Hi.

I'm building a subwoofer enclosure in my car, but I only need advice for normal ported box designing.

The box will be build inside of the trunk, so I can't precisely predict how big it will be.

I am estimating it would be between 180 and 250l big.

I have 8-10kW of power, so I need as big of a port as possible.

A 12" port would be Ideal, but it would be too long and take up too much air space inside the box, so I'm going with a 10" port.

I have had trouble finding one, but I finally did. A flared port with the inside diameter of 24cm, but it's only 50cm long.

I haven't really decided yet, but I'd want a tuning frequency of around 20-28Hz.

According to WinISD, if I get 250l out of the box, I'd get a 28Hz tuning with a 50cm long port.

But if I only get 200l, I'd get a 32Hz tuning.

Now this isn't that big of a difference, if the range was closer to 20Hz.

Now my question is, how could I lower thee tuning frequency?

I can't make the box bigger. I can't make the port smaller, because air velocity is already at like 60-70m/s.

I don't want to make a slot port, because the shape of the box is so odd, it's be hard, and I don't have the tools to round off all the edges easily.

I have heard, that by putting the port closer to one corner, or closer to the back wall, you can effectively lower the tuning. Is this true?

If so, how would I calculate the difference? Can HornResp simulate this somehow?

Are there any other ways?

They don't mention the outer diameter, but could it be, they are using normal waste pipe?

Could i saw the port in half and use waste pipe extenders to make it longer, without the integrity and air flow suffering too much?

I'm building a subwoofer enclosure in my car, but I only need advice for normal ported box designing.

The box will be build inside of the trunk, so I can't precisely predict how big it will be.

I am estimating it would be between 180 and 250l big.

I have 8-10kW of power, so I need as big of a port as possible.

A 12" port would be Ideal, but it would be too long and take up too much air space inside the box, so I'm going with a 10" port.

I have had trouble finding one, but I finally did. A flared port with the inside diameter of 24cm, but it's only 50cm long.

I haven't really decided yet, but I'd want a tuning frequency of around 20-28Hz.

According to WinISD, if I get 250l out of the box, I'd get a 28Hz tuning with a 50cm long port.

But if I only get 200l, I'd get a 32Hz tuning.

Now this isn't that big of a difference, if the range was closer to 20Hz.

Now my question is, how could I lower thee tuning frequency?

I can't make the box bigger. I can't make the port smaller, because air velocity is already at like 60-70m/s.

I don't want to make a slot port, because the shape of the box is so odd, it's be hard, and I don't have the tools to round off all the edges easily.

I have heard, that by putting the port closer to one corner, or closer to the back wall, you can effectively lower the tuning. Is this true?

If so, how would I calculate the difference? Can HornResp simulate this somehow?

Are there any other ways?

They don't mention the outer diameter, but could it be, they are using normal waste pipe?

Could i saw the port in half and use waste pipe extenders to make it longer, without the integrity and air flow suffering too much?

I have heard, that by putting the port closer to one corner, or closer to the back wall, you can effectively lower the tuning. Is this true?

This link may be helpful: https://www.avsforum.com/threads/ca...ylindrical port having cross-sectional area A.

Could i saw the port in half and use waste pipe extenders to make it longer, without the integrity and air flow suffering too much?

90 degree elbows are used to extend port length without major issues. A slightly increased air flow resistance may lower the tuning frequency a tad.

I skimmed this through. They were mostly talking about the end correction factor for slot ports, which doesn't really help me much.

I did see someone mention that placing a wall closer behind the port does indeed lower the tuning, but not how to factor that in.

I'm reluctant on using 90 degree turns in my port, as you said, it will increase air resistance, which is already very high with my power.90 degree elbows are used to extend port length without major issues. A slightly increased air flow resistance may lower the tuning frequency a tad.

I'm open to using a straight extender, but that would also insert ridges inside the port and make it less structurally sound.

I have an 18" subwoofer with 90mm peak to peak Xmax and 8kW of power, inside a car. The pressure will be quite high and a vibrating port would not help me much.

Glue might help, but I doubt it'd be as good as one piece of plastic.

Consider the port length resonance. At some point you'll want to consider using a smaller diameter.50cm

They were mostly talking about the end correction factor for slot ports, which doesn't really help me much.

It shows how different end correction factors (k) affect the tuning and answered your question in the positive.

Your proposed corner position port would correspond to k = 1.728 and can be compared to a centre position port with k = 0.732.

Anyhow, I'll have to hand you over to the loudspeaker design experts!

Hi,

If you get your final enclosure dimensions figured out, it would be easier to figure a wide skinny slot port on one of the shared largest faces on the cabinet. This gives you the largest end correction factor that will allow a lower tuning frequency for the length (due to sharing a wall with the cabinet and the geometry of the wide long rectangle). If you wanted a 10" diameter, you can make that effectively with a rectangle to be similar to allow proper length calculation but you could go up to 12" too. If your port's initial surface area is 113 inches^2 you can get a 12" effective diameter out of it. 4 inch by 28 inch for example would be a wide port and equal to about 112 inches^2. 112 inches^2 / pi = 35.65; 35.65 (square root) = 5.97 inch radius and doubled is 11.9 inches "effective" diameter. Then if you wanted to target a 25hz port, assuming a 250L enclosure, end correction of 2.227, the length of the port is 70.4 inches. The bigger your enclosure's net volume, the shorter the port will get. Not sure 5.8 feet will fit in a trunk though, but you could fold it internally, half way, which would be under 3 feet (even less, use the center of the air column, so if it were a 4 inch height on the port, and folded it would be 8 inches at the fold plus the material thickness, which would be included in the length, so your two folded lengths would be even less). If you made the port too short somehow, you simply decrease internal volume of the enclosure to lower the tuning value (as the port length relative to the net volume ratio just shifted).

Very best,

If you get your final enclosure dimensions figured out, it would be easier to figure a wide skinny slot port on one of the shared largest faces on the cabinet. This gives you the largest end correction factor that will allow a lower tuning frequency for the length (due to sharing a wall with the cabinet and the geometry of the wide long rectangle). If you wanted a 10" diameter, you can make that effectively with a rectangle to be similar to allow proper length calculation but you could go up to 12" too. If your port's initial surface area is 113 inches^2 you can get a 12" effective diameter out of it. 4 inch by 28 inch for example would be a wide port and equal to about 112 inches^2. 112 inches^2 / pi = 35.65; 35.65 (square root) = 5.97 inch radius and doubled is 11.9 inches "effective" diameter. Then if you wanted to target a 25hz port, assuming a 250L enclosure, end correction of 2.227, the length of the port is 70.4 inches. The bigger your enclosure's net volume, the shorter the port will get. Not sure 5.8 feet will fit in a trunk though, but you could fold it internally, half way, which would be under 3 feet (even less, use the center of the air column, so if it were a 4 inch height on the port, and folded it would be 8 inches at the fold plus the material thickness, which would be included in the length, so your two folded lengths would be even less). If you made the port too short somehow, you simply decrease internal volume of the enclosure to lower the tuning value (as the port length relative to the net volume ratio just shifted).

Very best,

Last edited:

I simulated it with hornresp and it will be over 100Hz, which will be no problem for me, as I'll be using the sub up to 80-100Hz and I use a DSP with 24-36dB/oct crossovers.Consider the port length resonance. At some point you'll want to consider using a smaller diameter.

But would it ever be a corner position when I'm using an "aero type" port? Or will it be that just with the back wall close?It shows how different end correction factors (k) affect the tuning and answered your question in the positive.

Your proposed corner position port would correspond to k = 1.728 and can be compared to a centre position port with k = 0.732.

Anyhow, I'll have to hand you over to the loudspeaker design experts!

Thank you for taking your time to explain, but as I said in the beginning, I don't want to make a slot port.Hi,

If you get your final enclosure dimensions figured out, it would be easier to figure a wide skinny slot port on one of the shared largest faces on the cabinet. This gives you the largest end correction factor that will allow a lower tuning frequency for the length (due to sharing a wall with the cabinet and the geometry of the wide long rectangle). If you wanted a 10" diameter, you can make that effectively with a rectangle to be similar to allow proper length calculation but you could go up to 12" too. If your port's initial surface area is 113 inches^2 you can get a 12" effective diameter out of it. 4 inch by 28 inch for example would be a wide port and equal to about 112 inches^2. 112 inches^2 / pi = 35.65; 35.65 (square root) = 5.97 inch radius and doubled is 11.9 inches "effective" diameter. Then if you wanted to target a 25hz port, assuming a 250L enclosure, end correction of 2.227, the length of the port is 70.4 inches. The bigger your enclosure's net volume, the shorter the port will get. Not sure 5.8 feet will fit in a trunk though, but you could fold it internally, half way, which would be under 3 feet (even less, use the center of the air column, so if it were a 4 inch height on the port, and folded it would be 8 inches at the fold plus the material thickness, which would be included in the length, so your two folded lengths would be even less). If you made the port too short somehow, you simply decrease internal volume of the enclosure to lower the tuning value (as the port length relative to the net volume ratio just shifted).

Very best,

First thing being, as I try to make the most out of the space in the trunk, the box will probably not be sqare on any side,

Or at most, the sides would be at 90 degree angles, but the top and bottom and front and back will not be.

So it would be very hard to make a port that shares 3 sides with the box and to simulate it, when it might get smaller and bigger, more like a horn.

And then there is the trouble of air velocity. If I make a slot port, it would have to be bigger in order to get similar air velocity.

And I would have to round all of the edgers very well. And as I don't own a router or any other tool that could make a smooth radius, I'd have to do it by hand.

I have done it in the past, but this would be too much work, as it would all be inside of my car.

That is why I want to use a round port. Also, if I want to change the tuning frequency in the future, It'll be much easier.

To do a round port, you can just get smaller sonotube (concrete forms). You can get 8", 10", 12" or larger. You can cut it and re-glue to bend it if you need to to make it more like a folded one.

Very best,

Very best,

That is actually my current solution, a 251mm concrete form. The problem with that is, I can't get rounded edges with it and it is too flimsy.To do a round port, you can just get smaller sonotube (concrete forms). You can get 8", 10", 12" or larger. You can cut it and re-glue to bend it if you need to to make it more like a folded one.

Very best,

I tried to soak it in fiberglass resin and then fiberglass mat on top, but it didn't want to soak in to the material, but just the outer layer.

Short answer: you tune lower either lengthen it or restrict/reduce its diameter.

dave

dave

Last edited:

That is actually my current solution, a 251mm concrete form. The problem with that is, I can't get rounded edges with it and it is too flimsy.

I tried to soak it in fiberglass resin and then fiberglass mat on top, but it didn't want to soak in to the material, but just the outer layer.

The flared port is only going to matter if your port is too small for the air velocity. What is your model showing as a peak air velocity?

Very best,

I can't make it smaller and there are no "easy", as good longer options.Short answer: yo tune lower either lengthen it or restrict/reduce its diameter.

dave

The flared port is only going to matter if your port is too small for the air velocity. What is your model showing as a peak air velocity?

Very best,

It's already close to 70 m/s, so yes, I need all the help reducing it I can get.

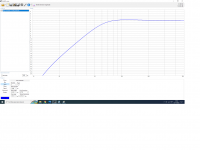

This is witha 250l box tuned to 28Hz with the 240mm wide and 500mm long port on 8kW.

Sonotube is treated to be water resistant so the wet concrete doesn’t turn it to mush! Just wrap the outside in fiberglass like a cast on an arm.if you find the right diameter tube you could use it as a former for the fiberglass and remove the cardboard after it has hardened making any shape possible.

I have two questions here - with the OP's permission - that I think are not far from the topic at hand:

1) Does the length of the tuning tube calculated by WINISD have the 0.732 correction factor already applied, or should we apply it ourselves?

For example in this attachment, I must multiply 40.28 x 0.732 and the actual length will be 29.48 cm? Or is 40.28 already calculated with the correction value?

2 ) The tuning frequency that we choose for WINISD to calculate the ports - which will depend on the volume of the box - must be equal to, less than or greater than the FS of the speaker - on air

free - specified by the manufacturer ? My subwoofer has FS 28hz, and I'm considering converting my sealed cabinets to BR.

Thank you ! 😉

1) Does the length of the tuning tube calculated by WINISD have the 0.732 correction factor already applied, or should we apply it ourselves?

For example in this attachment, I must multiply 40.28 x 0.732 and the actual length will be 29.48 cm? Or is 40.28 already calculated with the correction value?

2 ) The tuning frequency that we choose for WINISD to calculate the ports - which will depend on the volume of the box - must be equal to, less than or greater than the FS of the speaker - on air

free - specified by the manufacturer ? My subwoofer has FS 28hz, and I'm considering converting my sealed cabinets to BR.

Thank you ! 😉

Attachments

It's already close to 70 m/s, so yes, I need all the help reducing it I can get.

This is witha 250l box tuned to 28Hz with the 240mm wide and 500mm long port on 8kW.

Forget flaring, corner loading, etc., at ~35 m/s the vent is already 'choking' and pretty confident that your box will be a near enough sealed alignment at highest powers.

To prove it take a drinking straw and flow just enough water pressure to see it coming out in pulses due to its pipe harmonics and increase pressure till it's just dribbling due to flowing over/around it, but the vent can't be bypassed except by the driver, which of course is pressurizing the box/vent, so at some point it closes up to at best a leaky sealed box alignment and the question becomes; can the driver handle it at low distortion and is the box construction rigid/massive enough?

Frankly, with the ideal pipe size required, really need to make a TL or MLTL depending on the driver's specs and whether or not the driver can actually handle this much power down low, so what brand/model driver and quantity used?

No need for rounded edges and since the pressure modes are along its axis, immensely rigid for venting purposes once clamped at each end or other odd harmonic modes.That is actually my current solution, a 251mm concrete form. The problem with that is, I can't get rounded edges with it and it is too flimsy.

I tried to soak it in fiberglass resin and then fiberglass mat on top, but it didn't want to soak in to the material, but just the outer layer.

1. I think it already has the 0,732 correction, at least it shows to me, that it has. And it gives similar results to other calculators with the same parameters and K.I have two questions here - with the OP's permission - that I think are not far from the topic at hand:

1) Does the length of the tuning tube calculated by WINISD have the 0.732 correction factor already applied, or should we apply it ourselves?

For example in this attachment, I must multiply 40.28 x 0.732 and the actual length will be 29.48 cm? Or is 40.28 already calculated with the correction value?

2 ) The tuning frequency that we choose for WINISD to calculate the ports - which will depend on the volume of the box - must be equal to, less than or greater than the FS of the speaker - on air

free - specified by the manufacturer ? My subwoofer has FS 28hz, and I'm considering converting my sealed cabinets to BR.

Thank you ! 😉

2. If I understand correctly, you are asking if you can tune the box lower or higher that the Fs of the driver?

You "can" tune the box to whatever you want. You can always tune higher than, or at Fs, if that gives you the response you want, or the box size becomes too big.

If the driver has a "low" Qts, e.g. 0.1 - 0.5 ish, you can tune lower that Fs, as long as the driver doesn't bottom out.

I personally prefer ported and horn loaded subwoofers over sealed, because you just get more, free bass, at little to no cost in sound quality.

I can't make it smaller

Seems you may not be being creative enuff. Put something in the vent to make it smaller. Straws, ductseal, solid rods, and elacorate centre thing that turns it into a flow port (althou any i imagine also raise the tunign so counterproductive).

dave

Last edited:

1) Already and very dim memory 'says' the 'pro' version might have the option to change it. So many folks are still using it, tempted to reinstall it.1) Does the length of the tuning tube calculated by WINISD have the 0.732 correction factor already applied, or should we apply it ourselves?

2 ) specified by the manufacturer ? My subwoofer has FS 28hz, and I'm considering converting my sealed cabinets to BR.

2) Depends on if the difference between the two makes an audible difference, which usually means > ~10% and if this far off might be best to use full measured specs.

- Home

- Loudspeakers

- Subwoofers

- How do I lower tuning frequency with the same port?