EDIT: The problems encountered initially have been solved in this thread by numerous tests and with the assistance of jpk73 and mdardeniz as well as the contribution of element of the work of JeffYoung. I give files here and i will see to establish component list.

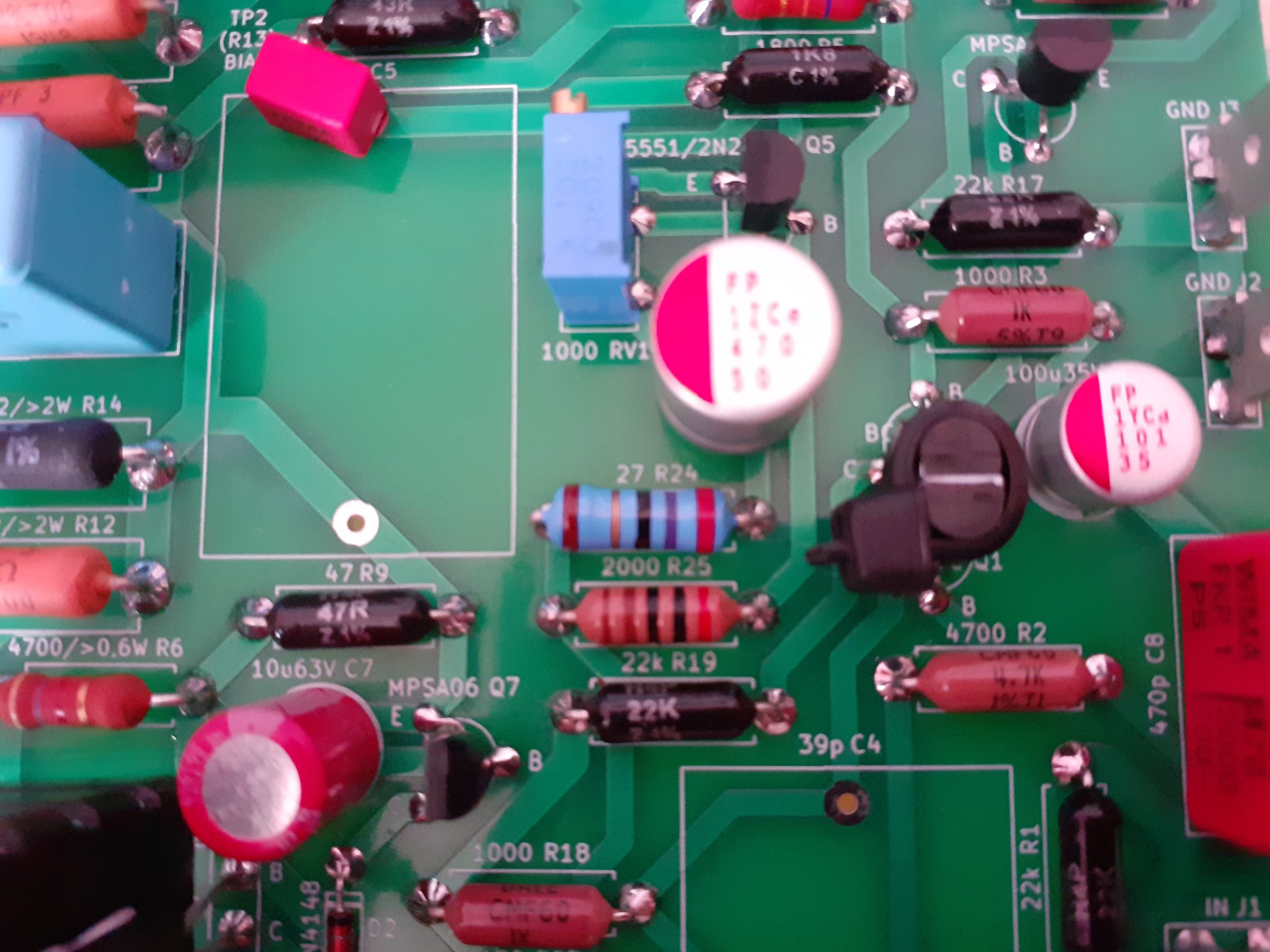

Hello everyone, three years ago I built two NAP 250 clones from naim, these were my first DIY projects and even if they already give (very) good results, I still made some errors so I wanted to launch myself into a new, more successful version, so I reworked all this on the net and on this forum as well.

I redid all the diagrams in Kicad directly in order to improve the design of the PCBs and their skillscreen printing by sticking as closely as possible to the original NAIM

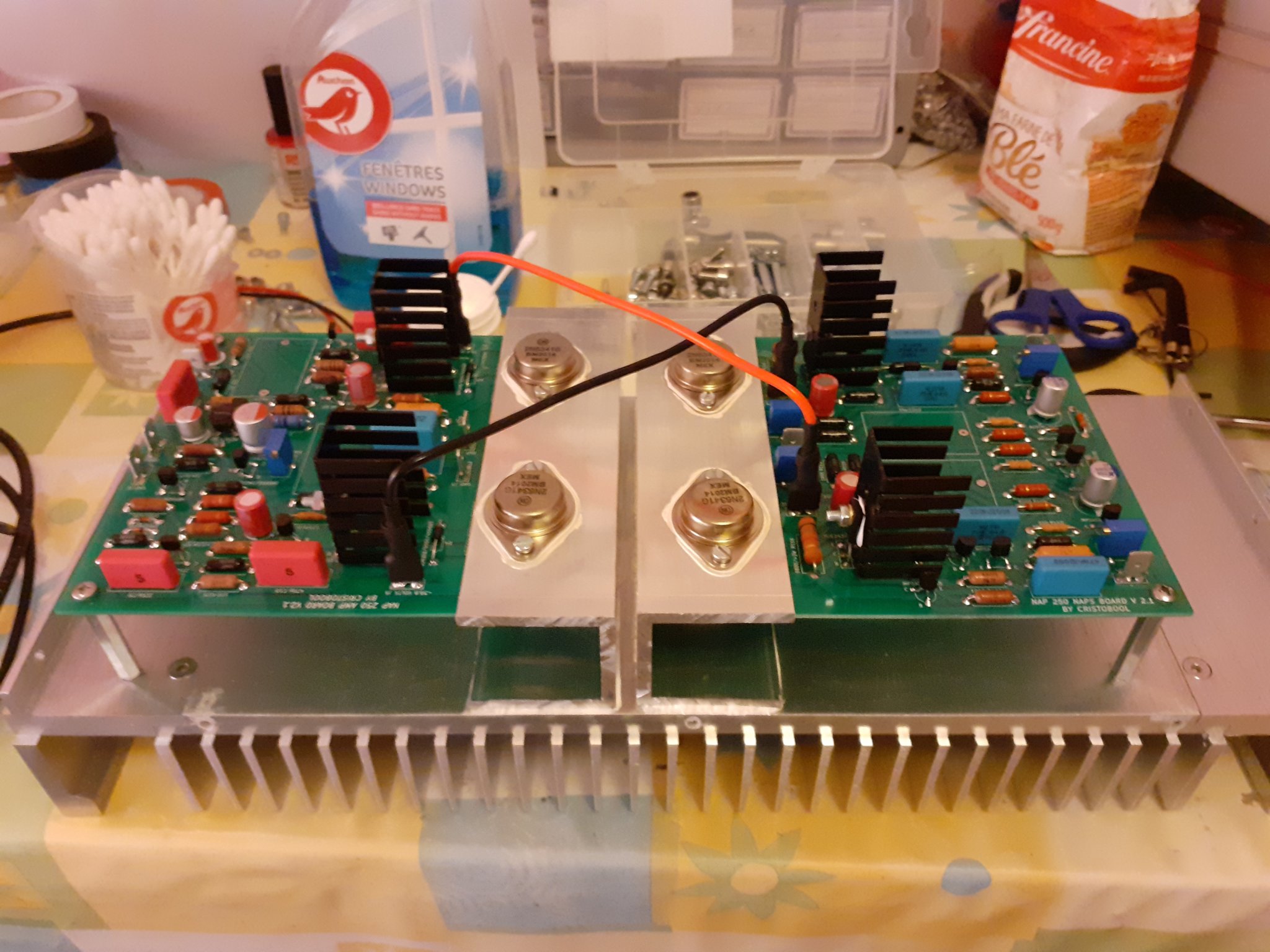

I placed output transistors on the PCBs and not wired in the air which improves stability and construction

I changed my PCBs to double-sided 70 microns instead of double-sided 35 microns like on the old versions

I note as my work progresses all the verified information in my diagram

I went through plenty of pictures of the original Naims to determine the correct values and was able to correctly determine and identify three versions of the phase correctors to the driver transistors as well.

I determined the values of the phase compensation resistors according to the output transistors used.

I was able to correct an error on a value of a capacitor, on the input filter it is a 470pF and not a 330pF.

I changed the output capacitors on the regulation card for "high" ESR capacities >1.7ohms which corrects an oscillation problem.

I was able to determine that without the protection circuit on the amplification board the sound is not particularly improved and that the offset is much longer to go down when switched off

this time I use the original drivers (MJE243/253) on the regulation cards and not those recommended by Neil mcbride which greatly improves performance and stability

I then searched for better substitutes for the unavailable transistors by closely studying many datasheets namely the VBE (ZTX384 or ZTX108) and the output ones, the Mj15003 not being the best.

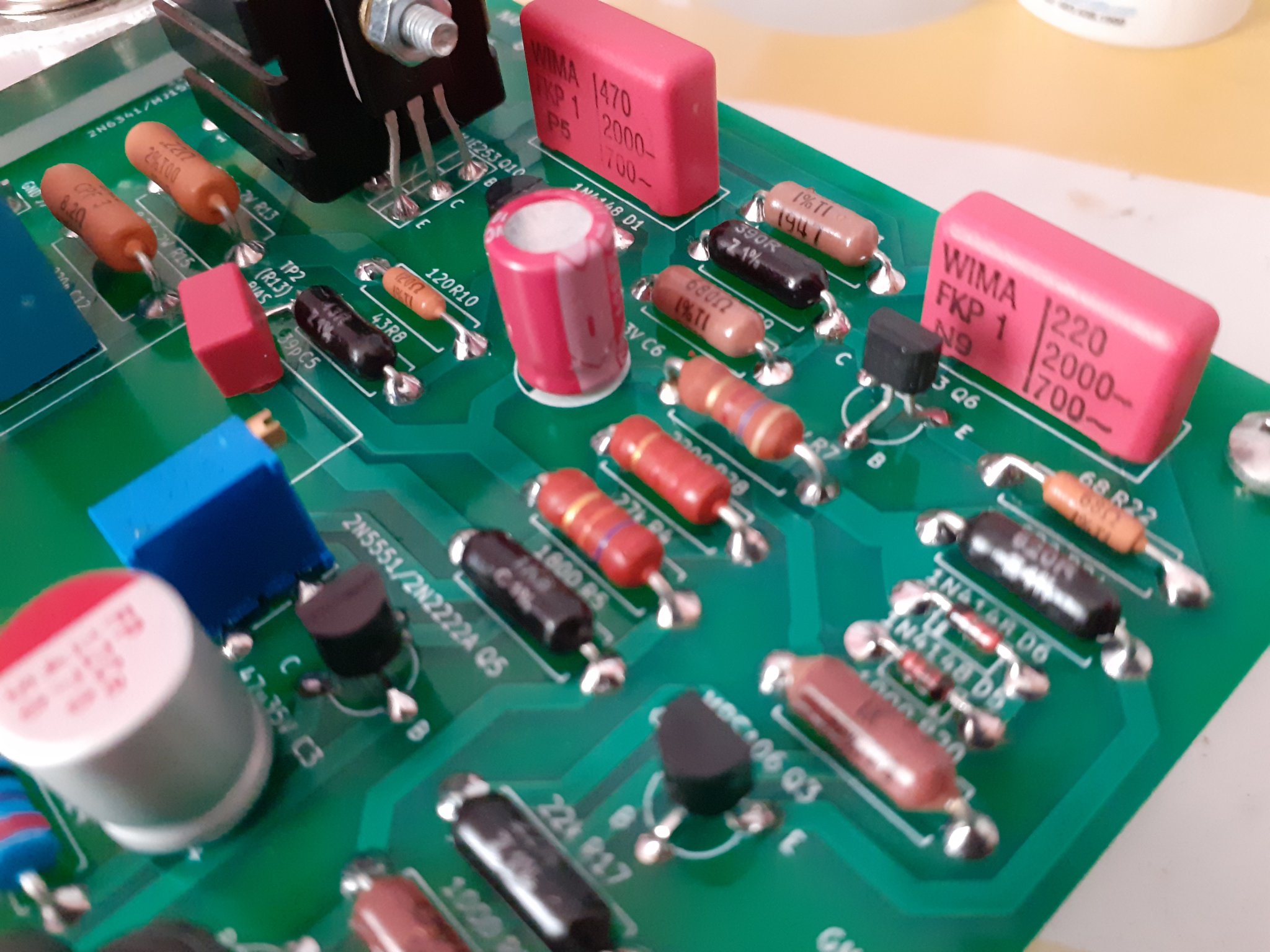

I thus tested with the oscilloscope and by ear for the VBE the 2N2222A in comparison with the 2n5551, my choice fell on the 2N2222A which seems to me a little better to the ear but also on the noise in the data sheet. I also tested the ZTX690B and 2N6428 it's works but it's not better.

For the output ones I tested:

BUV22 but they are not really suitable for the ear it is not very convincing and I think that the bias and the drivers are not suitable, there is too much crossover distorsion with MJ243/253 drivers.

Mj15024 they seem better to the ear than the Mj15003 but they are only 15A so there is no point in taking T0-3 boxes, there are also too much crossover distorsion with Mj243/253

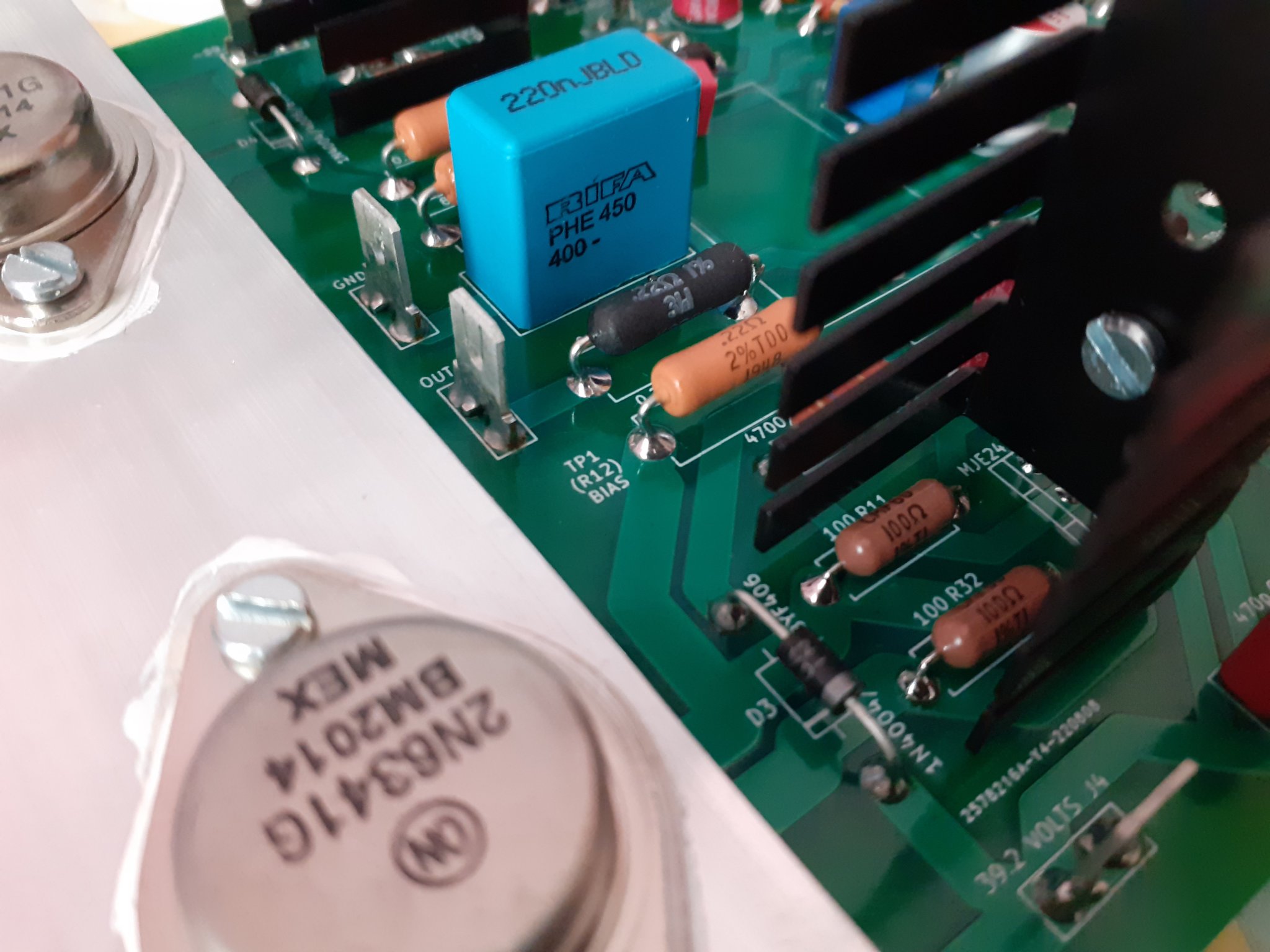

2N6341 They are suitable and sound better to the ear making 40mhz for 25 amps they are probably the best performing so I have chosen it for my new amplifier.

I had noticed Phase compensation problem with 2N6341, I didn't initially understand the problem, I was able to fix it as you can see later in the topic.

The adjustment of the phase compensation is more or less delicate it depends on each type of power transistor used but it also depends on the PCB layout. If the MJ15003 and the BUV22 are quite easy to adjust, the same is not true of the Mj15024 and especially the 2N6341. Having done the setting for the PCB layout used in my amplifier (V2.1) I cannot give the optimal values for the latest files I give here (V2.5)

I give the correct values for version 2.1 so that you can directly use these PCBs if you want to build the same amplifier without having to do the adjustment. For those who would like to use the latest more advanced version, you will have to make the adjustment yourself. The rest of the topic will show you how to do it.

For the components I chose the original MPSA06/56 from diotec and not those from central component as for my old creations, indeed central component makes copies and not originals, something that I did not know.

For capacitors I chose for the amplification card very high voltage WIMA and also for the miller. (on my old version I took 39pf in Mica, there I took 33pF and 47pF)

i take organic polymer low esr for the AMP BOARD

For the NAPS Board please note output capacitors 10Uf must have a esr >1,7 ohms for stability of the supply.

For filtering I chose a very high quality EPCOS 22000uF 100V capacitor 4 milliohms of ESR, 57 amps of rejection capacity in place of the previous Mundorf 22000uF 80V (7 milliohms 33Amps)

All my components are ordered on Mouser by preferentially choosing the manufacturers

For the resistors I chose to switch to 1W or 2W in metal layer in order to further reduce the noise against 0.5W on my previous realizations

only the 0.22 ohms on the output is wound due to lack of availability.

For the plugs I chose larger plugs more suitable for 2.5mm wiring and above all offering better contact and better manufacturing quality.

For the pairing of the transistors I invested in a second-hand RIGOL DG1022Z BF generator which allowed me with my oscilloscope in XY mode to draw the characteristic networks of the transistors which I had not done during my previous achievements, I had simply used the HFE.

I ordered series of transistors and as I had other of my previous orders I was able to operate pairings on:

BC550C in LTP are matched

VAS ZTX653/753 are matched

MPSA06/56 on the protection circuit are matched

MJE243/253 in drivers are matched

2n6341 output are matched

On the regulation boards I used identical paired MPSA06 series and also paired MPSA56 series

MJE243/253 drivers and 2n6341 output drivers are also paired

capacitors are MKP higth voltage general purpose

resistors are 1W-2W metal too

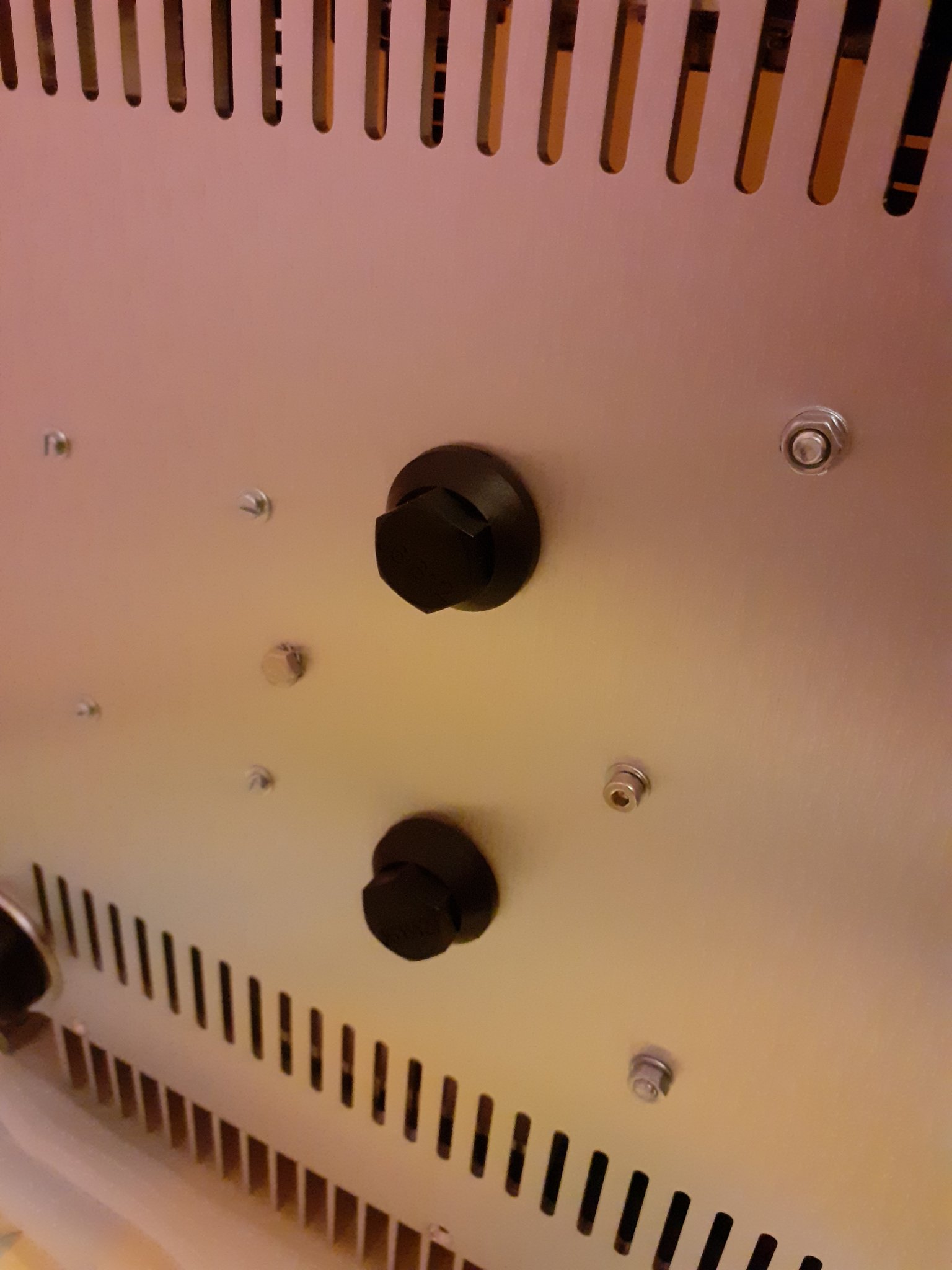

For the variable resistors I take multi-turns unlike my previous amplifiers, in fact the single-turns are not precise enough and can move with time and vibrations.

The transformer is a high quality encapsulated nuvotem talema 500VA to reduce vibration and ground buzz

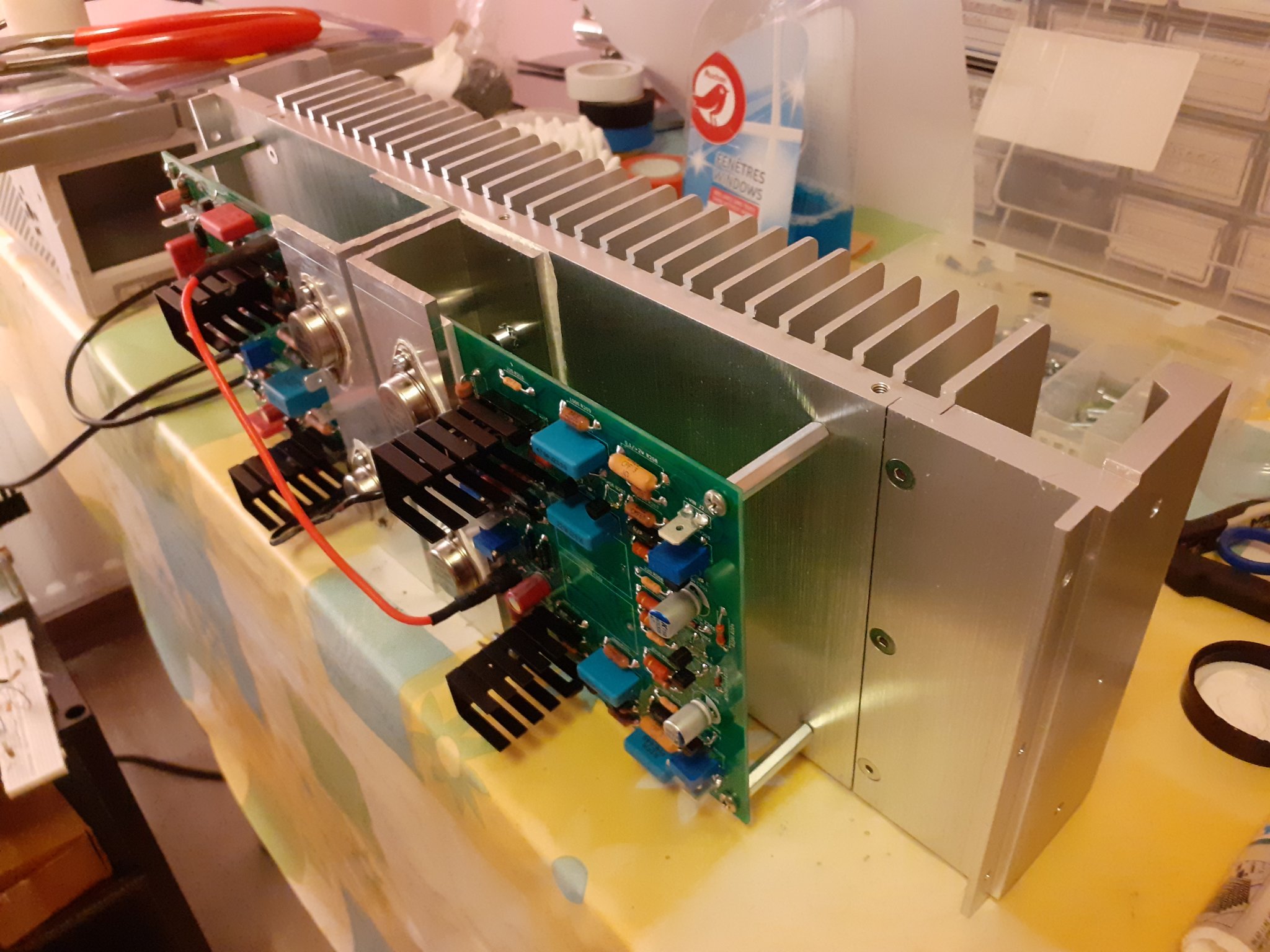

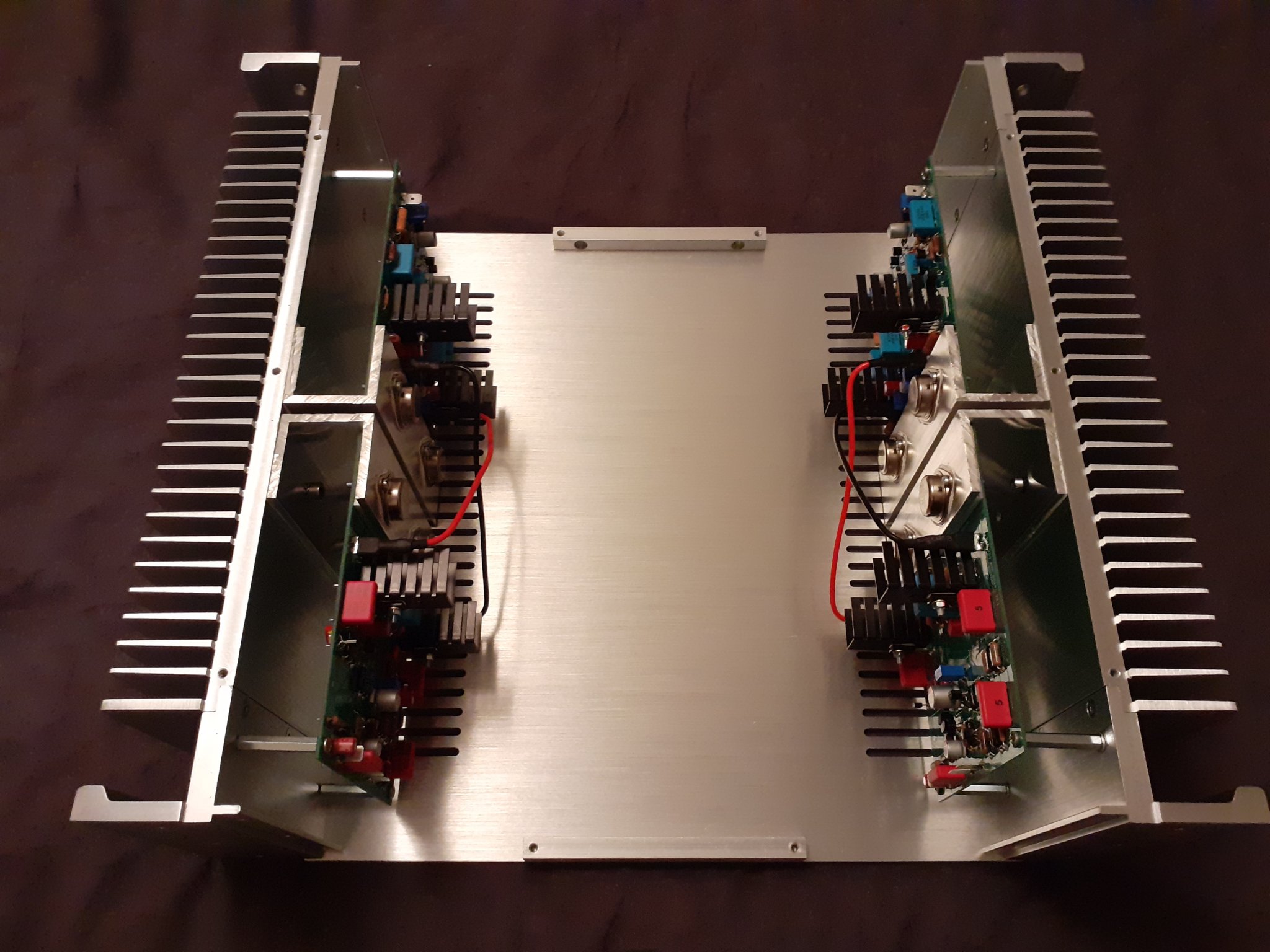

The 4 cards are mounted, I still have the last heatsink to manufacture, I am waiting for my aluminum case and the last parts in order to start the final assembly, I expect to receive the case in less than 15 days.

to note unfortunately on my PCBs I made a footprint error on the 39pF capacitors which were far too big, I was deceived by a bug in the Mouser search system which was giving me 4uF capacitors instead of 40pF.. .

I have since corrected the error in a new version of my PCBs in Kicad but my PCBs being already ordered I use those with this footprint error.

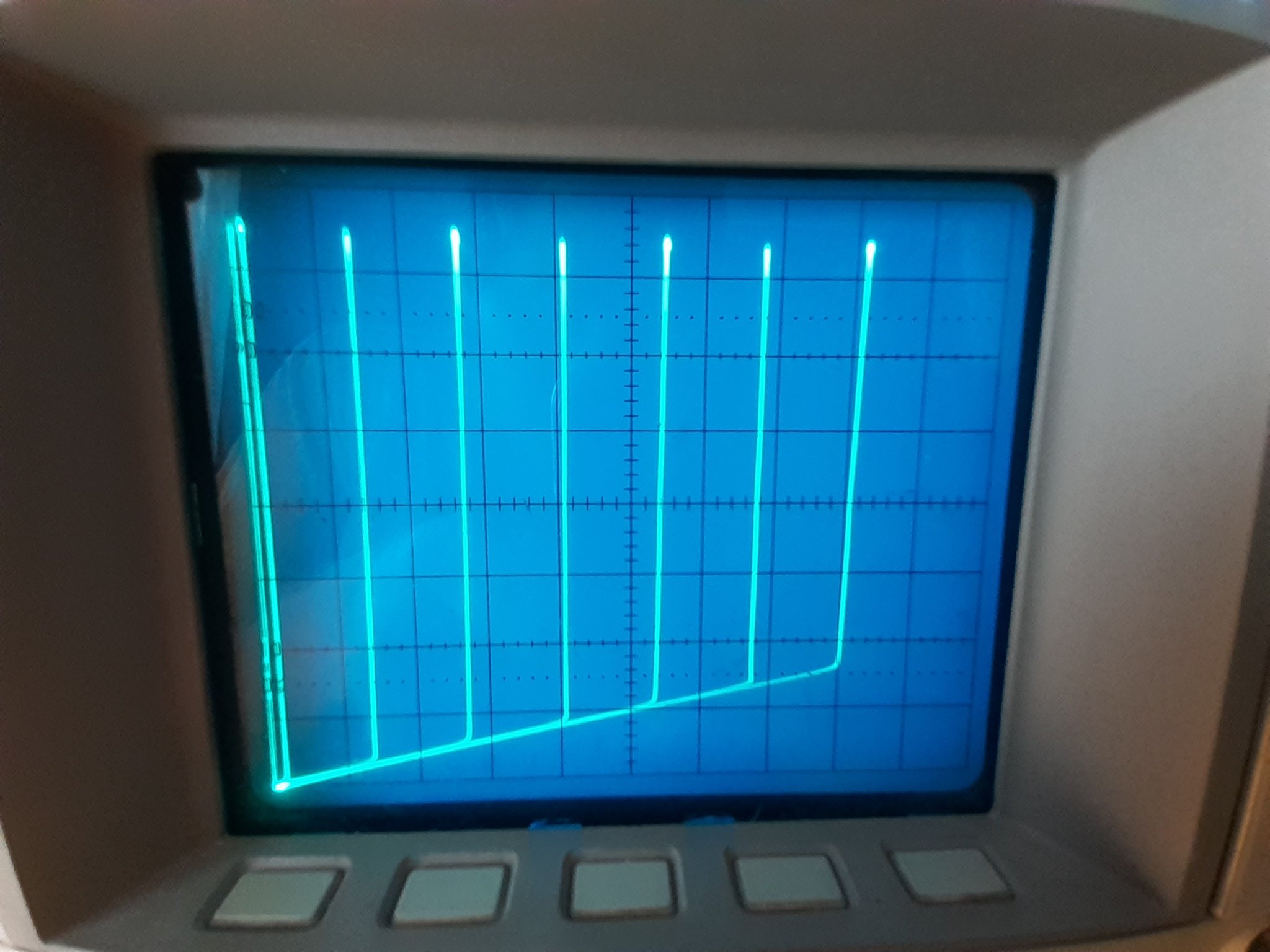

Here a caracteristics of a transistors i use two différent resistor for the base 100K and a 3300ohms for testing different currents

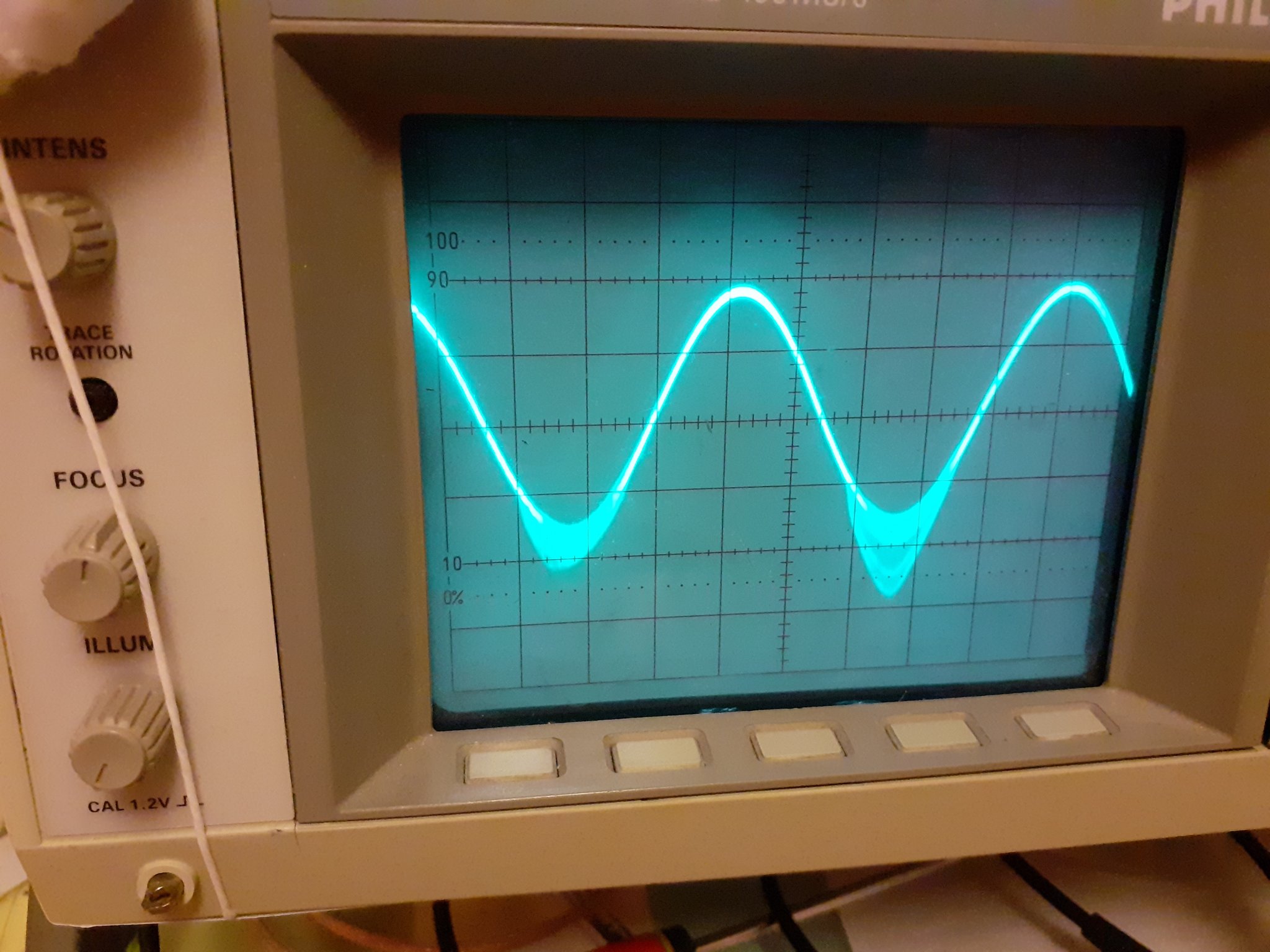

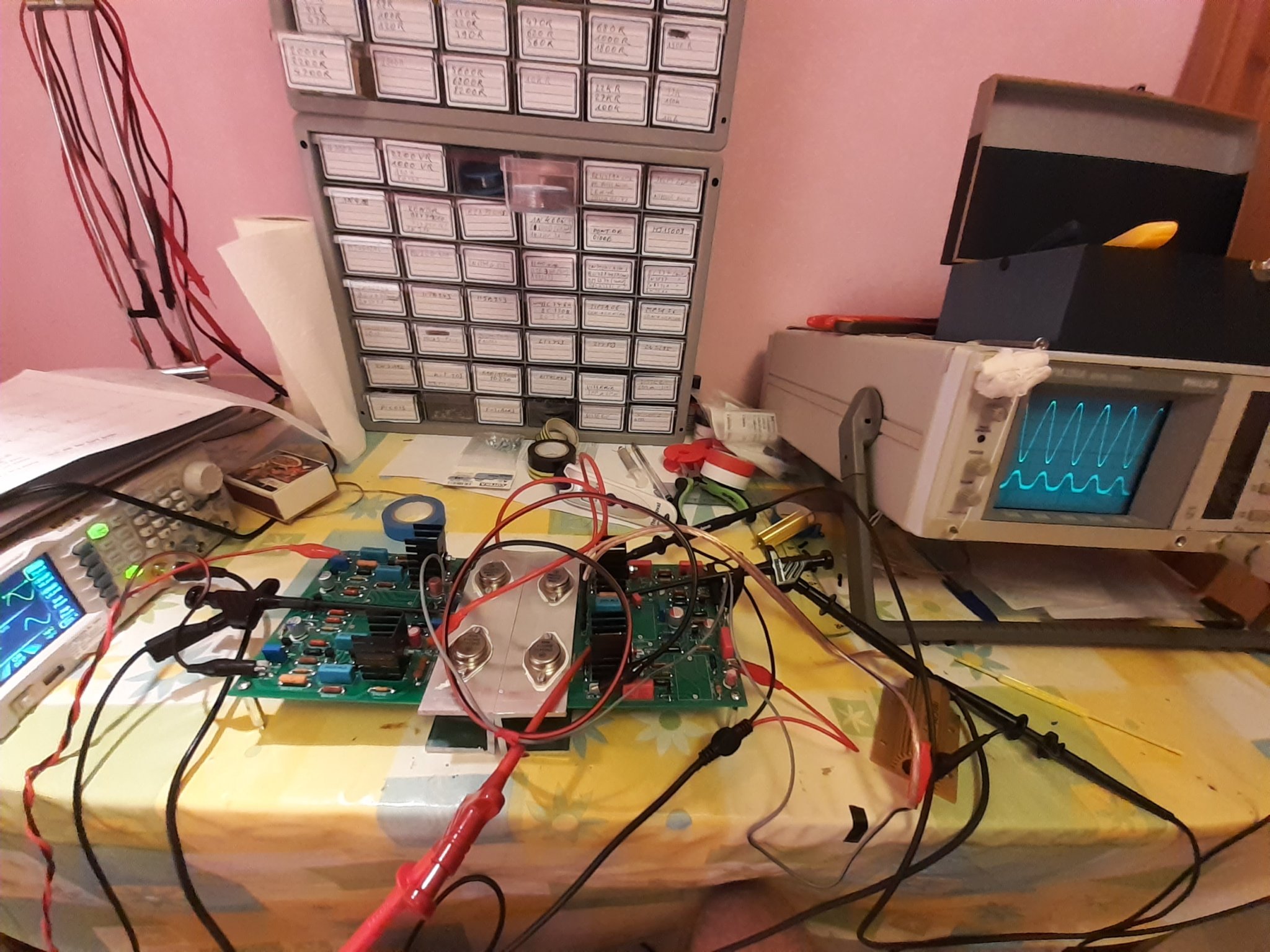

Here you can see phase compensation problem

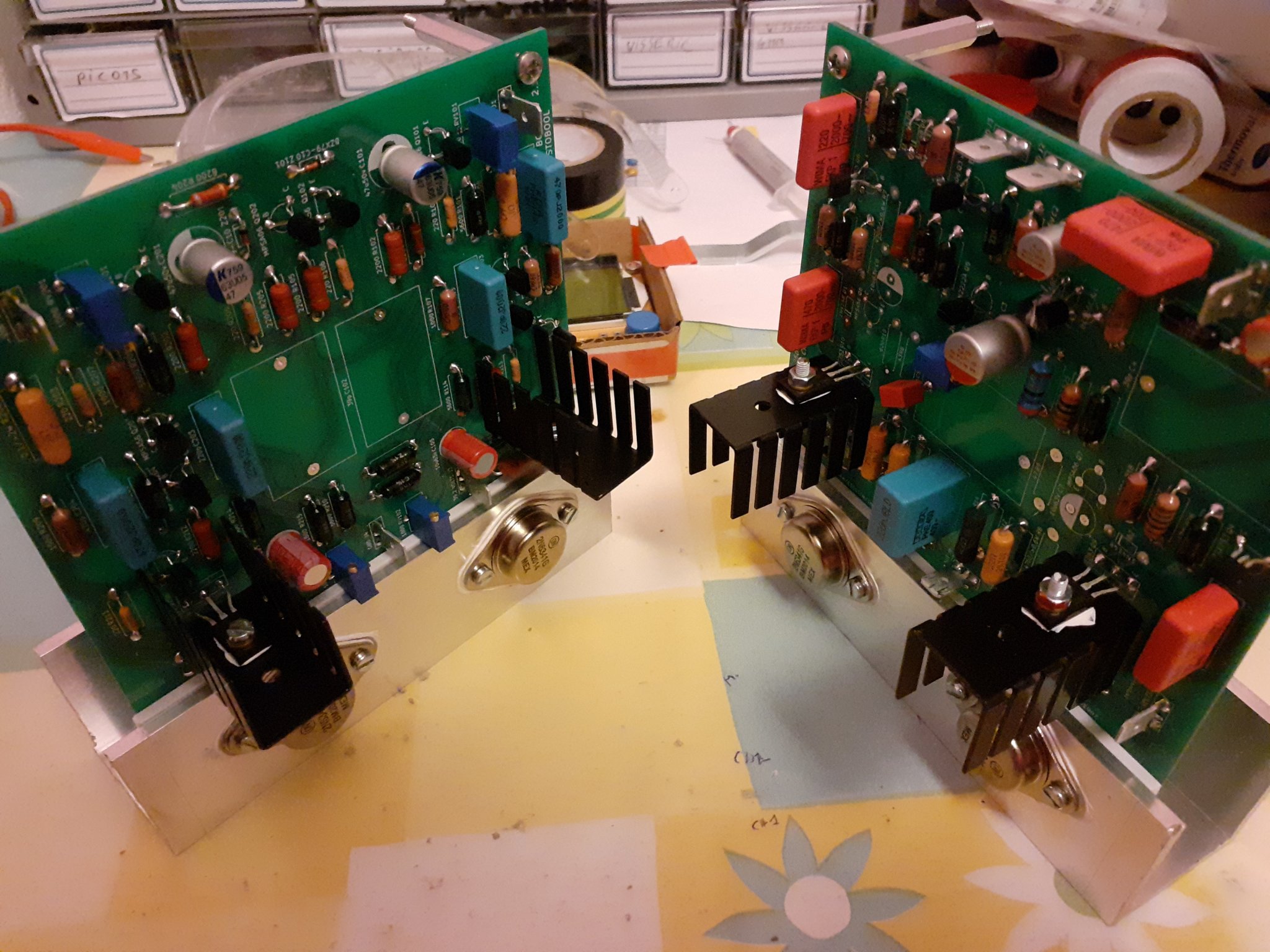

First regulator board, note larges Capacitors are organic polymers low esr and not electrolytics. C105/205 later changed by united chemicon electrolytic with 1,8 ohms ESR

On the first amp board there are not the circuit protection i want to test with ears with and without the circuit protection when the amplifier will be finish.

here on a 2Ohms resistor

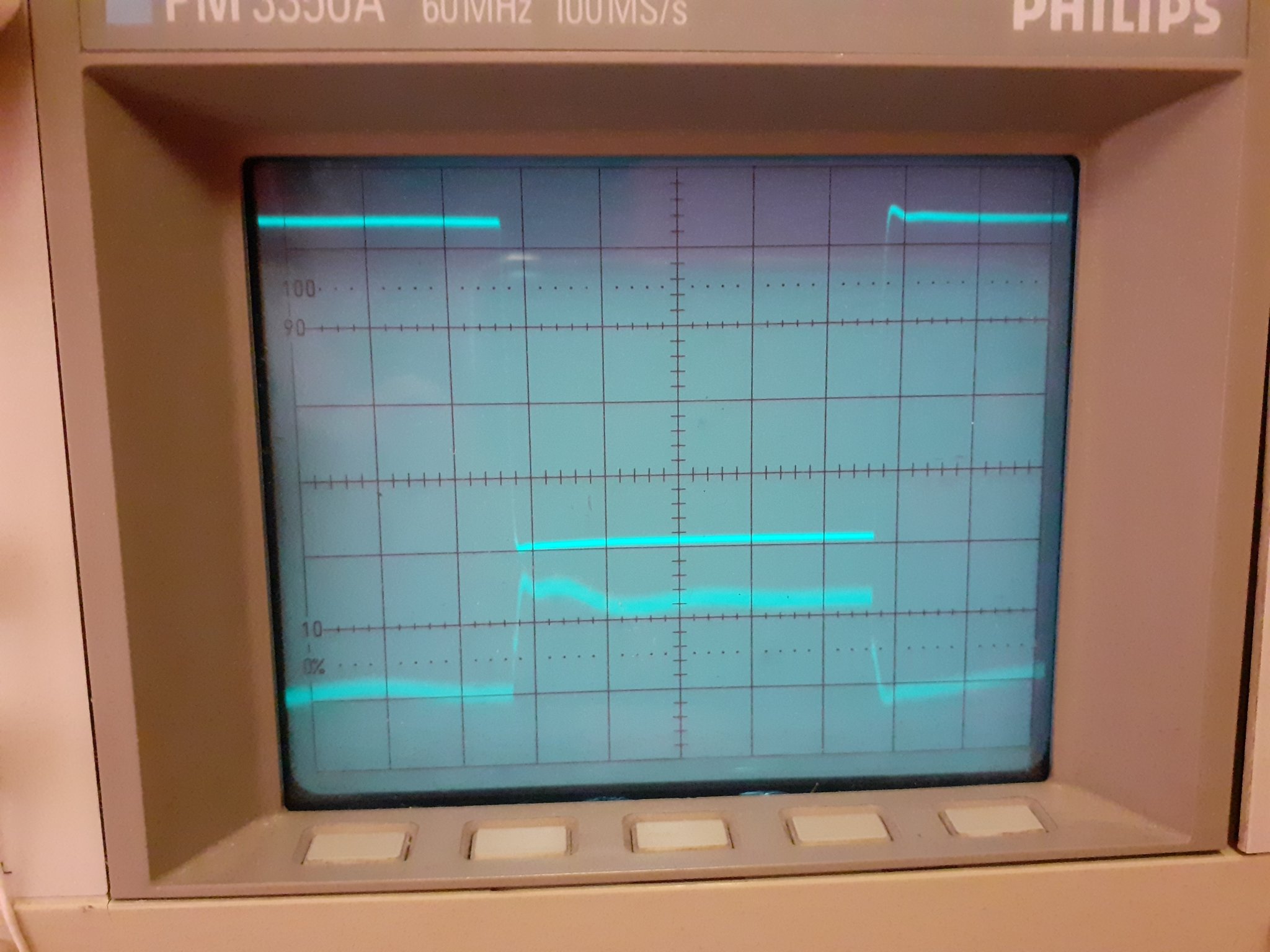

here the test of stability on the regulator down it's a power rail of the regulator board it's about 100-150 mv variation on a square wave 1000Hz 100mV in the amp

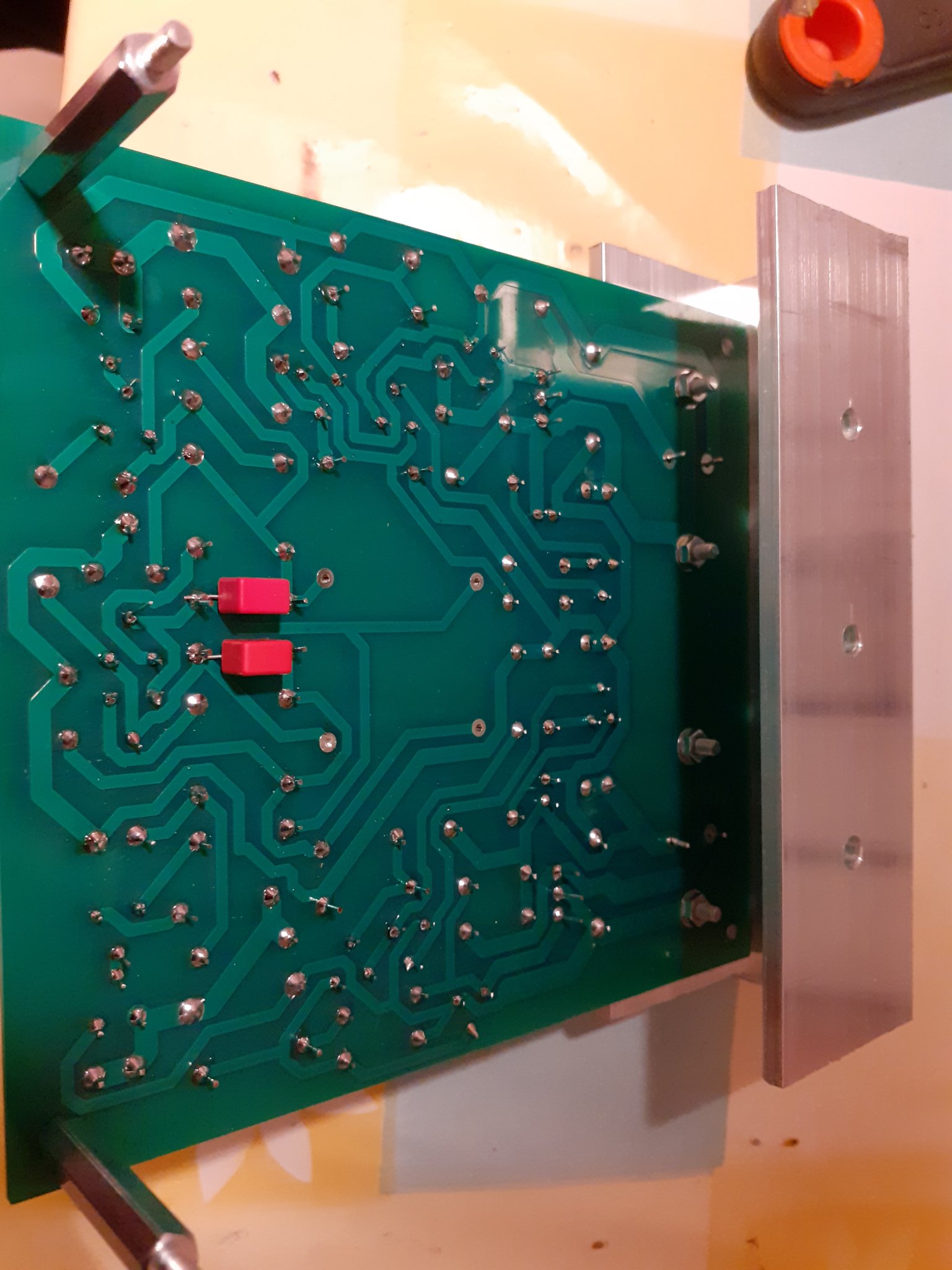

47pF are on the other side...

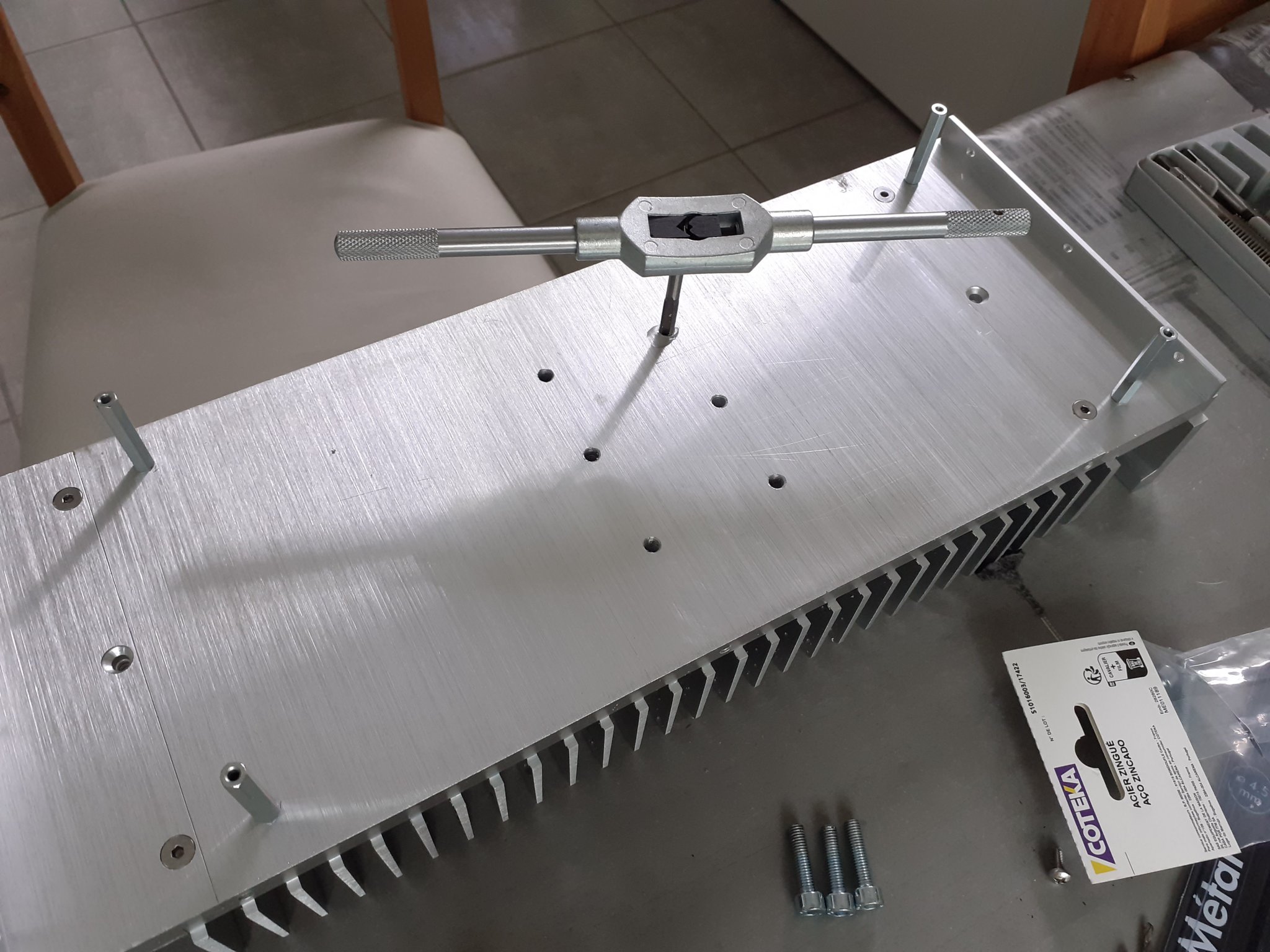

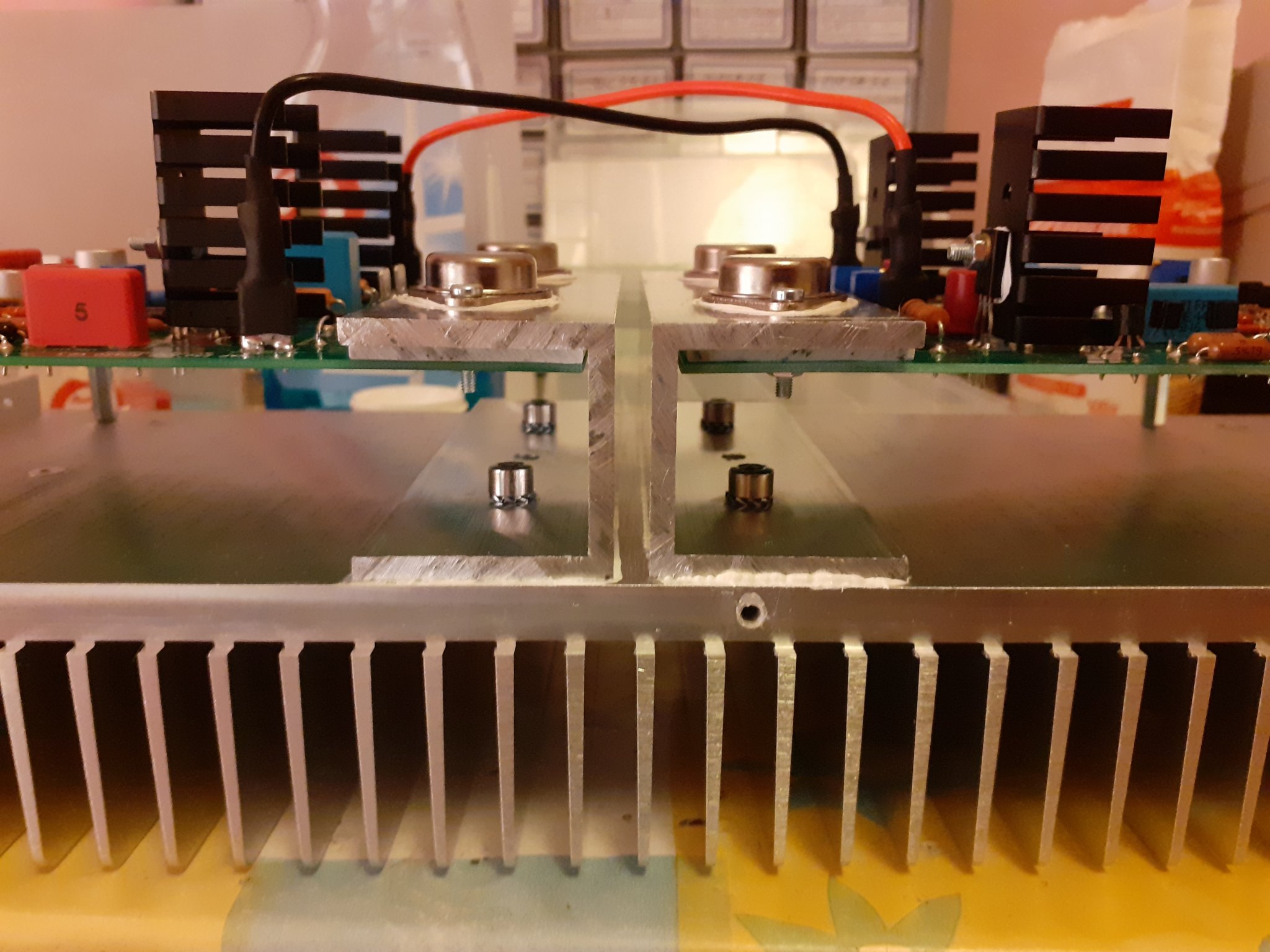

a heatsink with his isolate board to isolate from the PCB

Here V2.1 correct values for phase compensation are:

R26 1800 ohms

R27 1800 ohms

R29 2000 ohms

R30 2200 ohms

(note for the drilling of the heatsinks that the two output transistors are not perfectly aligned either on the AMP BOARD or the NAPS BOARD)

Here the last files of schematics and Kicad PCB V2.5 (V2.4 For regulation NAPS board), This version is better the holes are aligned for the T0-3 but the values for the phase compensation must be developed:

Hello everyone, three years ago I built two NAP 250 clones from naim, these were my first DIY projects and even if they already give (very) good results, I still made some errors so I wanted to launch myself into a new, more successful version, so I reworked all this on the net and on this forum as well.

I redid all the diagrams in Kicad directly in order to improve the design of the PCBs and their skillscreen printing by sticking as closely as possible to the original NAIM

I placed output transistors on the PCBs and not wired in the air which improves stability and construction

I changed my PCBs to double-sided 70 microns instead of double-sided 35 microns like on the old versions

I note as my work progresses all the verified information in my diagram

I went through plenty of pictures of the original Naims to determine the correct values and was able to correctly determine and identify three versions of the phase correctors to the driver transistors as well.

I determined the values of the phase compensation resistors according to the output transistors used.

I was able to correct an error on a value of a capacitor, on the input filter it is a 470pF and not a 330pF.

I changed the output capacitors on the regulation card for "high" ESR capacities >1.7ohms which corrects an oscillation problem.

I was able to determine that without the protection circuit on the amplification board the sound is not particularly improved and that the offset is much longer to go down when switched off

this time I use the original drivers (MJE243/253) on the regulation cards and not those recommended by Neil mcbride which greatly improves performance and stability

I then searched for better substitutes for the unavailable transistors by closely studying many datasheets namely the VBE (ZTX384 or ZTX108) and the output ones, the Mj15003 not being the best.

I thus tested with the oscilloscope and by ear for the VBE the 2N2222A in comparison with the 2n5551, my choice fell on the 2N2222A which seems to me a little better to the ear but also on the noise in the data sheet. I also tested the ZTX690B and 2N6428 it's works but it's not better.

For the output ones I tested:

BUV22 but they are not really suitable for the ear it is not very convincing and I think that the bias and the drivers are not suitable, there is too much crossover distorsion with MJ243/253 drivers.

Mj15024 they seem better to the ear than the Mj15003 but they are only 15A so there is no point in taking T0-3 boxes, there are also too much crossover distorsion with Mj243/253

2N6341 They are suitable and sound better to the ear making 40mhz for 25 amps they are probably the best performing so I have chosen it for my new amplifier.

I had noticed Phase compensation problem with 2N6341, I didn't initially understand the problem, I was able to fix it as you can see later in the topic.

The adjustment of the phase compensation is more or less delicate it depends on each type of power transistor used but it also depends on the PCB layout. If the MJ15003 and the BUV22 are quite easy to adjust, the same is not true of the Mj15024 and especially the 2N6341. Having done the setting for the PCB layout used in my amplifier (V2.1) I cannot give the optimal values for the latest files I give here (V2.5)

I give the correct values for version 2.1 so that you can directly use these PCBs if you want to build the same amplifier without having to do the adjustment. For those who would like to use the latest more advanced version, you will have to make the adjustment yourself. The rest of the topic will show you how to do it.

For the components I chose the original MPSA06/56 from diotec and not those from central component as for my old creations, indeed central component makes copies and not originals, something that I did not know.

For capacitors I chose for the amplification card very high voltage WIMA and also for the miller. (on my old version I took 39pf in Mica, there I took 33pF and 47pF)

i take organic polymer low esr for the AMP BOARD

For the NAPS Board please note output capacitors 10Uf must have a esr >1,7 ohms for stability of the supply.

For filtering I chose a very high quality EPCOS 22000uF 100V capacitor 4 milliohms of ESR, 57 amps of rejection capacity in place of the previous Mundorf 22000uF 80V (7 milliohms 33Amps)

All my components are ordered on Mouser by preferentially choosing the manufacturers

For the resistors I chose to switch to 1W or 2W in metal layer in order to further reduce the noise against 0.5W on my previous realizations

only the 0.22 ohms on the output is wound due to lack of availability.

For the plugs I chose larger plugs more suitable for 2.5mm wiring and above all offering better contact and better manufacturing quality.

For the pairing of the transistors I invested in a second-hand RIGOL DG1022Z BF generator which allowed me with my oscilloscope in XY mode to draw the characteristic networks of the transistors which I had not done during my previous achievements, I had simply used the HFE.

I ordered series of transistors and as I had other of my previous orders I was able to operate pairings on:

BC550C in LTP are matched

VAS ZTX653/753 are matched

MPSA06/56 on the protection circuit are matched

MJE243/253 in drivers are matched

2n6341 output are matched

On the regulation boards I used identical paired MPSA06 series and also paired MPSA56 series

MJE243/253 drivers and 2n6341 output drivers are also paired

capacitors are MKP higth voltage general purpose

resistors are 1W-2W metal too

For the variable resistors I take multi-turns unlike my previous amplifiers, in fact the single-turns are not precise enough and can move with time and vibrations.

The transformer is a high quality encapsulated nuvotem talema 500VA to reduce vibration and ground buzz

The 4 cards are mounted, I still have the last heatsink to manufacture, I am waiting for my aluminum case and the last parts in order to start the final assembly, I expect to receive the case in less than 15 days.

to note unfortunately on my PCBs I made a footprint error on the 39pF capacitors which were far too big, I was deceived by a bug in the Mouser search system which was giving me 4uF capacitors instead of 40pF.. .

I have since corrected the error in a new version of my PCBs in Kicad but my PCBs being already ordered I use those with this footprint error.

Here a caracteristics of a transistors i use two différent resistor for the base 100K and a 3300ohms for testing different currents

Here you can see phase compensation problem

First regulator board, note larges Capacitors are organic polymers low esr and not electrolytics. C105/205 later changed by united chemicon electrolytic with 1,8 ohms ESR

On the first amp board there are not the circuit protection i want to test with ears with and without the circuit protection when the amplifier will be finish.

here on a 2Ohms resistor

here the test of stability on the regulator down it's a power rail of the regulator board it's about 100-150 mv variation on a square wave 1000Hz 100mV in the amp

47pF are on the other side...

a heatsink with his isolate board to isolate from the PCB

Here V2.1 correct values for phase compensation are:

R26 1800 ohms

R27 1800 ohms

R29 2000 ohms

R30 2200 ohms

(note for the drilling of the heatsinks that the two output transistors are not perfectly aligned either on the AMP BOARD or the NAPS BOARD)

Here the last files of schematics and Kicad PCB V2.5 (V2.4 For regulation NAPS board), This version is better the holes are aligned for the T0-3 but the values for the phase compensation must be developed:

Attachments

Last edited:

Member

Joined 2009

Paid Member

Cristobool - excellent work and very interesting project.

I see that the spirit of DIY Audio is very much alive and well in this thread, it's a really nice project. Not just buying boards off ePay, you've taken the time to do the research, designed your own boards, sorted out parts, built and tested. I've become too much of an armchair hobbyist these days but I do enjoy reading about projects like this one. I may have to dust off my NAP 160 clone....

Tracking down the instability issues - wall socket? That's a new one on me. I'm not convinced that so much hash can be simply ascribed to a noisy wall socket and somehow got past the natural PSRR of your supply and amplifier. If it were me, I'd spend a bit more time on this a my 'gut' tells me there is some marginal stability issue with the amplifier - could simply be the benchtop wiring layout, but it maybe something else such as grounding, or many other things - more information from playing around with it would be helpful.

I see that the spirit of DIY Audio is very much alive and well in this thread, it's a really nice project. Not just buying boards off ePay, you've taken the time to do the research, designed your own boards, sorted out parts, built and tested. I've become too much of an armchair hobbyist these days but I do enjoy reading about projects like this one. I may have to dust off my NAP 160 clone....

Tracking down the instability issues - wall socket? That's a new one on me. I'm not convinced that so much hash can be simply ascribed to a noisy wall socket and somehow got past the natural PSRR of your supply and amplifier. If it were me, I'd spend a bit more time on this a my 'gut' tells me there is some marginal stability issue with the amplifier - could simply be the benchtop wiring layout, but it maybe something else such as grounding, or many other things - more information from playing around with it would be helpful.

Last edited:

For the LTP i do not use resistors degeneration, i respect the original diagram of NAIM

Ty Bigun

For the HF parasite i'm surprise too but the problem disappears completely by connecting the power supply to another line ... so

I deduced that it came from the sector, I don't know how the laboratory power supply is made, maybe there is a filter fault. Maybe it's the amplifier that is very sensitive compared to other circuits, I don't know, but with the Mj15003 the problem existed but was barely detectable on the oscilloscope, on the other hand with faster transistors the problem becomes more important. I hope I won't have this problem with the final assembly

It should also be noted that when I put a 50hz signal in the amplifier the problem disappeared which is the mains frequency (230 Volts 50Hz in my country) and that it was more important at low frequency than at high frequency beyond 2000 Hz the problem disappeared

Ty Bigun

For the HF parasite i'm surprise too but the problem disappears completely by connecting the power supply to another line ... so

I deduced that it came from the sector, I don't know how the laboratory power supply is made, maybe there is a filter fault. Maybe it's the amplifier that is very sensitive compared to other circuits, I don't know, but with the Mj15003 the problem existed but was barely detectable on the oscilloscope, on the other hand with faster transistors the problem becomes more important. I hope I won't have this problem with the final assembly

It should also be noted that when I put a 50hz signal in the amplifier the problem disappeared which is the mains frequency (230 Volts 50Hz in my country) and that it was more important at low frequency than at high frequency beyond 2000 Hz the problem disappeared

Member

Joined 2009

Paid Member

In my opinion, LTP degeneration is linked with the LTP idle current. When run at low currents, e.g. 0.5mA per device, degeneration may not be beneficial but at higher currents a few ohms can be a good thing. Much has been written about the need for degeneration in controlling certain distortions but to retain the Open Loop Gain with degeneration you have to run the LTP at higher current. A 'modern' design would use degeneration with higher current but this is a clone project.

Wall socket - could be a grounding / radiating issue?

Wall socket - could be a grounding / radiating issue?

maybe radiating grounding pb i don't know

but i noted that twisting câbles between the power supply and the amp reduced parasites.

I just go to do another tests about this problem i d'ont detect HF parasites directly on the power supply with mu oscilloscope

then i do the test with the amp board connected on the regulator board, in that configuration there i no HF parasites, the regulator filter the problem

maybe a ground circle ?

In any case with the regulation card the problem seems to be resolved I suppose that with a good power supply there will not be this problem

but i noted that twisting câbles between the power supply and the amp reduced parasites.

I just go to do another tests about this problem i d'ont detect HF parasites directly on the power supply with mu oscilloscope

then i do the test with the amp board connected on the regulator board, in that configuration there i no HF parasites, the regulator filter the problem

maybe a ground circle ?

In any case with the regulation card the problem seems to be resolved I suppose that with a good power supply there will not be this problem

Member

Joined 2009

Paid Member

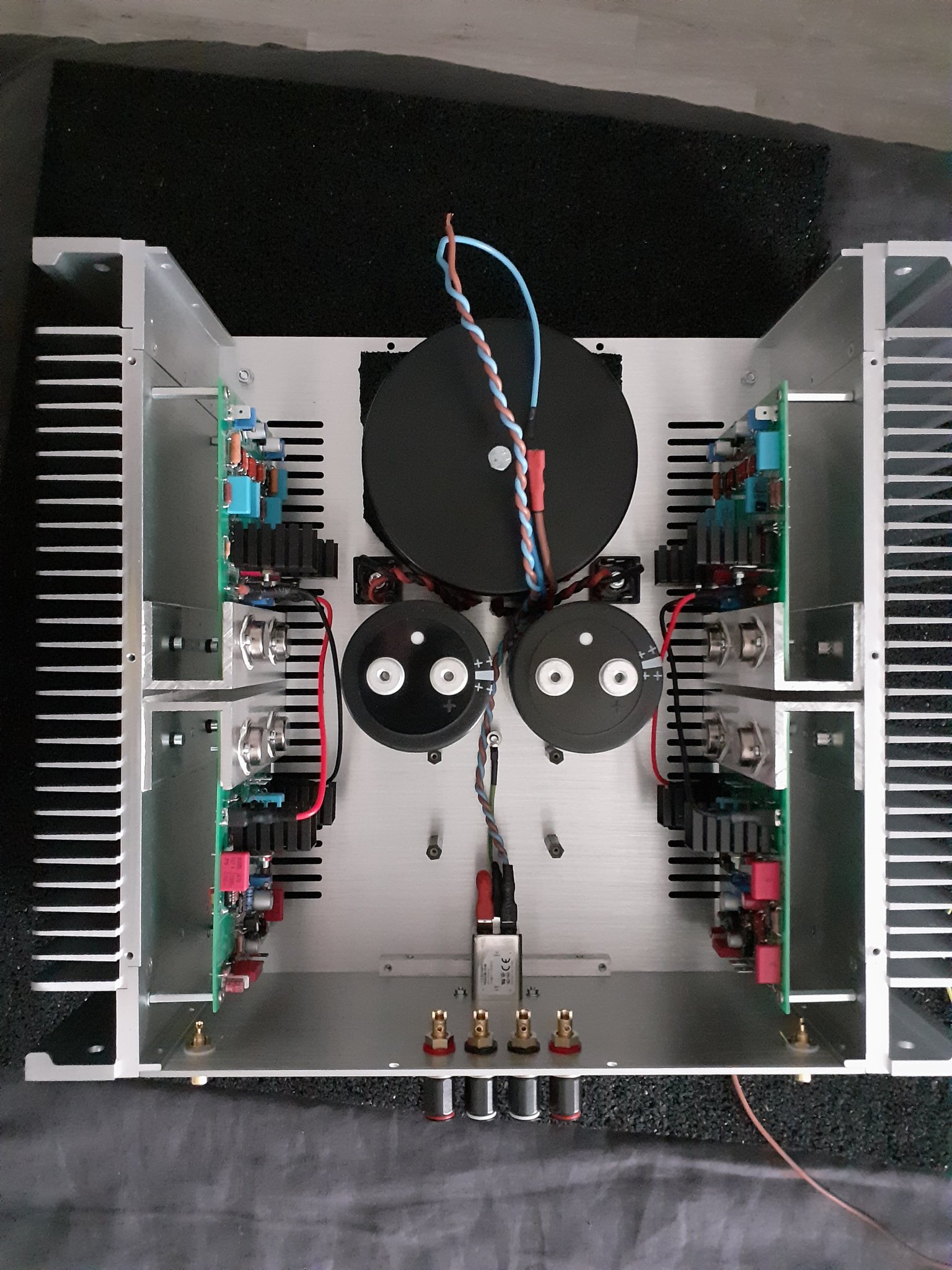

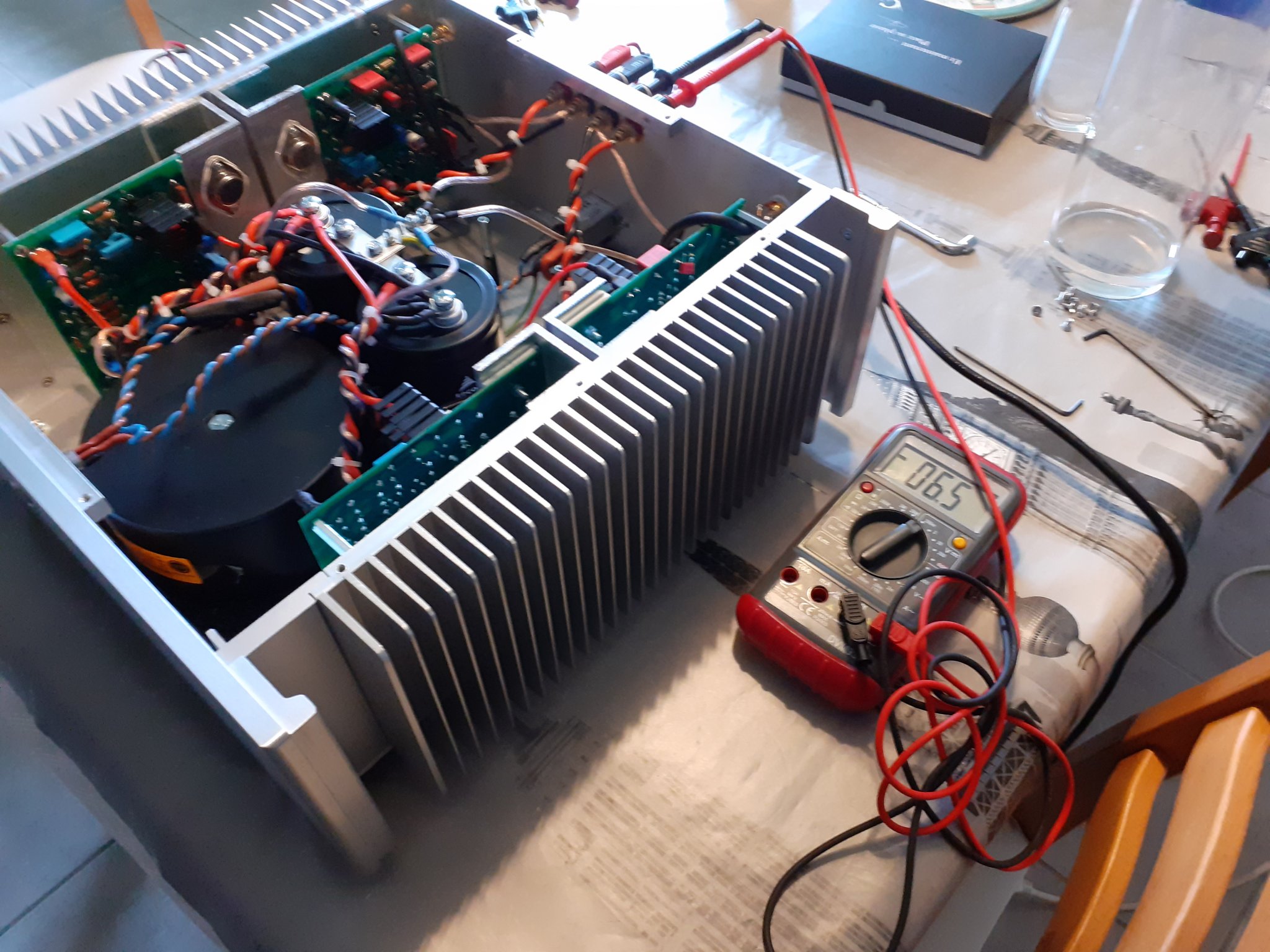

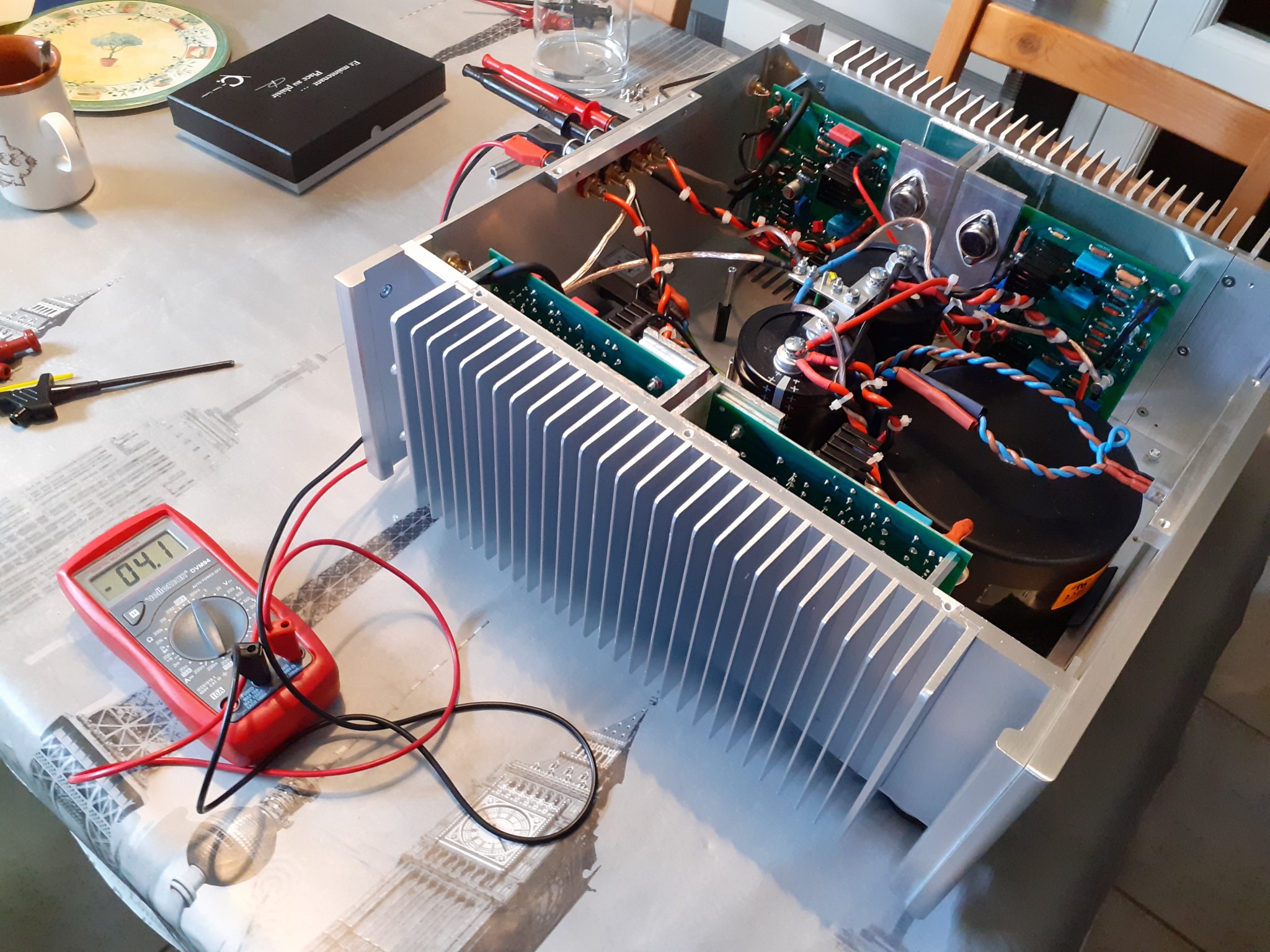

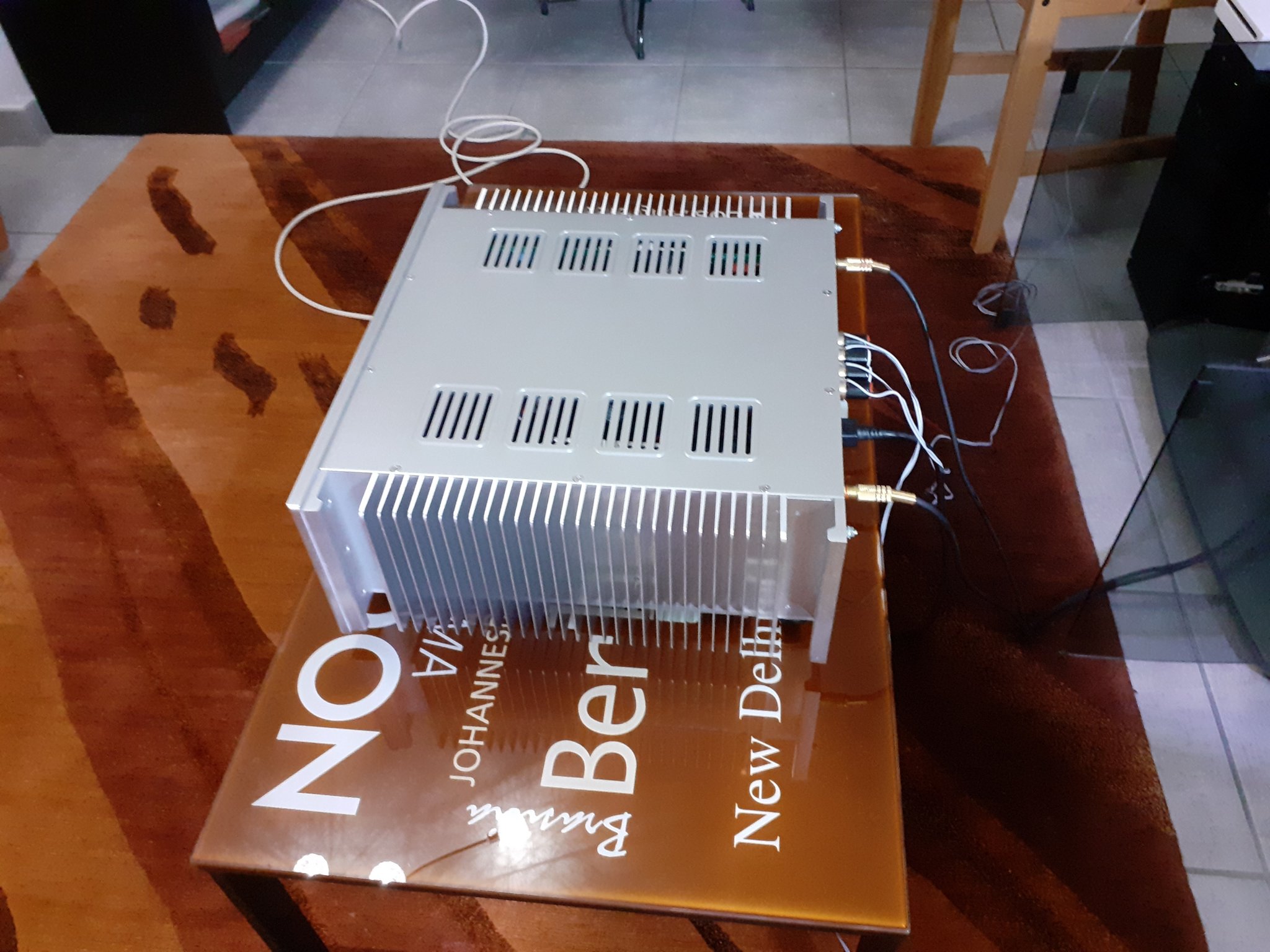

Hello here is progress of the project. unfortunately I'm not moving fast, I must say that I'm very busy with my work these days.

I finished and tested the second regulation board

then i cleaned the solder flux from all four boards.

I received the final box

and I mounted the cards on the two heatsinks of the box and it was not without difficulties but finally we got there.

I finished and tested the second regulation board

then i cleaned the solder flux from all four boards.

I received the final box

and I mounted the cards on the two heatsinks of the box and it was not without difficulties but finally we got there.

Wow, that's a great box that would suit even a medium size class A amp. You will never need that amount of heatsinking for any NAP model though. Like other early models, the original 250 types just used the aluminium case with sliding tray (if fitted) as a heatsink and that proved fine, even in warm climates. It may not be a problem or matter much to you, but having excess heatsinking means a bias that never stabilizes and the bias level is often important for consistent, best sound quality.

Yes the heatsinks are oversized, but who can do more can do less. It is true that by heating very little the bias will remain lower, maybe I should just raise the bias a little at rest.

I bought this box on audiophonics. It's made in China in fact, you can find it on ebay. i chose it because it was suitable for the size for the assembly and for the aesthetics too.

I bought this box on audiophonics. It's made in China in fact, you can find it on ebay. i chose it because it was suitable for the size for the assembly and for the aesthetics too.

I'm really confused about the thermal regulation of the amp.

Even by sticking the temperature detection transistor directly on the heatsink, the latency time may be too long, moreover, whether it is mounted on or under the pcb, it will find itself in the middle of a draft. cause of the opening in the case.

this amp is only really reliable in a closed box or possibly open on the top with louvers, otherwise it may be unstable.

Even by sticking the temperature detection transistor directly on the heatsink, the latency time may be too long, moreover, whether it is mounted on or under the pcb, it will find itself in the middle of a draft. cause of the opening in the case.

this amp is only really reliable in a closed box or possibly open on the top with louvers, otherwise it may be unstable.

On real NAIM amps the VBE is not mounted on the heatsink and this is not a problem, I have tested this amplifier at good power there is no thermal runaway problem (out of 2 Ohms the amplifier drawing 4 amps continuously). After, as on the original NAIM amps, it should not be pushed like a PA amp. in HI-Fi use there is no problem.

The fact that the box is ventilated can easily be resolved by plugging the vents. once finished I would do some tests anyway, I would see if there is a problem but honestly that's not what worries me.

The fact that the box is ventilated can easily be resolved by plugging the vents. once finished I would do some tests anyway, I would see if there is a problem but honestly that's not what worries me.

just my opinion, do what you want 😉

and nothing to complain about the excellent quality of your work

and nothing to complain about the excellent quality of your work

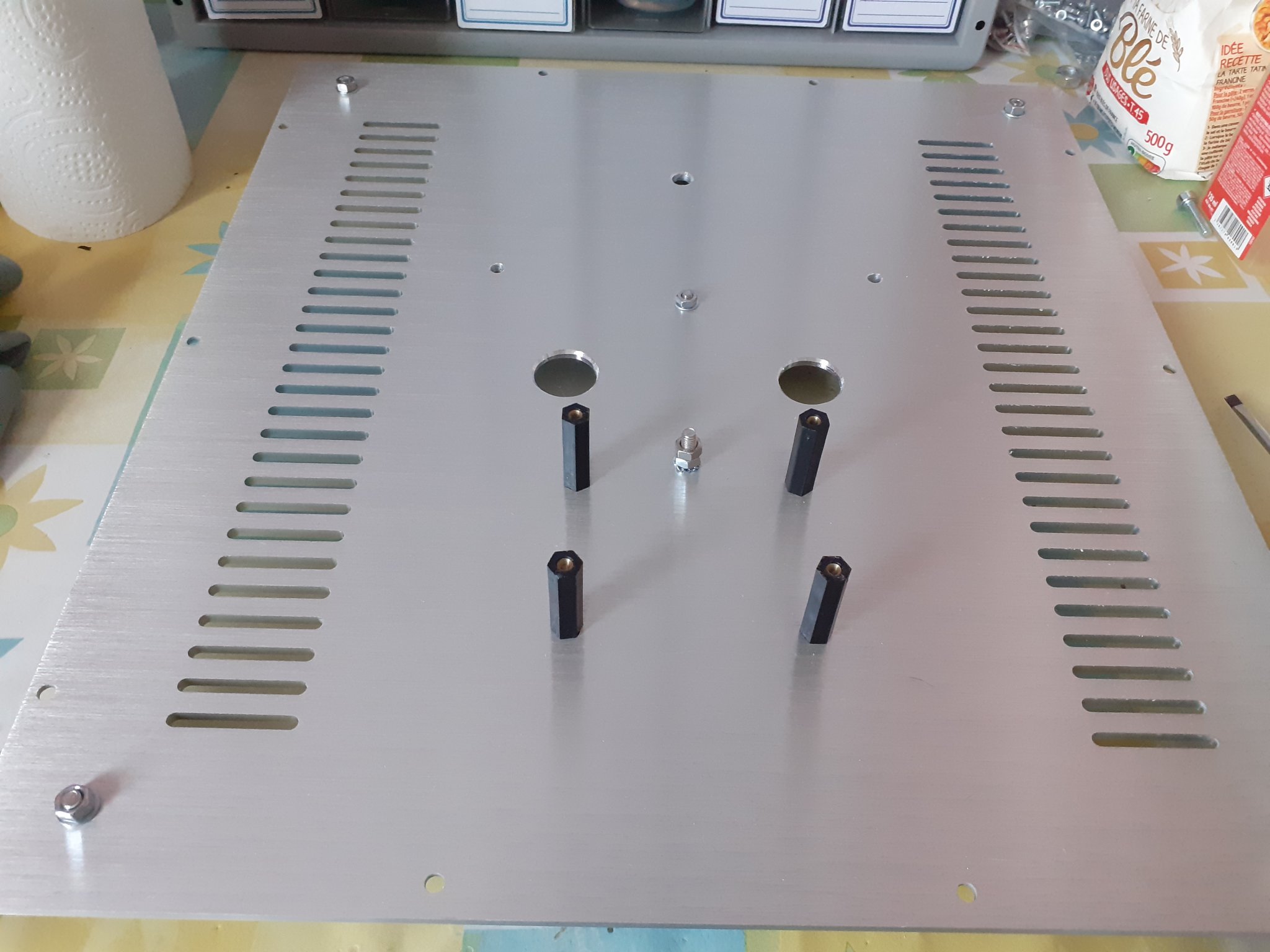

I still have some wiring to do, the essential is done. I expect my last order not before December 16 for the switch that I put on the front and a protection relay for the loudspeakers.

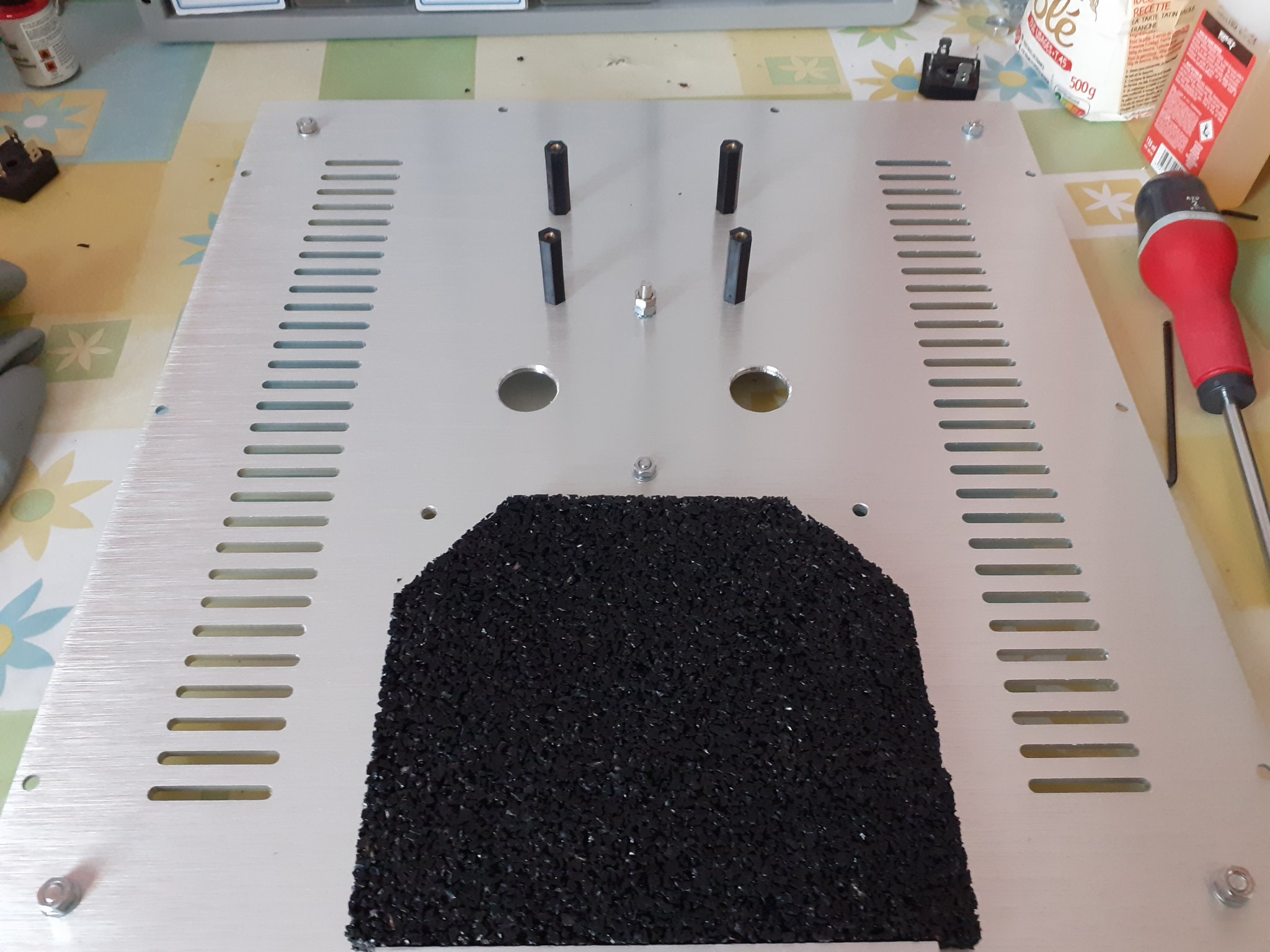

The filter capacitors are isolated from the chassis by parts specially sold by EPCOS for these models. This requires making large holes

They are 22,000uf 100V, 35A, ESR 6 milliohms.

A thick rubber plate under the transformer for vibrations and the passage of cables which is done from below on this model of transformer.

The filter capacitors are isolated from the chassis by parts specially sold by EPCOS for these models. This requires making large holes

They are 22,000uf 100V, 35A, ESR 6 milliohms.

A thick rubber plate under the transformer for vibrations and the passage of cables which is done from below on this model of transformer.

I finished. I haven't had a mass buzz issue so I'm happy. I had a problem adjusting the supply voltage because I had made an assembly error. I had taken 15 volt zener diodes instead of 10 volts result I could not lower the power supply below 45 volts. Once changed the zener the problem was solved. As for the protection relay for the loudspeakers, the one I was planning to put in is not suitable I thought it had a built-in transformer but in reality it is a switching power supply so there is no question of putting that with all the high frequency noise that it will generate. I might see to making myself a protection relay later...

Precisely about the offset voltage at the output I had left one of the two amp cards without the protection circuit of the output stage to do comparative tests between the two channels in order to know if it really improves the audio quality to remove it (I hadn't heard a difference during my tests on the laboratory power supply)

Well, the residual offset voltage when the amplifier is turned off takes much longer to drop if the protection circuit is not present, it persists at more than 100 mv for more than a minute. Once the protection is mounted, the two channels react the same. So i don't think it's necessarily reasonable to remove this protection if you don't have a loudspeaker protection relay.

here last pics ! and a little video, i will finalise Kicad files, schematics, gerber files and components list later and i will share it.

supply voltage adjustment (39.2V/-39.8V)

Special screw to insulate filter can.

Dc offset -6,5mV

Dc offset -4,1mV

Precisely about the offset voltage at the output I had left one of the two amp cards without the protection circuit of the output stage to do comparative tests between the two channels in order to know if it really improves the audio quality to remove it (I hadn't heard a difference during my tests on the laboratory power supply)

Well, the residual offset voltage when the amplifier is turned off takes much longer to drop if the protection circuit is not present, it persists at more than 100 mv for more than a minute. Once the protection is mounted, the two channels react the same. So i don't think it's necessarily reasonable to remove this protection if you don't have a loudspeaker protection relay.

here last pics ! and a little video, i will finalise Kicad files, schematics, gerber files and components list later and i will share it.

supply voltage adjustment (39.2V/-39.8V)

Special screw to insulate filter can.

Dc offset -6,5mV

Dc offset -4,1mV

So my Amp works fine since few days i share my Work here for those who want made NAP Clone, i will share the components list later i have to do it correctly.

Attachments

- Home

- Amplifiers

- Solid State

- NAIM NAP250 Original clone build thread