I asked the very same question Here.The "small" DC-link caps are PCB-mount. How do you mount them in your hard wired PSUs? Fishing for some brilliant PCB-less alternatives here. 🙂

I have soldered mine to a cheap FR4 protoboard (like eg https://www.ebay.de/itm/13383145926...SojrH60eX7t2IZbjpDHC|ampid😛L_CLK|clp:2047675), some extension wire and holes in the board for fixing it to the chassis.

I use hexagonal nylon spacers for everything that's point to point. Male to female, stackable. M3 screw through the chassis and a solder tag on top of the spacer. This tag attaches to the capacitor, or anything else.

Benefit is I can place the spacers anywhere, downside is holes in the chassis.

https://www.rapidonline.com/r-tech-524352-nylon-hexagonal-m3-m-f-spacers-15mm-pack-of-100-52-4352

Benefit is I can place the spacers anywhere, downside is holes in the chassis.

https://www.rapidonline.com/r-tech-524352-nylon-hexagonal-m3-m-f-spacers-15mm-pack-of-100-52-4352

The "small" DC-link caps are PCB-mount. How do you mount them in your hard wired PSUs? Fishing for some brilliant PCB-less alternatives here. 🙂

I understand, PCB parts don't always lend themselves to point to point wiring. One option is to zip tie the capacitors upright on a small piece of Garolite board, wire them underneath to turrets, then out from there. Mount the Garolite board neatly. I cut garolite very cleanly on my trim miter saw. Drill holes, then swage in the turrets.

https://www.mcmaster.com/phenolic-boards/

Thanks for many fine suggestions.

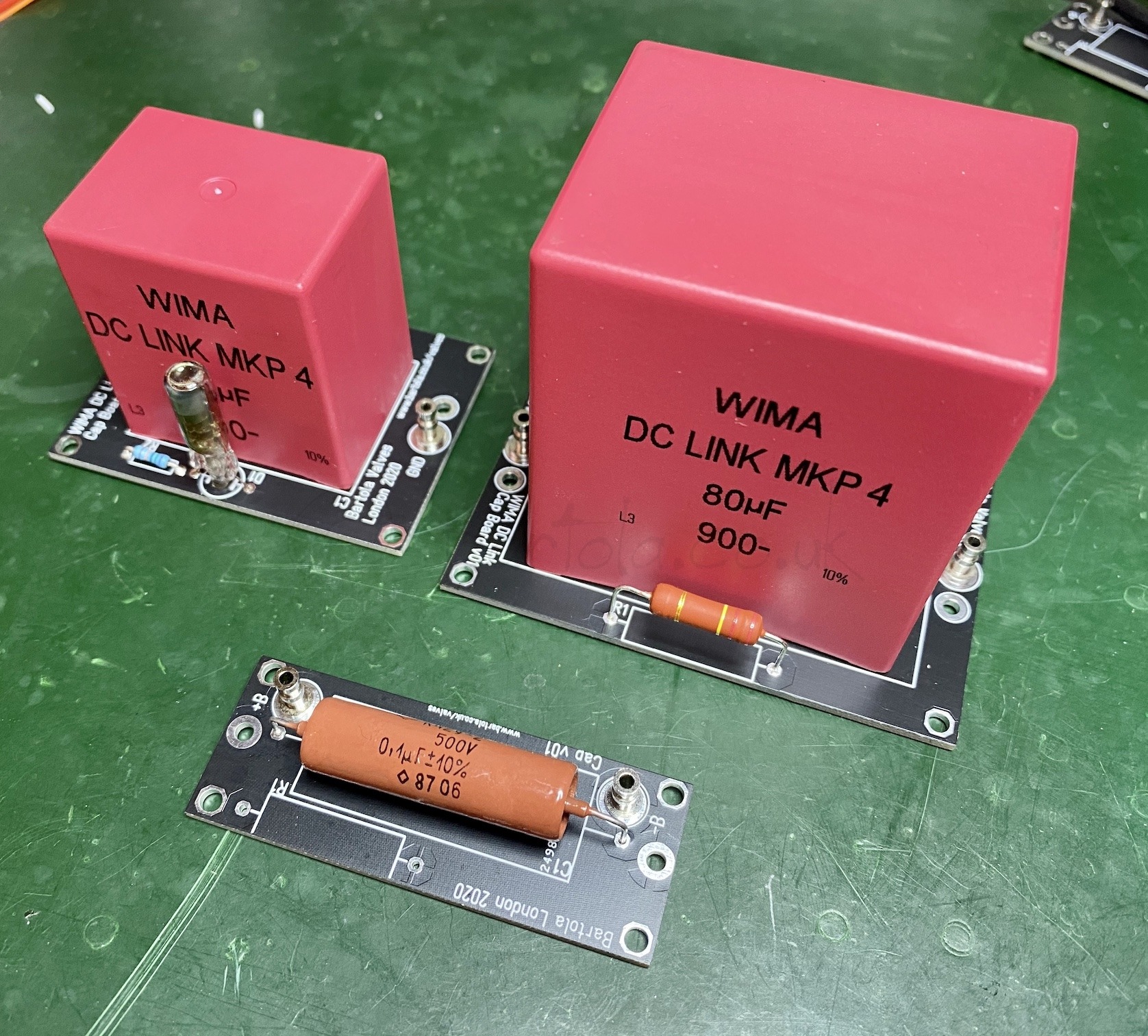

Ale Moglia (https://www.bartola.co.uk/valves/about-me/) has some very neat boards, but I do not think that they are fore sale.

Ale Moglia (https://www.bartola.co.uk/valves/about-me/) has some very neat boards, but I do not think that they are fore sale.

Hello,

I think it would be helpful if some with experience with these DC Link caps could post their experience with indication of the types used (maker and part numbers would be helpful), whether they are rectangular plastic encased or in aluminum cans, whether they are 2 pin or 4 pin. In other words, what have you tried, where, and with what results? Did I ask for part numbers? I'd also ask for suppliers.

Very Best, Robert

P.S. The only ones that I have found that would fit in an LCLC HT PSU that I might build are Kemet C4AQIBW5400A3OJ which are 40uF rectangular plastic case with 4 pins, found at Mouser for $11.28 each...they would be the first C. Beyond that, I am challenged, sorry to admit...but if anyone has suggestions for the rest of my PSU, please share.

I think it would be helpful if some with experience with these DC Link caps could post their experience with indication of the types used (maker and part numbers would be helpful), whether they are rectangular plastic encased or in aluminum cans, whether they are 2 pin or 4 pin. In other words, what have you tried, where, and with what results? Did I ask for part numbers? I'd also ask for suppliers.

Very Best, Robert

P.S. The only ones that I have found that would fit in an LCLC HT PSU that I might build are Kemet C4AQIBW5400A3OJ which are 40uF rectangular plastic case with 4 pins, found at Mouser for $11.28 each...they would be the first C. Beyond that, I am challenged, sorry to admit...but if anyone has suggestions for the rest of my PSU, please share.

I used Panasonic EZPV series DC link capacitors. This was in a 3C24 amp and not a 300B. I used two 100uf 600V caps fed from a pair of 866A rectifiers. Seems to work nicely.

Below are some pictures as to how I mounted them. I used some buss wire and just soldered that directly to the terminals. Connections to other components attached to the thick buss wires. Been in daily use for a year without problems,

Below are some pictures as to how I mounted them. I used some buss wire and just soldered that directly to the terminals. Connections to other components attached to the thick buss wires. Been in daily use for a year without problems,

WntrMute2,

Thank you for that...it gives us a starting point about how to connect 4 pin capacitors.

The only rational guidance I've been able to find about this topic is at the Clarity Cap website, and is shown in the attached image, which also indicates the advantages of the connexions.

Anyone else aware of this, have you tried it?

Best, Robert

Attachments

Those 4 pins are NOT Kelvin connections.

There is no mention of that type in the data sheet. I had a discussion regarding that in a thread over at HiFi Haven.

Kelvin Connections

There is no mention of that type in the data sheet. I had a discussion regarding that in a thread over at HiFi Haven.

Kelvin Connections

I'd guess that you are saying that not all 4 pin capacitors are Kelvin capacitors. I'm just trying to figure out who's on first...and WTF is up with 4 pin capacitors. There does not seem to be an accessable tutorial on the subject with understandable details. Jus t tryin' to learn..

Large rectangular capacitors (and also, large-can electrolytics) have extra pins usually to add mechanical robustness, with secondary benefits like lower inductance and broadband current handling.

2-pins are not strong enough to support heavy capacitors; think about dropping some end-user equipment: this would often result in the cap breaking off the PCB.

But if you are using them as the first cap against the rectifiers, you may still have a certain benefit from assigning one pin for IN and one for OUT. THis way the common-inductance caused by the pins is eliminated, and pin material is more inductive than the "plates". Whether this makes any difference will be highly variable, but there is always the satisfaction of doing things in the optimum way.

2-pins are not strong enough to support heavy capacitors; think about dropping some end-user equipment: this would often result in the cap breaking off the PCB.

But if you are using them as the first cap against the rectifiers, you may still have a certain benefit from assigning one pin for IN and one for OUT. THis way the common-inductance caused by the pins is eliminated, and pin material is more inductive than the "plates". Whether this makes any difference will be highly variable, but there is always the satisfaction of doing things in the optimum way.

I think I would be a bit nervous of some unforeseen eventuality that caused the caps to shift by 1cm either way, causing a short to that metal bar across them (say is the nuts became loose if they are not nyloc types). Do you protect against that? Maybe some shrink tubing over that metal bar could be belt and braces?I used Panasonic EZPV series DC link capacitors. ...

Good point. I do have the caps stuck down with 3M heavy duty double sided tape. Also, the studs thread into some rubber insets so the bar isn't grounded. I am using KEP nuts but nylocks would be better. I could also make the bar out of some carbon fiber strut I have laying around somewhere.

Thanks

Thanks

"I could also make the bar out of some carbon fiber strut I have laying around somewhere."

Or out of Ash, Oak, Hickory, Cherry, Walnut or Maple. Any of which would accomodate machining to retain the caps in their proper place.

Or out of Ash, Oak, Hickory, Cherry, Walnut or Maple. Any of which would accomodate machining to retain the caps in their proper place.

Further on this , here is a link to Resistivity and Conductivity of materials from Silver to Teflon:

https://www.thoughtco.com/table-of-electrical-resistivity-conductivity-608499

Best, Robert

https://www.thoughtco.com/table-of-electrical-resistivity-conductivity-608499

Best, Robert

I think next time I have it apart (may be years!) I'll just slide some heat-shrink tubing over the part that could short anything out.

I used Panasonic EZPV series DC link capacitors. This was in a 3C24 amp and not a 300B. I used two 100uf 600V caps fed from a pair of 866A rectifiers. Seems to work nicely.

Are you using a choke input or some type of soft start? That’s an insane amount of capacitance for mercury rectifiers.

The primary reason for four leads is mechanical support. You will see this on all such large caps. It is necessary to pass "Shock and Vibration" testing for product qualification.

Tuv Sud is a certification agency for Functional Safety certification as well as standard products.

Tuv Sud is a certification agency for Functional Safety certification as well as standard products.

- Home

- Amplifiers

- Tubes / Valves

- 300B B+ PSU caps