What are you making?I did the math. The pending project I have them for will be a 150 active and 180PR.

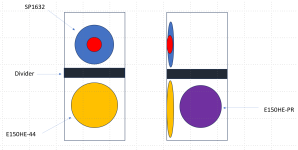

Your woofer should not be "sharing a space" with anything but the PRs.I was actually thinking two of the 7" PRs only because the epique is going to be sharing a space with another speaker. Yay or nay?

The REW (freeware test gear) USB o-scope/sig gen has enough resolution to "get the job done" for audio, though don't know that an o-scope will help determine Xmech/Xlim.Funny you should mention that. I've been looking around lately at USB o-scope/sig gens. I know it's not going to be nearly as powerful as the stuff I used to use when I worked on radar (definitely don't need an RF spec an for audio) but I think for an audio project it should have enough resolution to get the job done.

That said, you will need around 80volts to push the E150HE-44 past Xmax in a box, does the TPA3255 you were planning to use have that output?

Your woofer should not be "sharing a space" with anything but the PRs.

My bad. I thought you meant as in "in the same enclosure."A pair of passive radiators in horizontal opposition would be one on each side of the cabinet.

The coax and E150HE-44 would be on the front side as closely spaced as possible, the cabinet elevated to ear height at your primary listening location.

https://www.roomeqwizard.com/ is this correct REW?The REW (freeware test gear) USB o-scope/sig gen has enough resolution to "get the job done" for audio

https://www.ti.com/lit/ds/symlink/tpa3255-q1.pdf?ts=1695959770684&ref_url=https%3A%2F%2Fwww.ti.com%2Fproduct%2FTPA3255-Q1That said, you will need around 80volts to push the E150HE-44 past Xmax in a box, does the TPA3255 you were planning to use have that output?

Seems not. Recommended supply voltage is 51V and max at 69V. I could try to take my sacrificial lamb driver to work tomorrow and use a bench power supply there... or I may just call Dayton tech support and see if they know anything (by that I mean if they would even have that info on hand as opposed to being just there for returns etc).

@weltersys Hey Art,

I gave Dayton a call this morning. Apparently for the E150HE-44 the Xmech/Xlim is just double Xmax (29.4mm). Additionally, I know we had talked about MFB before and asked them if there was a way to remove the dust cap (although it would void the warranty). It's just regular old epoxy. I thought it would be something different to adhere specifically carbon fiber, but it's not. That said, a little heat and it should come right off.

Oh and fun fact: they used software for the calculation. Something called Bassbox. May pick up a copy from parts express myself.

Another thought I had though: would I be stuffing this speaker and would that effect heat coming from the drivers?

I gave Dayton a call this morning. Apparently for the E150HE-44 the Xmech/Xlim is just double Xmax (29.4mm). Additionally, I know we had talked about MFB before and asked them if there was a way to remove the dust cap (although it would void the warranty). It's just regular old epoxy. I thought it would be something different to adhere specifically carbon fiber, but it's not. That said, a little heat and it should come right off.

Oh and fun fact: they used software for the calculation. Something called Bassbox. May pick up a copy from parts express myself.

Another thought I had though: would I be stuffing this speaker and would that effect heat coming from the drivers?

Last edited:

"A little heat" could be around 302 °F (150 °C) to 356 °F (180 °C) or more before the epoxy starts to break down, good luck keeping that away from the surround..

BassBox pro is a box design simulation program. I don't understand what calculation you are referring to, you load speaker, box, and fill ("stuffing") parameters into the simulator to arrive at what the combined response will theoretically be.

The free Hornresp simulator which can simulate far more design possibilities than BassBox pro, though has a bit of a learning curve:

http://www.hornresp.net/

David McBean, the designer is still regularly updating and answering questions in the Hornresp sticky thread in this section.

I find it odd Dayton rates the Xmech at just 19mm for the E150HE-44PR, but would then claim 29.4mm Xmech for the E150HE-44. It seems too convenient that Xmech would be exactly double Xmax, I've seen more or less, but never the same.

At around 29.4mm (one way) looks like the cone and spider would both hit the basket's magnet structure attachment ring, assuming the coil former does not hit the back plate first.

Anyway, push the cone in and out and tell us if the person you talked to at Dayton has the right figure.

That said, if the E150HE-44 has 29.4mm Xlim, the E150HE-44PR won't "clunk" until it's rocking almost 59mm peak to peak, over 2.25 inches, and you certainly won't reach that excursion with the TPA3255.

"Stuffing" is used on sealed boxes to increase the apparent volume.

Lining the walls of a vented or passive radiator enclosure to reduce higher frequency internal reflections and resonance may be useful, but stuffing reduces the vent/PR output considerably (3-4 dB or more), to the point where it would behave like a sealed box.

https://sound-au.com/articles/boxstuff.htm

Stuffing retains heat in the box, reducing voice coil heat exchange. Since about 98% of the tiny speaker's power is wasted as heat, the temperature in a sealed box can rise considerably over ambient, especially with compressed bass lines in some genres of music that may approach the the crest factor of a sine wave, 3dB(log).

Fortunately, most music has a dynamic range and duty cycle that will present average levels 10dB or more down from peaks- 200 watts peak would be only 20 watts. Still, 20 watts in a sealed, well insulated box can get hot.

As the voice coil temperature rises, it's impedance increases, causing "thermal compression"- double the impedance, half the power for a given voltage.

Art

BassBox pro is a box design simulation program. I don't understand what calculation you are referring to, you load speaker, box, and fill ("stuffing") parameters into the simulator to arrive at what the combined response will theoretically be.

The free Hornresp simulator which can simulate far more design possibilities than BassBox pro, though has a bit of a learning curve:

http://www.hornresp.net/

David McBean, the designer is still regularly updating and answering questions in the Hornresp sticky thread in this section.

I find it odd Dayton rates the Xmech at just 19mm for the E150HE-44PR, but would then claim 29.4mm Xmech for the E150HE-44. It seems too convenient that Xmech would be exactly double Xmax, I've seen more or less, but never the same.

At around 29.4mm (one way) looks like the cone and spider would both hit the basket's magnet structure attachment ring, assuming the coil former does not hit the back plate first.

Anyway, push the cone in and out and tell us if the person you talked to at Dayton has the right figure.

That said, if the E150HE-44 has 29.4mm Xlim, the E150HE-44PR won't "clunk" until it's rocking almost 59mm peak to peak, over 2.25 inches, and you certainly won't reach that excursion with the TPA3255.

"Stuffing" is used on sealed boxes to increase the apparent volume.

Lining the walls of a vented or passive radiator enclosure to reduce higher frequency internal reflections and resonance may be useful, but stuffing reduces the vent/PR output considerably (3-4 dB or more), to the point where it would behave like a sealed box.

https://sound-au.com/articles/boxstuff.htm

Stuffing retains heat in the box, reducing voice coil heat exchange. Since about 98% of the tiny speaker's power is wasted as heat, the temperature in a sealed box can rise considerably over ambient, especially with compressed bass lines in some genres of music that may approach the the crest factor of a sine wave, 3dB(log).

Fortunately, most music has a dynamic range and duty cycle that will present average levels 10dB or more down from peaks- 200 watts peak would be only 20 watts. Still, 20 watts in a sealed, well insulated box can get hot.

As the voice coil temperature rises, it's impedance increases, causing "thermal compression"- double the impedance, half the power for a given voltage.

Art

Last edited:

Even if I use one with a direct nozzle?"A little heat" could be around 302 °F (150 °C) to 356 °F (180 °C) or more before the epoxy starts to break down, good luck keeping that away from the surround..

Cool! Will definitely look into this 🙂The free Hornresp simulator which can simulate far more design possibilities than BassBox pro, though has a bit of a learning curve:

http://www.hornresp.net/

David McBean, the designer is still regularly updating and answering questions in the Hornresp sticky thread in this section.

I would tend to agree. Even not being armed with that knowledge, I would think if you're doing some sort of calculation, you would need other parameters. Those could have varied widely.I find it odd Dayton rates the Xmech at just 19mm for the E150HE-44PR, but would then claim 29.4mm Xmech for the E150HE-44. It seems too convenient that Xmech would be exactly double Xmax, I've seen more or less, but never the same.

I'll do that when I get home from work. However, would it make a difference or not whether I just pushed down on it, or run it at 80V like you recommended before? Yes, pushing it down I would be taking a measurement, but would that be as accurate of a measurement as compared to if I were operating the speaker electrically?Anyway, push the cone in and out and tell us if the person you talked to at Dayton has the right figure- iThat said, if the E150HE-44 has a you won't need to worry that the PR will "clunk" until it's rocking almost 59mm peak to peak, over 2.25 inches.

Maybe give it 60 degrees Celsius in the oven and see if it gets soft enough to easily cut through? I dont even know if that would be safe for the rest of the speakers.

Epoxy can have very varied egenskaber.

Cheese!

Epoxy can have very varied egenskaber.

Cheese!

I have not yet commenced on the build. The info I have was posted in the link above about how to safely implement the 2 ohm wiring on a 4 ohm stable amplifier.

I plan to call them Amaranthine, or "limitless". I have a few options for mids entertained, but it depends on actual measured performance. I have a feeling 1 of 3 will not make the cut. Tweeters will be a set of Airborne AMTs. These will also not look as the average design does.

I plan to call them Amaranthine, or "limitless". I have a few options for mids entertained, but it depends on actual measured performance. I have a feeling 1 of 3 will not make the cut. Tweeters will be a set of Airborne AMTs. These will also not look as the average design does.

If you have the cash I found these guys a little while ago. On paper they're terrific and there's a lot of good reviews about them. If I ever made an upgraded version of the speakers I'm making, I would probably use these myself. https://www.madisoundspeakerstore.c...a-01-6.5-ultra-low-distortion-midrange-4-ohm/ hope this helps 🙂I have a few options for mids entertained

I used a pair of 5 1/2” drivers per side in my compact active 3 way towers. Each driver has its own 80W amp. Each was in a 4L air chamber that pushed the resonance up to about 85Hz. I used a transform to level it to about 45Hz. I tried lower, but electronic music played loud was too much excursion and that really doesn’t sound nice!

There isn’t as much bass as I got from my old 10” drivers, but it’s not far behind and the quality of the bass is vastly better, much more articulate and tuneful.

I used carbon fibre coned monacor units, SPH135C.

There are some pics in hifijims compact low cost speaker thread.

I look forward to hearing what you decide on!

There isn’t as much bass as I got from my old 10” drivers, but it’s not far behind and the quality of the bass is vastly better, much more articulate and tuneful.

I used carbon fibre coned monacor units, SPH135C.

There are some pics in hifijims compact low cost speaker thread.

I look forward to hearing what you decide on!

So it looks like the spider is hitting first. When I push it down, it doesn't feel like the coil is bottoming out against the magnet.

Attachments

Well, again, depending on how much you want to spend, there's always something like the RAAL mid tweeters (https://www.madisoundspeakerstore.c...l-140-15d-ribbon-tweeter-with-amorphous-core/). Another option could be using an exciter and going bending wave. The only tricky parts to making one is decoupling the modulating mass from the frame, and standing waves on the modulating mass (there's a few examples out there, but they all have funky shapes).I'm limited to 100mm frame in the build I'm doing, but thanks anyway.

You didn't share the Xmech measurement in the push tests posted in #55, but appears to be less than 29.4mmHowever, would it make a difference or not whether I just pushed down on it, or run it at 80V like you recommended before? Yes, pushing it down I would be taking a measurement, but would that be as accurate of a measurement as compared to if I were operating the speaker electrically?

My statement "you will need around 80volts to push the E150HE-44 past Xmax in a box" was not a test recommended for you, it was based on a simulation:

https://audioxpress.com/article/tes...e-subwoofer-from-the-dayton-audio-epique-line

If you use 78/90volts sine wave into the series coils (1000 watts at nominal 8 ohms), I'd expect you would see the magic smoke in a matter of seconds, though peaks in that range should be survivable.

Only 45 volts at 2 ohms (parallel coils) would be required for the same.

Simulations are based on the Bl and suspension behaving linearly, which they are not past Xmax.

Past Xmax, the Bl reduces considerably while the suspension gets tighter and a non-linear amount of voltage is required for further excursion- for all I know it could take 180 volts to push the cone as far as you did by hand.

Art

I already have 2 drivers of interest for mids, and I have the woofer, AMT, and PR units already.Well, again, depending on how much you want to spend, there's always something like the RAAL mid tweeters (https://www.madisoundspeakerstore.c...l-140-15d-ribbon-tweeter-with-amorphous-core/). Another option could be using an exciter and going bending wave. The only tricky parts to making one is decoupling the modulating mass from the frame, and standing waves on the modulating mass (there's a few examples out there, but they all have funky shapes).

We'll see how it goes. Thanks for your interest.

Oopsie 😅You didn't share the Xmech measurement in the push tests posted in #55

I don't really intend to push these past 100 watts anyway so I guess it's good to go and so are the PRs... well once I get the simulations done. Should be a little easier though since all the info is online so I can just plunk that into VCAD.Simulations are based on the Bl and suspension behaving linearly, which they are not past Xmax.

Past Xmax, the Bl reduces considerably while the suspension gets tighter and a non-linear amount of voltage is required for further excursion- for all I know it could take 180 volts to push the cone as far as you did by hand.

You're welcome 🙂 Good luck!I already have 2 drivers of interest for mids, and I have the woofer, AMT, and PR units already.

We'll see how it goes. Thanks for your interest.

- Home

- Loudspeakers

- Subwoofers

- Small Subwoofer Design Considerations