Cloth Rolled Edge or Accordion surround

Common with pro sound drivers.

Gets a generous amount of " Goop" during manufacturing

to seal the cloth edge.

In all simplicity, Yes a cloth edge speaker takes longer to break in.

I wouldn't worry about a thing.

Enjoy your speakers

Common with pro sound drivers.

Gets a generous amount of " Goop" during manufacturing

to seal the cloth edge.

In all simplicity, Yes a cloth edge speaker takes longer to break in.

I wouldn't worry about a thing.

Enjoy your speakers

But where is the truth if the Fs depends of the input voltage test in order to have a decision ? 10 to 15% variation is good enough to sim a cabinet ?

Paul,From the tone of the other respondents no one seems very surprised at such a large deviation from spec - is this normal for "pro" drivers?

Yes, Fs coming in well above factory spec for brand new drivers at low drive levels is normal.

Pro woofers are often driven well above Xmax in normal use.

Your drivers have an Xmax of 7.37mm, Xdamage of 17mm.

Unless you have seen close to 34mm peak to peak movement, the driver's suspension has not been fully extended.

You can push/pull the cones by hand to full excursion without heating the voice coil at all.

That said, the suspension warms up and loosens when driven, testing a "broken in" cold driver at low power will still read a higher Fs if it was not driven with a voltage large enough for the driver to move past Xmax just prior to the measurement.

Art

My understanding was that T/S parameters are by definition small signal measurements - although I'm not sure there is a defined limit to what constitutes a "small signal" in this context?Look again at TBTL's suggestion.

Most manufacturers use a small signal to determine T/S parameters, like 0.1 V or even less. However others use a large signal, such as 1 V or more. It makes a difference. Any woofer will have a different Fs at a 0.05 V level than it will at a 5 V level, and all the other T/S parameters change as well.

There is no right answer, and both small signal T/S and large signal T/S have pros and cons.

j.

I also wasn't aware impedance or resonant frequency change materially with voltage - my understanding is that both are electrically dependent only on frequency - I clearly need to do some more reading!

Cheers Paul.

Thanks Art - so are you suggesting the cones need to pushed to Xdamage during burnin to get to a point of stability near spec - that seems quite extreme to me?Paul,

Yes, Fs coming in well above factory spec for brand new drivers at low drive levels is normal.

Pro woofers are often driven well above Xmax in normal use.

Your drivers have an Xmax of 7.37mm, Xdamage of 17mm.

Unless you have seen close to 34mm peak to peak movement, the driver's suspension has not been fully extended.

You can push/pull the cones by hand to full excursion without heating the voice coil at all.

That said, the suspension warms up and loosens when driven, testing a "broken in" cold driver at low power will still read a higher Fs if it was not driven with a voltage large enough for the driver to move past Xmax just prior to the measurement.

Art

Faitals directions as to required burnin were as follows:

unfortunately not very helpful in relation to required excursion!• Hang the loudspeaker using a hook

• Take a sinusoidal signal and make it loop through a soundcard connected to an amplifier nominal on 16 Ohms

• Put the amplifier in MUTE and connect the loud speaker

• Remove the mute function and let the test run for 60 minutes

• After 60 minutes slowly turn down the the input signal. Please slowly until you reach zero

• wait one hour and let the speaker cool down.

• At this point the burn in is complete.

Cheers Paul

You're understanding is correct, unfortunately not all manufactures measure their loudspeakers this way.My understanding was that T/S parameters are by definition small signal measurements - although I'm not sure there is a defined limit to what constitutes a "small signal" in this context?

I also wasn't aware impedance or resonant frequency change materially with voltage - my understanding is that both are electrically dependent only on frequency - I clearly need to do some more reading!

Cheers Paul.

Some even measure those at least at 2-5Vrms, or just cherry pick at what frequency they would like to market the product.

Others don't use the defined DC resistance (Re), but instead use their own definition from curve fitting etc etc.

(which will give a much higher number).

The only way to validate the T/S parameters from a datasheet, is to ask the manufacture how they were being measured and replicate.

But in general with T/S parameters, nothing is what is seems.

I can write multi page blog about that (which I might do at some point) from all manufactures I contacted over all those years.

In the end it always ends up in a chicken-egg debate, since there are no real agreement on anything.

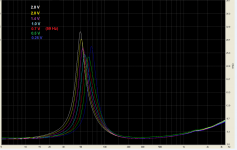

Here is an example from a very well known (and respected) manufacturer, cherry picking the Fs, as well as the Bl and Cms.

fyi, for those who don't know, the standard T/S according AES is normally done by 0.1V

Attachments

Wow - so basically resonance freq looks to be inversely related voltage - is that generalised across cone based transducers - or specific to this driver?

How on earth do designers factor this into enclosure and multi-driver design - I guess it means a speaker has to be optimized for a single volume level - and will be suboptimal at louder or quieter volumes.

Thats a big movement though - c 40% change in Fs for a 20dB voltage change - which for a 64dB volume dial is only c 15% either side of middle - that sounds too much - am I misinterpreting this?

How on earth do designers factor this into enclosure and multi-driver design - I guess it means a speaker has to be optimized for a single volume level - and will be suboptimal at louder or quieter volumes.

Thats a big movement though - c 40% change in Fs for a 20dB voltage change - which for a 64dB volume dial is only c 15% either side of middle - that sounds too much - am I misinterpreting this?

Paul,Thanks Art - so are you suggesting the cones need to pushed to Xdamage during burnin to get to a point of stability near spec - that seems quite extreme to me?

Faitals directions as to required burnin were as follows:

As posted, Faital's directions are useless- no voltage or excursion was specified.

My suggestion is that you probably have not sufficiently exercised the suspension unless you have actually exceeded Xmax by some margin, and also that the suspension needs to be warmed up before testing to give valid Fs results.

"Xdamage" could be a one-time deal if it means crashing the coil former on the back plate in an electrical test, but pushing by hand until the suspension is stretched avoids that.

You are testing a 16ohm driver, voltage needs to be about 4 volts to get the equivalent excursion of 2.83 volts into 8 ohms.

You might also check your test set up readings with a simple test as follows:

To measure a driver’s resonant frequency (Fs), connect the “+” output of a frequency generator/amplifier output directly to the driver “+”, place a 10 ohm resistor in series to the driver “-“ . Connect an AC voltmeter across the resistor leads. Adjust the frequency up and down until the voltage across the resistor reaches it’s minimum. The voltage minima is the resonant frequency.

I performed that test on a brand new B&C 8NDL64-8 and measured the Fs at 87 Hz, 7 Hz higher than the spec sheet rating of 80 Hz.

I then “broke in” the speaker by pushing the cone in and out by hand to around Xlim (as far as the suspension would allow, about double Xmax) several times, then repeated the test, the Fs dropped to 78 Hz.

I had used around 4V for the two initial tests, after a few minutes used 1V and read around 82 Hz, 4 Hz higher.

Bringing the voltage back up to 4V, the Fs dropped to 80Hz.

The suspension probably was still not fully broken in after those tests.

At any rate, if you have not verified reaching excursion between Xmax and Xlim, your driver's suspension is still probably not fully broken in either.

Art

There is nothing wow about this part.Wow - so basically resonance freq looks to be inversely related voltage - is that generalised across cone based transducers - or specific to this driver?

How on earth do designers factor this into enclosure and multi-driver design - I guess it means a speaker has to be optimized for a single volume level - and will be suboptimal at louder or quieter volumes.

Thats a big movement though - c 40% change in Fs for a 20dB voltage change - which for a 64dB volume dial is only c 15% either side of middle - that sounds too much - am I misinterpreting this?

What you're seeing is just the effect of the compliance vs cone excursion.

Exactly what can be seen with those Klippel measurements.

So yes, this in how generally ALL speakers work!

Just one random example;

https://audioxpress.com/article/test-bench-bold-north-audio-ms-10w-a-legendary-6-5-woofer-from-misco

scroll down, see the Kms(x) graph.

Kms is the stiffness, so 1/Cms (the inverse of the compliance)

You see that the stiffness (compliance) isn't lineair.

The same goes for the BL, the Force Factor graph vs excursion.

Since the mass of the driver doesn't change, the Fs is proportional to the difference in compliance.

At the same time, the height of the peak of the impedance, is proportional to the (change in) Bl.

(the Kms is assumed to be a constant as wel)

As for the last question.

That is a very good question actually!

One of the biggest reasons why it is VERY important to know how the T/S are being measured (meaning at what voltage) and also a big reason why those Klippel measurements are so damn important!!!!

Because at this point there are two very major problems;

1 - Are different drivers measured with the same voltage (or power or cone excursion)

2 - How much will the Bl and Cms (Kms) change vs voltage/power/cone excursion

For some who think this is also theoretical voodoo blah.

In the case of the previous example I showed (which is data from the manufacturer btw!), the shift in Fs and BL was VERY clearly audible. Even more so because this was a smaller driver were most users would use it on much lower output voltages (power).

(sorry, I am not gonna disclose who this manufacturer is for obvious reasons)

In other words, how straighter those Kms(x) and BL(x) graphs, the better.

That being said, but these are just my thoughts, I have a very big suspicion that some of those effects also don't show up well in the Kms(x) and BL(x) graphs for low(er) voltages.

I have to dive into the papers again, but Novak; https://ant-novak.com/publications/

Also showed that some of these effects also have different distortion elements.

I will have to check which paper that was exactly (has been a while, been busy with other things 😉 )

This goes to show how maybe a simple question, actually opens a big can of worms.

One that is a lot more than just "burn-in" / "broken-in" and all.

I have measured hundreds of T/S parameters over the years from all kinds (big, small, hifi, PA, studio etc).

The usual "differences" most people claim all fall within ±5% to max ±10-15%.

Bigger differences are sometimes a result of just poor production quality and consistency (which also happens a lot btw!)

But with well respected manufacturers, this consistency is totally fine (meaning, getting repeatable results).

The main discrepancies are all because of the previous explained problems.

As soon as one follows the conditions that the manufacturer used, the results are on par again.

Which unfortunately results in datasheets that just simply can't be compared 🙁

One that is a lot more than just "burn-in" / "broken-in" and all.

I have measured hundreds of T/S parameters over the years from all kinds (big, small, hifi, PA, studio etc).

The usual "differences" most people claim all fall within ±5% to max ±10-15%.

Bigger differences are sometimes a result of just poor production quality and consistency (which also happens a lot btw!)

But with well respected manufacturers, this consistency is totally fine (meaning, getting repeatable results).

The main discrepancies are all because of the previous explained problems.

As soon as one follows the conditions that the manufacturer used, the results are on par again.

Which unfortunately results in datasheets that just simply can't be compared 🙁

Thanks b_force - Learning curve is starting to get pretty steep about now...

Leaving aside the rather large can of worms this has opened (for me at least) - the principle implications for my immediate issue seems to be that

Reading Fs of 60hz vs 50hz spec may be:

1. on spec but read at too low a voltage => need to check testing voltage with Faital, and redo test at that voltage.

2. on spec but driver not yet fully broken in => do a bit of more hardcore manual manipulation on driver and retest

3. on spec but variation due to measurement/setup/calibration inaccuracy => do manual Fs test as described above to verify current results

4. off spec => cry, redesign speaker.

Will work through 1-3 above and revert. Many thanks for all the input!

Cheers Paul.

Leaving aside the rather large can of worms this has opened (for me at least) - the principle implications for my immediate issue seems to be that

Reading Fs of 60hz vs 50hz spec may be:

1. on spec but read at too low a voltage => need to check testing voltage with Faital, and redo test at that voltage.

2. on spec but driver not yet fully broken in => do a bit of more hardcore manual manipulation on driver and retest

3. on spec but variation due to measurement/setup/calibration inaccuracy => do manual Fs test as described above to verify current results

4. off spec => cry, redesign speaker.

Will work through 1-3 above and revert. Many thanks for all the input!

Cheers Paul.

Do give a more simple answer; just turn up the gain/volume, measure again and see how much the Fs shifts 😉 😀Thanks b_force - Learning curve is starting to get pretty steep about now...

Leaving aside the rather large can of worms this has opened (for me at least) - the principle implications for my immediate issue seems to be that

Reading Fs of 60hz vs 50hz spec may be:

1. on spec but read at too low a voltage => need to check testing voltage with Faital, and redo test at that voltage.

2. on spec but driver not yet fully broken in => do a bit of more hardcore manual manipulation on driver and retest

3. on spec but variation due to measurement/setup/calibration inaccuracy => do manual Fs test as described above to verify current results

4. off spec => cry, redesign speaker.

Will work through 1-3 above and revert. Many thanks for all the input!

Cheers Paul.

Only, to do this well, the standard resistor divider network method doesn't work, has to be constant voltage.

These low level devices (like Dayton has) are totally unsuitable for these measurements.

got it - should be indicative in any event.Do give a more simple answer; just turn up the gain/volume, measure again and see how much the Fs shifts 😉 😀

Only, to do this well, the standard resistor divider network method doesn't work, has to be constant voltage.

These low level devices (like Dayton has) are totally unsuitable for these measurements.

yes, definitely.got it - should be indicative in any event.

Oh yes, also sine sweep, not pink noise.

Although I often use the pink noise on the lowest gain setting and than switch to sine sweep at first the same gain (as the noise) and higher levels.

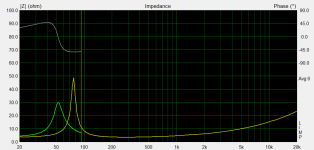

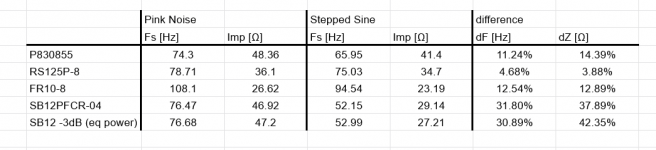

Although much smaller speakers, here the result of some measurements I did a while ago

(not related to the previous graphs btw)

In the last row we can see the difference in Fs as well as the height of the impedance peak (max peak minus Re if I recall well)

What you're seeing is ONLY the difference in voltage at the speaker terminals.

Pink noise has a much lower equivalent power compared to a sine wave, so this was used to enlarge the differences.

(the system I was measuring on was having some issues with lower voltages sine waves, but this gives a very similar idea)

(not related to the previous graphs btw)

In the last row we can see the difference in Fs as well as the height of the impedance peak (max peak minus Re if I recall well)

What you're seeing is ONLY the difference in voltage at the speaker terminals.

Pink noise has a much lower equivalent power compared to a sine wave, so this was used to enlarge the differences.

(the system I was measuring on was having some issues with lower voltages sine waves, but this gives a very similar idea)

Attachments

OK - so I think I've ruled out Fs variability due to signal level.

the setup: Run sine wave through amp & measure the voltage drop over a 10ohm resistor (R) between amp and negative driver terminal, positive connected directly from amp to driver.

the test: varied sine wave freq to find frequency with min V drop over R => Fs, repeat test at 3 dif input levels 0.5V, 1.0 V & 1.5V (as measured at 10Hz across speaker terminals).

results: (attached) at the level of accuracy I was able to work at Fs was within 1 Hz of 60Hz across all 3 voltages tested. This result is also consistent with the Fs obtained from REW.

conclusions:

1. my measurement of Fs @ 60Hz has now been confirmed by two different measuring setups - so the likelihood of testing setup stuffups is low

2. the measured difference between my drivers and the spec is not likely to be caused by differences in the signal level used for the spec. (pending hearing back from Faital on exactly what signal level they use to cal their specs - if it is significantly outside the range of 0.5-1.5V then I'll retest at that level to confirm)

next step - eliminate the possibility that the drivers are still stiff due to lack of excursion during the 20 of hours of brake in.

cheers Paul.

the setup: Run sine wave through amp & measure the voltage drop over a 10ohm resistor (R) between amp and negative driver terminal, positive connected directly from amp to driver.

the test: varied sine wave freq to find frequency with min V drop over R => Fs, repeat test at 3 dif input levels 0.5V, 1.0 V & 1.5V (as measured at 10Hz across speaker terminals).

results: (attached) at the level of accuracy I was able to work at Fs was within 1 Hz of 60Hz across all 3 voltages tested. This result is also consistent with the Fs obtained from REW.

conclusions:

1. my measurement of Fs @ 60Hz has now been confirmed by two different measuring setups - so the likelihood of testing setup stuffups is low

2. the measured difference between my drivers and the spec is not likely to be caused by differences in the signal level used for the spec. (pending hearing back from Faital on exactly what signal level they use to cal their specs - if it is significantly outside the range of 0.5-1.5V then I'll retest at that level to confirm)

next step - eliminate the possibility that the drivers are still stiff due to lack of excursion during the 20 of hours of brake in.

cheers Paul.

Attachments

The jury is in - the drivers are still breaking in - these are tough cones!

.

Im seeing small (as in 1 Hz) drops in Fs from physical manipulation (as per b-force advice - thanks!). It is a bit nerve racking pushing and pulling the cone to its extremes - almost feels like the cone is going to pull away - but each series of 2-3 pushes & pulls is dropping Fs by c 1Hz - I'm now down to 53Hz and still going.

It is quite remarkable how effective this is.

So the answer to original question in the thread is that a 20% deviation from spec Fs for (at least this model 10PR320-16 Faital) new driver, is effectively within spec - and just needs breaking in.

I found that even 20 odd + hours of reasonable excursion break-in did not do the business - b_force's trick of physical pushing & pulling the cone to its physical limits was required (repeatedly!).

Along the way I also discovered that:

1. this driver has an Fs which is not sensitive to signal level (at least between 0.5V & 1.5V)

2. there was no material difference in the impedance curve measured whether the drive was mounted firmly in a baffle-less bracket, hung from a hook or just rested on its back on the bench.

Thanks for all the assistance - especially b_force, weltersys and air void - it is so helpful having input from a few experienced hands (brains) - even on what appeared to be a relatively simple issue!!

Cheers Paul.

.

Im seeing small (as in 1 Hz) drops in Fs from physical manipulation (as per b-force advice - thanks!). It is a bit nerve racking pushing and pulling the cone to its extremes - almost feels like the cone is going to pull away - but each series of 2-3 pushes & pulls is dropping Fs by c 1Hz - I'm now down to 53Hz and still going.

It is quite remarkable how effective this is.

So the answer to original question in the thread is that a 20% deviation from spec Fs for (at least this model 10PR320-16 Faital) new driver, is effectively within spec - and just needs breaking in.

I found that even 20 odd + hours of reasonable excursion break-in did not do the business - b_force's trick of physical pushing & pulling the cone to its physical limits was required (repeatedly!).

Along the way I also discovered that:

1. this driver has an Fs which is not sensitive to signal level (at least between 0.5V & 1.5V)

2. there was no material difference in the impedance curve measured whether the drive was mounted firmly in a baffle-less bracket, hung from a hook or just rested on its back on the bench.

Thanks for all the assistance - especially b_force, weltersys and air void - it is so helpful having input from a few experienced hands (brains) - even on what appeared to be a relatively simple issue!!

Cheers Paul.

Last edited:

I don't remember giving that advice? Lol!!

But sometimes I do "massage" the speakers as well.

(So it could have been my advice)

If you want to break in, this has to be done at a (very) low frequency. Say at least 2x lower then Fs and at full cone excursion. The lower this frequency the better it seems.

As for your last remarks.

Resting a speaker on its back is a bad idea. In that case gravity will create an extra force on the cone (Mms). Which can result in big errors in some cases.

I have seen also little difference between holding a speaker or clamping it on a frame.

I have never tried totally free hanging. But in theory this could also result in potential errors.

But sometimes I do "massage" the speakers as well.

(So it could have been my advice)

If you want to break in, this has to be done at a (very) low frequency. Say at least 2x lower then Fs and at full cone excursion. The lower this frequency the better it seems.

As for your last remarks.

Resting a speaker on its back is a bad idea. In that case gravity will create an extra force on the cone (Mms). Which can result in big errors in some cases.

I have seen also little difference between holding a speaker or clamping it on a frame.

I have never tried totally free hanging. But in theory this could also result in potential errors.

Whoops, sorry, it was weltersys who suggested the physical manipulation - many thanks!I don't remember giving that advice? Lol!!

But sometimes I do "massage" the speakers as well.

(So it could have been my advice)

If you want to break in, this has to be done at a (very) low frequency. Say at least 2x lower then Fs and at full cone excursion. The lower this frequency the better it seems.

As for your last remarks.

Resting a speaker on its back is a bad idea. In that case gravity will create an extra force on the cone (Mms). Which can result in big errors in some cases.

I have seen also little difference between holding a speaker or clamping it on a frame.

I have never tried totally free hanging. But in theory this could also result in potential errors.

Re speaker on the bench, I was quite surprised, I only did it for the quick and dirty measurements when I was following the progress of initial break in, but when I retested hanging and in a stand, I found there was negligible difference. Maybe the impact may increase as the cones soften up a bit?

Cheers Paul.

Resting a speaker on its back is a bad idea. In that case gravity will create an extra force on the cone (Mms). Which can result in big errors in some cases.

Are we leaving in a black hole ? In the sames idea, is the gravity less important when the driver changes its position at iso mass of the cone ? 90% atraction change? Does the voice coil hits the edge then ? Or maybe that is the weigth of air that not slides as if the cone was in vertical position ???

- Home

- Loudspeakers

- Multi-Way

- How much above Fs should a new driver be?