Looking for a replacement option in my Hitachi HMA-6500 amp and not able to get specs of the relay on the web. The relay is made by Fujitsu, FRL-264 and D024/04AL -01 are the numbers on the relay.

Omron/TE connectivity and few other vendors seems to have some options on Mouser and Digi key but I cannot figure which one will be a good option and some guidance will be greatly appreciated.

Omron/TE connectivity and few other vendors seems to have some options on Mouser and Digi key but I cannot figure which one will be a good option and some guidance will be greatly appreciated.

Attachments

RY1 is a 4 pole single throw relay with a 24V DC coil.

As such, a generic part.

And a 2 pole relay can also be used, as it is 2 poles in parallel.

Find the contact ratings, and the PCB pin spacing.

Omron, Fujitsu, Matsushita, O/E/N, and many others make good relays, find one that is easy to obtain, there are stupid shortages everywhere.

As such, a generic part.

And a 2 pole relay can also be used, as it is 2 poles in parallel.

Find the contact ratings, and the PCB pin spacing.

Omron, Fujitsu, Matsushita, O/E/N, and many others make good relays, find one that is easy to obtain, there are stupid shortages everywhere.

Hi, the bottom of Omron MY4 ( and many similar relays too ) there are flat contacts which do not allow to mount it on a pcb. Any suggestions what to do ?

There exist sockets for that, and a PCB version of the relay should be available.

See Post#3 above as a guide.

Also, some sellers make a bolt on version, it is bolted to the chassis, and wires used to handle the various signal needs.

See Post#3 above as a guide.

Also, some sellers make a bolt on version, it is bolted to the chassis, and wires used to handle the various signal needs.

If you have the Omron MY4 with flat contacts, use the PY14-02 socket for PCB mount.Hi, the bottom of Omron MY4 ( and many similar relays too ) there are flat contacts which do not allow to mount it on a pcb. Any suggestions what to do ?

Last edited:

Of course the Omron is not a good relay for that purpose with only 3A rated contacts. Contacts in parallel is wrong practice too as they will never be making contact 100% at the same time. In practice the too lightly rated contacts will have pitting effects. My advice if you like 1 time solutions: use a 8 or 10A rated 24V 2 pole relay with hard silver bifurcated contacts of a reputable brand on an adapter PCB. Or use the new relay upside down with wires. Avoid sockets as they are yet another fault possibility. You can use a 2 pole relay and have less power lost to the relay at the same time. Overcome the resistance against the wrong format of the new relay: you won't find a suitable replacement in the old format that will last. The failure mode your amplifier has is THE failure mode of older Japanese amplifiers as very often exactly the wrong relays were chosen.

Pitiful as it is: older but unused A branded relays are of higher quality than what can be found on todays market (made in China).

Extra tip: the HMA-6500 will sound nicer with a good quality (MKS) film cap 1 µF in 5 mm pitch for C701. If you use it with "condenser coupling" input that is 🙂 I think I also replaced all 10 µF electrolytic caps for 10 µF film caps.

Pitiful as it is: older but unused A branded relays are of higher quality than what can be found on todays market (made in China).

Extra tip: the HMA-6500 will sound nicer with a good quality (MKS) film cap 1 µF in 5 mm pitch for C701. If you use it with "condenser coupling" input that is 🙂 I think I also replaced all 10 µF electrolytic caps for 10 µF film caps.

Last edited:

An electrical contactor with 16A rating, and suitable coil voltage will be an option as well, if chassis mounting can be done.

The Fujitsu, FRL-264 D024/04AL is 3A rated, the Omron MY4-02-DC24 is a drop in replacement with no modification required.

If replace with other relay, please make sure the coil resistance is compatible.

BTW, the Hitachi HMA-6500 is at least 40 years old!🤔

If replace with other relay, please make sure the coil resistance is compatible.

BTW, the Hitachi HMA-6500 is at least 40 years old!🤔

Last edited:

Yes please don't think "original" means best choice by design. Japanese amplifiers of that era (regardless of brand) very often have the same fault as apparently the otherwise competent Japanese designers had the same education or something like that. A drop in replacement with the same properties is again a non optimal choice, it wil be error by choice. It is surprising how high the threshold for this error is with the average consumer. Contacts may be unreliable or high ohmic for years, only when channels really stop playing the error is acknowledged 😀

Long ago I worked at a Japanese audio brand and wrongly chosen and therefor faulty relays were already then known as a series error. Use kaizen (改善)! Make it better.

Long ago I worked at a Japanese audio brand and wrongly chosen and therefor faulty relays were already then known as a series error. Use kaizen (改善)! Make it better.

Last edited:

There exist relays with higher rating in exactly the same package, and the price difference is negligible.

Among the reasons I use locally made O/E/N relays is that there are no fakes, the Chinese ones are much cheaper, but erratic in quality.

By the way, they are really world class, I do get Omron, Panasonic and others here, but I have opened O/E/N to look at the contacts, they have big hard contacts which resist pitting for a long time.

I mean paying $50 to replace a $10 relay, and the hassle of taking the set back and forth from repair...is kind of foolish...better put the highest rated one first time .

Among the reasons I use locally made O/E/N relays is that there are no fakes, the Chinese ones are much cheaper, but erratic in quality.

By the way, they are really world class, I do get Omron, Panasonic and others here, but I have opened O/E/N to look at the contacts, they have big hard contacts which resist pitting for a long time.

I mean paying $50 to replace a $10 relay, and the hassle of taking the set back and forth from repair...is kind of foolish...better put the highest rated one first time .

Why not tell us the make and model of such relays instead? I think it will provide much better help.There exist relays with higher rating in exactly the same package, and the price difference is negligible.

OP is a USA forum member, any relay you can recommend?Among the reasons I use locally made O/E/N relays is that there are no fakes, the Chinese ones are much cheaper, but erratic in quality.

What relay cost $50? How often you think he need to replacing the relay?I mean paying $50 to replace a $10 relay, and the hassle of taking the set back and forth from repair...is kind of foolish...

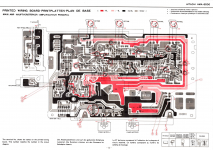

These in exactly this version. Install and forget. Practically never fail in this application. 改善

Attachments

Last edited:

See Post #2, I said it is a generic part, gave some names.

$50 will be the amount paid to a technician to replace the relay, if the owner is unable to do so.

$10 will be the highest part cost, IMO, the cost here in India will be much less.

Let the OP do some work, it is his decision to take or ignore our well meant advice.

Then comes the issue of choosing make and model depending on local availability, and sometimes a person may get a good deal on a combined order from a parts selling firm.

Those are things we do not know about, so let the purchaser decide.

I had to replace only 2 relays in my injection molding machine, in 25 years, they were in 2 temperature controllers, controlling heater contactors.

Life went up drastically after putting MOVs across their contacts, the failures were in the first 5 years or so. I still have a spare or 2 lying in storage, 28 V coils.

The original and replacements are all O/E/N, almost double the price of the branded local made competitors.

I think speaker relay failure is rarely caused by short circuits, it is usually the contact rating and number of operation cycles that cause the failure.

Replacement means a risk of PCB damage, and so on, so it is better practice to put a higher rated relay, as Jean-Paul says above.

He has said elsewhere that he is a former Akai tech, so please pay attention to his hard earned practical advice.

$50 will be the amount paid to a technician to replace the relay, if the owner is unable to do so.

$10 will be the highest part cost, IMO, the cost here in India will be much less.

Let the OP do some work, it is his decision to take or ignore our well meant advice.

Then comes the issue of choosing make and model depending on local availability, and sometimes a person may get a good deal on a combined order from a parts selling firm.

Those are things we do not know about, so let the purchaser decide.

I had to replace only 2 relays in my injection molding machine, in 25 years, they were in 2 temperature controllers, controlling heater contactors.

Life went up drastically after putting MOVs across their contacts, the failures were in the first 5 years or so. I still have a spare or 2 lying in storage, 28 V coils.

The original and replacements are all O/E/N, almost double the price of the branded local made competitors.

I think speaker relay failure is rarely caused by short circuits, it is usually the contact rating and number of operation cycles that cause the failure.

Replacement means a risk of PCB damage, and so on, so it is better practice to put a higher rated relay, as Jean-Paul says above.

He has said elsewhere that he is a former Akai tech, so please pay attention to his hard earned practical advice.

In my own words: that does not say a thing about competence so take my words like anyone elses. With a grain of salt that is. Always be critical.

It helps to keep volume low when switching on amplifiers.

It helps to keep volume low when switching on amplifiers.

Last edited:

Look at the prices of hermetically sealed mil grade relays with gold plated contacts, those are very expensive.

Or similar relays with exotic contact materials which are intended to be fail safe.

Or similar relays with exotic contact materials which are intended to be fail safe.

I know...

Which is why I mentioned that hard metal contacts of best size are durable.

Some cheap relays have tiny contacts of brass (!), and some good ones use large tungsten alloy tips....

Gold is occasionally used , simply because in some applications the cause of failure can be corrosion in a harsh environment.

In a home audio setting, that is not relevant.

Which is why I mentioned that hard metal contacts of best size are durable.

Some cheap relays have tiny contacts of brass (!), and some good ones use large tungsten alloy tips....

Gold is occasionally used , simply because in some applications the cause of failure can be corrosion in a harsh environment.

In a home audio setting, that is not relevant.

Yes it is.

- Gold (plating) is for signal/voltage. In audio input selection, output muting of sources etc.

- Silver (alloys) are for current. In audio speaker/power on-off protection.

Of course it is needless to say one should use fully sealed relays in audio. Always, regardless of what type the manufacturer had chosen to use. Moist, dust and other debri are enemies of good equipment.

- Gold (plating) is for signal/voltage. In audio input selection, output muting of sources etc.

- Silver (alloys) are for current. In audio speaker/power on-off protection.

Of course it is needless to say one should use fully sealed relays in audio. Always, regardless of what type the manufacturer had chosen to use. Moist, dust and other debri are enemies of good equipment.

Last edited:

- Home

- Design & Build

- Parts

- Speaker protection relay Fujistu replacement FRL-264 options