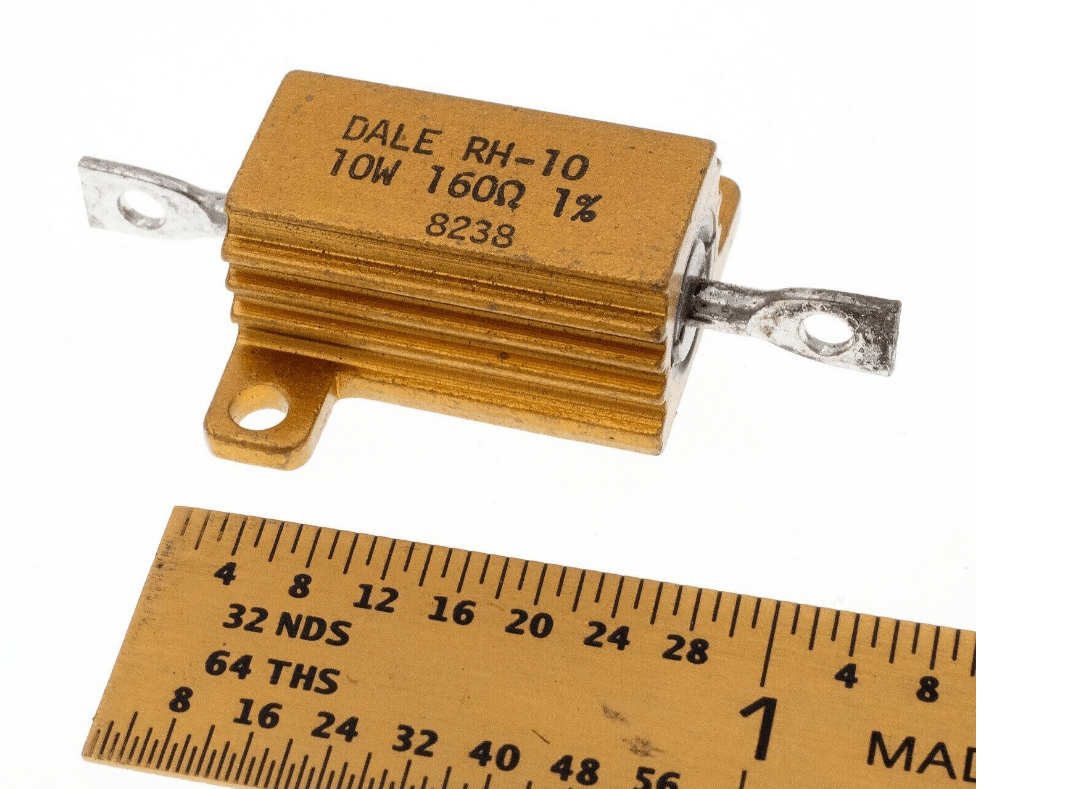

If R1 is going to get extremely hot when running due to the increase, I could chassis-mount something like this:

Do you have explicit instructions that the transformer should be measured unloaded and compared with those nominal figures you quoted earlier? If the transformer is 'specified' to be 275VAC then that is the voltage under load. The loaded voltage is normally around 10% under the unloaded voltage, so that puts your readings in the ballpark.

The only outlier is that 6.3VAC winding that reads 9.6V. Could you have actually read 6.9VAC and transcribed incorrectly?

Heater voltages are potentially more important than B+ voltages since that is a key driver for the life of the tube, and also can have an impact on the characteristics of the tube if it is more than 10% incorrect either way.

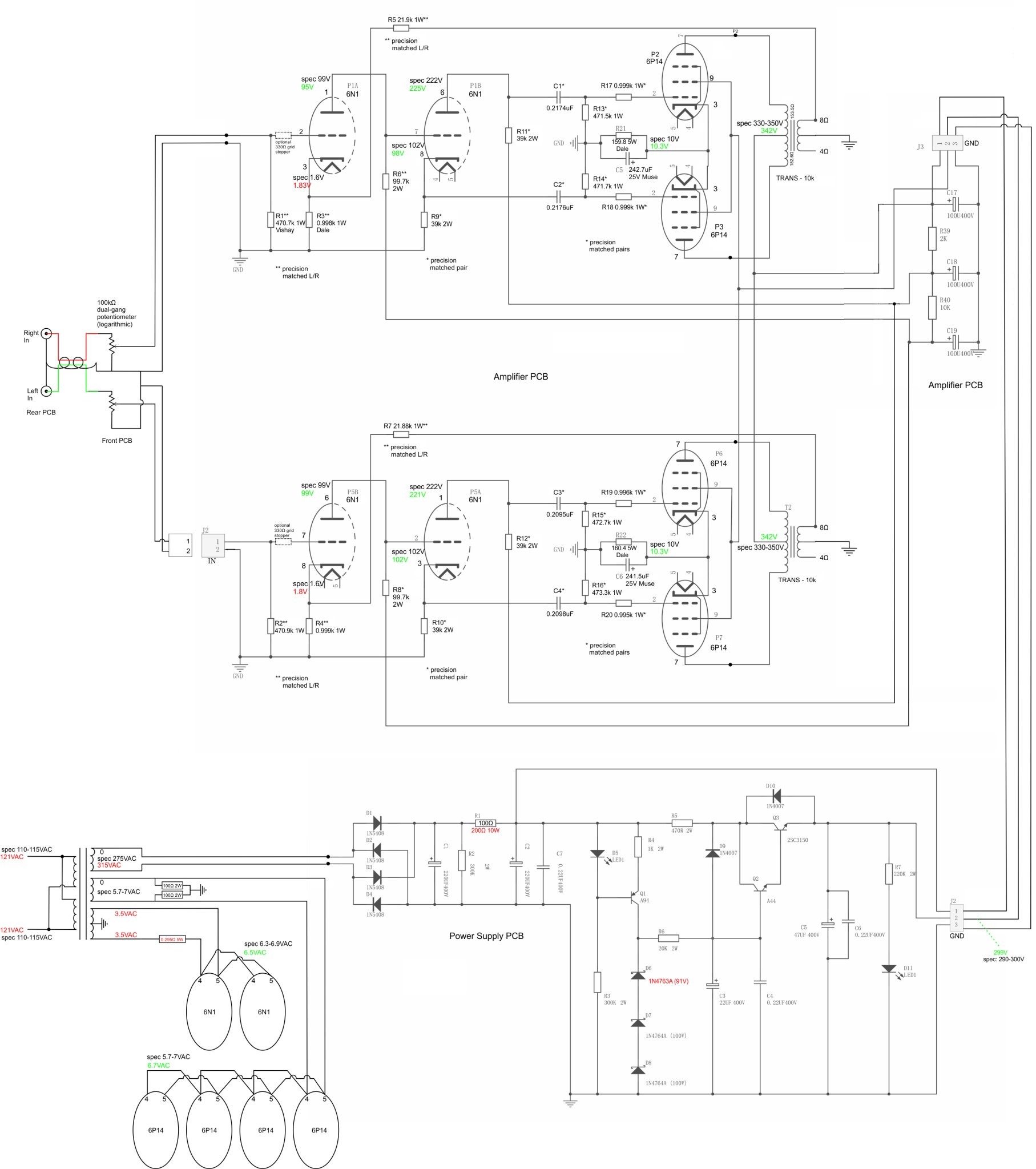

AIUI the main concern is the regulated screen voltage, and 300VDC is the hard limit? Since the screen supply is a low current supply it should be fairly easy to juggle with zeners and maybe a resistor to hit the sweet spot there. Perhaps it is possible to find a way to temporaily rig a supply for a lower voltage for the screens using a resistor divider across the OPT just so you can start up the amp and get some real data to make decisions. It does not need to play music, just be stable while you gather voltage readings.

The only outlier is that 6.3VAC winding that reads 9.6V. Could you have actually read 6.9VAC and transcribed incorrectly?

Heater voltages are potentially more important than B+ voltages since that is a key driver for the life of the tube, and also can have an impact on the characteristics of the tube if it is more than 10% incorrect either way.

AIUI the main concern is the regulated screen voltage, and 300VDC is the hard limit? Since the screen supply is a low current supply it should be fairly easy to juggle with zeners and maybe a resistor to hit the sweet spot there. Perhaps it is possible to find a way to temporaily rig a supply for a lower voltage for the screens using a resistor divider across the OPT just so you can start up the amp and get some real data to make decisions. It does not need to play music, just be stable while you gather voltage readings.

Last edited:

Do you have explicit instructions that the transformer should be measured unloaded and compared with those nominal figures you quoted earlier?

1. Test whether the working voltage of the power board is normal. After installing the components, measure the no-load

voltage of the power board. Under normal circumstances, the v+ no-load load voltage is 1.4 times that before rectification, and

the voltage is about 380V.

Just to make sure I'm not losing my mind, I tested it again just now. Today I get 408V.

The only outlier is that 6.3VAC winding that reads 9.6V. Could you have actually read 6.9VAC and transcribed incorrectly?

It is 6.9VAC ... typo. Oops! 😳

... concern is the regulated screen voltage, and 300VDC is the hard limit?

3. Regulated high voltage test

Grid high voltage regulator: the requirement is 300V, and the recommended voltage is 290V - 305V. The power tube in this voltage range will last longer.

Please note: when testing, high voltage power supply board not to be connected to the main amplifier board. Only after the power is normal, then connect.

After seeing at least two people comment online that the regulation absolutely is not necessary, I did some research to find out why they went to the trouble to do it. It turns out that the Chinese 6P14 can not handle anything over 300 volts on the screen without quickly self-destructing. I found this out by translating a whole bunch of comments from Chinese to English discussing the tube and its limitations. As quoted above from the instructions, the absolute maximum is 305V, and based on what I read, even that is not ideal. Just below 300V is ideal. The Russian 6P14P or the EL84 might be more forgiving. I don't know. I'd rather get it correct per the specifications before proceeding regardless of what tubes I ultimately put in it. The Chinese 6P14 tubes came with it, and I'd prefer not to change the four of them right away.

So I tested it again today, and I get 314V, up a little from my last test.

BTW, the building process is on hold as I wait for the world's slowest ebay seller to ship me more solder. What an inconvenient time to run out. I also am waiting on speaker binding posts and input jacks shipped from China that are moving at a snail's pace.

Last edited:

So I tested it again today, and I get 314V, up a little from my last test.

1) And I get 315V today. I guess I'll try swapping one of the 100V zener diodes for the "optional" 91V zener diode included in the kit. In his YouTube video of this amplifier, Xraytonyb said something about the zener diodes establishing a reference voltage for the regulated supply. I am assuming that dropping that reference voltage with the 91V zener diode drops the regulated voltage output. If so, it makes sense why it's in the kit.

2) How much effect does the draw on one secondary winding have on the other secondary windings? In other words, when all of the tubes are in place and the amplifier is powered on, how much will the big draw on the 275V secondary affect the voltages of the 6.3V filament outputs?

I put a test load on the winding for the 6N1 filaments and got 6.77V. Spec for the 6N1 tube is 6.3V (6.3 min - 6.9V max), so at least that appears that it will be in range.

The 6.9V output I measured for the 6P14 filaments without a load is already in range. Spec for the 6P14 is 6.3V (5.7 min - 7V max) so I am hoping that will turn out fine under load.

Last edited:

China glass 91V zener diode plus a little pressure = shattered diode. Sigh. 🤕 It had very, very, very stiff leads on it. Very hard to bend. The other Zeners were not glass and had much softer leads. Not sure why this one was so very different.

I put a test load on the transformer winding for the 6N1 filaments, and I got 6.77V. Spec for the 6N1 tube is 6.3V (6.3 min - 6.9V max), so at least that appears that it will be in range.

With a test load on the transformer winding for the 6P14 filaments, I got 6.8V. Spec for the 6P14 is 6.3V (5.7 min - 7V max) so 6.8V appears that it will be in range.

I read that a little too high is better than a little too low when it comes to filament voltage and tube life. Not sure if it's true, but found it multiple places.

200 ohm 10 watt resistor on order to replace the 100 ohm R1 (if needed).

So, progress today, but also a setback with the shattered diode.

I put a test load on the transformer winding for the 6N1 filaments, and I got 6.77V. Spec for the 6N1 tube is 6.3V (6.3 min - 6.9V max), so at least that appears that it will be in range.

With a test load on the transformer winding for the 6P14 filaments, I got 6.8V. Spec for the 6P14 is 6.3V (5.7 min - 7V max) so 6.8V appears that it will be in range.

I read that a little too high is better than a little too low when it comes to filament voltage and tube life. Not sure if it's true, but found it multiple places.

200 ohm 10 watt resistor on order to replace the 100 ohm R1 (if needed).

So, progress today, but also a setback with the shattered diode.

Last edited:

Based on getting 315 volts, you might want an 82 volt zener anyway. Knocking it down 9V might not be enough but 18 will.

I could replace two of the three to get an 18V drop, assuming that's how this power supply works. The seller only sells them in lots of 25.

The fundamental problem with all of these amplifiers from China, even some of the pre-built ones, is that they all are designed to run on 110/220V instead of the 120V we typically get in the US. At this point, I am certain that the factory simply labeled the 110V input as 115 without changing the transformer one bit from previous versions of the kit. Given that this amplifier already is pushing the limits of all of the voltages already, the excess simply pushes it over the top or at least to the very tippy top. Add to that the fragile tubes made in China. Fortunately, this particular design seems to have a power supply that can be tweaked to account for some of it. We will see.

I am a touch annoyed with all of it, but it's a learning experience. I know so much more now than I did a few weeks ago. So far, I am into the kit for a total of $422 including all of the upgrade and replacement parts. If I end up with a decent little tube amp, the price is still pretty much impossible to beat. Plus the learning of course.

The fundamental problem with all of these amplifiers from China, even some of the pre-built ones, is that they all are designed to run on 110/220V instead of the 120V we typically get in the US. At this point, I am certain that the factory simply labeled the 110V input as 115 without changing the transformer one bit from previous versions of the kit. Given that this amplifier already is pushing the limits of all of the voltages already, the excess simply pushes it over the top or at least to the very tippy top. Add to that the fragile tubes made in China. Fortunately, this particular design seems to have a power supply that can be tweaked to account for some of it. We will see.

I am a touch annoyed with all of it, but it's a learning experience. I know so much more now than I did a few weeks ago. So far, I am into the kit for a total of $422 including all of the upgrade and replacement parts. If I end up with a decent little tube amp, the price is still pretty much impossible to beat. Plus the learning of course.

Last edited:

I think I used the 91v zener on mine. Can't remember the resulting voltage, but I'll check.

Adding a bucking transformer is the proper way to knock a supply designed for 110 volts down, so the entire thing runs properly when fed 120. A minimum-sized 6-0-6 toroid does the job, and gives you three voltage options. Twenty or thirty bucks, it will run cool, fit inside the chassis and nobody has to know it’s there.

If you are ordering from Mouser anyway just pick up some zeners. Those HV zeners are often WAY above rated voltage and trimming is often necessary even with the right mains voltage.

If you are ordering from Mouser anyway just pick up some zeners. Those HV zeners are often WAY above rated voltage and trimming is often necessary even with the right mains voltage.

Adding a bucking transformer ... fit inside the chassis and nobody has to know it’s there.

I would have tried that otherwise, but not in this tiny amplifier:

I read that a little too high is better than a little too low when it comes to filament voltage and tube life. Not sure if it's true, but found it multiple places.

This statement may not be 100% correct.

Because this build is intended to be a learning experience as much as anything else, I have been doing a lot of research on tubes, voltages, and tube life. It seems that all of the indirectly heated oxide tubes we use (as in this amplifier) aren't really that sensitive to filament voltages as long as we don't exceed the manufacturer's range. I do have some small 3 watt resistors to drop all of the filaments by .2 to .3 volts if needed.

For anyone who is interested, I found this on an antique radio forum somewhere with a bunch of older people who are quite accustomed to these things:

Thoriated filaments are tungsten wires coated with a thoria compound when built. They operate at a yellowish temperature and have enormous amounts of emmission capability. The majority of high power directly heated tubes fall into this category ... The thoria slowly evaporates while the tube is used ... A five percent decrease in filament voltage is known to double the life of the filament and a five percent overvoltage is known to cut the life of the tube by half.

On indirectly heated cathodes, the cathode is coated with an oxide type of material. Variations of filament voltage like mentioned for thoriated filaments do not affect the oxide type of emitters. The oxide emitters slowly evaporate or get poisoned from ion bombardment from residual gas particles in the tube as it is used.

I have ordered a bigger R1 (200Ω instead of 100Ω) for the power supply and the 91V zener diodes for the regulated voltage. I put in 160Ω bias resistors instead of 150Ω, which may still be too small and seriously shorten the life of the tubes.

The only way to find out is to finish building it and see what actually comes out at each test point when the amplifier is operational. So we wait. After 4 business days, an ebay seller still has not shipped my solder and isn't responding to messages. I'll have to cancel and place an order with a different seller I guess. Another week to wait. It's always something ...

A minimum-sized 6-0-6 toroid does the job

Do you have a link? I doubt that I could squeeze it in, but it depends on how small it is.

Last edited:

I think I used the 91v zener on mine. Can't remember the resulting voltage, but I'll check.

The zener diode to replace the one I broke arrived today.

Result: The optional 91V zener diode in the kit (marked "spare") brought the regulated voltage on my power supply down to 297V, which is exactly the specification for no load testing, so that must be why it's included. That will be perfect so long as it stays there when I replace R1 with 200Ω instead of 100Ω. I am hoping that increasing R1 won't affect the regulated voltage too much, if at all.

I also am hoping that increasing R1 from 100Ω to 200Ω will fix the 407V (no load) power supply output, which is supposed to be 380V (no load). After some reading online, I have found that some guitar amps run the EL84 as high as 400V without longevity or sound quality problems, so long as the screen is kept at 300V or below, which is the case in this amplifier. So, if I can drop the 407V just a little, it should be fine. I wish I had a dummy load to put on it, but I don't have anything on hand that can take that much power.

Two small value power resistors are on order to drop the filament voltages a little bit if needed.

After a week, the ebay seller never did ship my solder, so I had to order from another seller. No more progress until it arrives. Sigh.

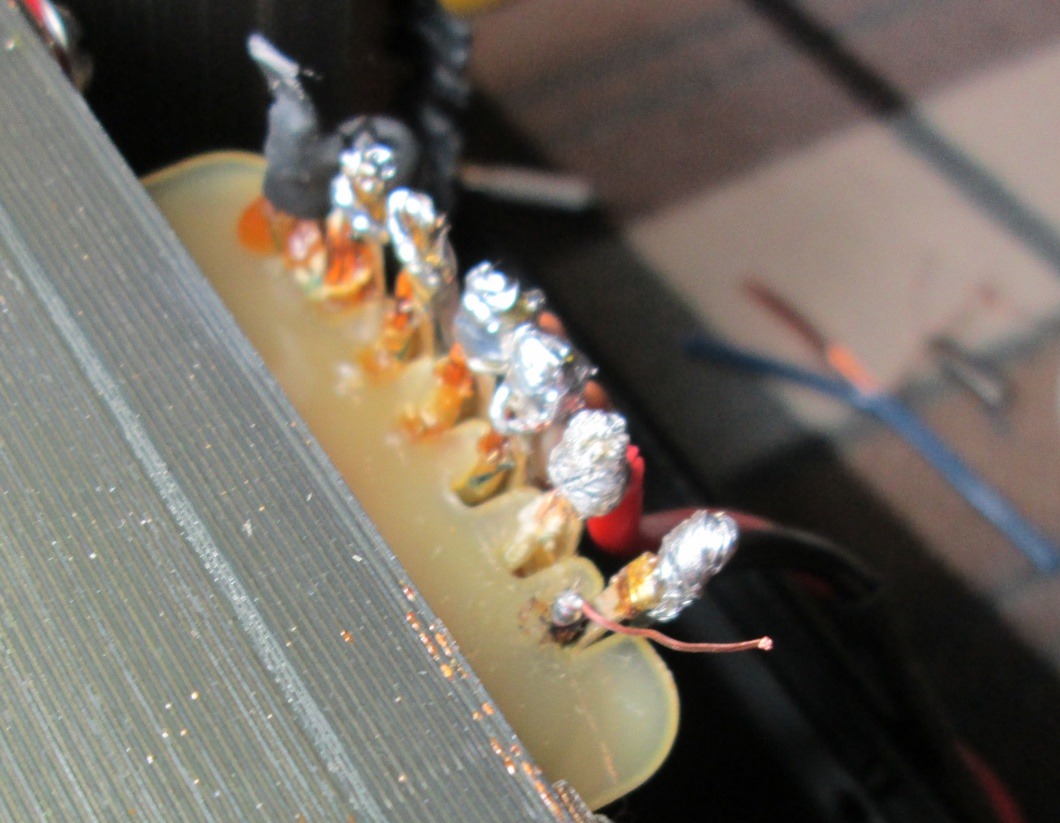

The day before yesterday, I finished the amplifier kit. I flipped the power switch with no tubes installed to check the power switch, power supply, wiring, etc. Nothing. No power going to the power supply board. The filament taps were providing power, but no high voltage output from the transformer. Odd since the high voltage had worked before installation. Sigh. 😡

I figured that I had a $400 brick on my hands since a replacement power transformer likely would be impossible to obtain.

After a few hours of fuming and stewing, I decided to investigate how this might have happened. There was no burning smell, no sparking, and no blown fuse. I couldn't find any shorts or bad connections. Nothing. A close inspection revealed that the very fine wire on one of the 0-275 outputs had broken loose from its output terminal. This happened when wrapping, soldering, and heat shrinking the connection. I was very, very fortunate to be able to conduct a repair and avoid a $400 brick. There was just enough of the fine wire exposed for me to tease back the insulation and fabricate an extension from similar AWG bare copper wire. I carefully wrapped a short piece of new wire around another piece of wire on the workbench to make a coil with 4 turns and a 1/2 inch extension. I was able to slip those 4 turns over the stub, solder it, and wrap and solder the extension to the output terminal. Just for insurance, I also reinforced and soldered the other terminal with additional fine wire. Wow was I glad when it actually worked, with what I hope will be a permanent solution. It's now soldered and heat shrinked in place, and with luck I'll never have to disturb it again.

I gave sigh of relief when I flipped the power switch and the power supply started working. Then I put in the driver tubes, and the voltages for those tested ok. Finally I put in the power tubes, and everything tested ok there too, with one little variance on the driver tubes that I hope will be tolerable. Most values are within spec, and replacing R1 with 200 ohms instead of 100 ohms got me a perfect 342 volts. Another resistor got me a perfect 6,5 volts to the driver tube filaments. The output tube filament voltage turned out to be fine with no changes. The 91V zener diode that I swapped in produced a perfect 299 volt regulated output. So, I succeeded with no bucking transformer and only two resistor changes and a zener diode swap. Not too much work there, and it all fits neatly inside the amplifier.

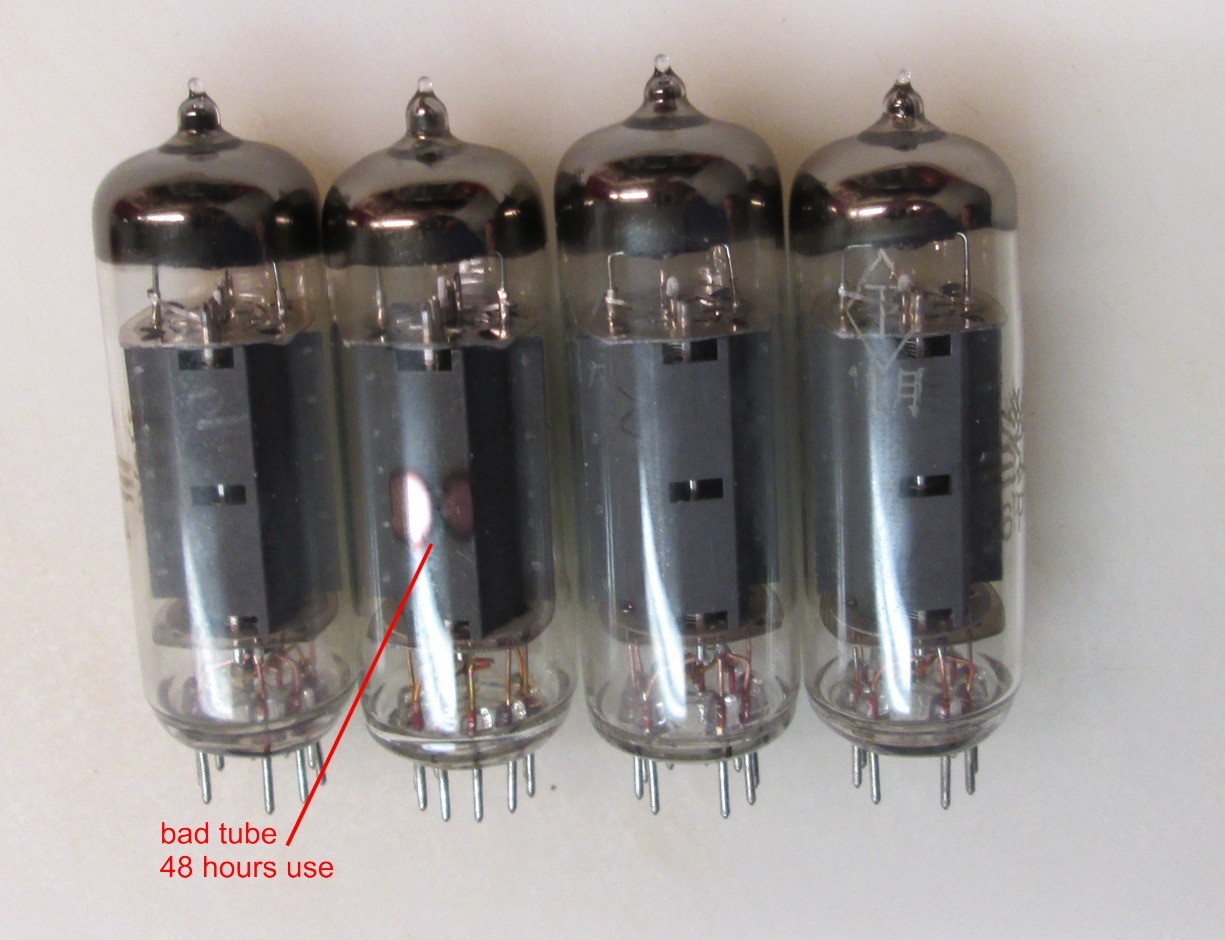

It sounded fine when I first listened. After 24 hours of burn in, I decided that the Chinese tubes don't sound too bad. Unfortunately, they also don't last. Another 24 hours of burn in resulted in a frequent popping noise and a discolored output tube. I suspected this one tube was way out of whack when I was doing the initial voltage testing. One channel measured 0 milliamps between the plates of its two output tubes when tested, and the other channel measured about 22 milliamps. Odd. So I swapped the outer two tubes left to right. Same result on the same channel. So, I figured the inner tube on that channel had a problem. Sure enough, that same tube failed after 48 hours of burn in. I took the left pair out (the bad pair) and the right channel sounds fine. So I put the right channel tubes in the left channel, and it sounds fine. It actually will play music with the bad tube in place, but I certainly don't want to risk that with all of the popping noises and the discolored tube. I am hoping that new tubes will fix this. I can't find any voltages that are off anywhere in the amplifier or anything unique to that socket? Just a bad tube and not some other issue with that one socket I hope. That one tube also is very, very badly microphonic when tapped lightly and the other three are not microphonic at all. I hope that's another indication that it's the tube itself that is the problem here. The Chinese 6P14 tubes do not have a reputation for good quality control or durability. I ordered an inexpensive matched quad of Russian 6P14P tubes from a nearby ebay seller with Priority Mail 2-day shipping so they should be here Friday with luck.

Thoughts on all of this and suggestions are always welcome.

I figured that I had a $400 brick on my hands since a replacement power transformer likely would be impossible to obtain.

After a few hours of fuming and stewing, I decided to investigate how this might have happened. There was no burning smell, no sparking, and no blown fuse. I couldn't find any shorts or bad connections. Nothing. A close inspection revealed that the very fine wire on one of the 0-275 outputs had broken loose from its output terminal. This happened when wrapping, soldering, and heat shrinking the connection. I was very, very fortunate to be able to conduct a repair and avoid a $400 brick. There was just enough of the fine wire exposed for me to tease back the insulation and fabricate an extension from similar AWG bare copper wire. I carefully wrapped a short piece of new wire around another piece of wire on the workbench to make a coil with 4 turns and a 1/2 inch extension. I was able to slip those 4 turns over the stub, solder it, and wrap and solder the extension to the output terminal. Just for insurance, I also reinforced and soldered the other terminal with additional fine wire. Wow was I glad when it actually worked, with what I hope will be a permanent solution. It's now soldered and heat shrinked in place, and with luck I'll never have to disturb it again.

I gave sigh of relief when I flipped the power switch and the power supply started working. Then I put in the driver tubes, and the voltages for those tested ok. Finally I put in the power tubes, and everything tested ok there too, with one little variance on the driver tubes that I hope will be tolerable. Most values are within spec, and replacing R1 with 200 ohms instead of 100 ohms got me a perfect 342 volts. Another resistor got me a perfect 6,5 volts to the driver tube filaments. The output tube filament voltage turned out to be fine with no changes. The 91V zener diode that I swapped in produced a perfect 299 volt regulated output. So, I succeeded with no bucking transformer and only two resistor changes and a zener diode swap. Not too much work there, and it all fits neatly inside the amplifier.

It sounded fine when I first listened. After 24 hours of burn in, I decided that the Chinese tubes don't sound too bad. Unfortunately, they also don't last. Another 24 hours of burn in resulted in a frequent popping noise and a discolored output tube. I suspected this one tube was way out of whack when I was doing the initial voltage testing. One channel measured 0 milliamps between the plates of its two output tubes when tested, and the other channel measured about 22 milliamps. Odd. So I swapped the outer two tubes left to right. Same result on the same channel. So, I figured the inner tube on that channel had a problem. Sure enough, that same tube failed after 48 hours of burn in. I took the left pair out (the bad pair) and the right channel sounds fine. So I put the right channel tubes in the left channel, and it sounds fine. It actually will play music with the bad tube in place, but I certainly don't want to risk that with all of the popping noises and the discolored tube. I am hoping that new tubes will fix this. I can't find any voltages that are off anywhere in the amplifier or anything unique to that socket? Just a bad tube and not some other issue with that one socket I hope. That one tube also is very, very badly microphonic when tapped lightly and the other three are not microphonic at all. I hope that's another indication that it's the tube itself that is the problem here. The Chinese 6P14 tubes do not have a reputation for good quality control or durability. I ordered an inexpensive matched quad of Russian 6P14P tubes from a nearby ebay seller with Priority Mail 2-day shipping so they should be here Friday with luck.

Thoughts on all of this and suggestions are always welcome.

Last edited:

Glad you found the fault and could fix it! Pity about that bad tube, but in my experience the quality of old Soviet/Chinese tubes is all over the place. Mine are working fine so far, touch wood.

I have a couple of "matched" quads of 6P14P tubes which I have tested in my uTracer 3+, and the tubes measure wildly different in my tester. Makes me wonder how they have been matched ...

I have a couple of "matched" quads of 6P14P tubes which I have tested in my uTracer 3+, and the tubes measure wildly different in my tester. Makes me wonder how they have been matched ...

Yes, I have read many things to that effect, so I asked the question about this amplifier and also my Dynaco ST70 series ii. Apparently, even if a pair or quad are matched (using one of many techniques) when the tubes are new, they may not stay matched over time, and also they may not be truly matched when actually playing music instead of sitting idle.

An interesting video on the subject:

I got two different answers about matching the tubes in this amplifier:

Knowing the OT primary's DC resistance will also be helpful to find out how well the pair of output tubes is matched. Measuring the voltage drop across each half primary and Ohm's law tells you the actual plate current of each tube, which should not differ too much.

So, I took measurements of each of the four half primaries for these transformers before I installed them. That's not possible with my Dynaco since they are permanently installed.

You don't even need to know the OT's primary DC resistance values. Instead, you'd put a current meter in the low milliamp range between both plates. Plate currents are balanced if the meter reads zero milliamps. This works well with a single pair of output tubes.

I hope this is accurate because it's so simple. This is why I put my meter across the pins for the plates of each pair when I first powered up the amplifier for testing. One pair read 0 milliamps as I expected. The other pair read ~22 milliamps, which I did not expect. So, I swapped outer tubes, but the difference remained the same in each channel. I reasoned that the inner tube on the channel that was reading ~22mA must have a problem. Sure enough, that tube started popping, became terribly microphonic, and discolored after 48 hours of use.

Transformer balance, unfortunately, is all over the place. Very high quality OPTs which have proper interleaving can get the DCRs close. But with “cheap” ones anything goes. 20% difference is possible. It should be no problem to measure the DCR, even in circuit. Just power it down, discharge your caps, and pull the output tubes.

Measuring cathode currents isn’t a fool proof way of balancing either. Cathode current is plate plus screen (and g1) current. I’ll bet that bad tube had a lot of screen current - hence all that spewed out material that came out the hole in the plate and hit the glass. It was probably making a hell of a getter at the time. When you get a bad tube you get a bad tube. It happens. If you’re getting them from some place “cheap” and you need four, buy six. If all 6 are good you have a spare pair for one channel if YOU break one. It happens too.

If the tubes are good, and at least in proper ranges the plate and screen should at least track. Measuring cathode current balance will get the plates close - at least as close as balancing using not quite equal DCRs in the plate circuit.

Measuring cathode currents isn’t a fool proof way of balancing either. Cathode current is plate plus screen (and g1) current. I’ll bet that bad tube had a lot of screen current - hence all that spewed out material that came out the hole in the plate and hit the glass. It was probably making a hell of a getter at the time. When you get a bad tube you get a bad tube. It happens. If you’re getting them from some place “cheap” and you need four, buy six. If all 6 are good you have a spare pair for one channel if YOU break one. It happens too.

If the tubes are good, and at least in proper ranges the plate and screen should at least track. Measuring cathode current balance will get the plates close - at least as close as balancing using not quite equal DCRs in the plate circuit.

Transformer balance, unfortunately, is all over the place. Very high quality OPTs which have proper interleaving can get the DCRs close. But with “cheap” ones anything goes. 20% difference is possible. It should be no problem to measure the DCR, even in circuit. Just power it down, discharge your caps, and pull the output tubes.

Thanks for the tip. I'll apply that to my Dynaco, which I haven't ever measured. Back in 1992 they were regarded as being quality transformers, but who knows.

On the output transformers for this Chinese amplifier kit I measured:

153.5Ω

152.6Ω

152.2Ω

151.6Ω

Those seem pretty close to me.

If you’re getting them from some place “cheap”

Yes, these were the cheapest of the cheap tubes - the Chinese 6P14's that came with the kit. I was surprised to see that stuff spewed out inside that one tube though. I haven't ever seen that before. They are so inexpensive that I probably will order a replacement pair from China to give me five of them. They can be used in emergencies. Actually, they don't sound bad, if I end up with four that last. They gave me enough time to determine that this amplifier may very well be a keeper rather than a toy.

The Russian 6P14P tubes (imported by the US seller from Ukraine to the US) were tested on a tube tester by the seller, who seems reputable. We will see if they last and how they sound when they arrive tomorrow. If they sound ok, he has more, still located in Ukraine though.

I wouldn’t actually expect to see the DCRs that close on a cheap China transformer. So what you have is better than average.

When tubes or any component are inexpensive you simply buy extra. It’s like ordering small signal transistors and resistors from Mouser - you just buy 100 (or 10) piece lots - never just one. When I was paying full price for tubes - when EH/Tungsol/Sovtek werent off the table I only ordered what I needed. Just payed for the match and burn in. When my builds moved to NOS TV tubes, I ordered at least enough to build twice. When they are $3-5 it just makes more sense. Easier to match pairs from a larger selection and that particular type may dry up completely so extras on hand may be needed years from now.

When tubes or any component are inexpensive you simply buy extra. It’s like ordering small signal transistors and resistors from Mouser - you just buy 100 (or 10) piece lots - never just one. When I was paying full price for tubes - when EH/Tungsol/Sovtek werent off the table I only ordered what I needed. Just payed for the match and burn in. When my builds moved to NOS TV tubes, I ordered at least enough to build twice. When they are $3-5 it just makes more sense. Easier to match pairs from a larger selection and that particular type may dry up completely so extras on hand may be needed years from now.

With regards to the longevity of the Russian tubes:

Many years ago I acquired two Mingda 6P14P SE amps. I bought a couple dozen Russian made 6P14P-EV tubes for use with them. One of the amps is in my office and probably saw a 2-3 hours a day of use for 5 years. I am still using the first pair of tubes. The other amplifier I gave to my son a couple years ago with an extra set of tubes. He has not had to replace the tubes.

With regards to matching 6P14P tubes:

I have an SE amplifier test mule that uses variable regulated bench supplies to provide B+, screen voltage and grid voltage. I tested many of the tubes at the same voltages and measured current through a small cathode resistor. While there was variation from tube to tube, matching was easy and I did not find any huge differences. I did find some tubes that matched within 0.1 ma. Almost all of the ones I got would have worked fine in a push pull amplifier.

Steve

Many years ago I acquired two Mingda 6P14P SE amps. I bought a couple dozen Russian made 6P14P-EV tubes for use with them. One of the amps is in my office and probably saw a 2-3 hours a day of use for 5 years. I am still using the first pair of tubes. The other amplifier I gave to my son a couple years ago with an extra set of tubes. He has not had to replace the tubes.

With regards to matching 6P14P tubes:

I have an SE amplifier test mule that uses variable regulated bench supplies to provide B+, screen voltage and grid voltage. I tested many of the tubes at the same voltages and measured current through a small cathode resistor. While there was variation from tube to tube, matching was easy and I did not find any huge differences. I did find some tubes that matched within 0.1 ma. Almost all of the ones I got would have worked fine in a push pull amplifier.

Steve

- Home

- Amplifiers

- Tubes / Valves

- 6P14/EL84 amplifier kit building questions - before I build - maybe during if I do