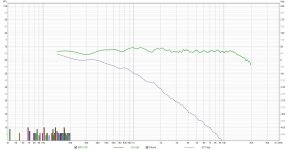

Just updating this old thread. I was completely disappointed with the performance Audex drivers so I gave up on this project and gave the drivers away. I decided to explore in a new direction for me. I've always used ribbon or AMT tweeters with metal woofers in mostly 3 way designs. For a complete change up I decided to design a 2 way with a fabric dome tweeter and a paper woofer. I understand this is a very common approach, but new to me. I will be creating a new thread in the near future but here a a sneak preview. A gated frequency response measurement and a photo of the completed speakers with the grills off.

I'm planning to use up some drivers I have to design a 3 way to give as a gift. I'm trying not to buy too many more drivers because I have too many now. Here is what I have to work with.

2 Audax HM170Z0 aurogel 6.5 inch mid-woofer. 8 ohm 91 db

2 Audax HM130Z0 aurogel 5.25 inch mid. 8 ohm 92 db

2 Audax HM100X2 poly 4 inch mid. 8 ohm 94 db

I think the 6.5 and the 4 inch would be best, but one of the 4 inch mids has a 1 inch crack in the cone and I don't see a way to fix it. I'm concerned the 5.25 inch mid is too big to pair with the 6.5 inch mid woofer. These seem to be high quality drivers and are from the same product line. I also have some poly cell drivers from some scraped Infinity RS8B that I might try. Ultimately I might have to buy a pair of mids and tweeters and use the 5.25 an the poly cell for some two ways.

I'm planning to use up some drivers I have to design a 3 way to give as a gift. I'm trying not to buy too many more drivers because I have too many now. Here is what I have to work with.

2 Audax HM170Z0 aurogel 6.5 inch mid-woofer. 8 ohm 91 db

2 Audax HM130Z0 aurogel 5.25 inch mid. 8 ohm 92 db

2 Audax HM100X2 poly 4 inch mid. 8 ohm 94 db

I think the 6.5 and the 4 inch would be best, but one of the 4 inch mids has a 1 inch crack in the cone and I don't see a way to fix it. I'm concerned the 5.25 inch mid is too big to pair with the 6.5 inch mid woofer. These seem to be high quality drivers and are from the same product line. I also have some poly cell drivers from some scraped Infinity RS8B that I might try. Ultimately I might have to buy a pair of mids and tweeters and use the 5.25 an the poly cell for some two ways.

Attachments

Last edited:

The HM130zo is a midrange not a woofer. good candidate for a 3 ways.

With the HM 17 you can make the two ways though.

With the HM 17 you can make the two ways though.

There is one good reason, I like three ways. Yes, I may just use the 6.5 in a two way, it just isn't much of a challenge.There's no good reason not to do a 2 way system with that 6.5 inch mid-bass driver coupled with a nice 1 inch silk dome.

I might just use the HM130Z0, I made my first draft of the baffle. It is 13 inch by 19 inch with a 1.5 inch chamfer all the way around. I'm thinking of using an SB29SDAC tweeter unless someone else can suggest something better. As to fixing the crack on the HM100X2, I will pass, but if anyone wants to try I will give them the pair for free.

Attachments

For reference, check this demo project made in VituixCad2 by Kimmo Saunisto.

It's a 3-way with a HM170Z18, a 4" Vifa M10MD and a Peerless D27 tweeter.

https://kimmosaunisto.net/Software/VituixCAD/Epe-3W_demo.zip

It's a 3-way with a HM170Z18, a 4" Vifa M10MD and a Peerless D27 tweeter.

https://kimmosaunisto.net/Software/VituixCAD/Epe-3W_demo.zip

for inspiration-

try Google Translate

https://translate.google.com/

http://www.madisound.com/pdf/audaxcatalog.pdf

under Projects, DoppelWhopper

http://web.archive.org/web/20040804113015fw_/http://www.picosound.de/E_index.htm

-Audax projects but none of the OP exact drivers:

HM170Z18 (?)

http://web.archive.org/web/20090516031325/http://www.diyaudio.gr/oldnimiel.htm

http://web.archive.org/web/20090516040148/http://www.diyaudio.gr/oldmylo.htm

HM170G0

http://ekingsbu.users4.50megs.com/blurb3.html

France DIY Speakers

http://enceinte.diy.pagesperso-orange.fr/realisations/realisation.htm

try Google Translate

https://translate.google.com/

http://www.madisound.com/pdf/audaxcatalog.pdf

under Projects, DoppelWhopper

http://web.archive.org/web/20040804113015fw_/http://www.picosound.de/E_index.htm

-Audax projects but none of the OP exact drivers:

HM170Z18 (?)

http://web.archive.org/web/20090516031325/http://www.diyaudio.gr/oldnimiel.htm

http://web.archive.org/web/20090516040148/http://www.diyaudio.gr/oldmylo.htm

HM170G0

http://ekingsbu.users4.50megs.com/blurb3.html

France DIY Speakers

http://enceinte.diy.pagesperso-orange.fr/realisations/realisation.htm

Last edited:

I looked over your v2 version, here is what I have so far, how close did I get?For reference, check this demo project made in VituixCad2 by Kimmo Saunisto.

It's a 3-way with a HM170Z18, a 4" Vifa M10MD and a Peerless D27 tweeter.

https://kimmosaunisto.net/Software/VituixCAD/Epe-3W_demo.zip

Woofer crossed at 575 Hz with a low pass LR2

Mid crossed at 500 Hz with a high pass LR2, 2800 Hz low pass BW3 plus a series notch at 1800 with a Q = 1.75

Tweeter at 2600 with a high pass BW3

These are the acoustic slopes, not the electrical slopes. What you did with the mid is interesting. You added the series notch to flatten out the frequency response between 1KHz and 2.5Khz which don't show on the raw driver. I suspect the cause is the high pass and low pass components are two close in frequency causing the resonance that the notch is fixing. I would cross the woofer to mid lower, closer to 300 Hz and cross mid to tweeter higher. The books say to make the high pass 8 to 10 times higher than the low pass. I prefer 10 times to keep the two filters from interfering with each other. Thanks for the help.

That is a project by Kimmo - the creator of VituixCad - I'm not that good.

According to the Audax datasheet the hm130z0 has Fs 68Hz so it's possible to cross it a bit lower than 500Hz. The FR is very nice from 150 to 4000Hz.

According to the Audax datasheet the hm130z0 has Fs 68Hz so it's possible to cross it a bit lower than 500Hz. The FR is very nice from 150 to 4000Hz.

Here is a picture of the test cabinet and a real rough frequency response from a simulated crossover. Just to see if it has any chance of working, I made some on axis measurements in my 10' by 10' office. The room clearly dominates the measurements so I used ERB smoothing. Next step will be using a DSP to simulate a crossover and give it a listen, if it seems OK I will then drag everything outside for some better measurements.

Attachments

I'm trying the offset tweeter in an attempt to smooth out the edge diffraction. It was an an old-school method, Once I moved the tweeter towards one edge I decided what the hell, offset the mid. I may abandon this approach when I make the real enclosures. In line will be easier to build, the offset mid's internal enclosure will be simpler to build. I have the power amp and DSP connected, just need to configure the DSP.

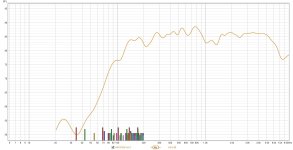

Looks like I'm going to give up all together or just make a two way. The HM130Z0 is the problem. It has a huge dip in response (5db) between 800 and 1600 hz. At first I thought was the quick measurements I made, but yesterday I brought the test cabinet outside and it was still there. Maybe it is from sitting around for 30 years? Here is what I'm talking about.

Attachments

- Home

- Loudspeakers

- Multi-Way

- Opinions on a potential 3 way using some older drivers