On the choke/toroid placement, would you want the same power/output 90 degree orientation to minimize magnetic field interaction? Not sure what that looks like with a toroid and a choke.

^ Definitely going to play with more layouts. Thanks! Note, the chassis will likely be standard width / 400 deep / 3U. I might go with 4U if needed. I'll probably get a Pestante, since the Galaxy and Slimline won't likely give me the breathing room, and space isn't too much of a consideration. It's likely going to start life in a Dissipante 5U / 400 since I have a few already, and I can test the layouts.

It would be easier if aesthetics didn't play a role. If I were willing to have the IEC on the "back" and the DC output on the "front", the layout would be so much easier. Even I'm not willing to go that far. 🙂

So far, the considerations are:

No matter how it finds its way into a chassis, I'm sure it will be a great PSU, but why not fiddle with variants... Silly, I know. 🙂

- Keeping the AC lines as far away from DC as practical. There are (at least) three options I'm fooling with. Some may be combined.

- Left / Right / Center. AC up the middle with DC routed to the outputs on the right and left of the chassis.

- Left / Right - AC to one side and DC on the other.

- Top / Bottom - AC wiring under the base plate. DC on top. Use of other plates / mezzanines for extra distance and layout space.

- Distance from the toroids to chokes and/or EMI shielding for the toroids. I haven't seen this brought up before. However, with layouts for tube amps, people seem to take great care in placement of power transformers and output transformers. I know we're not dealing with the same thing ... DC smoothing choke vs. power toroid instead of output transformer vs. power transformer ... but this is where not knowing anything doesn't help too much. It seems to be a low priority, but it seems silly to squash the choke up against the toroid if it's not necessary.

Have a look at MT-043, Figure 3.... treat your amplifier the same as you'd treat that OP Amp (well.... as close as physically possible...)...

Regarding grounding (you asked earlier...).... have a look at that Rane pdf.... Figure 1b. Implement the exact same principle to your PS PCB grounding scheme.

Attachments

I've been doing more reading... thinking... guessing... and fooling around with things.

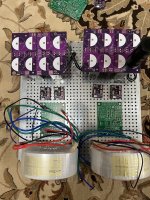

Re: the PSU layout itself; the pic attached should be roughly how it winds up.

I decided to go ahead with a 5U solution. It's not ideal, but I have the space in the rack.

That will allow me to (hopefully) do things more properly in terms of separating AC/DC lines etc. along with giving me enough space to mount the toroids vertically and mount the tall(ish) caps over the chokes.

That solution frees up enough floor space to easily include Mark's H9KPXG boards.

I still haven't reached out directly to Neutrik yet. I think I have a better idea of which way this is heading, so I may give them a ring later this week.

I believe I have a grasp on the articles provided above and how to implement the concepts contained within. I need to come up with a plan re: parts placement and wiring within the amp chassis for the local caps. I'll likely use standard cap bands and mount them to chassis floor along with point-to-point wiring. I also need to finalize the wiring scheme within the PSU chassis along with between and within the amp chassis.

Once I get a more detailed wiring diagram put together, I'll post it here for a critique / further ideas. All the help thus far is greatly appreciated!

Any further ideas re: layout (or anything else for that matter) are appreciated also.

Edited to add - One of the cap boards is backwards... (DC output facing the middle of the chassis vs. the back panel) but you get the idea.

Re: the PSU layout itself; the pic attached should be roughly how it winds up.

I decided to go ahead with a 5U solution. It's not ideal, but I have the space in the rack.

That will allow me to (hopefully) do things more properly in terms of separating AC/DC lines etc. along with giving me enough space to mount the toroids vertically and mount the tall(ish) caps over the chokes.

That solution frees up enough floor space to easily include Mark's H9KPXG boards.

I still haven't reached out directly to Neutrik yet. I think I have a better idea of which way this is heading, so I may give them a ring later this week.

I believe I have a grasp on the articles provided above and how to implement the concepts contained within. I need to come up with a plan re: parts placement and wiring within the amp chassis for the local caps. I'll likely use standard cap bands and mount them to chassis floor along with point-to-point wiring. I also need to finalize the wiring scheme within the PSU chassis along with between and within the amp chassis.

Once I get a more detailed wiring diagram put together, I'll post it here for a critique / further ideas. All the help thus far is greatly appreciated!

Any further ideas re: layout (or anything else for that matter) are appreciated also.

Edited to add - One of the cap boards is backwards... (DC output facing the middle of the chassis vs. the back panel) but you get the idea.

Attachments

I would consider mounting the soft start PCBs vertically, either on the case sides, or from the case bottom using L brackets. This would leave the centre area free so the capacitors would not need to be stacked on the chokes.

^ I will give that a look, thank you!

For clarity... is it not a good idea to put the caps above the chokes for a performance reason and/or are you trying to help me get my total height lowered?

For clarity... is it not a good idea to put the caps above the chokes for a performance reason and/or are you trying to help me get my total height lowered?

I don't know if caps above chokes is bad, but to me, it seems like it would be more efficient use of the total space. There is a great variation in density, now.

Also, I like to see all the components laid out in front of me. It's easier to see the circuit and to troubleshoot.

I guess it's aesthetics as well. Kind of like feng shui. But that's a personal thing.

Also, I like to see all the components laid out in front of me. It's easier to see the circuit and to troubleshoot.

I guess it's aesthetics as well. Kind of like feng shui. But that's a personal thing.

I'm always allowing that my feng doesn't need to be same as your shui .......

that's why I'm posting plethora of build pictures, whenever I can, so everyone can learn from my mistakes

chokes beneath cap banks - means shortest possible twisted leads to chokes, replacing R in CRC

unused space on amp floor is good thing, being second only to proper grouping of functional blocks

it's always nice to actually have some space for hands, while powering up for first time and conducting setting procedure; I tried twidling trimpots by sheer will force, and I'm successful only half of time

my Zen is still weak

that's why I'm posting plethora of build pictures, whenever I can, so everyone can learn from my mistakes

chokes beneath cap banks - means shortest possible twisted leads to chokes, replacing R in CRC

unused space on amp floor is good thing, being second only to proper grouping of functional blocks

it's always nice to actually have some space for hands, while powering up for first time and conducting setting procedure; I tried twidling trimpots by sheer will force, and I'm successful only half of time

my Zen is still weak

@pinholer and @Zen Mod -

Thank you both. The ideas along with the reasoning help the overall concepts and knowledge sink into my brain a bit. It's certain that I'll make a few errors with this PSU, but it's been a great deal of fun, and I'm learning as I go.

Without extending the existing wires from the chokes, their placement relative to the cap boards is limited. Since I have the space vertically, I'll likely keep the chokes under the caps, but I'm still fiddling.

I do like having as much space as practical to maneuver around w/o knocking something. I still have to put in fuses for each toroid etc... so not everything is in there. I don't think I'll have the need for any terminal blocks or similar...

I am still playing 3D Tetris with all the parts / boards while trying to visualize wire paths. I like the idea of considering options for all the boards instead of thinking they all need to be parallel to the floor. I've seen some nifty amp builds with the cap banks on the front panel etc. I didn't consider that type of thing until pinholer brought it up.

More fun...

Cheers!

Thank you both. The ideas along with the reasoning help the overall concepts and knowledge sink into my brain a bit. It's certain that I'll make a few errors with this PSU, but it's been a great deal of fun, and I'm learning as I go.

Without extending the existing wires from the chokes, their placement relative to the cap boards is limited. Since I have the space vertically, I'll likely keep the chokes under the caps, but I'm still fiddling.

I do like having as much space as practical to maneuver around w/o knocking something. I still have to put in fuses for each toroid etc... so not everything is in there. I don't think I'll have the need for any terminal blocks or similar...

I am still playing 3D Tetris with all the parts / boards while trying to visualize wire paths. I like the idea of considering options for all the boards instead of thinking they all need to be parallel to the floor. I've seen some nifty amp builds with the cap banks on the front panel etc. I didn't consider that type of thing until pinholer brought it up.

More fun...

Cheers!

Hi Everyone -

I just had a conversation with Fred at Neutrik. I learned a lot. First... I learned that the pronunciation is similar to Noy-trick not Nue-trik. I had it wrong for years. 🙂

More importantly, he said that he encourages anyone to call or e-mail with questions. He's in technical support at +1-704-972-3050. I asked permission, and he encouraged me to paraphrase his overall thoughts.

For my application (thank you, Ben!) which is up to 50VDC at up to 5A on the highest side; he said the only product that they have which is suitable are certain XLRs; rated at up to 50VDC at 10A. He said in plain terms to not use either the PowerCon nor the SpeakOn for DC applications at all. I asked him if he could please explain at a novice level for my specific application. I asked was it dangerous / what could go wrong etc.?

He took the time to explain to me why those products were not suitable for me. That is not to say that they aren't suitable for anyone else... he was very polite, but strong in his wording that he doesn't think it's a good idea to use those products for DC. He'd be happy to explain why to anyone for their particular application over a quick / direct inquiry.

He was even so kind as to recommend that I look into companies like Bulgin and Souriau for more appropriate connectors. I have not done that, but I will.

For clarity... I am not saying that anyone that uses the SpeakOn or PowerCon for DC is doing anything wrong. I am simply sharing a paraphrased conversation with an expert re: my application and suitable DC power connectors made by Neutrik in general. It's DIY, we make informed decisions all the time to use products in applications for which they're not originally designed... I'm just not skilled enough to make an informed decision without a lot of help.

My decision is to use XLR or something else designed for my application.

If anyone wants to choose a Neutrik product suitable for a particular application, Fred said to please call or e-mail. He said to use his name directly. He was a delight to learn from.

Thanks to all for the encouragement in the thread and via PM / e-mail.

I just had a conversation with Fred at Neutrik. I learned a lot. First... I learned that the pronunciation is similar to Noy-trick not Nue-trik. I had it wrong for years. 🙂

More importantly, he said that he encourages anyone to call or e-mail with questions. He's in technical support at +1-704-972-3050. I asked permission, and he encouraged me to paraphrase his overall thoughts.

For my application (thank you, Ben!) which is up to 50VDC at up to 5A on the highest side; he said the only product that they have which is suitable are certain XLRs; rated at up to 50VDC at 10A. He said in plain terms to not use either the PowerCon nor the SpeakOn for DC applications at all. I asked him if he could please explain at a novice level for my specific application. I asked was it dangerous / what could go wrong etc.?

He took the time to explain to me why those products were not suitable for me. That is not to say that they aren't suitable for anyone else... he was very polite, but strong in his wording that he doesn't think it's a good idea to use those products for DC. He'd be happy to explain why to anyone for their particular application over a quick / direct inquiry.

He was even so kind as to recommend that I look into companies like Bulgin and Souriau for more appropriate connectors. I have not done that, but I will.

For clarity... I am not saying that anyone that uses the SpeakOn or PowerCon for DC is doing anything wrong. I am simply sharing a paraphrased conversation with an expert re: my application and suitable DC power connectors made by Neutrik in general. It's DIY, we make informed decisions all the time to use products in applications for which they're not originally designed... I'm just not skilled enough to make an informed decision without a lot of help.

My decision is to use XLR or something else designed for my application.

If anyone wants to choose a Neutrik product suitable for a particular application, Fred said to please call or e-mail. He said to use his name directly. He was a delight to learn from.

Thanks to all for the encouragement in the thread and via PM / e-mail.

Last edited:

I would think the Amphenol Industrial connectors (maybe 97 series?) would be great for high current DC connections with umbilicals. We use them all the time in our railway electronics that I service. With our heavily used in-house test boxes, we normally build them without the locking collar on the cable end. They fit plenty snug without it... the locking collar is just a hassle for constant use. Just an idea..

^ Thank you!!! I'll look into those.

I debated posting a bit of a stronger recommendation re: the Neutrik products ... I hope this is appropriate.

My unfiltered thoughts are -

If anyone is uncertain about whether their existing Neutrik product is suitable... please call or e-mail them! Fred seemed genuinely concerned re: using these products for similar things to what I described as my application. He was VERY specific re: my application, and I've made my choice. If people absolutely know from their own expertise, that the product is okay for their application, I don't want to worry anyone. That's not my place, and it's definitely not my expertise. I am not here to second guess anyone's decisions. He might 🙂

However, I do think I'd be doing a disservice if I didn't mention the concern I heard (and asked for clarification around) in his voice. Maybe it's no big deal... I'm not trying to cry fire in a theater. I'm simply conveying a perceived concern. He was extremely nice to speak with, and the call was well worth my time.

tl;dr - If anyone has a concern or is wondering at all, please contact the experts directly. It won't take but a moment of your time.

I debated posting a bit of a stronger recommendation re: the Neutrik products ... I hope this is appropriate.

My unfiltered thoughts are -

If anyone is uncertain about whether their existing Neutrik product is suitable... please call or e-mail them! Fred seemed genuinely concerned re: using these products for similar things to what I described as my application. He was VERY specific re: my application, and I've made my choice. If people absolutely know from their own expertise, that the product is okay for their application, I don't want to worry anyone. That's not my place, and it's definitely not my expertise. I am not here to second guess anyone's decisions. He might 🙂

However, I do think I'd be doing a disservice if I didn't mention the concern I heard (and asked for clarification around) in his voice. Maybe it's no big deal... I'm not trying to cry fire in a theater. I'm simply conveying a perceived concern. He was extremely nice to speak with, and the call was well worth my time.

tl;dr - If anyone has a concern or is wondering at all, please contact the experts directly. It won't take but a moment of your time.

I was originally planning to use a 4 pin XLR for the power umbilical. I have since changed around my power supplies to be modular, but still internal to the amp. Will use RC connectors on the interior between the amp and the power supply.

^ I type a lot ... which can be problematic.

Buried up in my wall of text is that certain XLRs are absolutely suitable for up to 50V, 10A DC. That is confirmed both in the spec sheets and through Fred directly.

The products that (I think) it would be wise to contact Neutrik directly about if there are any questions are the PowerCon and SpeakOn.

I hope my post did not discourage you / make you change your mind re: the XLRs, if the ones you had already chosen were appropriate.

Buried up in my wall of text is that certain XLRs are absolutely suitable for up to 50V, 10A DC. That is confirmed both in the spec sheets and through Fred directly.

The products that (I think) it would be wise to contact Neutrik directly about if there are any questions are the PowerCon and SpeakOn.

I hope my post did not discourage you / make you change your mind re: the XLRs, if the ones you had already chosen were appropriate.

PL XS are equipped with Powercons, for heavy DC conduction

I know that Neutrik team specifies them only for AC, but another example where engineer/designer is choosing part according to gut feel and experience

I know that Neutrik team specifies them only for AC, but another example where engineer/designer is choosing part according to gut feel and experience

Great, great, great, nice to see more external PSUs being bornI've been doing more reading... thinking... guessing... and fooling around with things.

Re: the PSU layout itself; the pic attached should be roughly how it winds up.

I decided to go ahead with a 5U solution. It's not ideal, but I have the space in the rack.

That will allow me to (hopefully) do things more properly in terms of separating AC/DC lines etc. along with giving me enough space to mount the toroids vertically and mount the tall(ish) caps over the chokes.

That solution frees up enough floor space to easily include Mark's H9KPXG boards.

I still haven't reached out directly to Neutrik yet. I think I have a better idea of which way this is heading, so I may give them a ring later this week.

I believe I have a grasp on the articles provided above and how to implement the concepts contained within. I need to come up with a plan re: parts placement and wiring within the amp chassis for the local caps. I'll likely use standard cap bands and mount them to chassis floor along with point-to-point wiring. I also need to finalize the wiring scheme within the PSU chassis along with between and within the amp chassis.

Once I get a more detailed wiring diagram put together, I'll post it here for a critique / further ideas. All the help thus far is greatly appreciated!

Any further ideas re: layout (or anything else for that matter) are appreciated also.

Edited to add - One of the cap boards is backwards... (DC output facing the middle of the chassis vs. the back panel) but you get the idea.

Hi Everyone -

I just had a conversation with Fred at Neutrik. I learned a lot. First... I learned that the pronunciation is similar to Noy-trick not Nue-trik. I had it wrong for years. 🙂

More importantly, he said that he encourages anyone to call or e-mail with questions. He's in technical support at +1-704-972-3050. I asked permission, and he encouraged me to paraphrase his overall thoughts.

For my application (thank you, Ben!) which is up to 50VDC at up to 5A on the highest side; he said the only product that they have which is suitable are certain XLRs; rated at up to 50VDC at 10A. He said in plain terms to not use either the PowerCon nor the SpeakOn for DC applications at all. I asked him if he could please explain at a novice level for my specific application. I asked was it dangerous / what could go wrong etc.?

He took the time to explain to me why those products were not suitable for me. That is not to say that they aren't suitable for anyone else... he was very polite, but strong in his wording that he doesn't think it's a good idea to use those products for DC. He'd be happy to explain why to anyone for their particular application over a quick / direct inquiry.

He was even so kind as to recommend that I look into companies like Bulgin and Souriau for more appropriate connectors. I have not done that, but I will.

For clarity... I am not saying that anyone that uses the SpeakOn or PowerCon for DC is doing anything wrong. I am simply sharing a paraphrased conversation with an expert re: my application and suitable DC power connectors made by Neutrik in general. It's DIY, we make informed decisions all the time to use products in applications for which they're not originally designed... I'm just not skilled enough to make an informed decision without a lot of help.

My decision is to use XLR or something else designed for my application.

If anyone wants to choose a Neutrik product suitable for a particular application, Fred said to please call or e-mail. He said to use his name directly. He was a delight to learn from.

Thanks to all for the encouragement in the thread and via PM / e-mail.

Thank you for taking the time to reach out to Neutrik tech support and summarize the advice they gave.^ Thank you!!! I'll look into those.

I debated posting a bit of a stronger recommendation re: the Neutrik products ... I hope this is appropriate.

My unfiltered thoughts are -

If anyone is uncertain about whether their existing Neutrik product is suitable... please call or e-mail them! Fred seemed genuinely concerned re: using these products for similar things to what I described as my application. He was VERY specific re: my application, and I've made my choice. If people absolutely know from their own expertise, that the product is okay for their application, I don't want to worry anyone. That's not my place, and it's definitely not my expertise. I am not here to second guess anyone's decisions. He might 🙂

However, I do think I'd be doing a disservice if I didn't mention the concern I heard (and asked for clarification around) in his voice. Maybe it's no big deal... I'm not trying to cry fire in a theater. I'm simply conveying a perceived concern. He was extremely nice to speak with, and the call was well worth my time.

tl;dr - If anyone has a concern or is wondering at all, please contact the experts directly. It won't take but a moment of your time.

For myself, I think the strongest reason by far against using Speak-On or PowerCon for DC cords is the possibility of catastrophic results if they are used: connection of AC to Powercon; and connection of DC power to a speaker from the PS. This is esp the situation if the PS is passed on to another user or to a tech, or other scenario not contemplated. I always remember the adage: truth is stranger than fiction.

YMMV, I recognize. Each person makes their own risk analysis; one only hopes it is an informed one, which is why your post is so useful!

^ Thank you!

For newer people, like myself, or really anyone that doesn't have a really deep knowledge of the fundamentals, I think we're constantly wondering, "What matters?" re: a part selection.

We're very, very, very lucky to have experts in the field who lead by example and willingly share their knowledge. Many provide designs upon which to base our own creations or even go so far as to create full bills of materials and build guides for us. I loved a design so much, I wanted everyone else to have it too.

I'm sure... some of our resident experts get a bit frustrated with the consistent questions re: part substitutions. Moreover, they probably don't like repeating over and over why they chose this part instead of some other one. Many of us try our level best to build up a set of fundamentals. However, while I'm a bit of a risk-taker ... and I have trust and faith in quite a number of people in this community... when I see something being used in a capacity that a spec sheet specifically says... don't do that... or not rated for that... I like to try and learn. What's important about that application? What parameters? The gentleman today took the time to explain his POV very clearly to me re: my specific application and his recommendations around it. He told me why. He didn't brush me off and tell me to read the spec sheets. He knew I was a novice DIYer that likely wasn't going to purchase more than a few pieces of anything anyway. It was greatly appreciated, and it affected my decision making.

I didn't call them for a lack of trust in those that have led by example here and even potentially used things in commercial designs. I trust quite a number of people around here with my safety and that of my loved ones through following their designs. I know that they know far more than I. However, I don't have insight into how they made their decision to use that product in that specific application. Asking them without doing some of my own homework first seems dismissive of their work.

This community is filled with brilliant people that can look at something in an instant and know its suitability for a task... I ain't there yet. 🙂

As I said earlier, this is DIY. People with knowledge use all kinds of things in their designs that may not have been originally intended for that use. I think I used the example of using the big Tokin VFETs originally designed for industrial applications (I think) in audio as an example. What a cool "discovery". In my own professional life, I've repurposed many pieces of machinery for uses they were never originally intended. I then worked with those manufacturers ... they got more business from my innovation and advertised their products (and in some cases modified them) to work with my solutions. Win-win.

Building a separate PSU, however basic, is a new challenge for me. I'm trying to learn as much as practical about choices in its design. I'm certainly not doing anything "new", but it's new to me. It's a ton of fun too.

Again... I type a lot... back to our regularly scheduled programming.

For newer people, like myself, or really anyone that doesn't have a really deep knowledge of the fundamentals, I think we're constantly wondering, "What matters?" re: a part selection.

We're very, very, very lucky to have experts in the field who lead by example and willingly share their knowledge. Many provide designs upon which to base our own creations or even go so far as to create full bills of materials and build guides for us. I loved a design so much, I wanted everyone else to have it too.

I'm sure... some of our resident experts get a bit frustrated with the consistent questions re: part substitutions. Moreover, they probably don't like repeating over and over why they chose this part instead of some other one. Many of us try our level best to build up a set of fundamentals. However, while I'm a bit of a risk-taker ... and I have trust and faith in quite a number of people in this community... when I see something being used in a capacity that a spec sheet specifically says... don't do that... or not rated for that... I like to try and learn. What's important about that application? What parameters? The gentleman today took the time to explain his POV very clearly to me re: my specific application and his recommendations around it. He told me why. He didn't brush me off and tell me to read the spec sheets. He knew I was a novice DIYer that likely wasn't going to purchase more than a few pieces of anything anyway. It was greatly appreciated, and it affected my decision making.

I didn't call them for a lack of trust in those that have led by example here and even potentially used things in commercial designs. I trust quite a number of people around here with my safety and that of my loved ones through following their designs. I know that they know far more than I. However, I don't have insight into how they made their decision to use that product in that specific application. Asking them without doing some of my own homework first seems dismissive of their work.

This community is filled with brilliant people that can look at something in an instant and know its suitability for a task... I ain't there yet. 🙂

As I said earlier, this is DIY. People with knowledge use all kinds of things in their designs that may not have been originally intended for that use. I think I used the example of using the big Tokin VFETs originally designed for industrial applications (I think) in audio as an example. What a cool "discovery". In my own professional life, I've repurposed many pieces of machinery for uses they were never originally intended. I then worked with those manufacturers ... they got more business from my innovation and advertised their products (and in some cases modified them) to work with my solutions. Win-win.

Building a separate PSU, however basic, is a new challenge for me. I'm trying to learn as much as practical about choices in its design. I'm certainly not doing anything "new", but it's new to me. It's a ton of fun too.

Again... I type a lot... back to our regularly scheduled programming.

I could not agree with you more. I second a general thank you to all who share knowledge and well thought out advice.

^ I type a lot ... which can be problematic.

Buried up in my wall of text is that certain XLRs are absolutely suitable for up to 50V, 10A DC. That is confirmed both in the spec sheets and through Fred directly.

The products that (I think) it would be wise to contact Neutrik directly about if there are any questions are the PowerCon and SpeakOn.

I hope my post did not discourage you / make you change your mind re: the XLRs, if the ones you had already chosen were appropriate.

I made the change a few months ago. So you didn't have anything to do with it. I am reusing the 4 pin XLRs for my Salas UFSP preamp for an outboard power supply. I'm sure I will reuse my other pair of them also at some point. My amps also use speakons and powercons, so I didn't want to use any of those connectors for the outboard DC connection. Ultimately I decided it was simpler to not have to be concerned with adding caps to the amp box. I am building tall and narrow amp boxes. 350mm tall x 300mm deep x 230 mm wide. Power supply is mounted to a baseplate at the bottom of the amp and heat sinks are at the top. Building Monoblocks. Still will be a while until I complete it.

I think I have one last 'important' decision to make before this all comes together.

Wait for it...

Rectification... and Snubbers

I thought I had finalized my choice. I did some further reading, a few segments copied below. I'm copying directly because I don't want to misquote. More importantly, my interpretation may be WAY off, I want to point toward the exact references. I also got some advice through a few PMs. I've also been encouraged to post more into the open forum, so we all can learn... here goes.

I have read Rod Elliott's excellent "Linear Power Supply Design" in full. From section 9, Rectifier Diodes, my takeaway was in essence... use decent monolithic bridge rectifiers and mount them to the chassis. He makes some very compelling arguments re: longevity and important specs. Peak Inverse Voltage in the range of parts I'm considering doesn't seem to be an issue. I've carefully considered rated current. However, he also mentions "speed". Rather than copy the entire section (linked below), here was one segment I found particularly interesting.

https://sound-au.com/power-supplies.htm#s9

Then... there is this lone tidbit... from Elliott's work.

I will be using a chokes as part of the filtering...

First, am I interpreting the massive intake of information properly? I'm sure there are finer details to consider, but this is my takeaway.

"Fast" rectifiers, while not generally necessary for technical purposes in most cases can't really hurt.

However, in my specific case, fast rectifiers are recommended.

Second...

Input vs. output 'snubbing'. I've read about snubbing for the rectifier and snubbing for the transformers. I've also read about snubbing for ringing in the chokes. The most common thing around the threads is using the 'Quasimodo' or similar for determining proper snubbing for transformer ringing. I've read Mark's excellent accompanying information for the Quasimodo a few times. The device itself is easy enough to use. Look to the Swap Meet for all my extras soon. With that said, I still don't fully 'get it', but I don't have to ... Those are solved for.

The ringing for the chokes (in my specific situation) seems to be a non-issue because of the series resistance of the choke itself ... I think... accompanied by the further resistance in the R of the following CRC along with the ESR of the caps ... I think...

So... what's the measure for knowing if you need to snub for the rectifiers? That's a total mystery? Should I just not worry about it?

And last... how fast is fast ... and what is "soft or hard recovery?" Does recovery matter?

I believe that these are appropriate for use... thoughts are sincerely appreciated.

I used these (just on a recommendation) in all my First Watt PSUs https://www.vishay.com/docs/88597/fep30xp-e3.pdf

These also came strongly recommended

https://www.mouser.com/ProductDetail/Vishay-Semiconductors/VS-C5PH6006LHN3?qs=vvQtp7zwQdPElCARV8/c6A==

If I wanted monolithic for form factor or chassis mounting for Elliott's recommendations ... I have not found a product marketed specifically as "fast" that fits the bill.

Those that are willing to read through a wall of text and provide comments and thoughts have my gratitude.

Edited to add - I got most of the information re: my thoughts on ringing from the chokes from this thread. https://www.diyaudio.com/community/threads/clc-vs-crc.337738/

Wait for it...

Rectification... and Snubbers

I thought I had finalized my choice. I did some further reading, a few segments copied below. I'm copying directly because I don't want to misquote. More importantly, my interpretation may be WAY off, I want to point toward the exact references. I also got some advice through a few PMs. I've also been encouraged to post more into the open forum, so we all can learn... here goes.

I have read Rod Elliott's excellent "Linear Power Supply Design" in full. From section 9, Rectifier Diodes, my takeaway was in essence... use decent monolithic bridge rectifiers and mount them to the chassis. He makes some very compelling arguments re: longevity and important specs. Peak Inverse Voltage in the range of parts I'm considering doesn't seem to be an issue. I've carefully considered rated current. However, he also mentions "speed". Rather than copy the entire section (linked below), here was one segment I found particularly interesting.

https://sound-au.com/power-supplies.htm#s9

At 50 or 60Hz, and with a sinewave input, the slowest diodes in the universe are still faster than they need to be. Despite this, high speed diodes actually do cause less 'disturbance' at the transformer's secondary. Not that it makes the slightest difference to the DC. Nelson Pass suggests that even the standard diodes should be slowed down with paralleled capacitors [2]. This might help, as it reduces the radiated and conducted harmonics from the diode switching. These switching harmonics can extend to several MHz, even with the normal 50/60Hz mains.

Typically, capacitors between 10 and 100nF (optionally with a small series resistance) are wired in parallel with each diode in the bridge, and this is quite common with some high end equipment and test gear where minimum radiated noise is essential. Some constructors like to add snubbers (a series resistor and capacitor) in parallel with the transformer secondaries.

Some reading from Self's book seems to generally concur.Then... there is this lone tidbit... from Elliott's work.

There is one application where fast diodes are definitely recommended, and that's for 'choke input' filters, where the diodes feed rectified AC to the filter cap(s) via an inductor. These are not covered here because they are extremely uncommon in modern equipment, although a superficially similar arrangement is often used in regulated switchmode power supplies.

I will be using a chokes as part of the filtering...

First, am I interpreting the massive intake of information properly? I'm sure there are finer details to consider, but this is my takeaway.

"Fast" rectifiers, while not generally necessary for technical purposes in most cases can't really hurt.

However, in my specific case, fast rectifiers are recommended.

Second...

Input vs. output 'snubbing'. I've read about snubbing for the rectifier and snubbing for the transformers. I've also read about snubbing for ringing in the chokes. The most common thing around the threads is using the 'Quasimodo' or similar for determining proper snubbing for transformer ringing. I've read Mark's excellent accompanying information for the Quasimodo a few times. The device itself is easy enough to use. Look to the Swap Meet for all my extras soon. With that said, I still don't fully 'get it', but I don't have to ... Those are solved for.

The ringing for the chokes (in my specific situation) seems to be a non-issue because of the series resistance of the choke itself ... I think... accompanied by the further resistance in the R of the following CRC along with the ESR of the caps ... I think...

So... what's the measure for knowing if you need to snub for the rectifiers? That's a total mystery? Should I just not worry about it?

And last... how fast is fast ... and what is "soft or hard recovery?" Does recovery matter?

I believe that these are appropriate for use... thoughts are sincerely appreciated.

I used these (just on a recommendation) in all my First Watt PSUs https://www.vishay.com/docs/88597/fep30xp-e3.pdf

These also came strongly recommended

https://www.mouser.com/ProductDetail/Vishay-Semiconductors/VS-C5PH6006LHN3?qs=vvQtp7zwQdPElCARV8/c6A==

If I wanted monolithic for form factor or chassis mounting for Elliott's recommendations ... I have not found a product marketed specifically as "fast" that fits the bill.

Those that are willing to read through a wall of text and provide comments and thoughts have my gratitude.

Edited to add - I got most of the information re: my thoughts on ringing from the chokes from this thread. https://www.diyaudio.com/community/threads/clc-vs-crc.337738/

Last edited:

- Home

- Amplifiers

- Pass Labs

- Universal Outboard Power Chassis for Pass