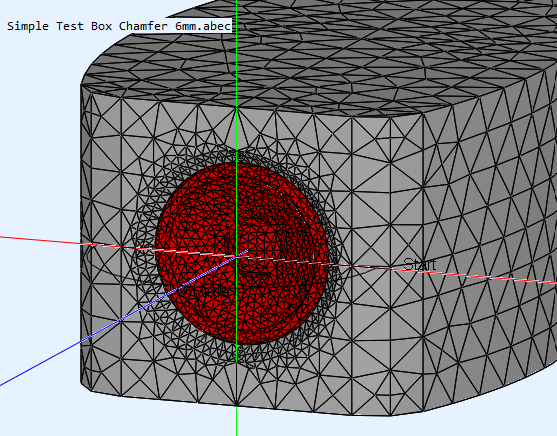

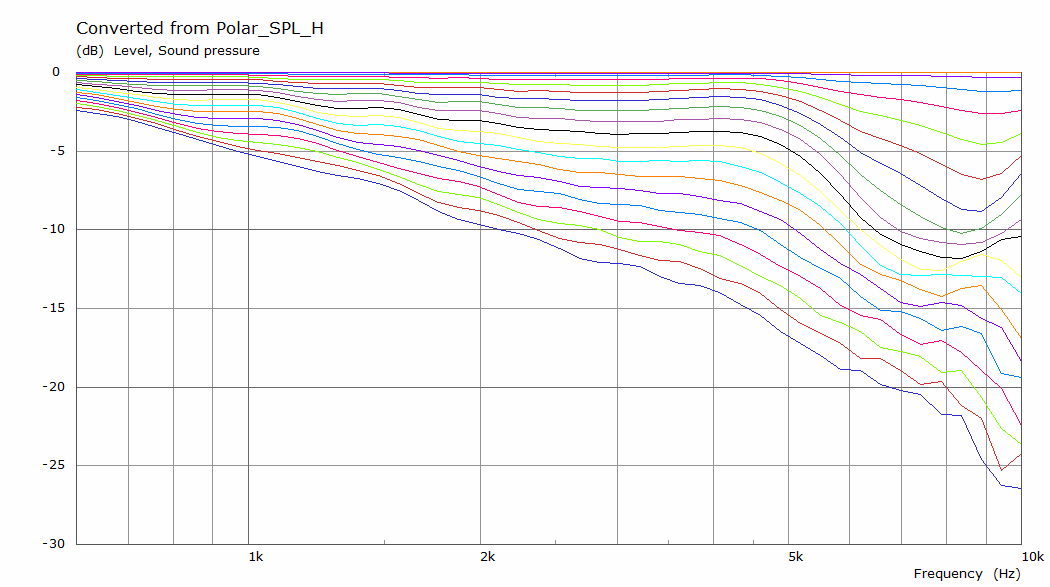

Taking this concept a step further, with the driver set back in the baffle with a small chamfer in front of the driver:

In my case I used a round-over as the waveguide shape.

I'd say it's well worth it to try or play with things like that. It does show much the shape of the enclosure can determine the outcome. Even such a small waveguide like shape in front of the cone does have an influence. The lower we go in frequency, the bigger those round-overs should be to have any effect though. But the enclosure shape and baffle details do matter.

From an earlier post of mine:

The shape of the cabinet determines a lot of what the off-axis energy looks like.

A while ago member @fluid ran sims for a driver in a flat baffle and the same driver with a rounded enclosure, the last example in

this row (with the set back or we could call it a short waveguide) is what I used, based on a hunch, but apparently a good one...

The relatively flat baffle with flush mounted driver simulation in ABEC:

Versus the rounded enclosure with flush mounted driver:

I'd say it is easy to spot differences. The first round-over used on that enclosure shape is only 25.5mm or about 1" radius. Yet the effect it has is quite obvious. A 2" round-over would get you enough of a noticeable effect i.m.h.o.

Taking this concept a step further, with the driver set back in the baffle with a small chamfer in front of the driver:

In my case I used a round-over as the waveguide shape.

I'd say it's well worth it to try or play with things like that. It does show much the shape of the enclosure can determine the outcome. Even such a small waveguide like shape in front of the cone does have an influence. The lower we go in frequency, the bigger those round-overs should be to have any effect though. But the enclosure shape and baffle details do matter.

If you think tiny details in your work don't care, you may not be the right man for high ende HIFI. Just like some do not care for what they eat, as long as it is enough to fill the belly...

I'd say your analogy could not be further from the truth, just on the verge of being pointlessly rude.

Couldn't say it any better. 👍Designing and building speakers is all about making rational choices. It is not necessary to recess drivers, but doing so will increase the potential performance. With surface mounted drivers, tweeters in particular, there will always be some added diffraction bumpiness to the response, both on and off axis. That does not mean the speaker will sound bad. It just means that the performance potential is limited by the presence of that diffraction.

We all work within the tools and skills that we have. If we don't have access to a router, table saw, band saw..., well, we have to do what we can. My first speaker was built with 3 tools... a jig saw, a drill, and a screw driver. it did not sound bad, in fact it sounded pretty good.

j.

A practical thing I would like to add, is to think within the entire context of a certain speaker.

The conversation always seems about only the objective "best".

Rather think in the "best" within a certain set of constraints.

Or in other words, how much can you optimize within a certain set of constraints.

That could be budget, but also tools, looks, whatever you just had on hand etc etc.

Btw, speaking about tweeter diffraction issues because of less ideal mounting.

The effect looks very dramatic with measurements.

But when you tune, filter and compromise it well, in practice it becomes bloody hard to hear in practice in some cases.

Also, there are building techniques where you don't need a router to get the same results. Like using a thin board (roughly) the same thickness of the flange of the tweeter, using felt etc etc.

Many creative options 🙂

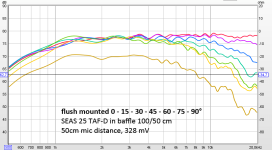

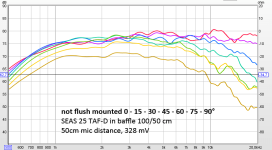

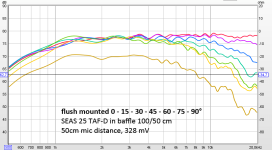

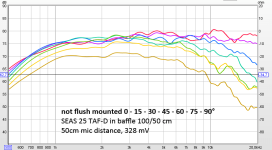

probably similar to zaph's measurements, here are my results for a 25 mm SEAS aluminium dome mounted on a large baffle (100 x 50 cm), gated measurements 1/24 octave smoothing, 50 cm mic distance, 328 mV signal, 0-90° in 15° steps.

use arrows in zoomed in view to toggle between the images!

slight differences below 1 kHz are probably due to slight rotation center difference (that is aligned with baffle surface).

depending on how much you take care of baffle edge diffrations those have a way more dramatic impact than flush-nonflush mounting.

use arrows in zoomed in view to toggle between the images!

slight differences below 1 kHz are probably due to slight rotation center difference (that is aligned with baffle surface).

depending on how much you take care of baffle edge diffrations those have a way more dramatic impact than flush-nonflush mounting.

Ehm no?Today Klippel is the first tool that can show you the cause for good, better and not so good chassis. A pitty it is so expensive. Before Klippel chassis could measure identical and perform very different.

The only thing Klippel does, is to do it in a very convenient way.

People have been making proper measurements for decades.

Even better after Toole's book, when the general understanding came that directivity is a important factor.

But there isn't much that a Klippel system can do more than measuring yourself with a bit of knowledge and creativity.

Yes, it can do one thing better, click a button and go do something else and that on a consistent and very convenient way.

It's only the consistency that is great for reviews and comparing products.

But from a designer perspective, it's not adding that much.

I feel this might actually be an assumption fed by the industry.If your ears are not totally clogged, you will certainly hear an important difference from doing anything the right way.

Indeed - or not. Or so marginally that the cost/benefit is poor.You can only attest the whole construction improved audible performance.

As I said, it may be that this is just an assumption, and received wisdom. Hence my question.So yes, if you are lazy, you may ignore points of a construction, but don't expect to get the same result and don't blame the construction for lower performance. By the way, this may often be the cause for totally different options about a subwoofer or speaker plan.

What's more, buyer's remorse tends to suggest that we would subconcsiously favour things that were harder to make or more expensive.

I guess it would take a double blind test to be sure, and with a statistically significant sample - but who does that outside of the industry?

I like that.If you think tiny details in your work don't care, you may not be the right man for high ende HIFI. Just like some do not care for what they eat, as long as it is enough to fill the belly...

a description i can aspire to..... a low-end dude, made for LO-FI audio 😀

Nothing in audio turns me off more than "high-end" pretensions.

I must admitt there is a very narrow border between high end, or call it high quality HIFI and voodoo. Sometimes hard to see where the improvement ends and the snake oil trace begins.

Anyway, if you can measure a difference of a few dB you should be able to hear it. On the other side, a non linear reproduction may sound much better than a linear one. All correct. Taste and music style lead to very different ideas of reproduction.

If you do not like a linear, low distortion reproduction with a defined in room dispersion, there should be an alternative. For me such a system is the starting point, even if it may be a little more work and time consuming to get there.

Klippel is a great way of finding faults in construction and production of speaker chassis, without destroying them. If you are not interested in such things, Klippel is not for you and just another "too expensive for me" tool. DIYS is "do what you want" and live with it. If you don't like to measure, build without it. It is a free world, basically, in some places at least.

It took me a long time to except that for a majority, a nice verneer sounds a million times better than a raw chipboard enclosure. Which is the cause I never present raw speakers to others any more.

Anyway, if you can measure a difference of a few dB you should be able to hear it. On the other side, a non linear reproduction may sound much better than a linear one. All correct. Taste and music style lead to very different ideas of reproduction.

If you do not like a linear, low distortion reproduction with a defined in room dispersion, there should be an alternative. For me such a system is the starting point, even if it may be a little more work and time consuming to get there.

Klippel is a great way of finding faults in construction and production of speaker chassis, without destroying them. If you are not interested in such things, Klippel is not for you and just another "too expensive for me" tool. DIYS is "do what you want" and live with it. If you don't like to measure, build without it. It is a free world, basically, in some places at least.

It took me a long time to except that for a majority, a nice verneer sounds a million times better than a raw chipboard enclosure. Which is the cause I never present raw speakers to others any more.

Wonder if the aluminium effect for enclosure makes nice veneers being cheap chipboard nowadays and suddendly make them sound bad !

I don't think that it is a direct analogy, but I tend to associate the building of a set of speakers (or system for that matter) with challenges encountered with racing cars. After a certain point of attention is reached with the car chassis and most of the rest, now increasingly important is the fuel that is in the fuel tank. It may have mattered less up to a point, and then it became 'the difference'.

- Home

- Loudspeakers

- Multi-Way

- Driver recessing - how important? And does it cause people to avoid DIY?