Here are some measurement from the excellent German magazine (what happened to the football team?)

The setup a wide band driver set in a box within a box

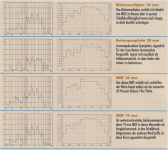

A front baffle is added and two things are measured. The sound througput through the board and secondly the vibrations of the board is measured with a contact microphone

Then a set of board are compared and with 19 mm MDF as the standard both for transmission and vibration levels

Picture 1 Findings

I. The 16 mm is very close to the 19 mm in both accounts even if thinner

II. "Concretchipboard" While hard to find superior to MDF

III. Beech plywood, slightly inferior to MDF

Picture 2

I.28 mm MDF better than 19 mm but not by so much as the increased thickness suggest

II. 20 mm Slate (stone) way better than anything else!

III. 19 mm Chipboard, while inferior to MDF it is cheaper so a given amount of investment gives a thicker board...

IV. Blockboard 19mm inferior to both MDF and chipbord

I am familiar with the BBC papers that guided both the LS3/5A and the Spendor BC1. Both had thin walls and a lot of damping to get the resonances out of the harmful midrange and down to the bass to cause less harm

The setup a wide band driver set in a box within a box

A front baffle is added and two things are measured. The sound througput through the board and secondly the vibrations of the board is measured with a contact microphone

Then a set of board are compared and with 19 mm MDF as the standard both for transmission and vibration levels

Picture 1 Findings

I. The 16 mm is very close to the 19 mm in both accounts even if thinner

II. "Concretchipboard" While hard to find superior to MDF

III. Beech plywood, slightly inferior to MDF

Picture 2

I.28 mm MDF better than 19 mm but not by so much as the increased thickness suggest

II. 20 mm Slate (stone) way better than anything else!

III. 19 mm Chipboard, while inferior to MDF it is cheaper so a given amount of investment gives a thicker board...

IV. Blockboard 19mm inferior to both MDF and chipbord

I am familiar with the BBC papers that guided both the LS3/5A and the Spendor BC1. Both had thin walls and a lot of damping to get the resonances out of the harmful midrange and down to the bass to cause less harm

Attachments

A comp i did from another German study (modestly braced MDF vrs plywood (quality unknown).

Based on the math in the basic science the likelihood of causing a resonance to express the higher in frequency the (potential) resonance is the less likely there will be the energy to excite it.

Further, if the Q of the potential resonance is high (frequency too), it is even less likely that sufficient sustained HF energy to excite the resonance.

I am guessing this came from the same or similar. Found it when looking for the above)

dave

Based on the math in the basic science the likelihood of causing a resonance to express the higher in frequency the (potential) resonance is the less likely there will be the energy to excite it.

Further, if the Q of the potential resonance is high (frequency too), it is even less likely that sufficient sustained HF energy to excite the resonance.

I am guessing this came from the same or similar. Found it when looking for the above)

dave

Last edited:

Although I do not support n58 in many of his allegations (he's not really opened to suggestions, eh?), I wanted to say that enclosures and materials used are a value to any drivers. Having a resonance free baffle will greatly help the overall sound.Nobody cares here. This is a SB-8 thread. Go start a thread about cabinet materials where you can profess your expertise.

In my example, I used the W8-1772, but the SB20 could have been used as well, it just wasn't available at the time... believe me, I wanted to use it since we saw the first prototype, but SBA had production issues that took a couple years to resolve.

I understand that plywood is better. Damping is better.

I want to see if someone can tell the difference between the sound of a plywood and mdf box.

Can you really hear a difference?

Maybe the difference increases if you play strongly?

I want to see if someone can tell the difference between the sound of a plywood and mdf box.

Can you really hear a difference?

Maybe the difference increases if you play strongly?

the thinner 16mm MDF has same performance as 18mm birch plywood.

Far as the superior hard to find concrete board.

It is very common in US

instead of mudding the sub floor for tile installation.

They use concrete board instead.

far as easier solution you could concrete

16mm mdf or 18mm birch

with normal tile mix/ tile mortar/ thin set.

it is basically a aggregate free, fast dry, light concrete

Far as the superior hard to find concrete board.

It is very common in US

instead of mudding the sub floor for tile installation.

They use concrete board instead.

far as easier solution you could concrete

16mm mdf or 18mm birch

with normal tile mix/ tile mortar/ thin set.

it is basically a aggregate free, fast dry, light concrete

Last edited by a moderator:

Hmm, Ga. Pacific told me some years ago that 3/4" MDF had a ~1.9 k psi MOE and 3/4" BB, apple, marine ply ~1.8 m psi, so MDF must be much thicker to match its stiffness = 0.75*(1.8/0.19)^0.33 = ~1.58" thick to match the ply's stiffness that we need in speaker box construction.

Yes you can when you use the right ply with some bracing for good measure in that the ply box doesn't sound like a box because it's stiff/rigid enough that there's nothing to excite its resonances regardless of input power, assuming of course it's designed for truly excessive power well beyond HIFI/HT apps.I understand that plywood is better. Damping is better.

I want to see if someone can tell the difference between the sound of a plywood and mdf box.

Can you really hear a difference?

Maybe the difference increases if you play strongly?

"box within a box"- does that mean a speaker inside a sealed box, or a speaker machannicaly decoupled from an outer box? I just want some better clarification ( the pictures don't show up well on my cheap phone) so I can understand the reasults a bit better. I prefer ply top, bottom and sides, with mdf front and back, but that's mostly from a practicality point of view.

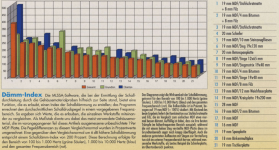

Here is an other set of measurement from Hobby HiFi. In the article they note the surprising effect of a humble layer of felt glued to the walls. (Just as Troels Gravesen does in his constructions). They also suggest that adding ceramic tiles to the walls adds both mass and damping. I recall a DIY article in the danish magazine High Fidelity with a 15" Tannoy in a large box with ceramic floor tiles covering the inside. The guy who built them needed several friend to help him move the speakers to the living room. One of them remarked that he did not need any theft insurance on the loudspeaker as nobody could move the damn things🙂

Now to the graph. Redish bar is average damping green is damping in 100-1000 Hz range and blue bars is 1-10 kHz.

The whole thing is normalized to 19mm MDF (100%) and then the constructions are in the order from best to worst average damping.

The take home messages are:

1. Damping and bracing is better than just thickness

2. Bracing is really good below 1 kHz but not above that

3. 4mmBitumen and felt glued on top of that is really good.

I hope the pictures are explanation enough and that translations are not needed.

Now to the graph. Redish bar is average damping green is damping in 100-1000 Hz range and blue bars is 1-10 kHz.

The whole thing is normalized to 19mm MDF (100%) and then the constructions are in the order from best to worst average damping.

The take home messages are:

1. Damping and bracing is better than just thickness

2. Bracing is really good below 1 kHz but not above that

3. 4mmBitumen and felt glued on top of that is really good.

I hope the pictures are explanation enough and that translations are not needed.

Attachments

They also suggest that adding ceramic tiles to the walls adds both mass and damping.

The glue adds damping, the tiles add stiffness, the mass is an unfortunate side-effect.

dave

Interesting! I built a pair of TQWTs in my inexperienced youth, the cabs were about 70 Litres, standing 100cm iirc. Built out of 1/2" inch chipboard and they sounded fantastic. Drive unit was from a company called Altai.

I think it was made for tv speaker/radiogram repairs. Anyway, it sounded fantastic and had much admiration from fellow audio friends. It was such a profound experience It started my diy hifi journey. It should have resonated like a drum lol 🙂.

All I could hear was a bloom on some female vocals - like Tracy Chapman who still causes me grief!

I think it was made for tv speaker/radiogram repairs. Anyway, it sounded fantastic and had much admiration from fellow audio friends. It was such a profound experience It started my diy hifi journey. It should have resonated like a drum lol 🙂.

All I could hear was a bloom on some female vocals - like Tracy Chapman who still causes me grief!

Last edited by a moderator:

If something as light as felt can make a difference, could fur also work? The only reason I ask is I was wearing a fury hat, and it does seem to have a marked effect on sound.

Especially when pulled over the ears (I find my faux version has that effect)...

Joking aside, probably. Although as has been alluded to, lower isn't necessarily better. Can be for midrange & HF chambers. Bass boxes? I'd rather shunt panel resonances above their operating band. I like heavy-metal engineering as much as the next person (the old long-ram V8s are one of my side-interests, albeit a tricky one from this side of the Atlantic) but it's not the most efficient when it comes to acoustics.

Joking aside, probably. Although as has been alluded to, lower isn't necessarily better. Can be for midrange & HF chambers. Bass boxes? I'd rather shunt panel resonances above their operating band. I like heavy-metal engineering as much as the next person (the old long-ram V8s are one of my side-interests, albeit a tricky one from this side of the Atlantic) but it's not the most efficient when it comes to acoustics.

Last edited:

What is this Hobby Hifi test supposed to demonstrate? The properties of the screwed on baffle as measured by a contact mic in the middle and a mic at some distance?

Boden

It try to model how the panels behave in a loudspeaker box. A "model" imply a simplification or constrains. Instead of having a contact mic at one point it would be better to measure the whole surface with laser as well as calculate the polar response of the panel and so on.

If I was to do a Ph D in accoustics and I had a very big grant to spend, I would love to go bananas on the Klippel tools and have the time and brains to use them properly. This in close work with people working with psycoaccoustics or what ever it is called and spelled.

The finding suggest that for a bass box good bracing will bring the resonances above the working range of the bass driver. For the mid and high range a "limp" box with thin walls and a lot of damping material (as per Spendor BC1, Harwood BBC LS3/5A) seems better than a brute force box with very thick walls

It try to model how the panels behave in a loudspeaker box. A "model" imply a simplification or constrains. Instead of having a contact mic at one point it would be better to measure the whole surface with laser as well as calculate the polar response of the panel and so on.

If I was to do a Ph D in accoustics and I had a very big grant to spend, I would love to go bananas on the Klippel tools and have the time and brains to use them properly. This in close work with people working with psycoaccoustics or what ever it is called and spelled.

The finding suggest that for a bass box good bracing will bring the resonances above the working range of the bass driver. For the mid and high range a "limp" box with thin walls and a lot of damping material (as per Spendor BC1, Harwood BBC LS3/5A) seems better than a brute force box with very thick walls

The finding suggest that for a bass box good bracing will bring the resonances above the working range of the bass driver. For the mid and high range a "limp" box with thin walls and a lot of damping material (as per Spendor BC1, Harwood BBC LS3/5A) seems better than a brute force box with very thick walls

For an example check out Waxx’s A10.3 WAW.

MidTweeter uses a too big BBC stylr box with resonances below the passband.

http://p10hifi.net/forum/waxx-a103-sat-220121.pdf

dave

You could i.m.o. move quite a way forward with measuring the entire surface with the contact mic at a matrix of closely spaced (e.g.1 cm) measuring points instead of just a single point "sort of in the middle". If I properly recall Earl Geddes long ago stated in another thread such panels tend to resonate in a rather chaotic way.

I am well aware of the BBC experiments, but that is now almost (or over) 50 years ago with rather crude measuring techniques.

I am well aware of the BBC experiments, but that is now almost (or over) 50 years ago with rather crude measuring techniques.

I am sure KEF, JBL, B&W and others have measurements, but public ones are hard to find" There is a PDF "

"Akustisch „optimale“ Materialien für Lautsprechergehäuse "With findings similar to the one above, the tapped a suspended panel and measured and recorded the output (I think I have the mp3 files somewhere but at the moment I can not find them and I have work to do)

"Akustisch „optimale“ Materialien für Lautsprechergehäuse "With findings similar to the one above, the tapped a suspended panel and measured and recorded the output (I think I have the mp3 files somewhere but at the moment I can not find them and I have work to do)

Yes, that works well, the woofer is a 10" in a stronly braced cabinet to bring the resonance higher than the passband, so the opposite of the top cabinet. The top was made in 12mm birch ply except the front and back plate and damped with bitumen. The woofer cabinet in 18mm birch ply. Like this the cabinet resonances are so reduced that they are even not felt anymore. This is a picture of it of a year ago. I build some more speakers so it's place is taken by a newer builds now. But it's still in use upstairs now, in my bedroom for the moment (but all move a lot here, a lot changed in that setup).For an example check out Waxx’s A10.3 WAW.

MidTweeter uses a too big BBC stylr box with resonances below the passband.

http://p10hifi.net/forum/waxx-a103-sat-220121.pdf

dave

Attachments

btw, some studies on this:

http://downloads.bbc.co.uk/rd/pubs/reports/1977-03.pdf

And my own conclusion on non scientific base: mdf is more dense, but less stiff than birch plywood. Stiffness and density are both important, but stiffness is more important. Next to that is that plywood is much more durable than mdf, and moisture and damp have little influmence on ply, while mdf is very sensitive to that, even sol called waterproof mdf. But both can be used to make great speakers when used right, and for the right purpose. I've used both, but prefer plywood. But now that the prices for ply are ridiculous high, i also consider mdf, as i'm waiting to do some experimenting, and already way to long...

http://downloads.bbc.co.uk/rd/pubs/reports/1977-03.pdf

And my own conclusion on non scientific base: mdf is more dense, but less stiff than birch plywood. Stiffness and density are both important, but stiffness is more important. Next to that is that plywood is much more durable than mdf, and moisture and damp have little influmence on ply, while mdf is very sensitive to that, even sol called waterproof mdf. But both can be used to make great speakers when used right, and for the right purpose. I've used both, but prefer plywood. But now that the prices for ply are ridiculous high, i also consider mdf, as i'm waiting to do some experimenting, and already way to long...

- Home

- Loudspeakers

- Full Range

- Cabinet material Measurement