Having replaced the e-caps 4 times in my ST70 power amp for low power (rail voltage) or excessive cathode current, I select for hours service life. Nothing less than 3000 hours, at either 85C or higher. That has gotten me >400 e-caps that had adequate all above parameters that kept hum & hiss below the background noise of my music room, TV room, and summer trailer. I haven't had to repeat replace any since I started intense repairs 2008. I have upgraded 9 power amps (4 stolen), 4 mixers (2 stolen), a preamp (stolen), 4 electric organs, a DTV tuner, two AM/FM radios, and have upgraded 2 electric organs and a mixer at different churches. I repaired the sweep in an oscilloscope, but not the vertical yet.

Note mains filter & rail filter if any in switcher power supplies require low ESR caps, except designs that pre-dated the availability of such caps. Switcher designs with 10 or more parallel 470 uf caps don't list high ESR on the parts list.

Note mains filter & rail filter if any in switcher power supplies require low ESR caps, except designs that pre-dated the availability of such caps. Switcher designs with 10 or more parallel 470 uf caps don't list high ESR on the parts list.

Last edited:

I look at the ripple current rating and use capacitors in parallel so that the actual current is a fraction of the rating.

Ed

Ed

Thank you @indianajo. I always enjoy your posts. I am in Indiana myself BTW.

To clarify my original question for anyone else who might respond, I am asking ONLY about traditional linear power supplies, not switching power supplies.

To clarify my original question for anyone else who might respond, I am asking ONLY about traditional linear power supplies, not switching power supplies.

Last edited:

I look at the ripple current rating and use capacitors in parallel so that the actual current is a fraction of the rating.

Ed

That is one of the points I am wondering about. Is there a lot of ripple current in decoupling caps on the rails of amplifier (linear) power supply?

My understanding is that the purpose of those caps is to stabilize DC voltage and drain off any (high frequency?) AC to keep the DC clean. I am wondering if those duties require a cap with high ripple current rating?

Yes. The diodes conduct for only a small part of the 120Hz cycle. The capacitors provide all the current for the remainder.

ETA: I realized your question pertains to smaller decoupling capacitors. Those are in parallel with the main filter capacitors and will need to handle some fraction of the ripple current.

Ed

ETA: I realized your question pertains to smaller decoupling capacitors. Those are in parallel with the main filter capacitors and will need to handle some fraction of the ripple current.

Ed

Thank you both for your replies 👍

I do not doubt that any good quality cap would be adequate in that role. And I only buy caps from Mouser or Digikey, and usually either Nichicon or Panasonic brands. But there are many different types and series of electrolytics available to me, and they vary in those parameters listed in my original post, with trade-offs in their design.

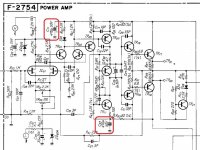

So just for fun, perhaps as a theoretical exercise, even though benefits may be marginal-if-any, which parameters might be most relevant (or non-relevant) for the capacitor role as shown in the pic above? This is more about learning than it is about choosing a cap for a particular project. The amp show above is merely a sample, and not a current project.

The point has been made that a high ripple current rating would not be important. Good information, thank you.

Leakage and ESR specs do vary among the electrolytic caps available....

Might it be good, theoretically, to use the lowest possible ESR here to maximize the speed with which the cap is able to correct voltage fluctuations?

Might it be good to use a cap designed to minimize leakage to ground as there will be DC voltage (even though not full rail voltage) on those caps?

I do not doubt that any good quality cap would be adequate in that role. And I only buy caps from Mouser or Digikey, and usually either Nichicon or Panasonic brands. But there are many different types and series of electrolytics available to me, and they vary in those parameters listed in my original post, with trade-offs in their design.

So just for fun, perhaps as a theoretical exercise, even though benefits may be marginal-if-any, which parameters might be most relevant (or non-relevant) for the capacitor role as shown in the pic above? This is more about learning than it is about choosing a cap for a particular project. The amp show above is merely a sample, and not a current project.

The point has been made that a high ripple current rating would not be important. Good information, thank you.

Leakage and ESR specs do vary among the electrolytic caps available....

Might it be good, theoretically, to use the lowest possible ESR here to maximize the speed with which the cap is able to correct voltage fluctuations?

Might it be good to use a cap designed to minimize leakage to ground as there will be DC voltage (even though not full rail voltage) on those caps?

Ripple current and ESR go together. To handle high ripple current, the ESR has to be low.

For supply bypassing, low ESR is good, but low inductance is better. You want a capacitor (or combination of capacitors) that works at RF.

Leakage current is negligible for supply bypassing.

If you are designing new equipment, the most important consideration is to choose the right type of capacitor. Only the large capacitors in the power supply should be electrolytics. Tantalum, film, and ceramic capacitors are more suitable for smaller values of capacitance.

Ed

For supply bypassing, low ESR is good, but low inductance is better. You want a capacitor (or combination of capacitors) that works at RF.

Leakage current is negligible for supply bypassing.

If you are designing new equipment, the most important consideration is to choose the right type of capacitor. Only the large capacitors in the power supply should be electrolytics. Tantalum, film, and ceramic capacitors are more suitable for smaller values of capacitance.

Ed

Usually the ones advertised as having low esr are not the best sounding to most.

Could probably use just about anything in that position however, 4.7uf mylar, 100-1500uf electrolytic. The standard types usually sound great, or an audio branded part as well.

Could probably use just about anything in that position however, 4.7uf mylar, 100-1500uf electrolytic. The standard types usually sound great, or an audio branded part as well.

- Home

- Design & Build

- Parts

- Most/least important electrolytic capacitor parameters for amplifier power rail decoupling?