Like I said just enjoy the music experience The rest is just conversation. Of course everyone including me should interject their opinion. Everything IS "enuff" to make a difference. Butterfly Effect!

Too full or noto fill.? All my experience in hobby speaker designs employ a cavity fill consideration. Totally imparts it's impact on sound quality.

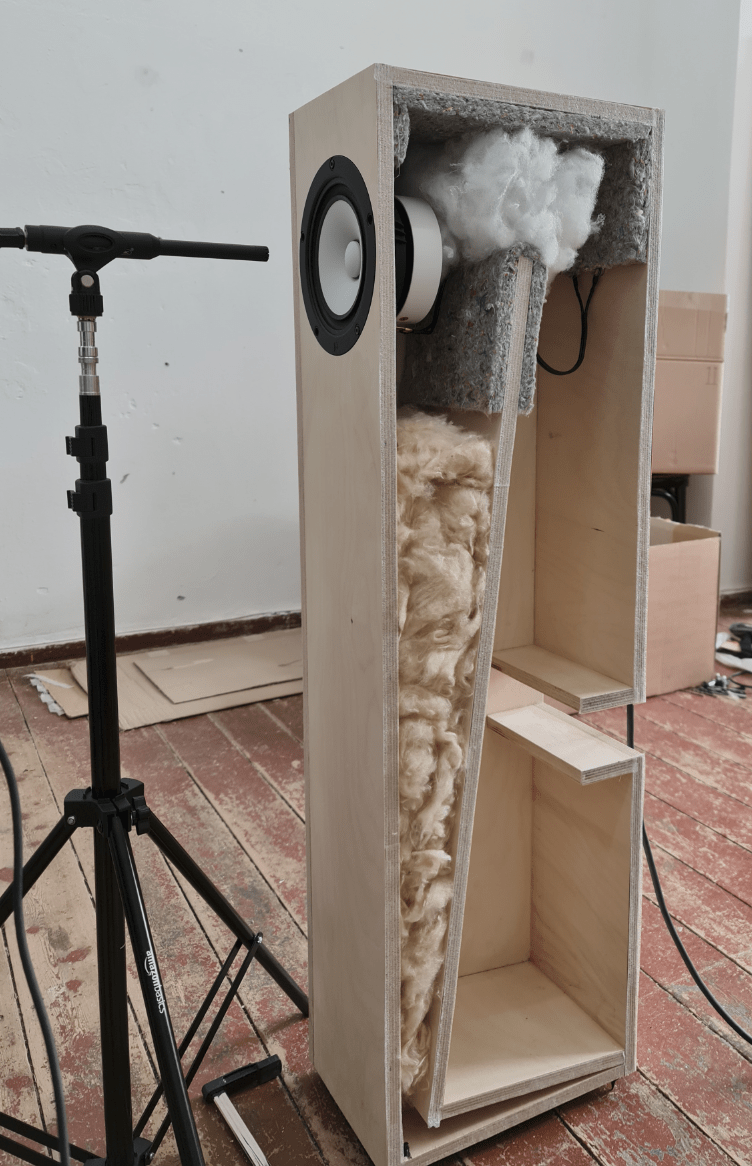

I've finally gotten around to assembling the speakers and started testing damping / tuning options.

I bought a cheapish calibrated measurement mic and have been using REW to test the different options.

I'm a novice at this, learning as I go so please forgive my ignorance.

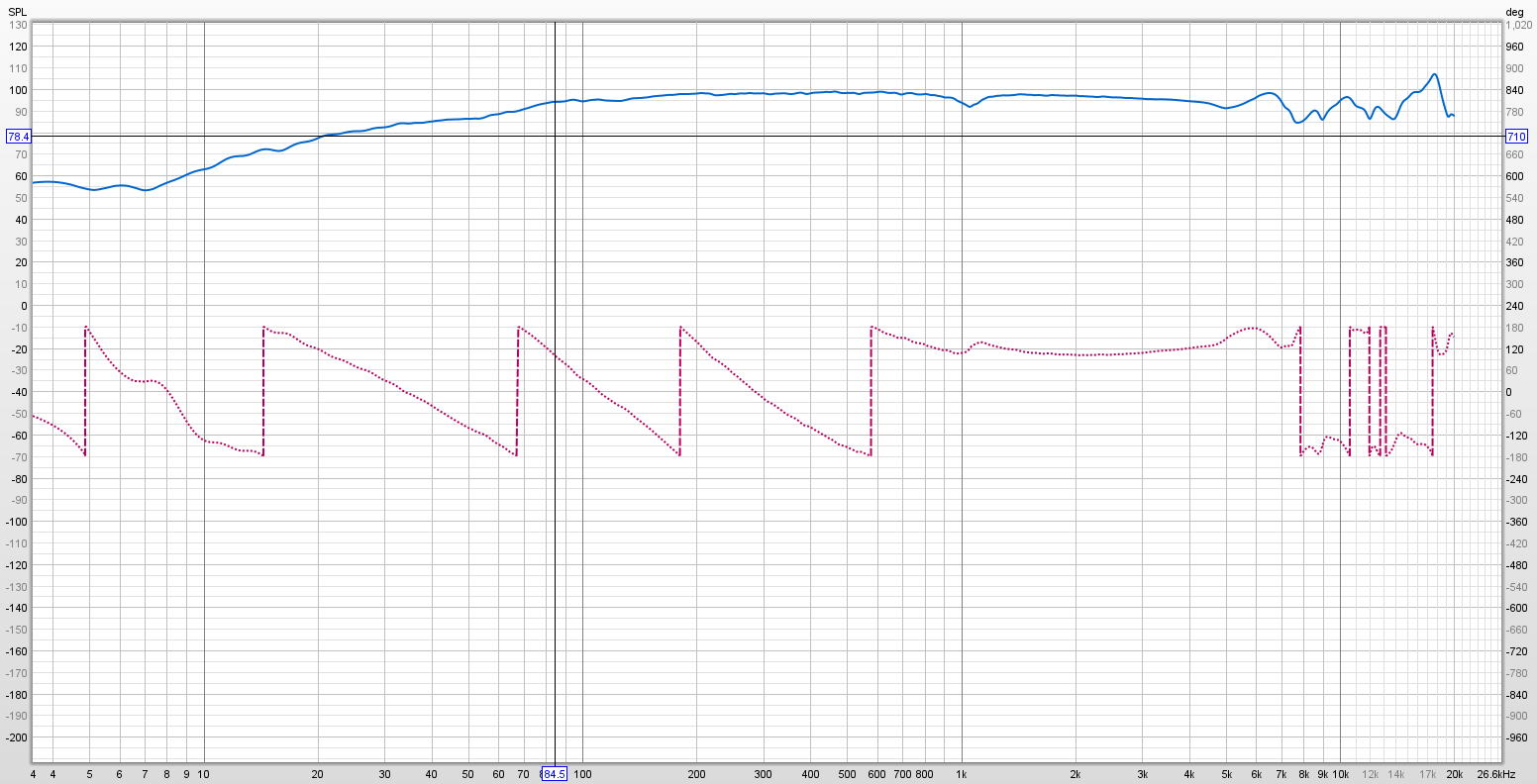

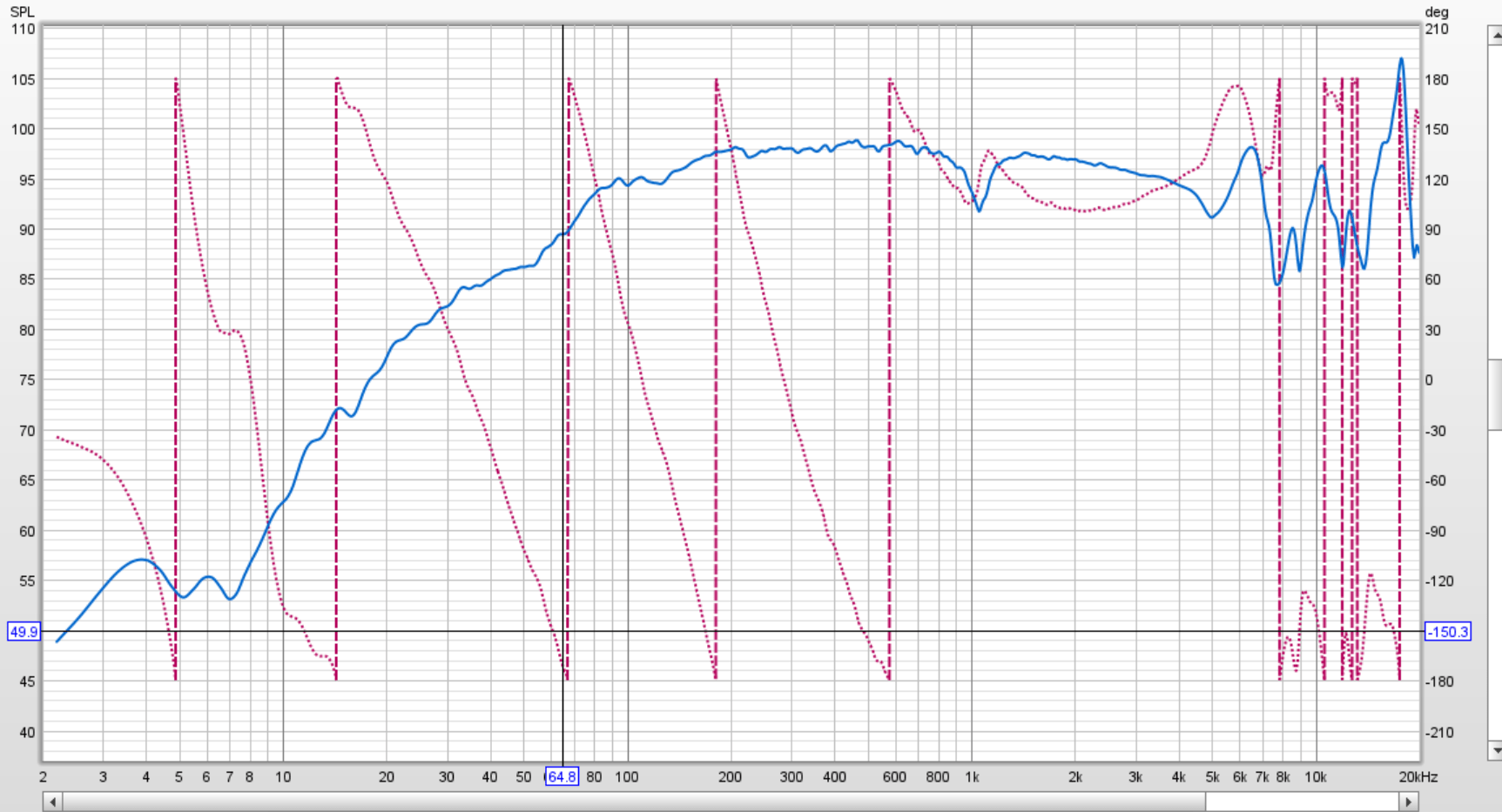

Here is how things are looking currently:

For testing, I have been using clamps to hold the side panel in place, with a thin strip of foam running around the edges hoping to create a reasonable seal.

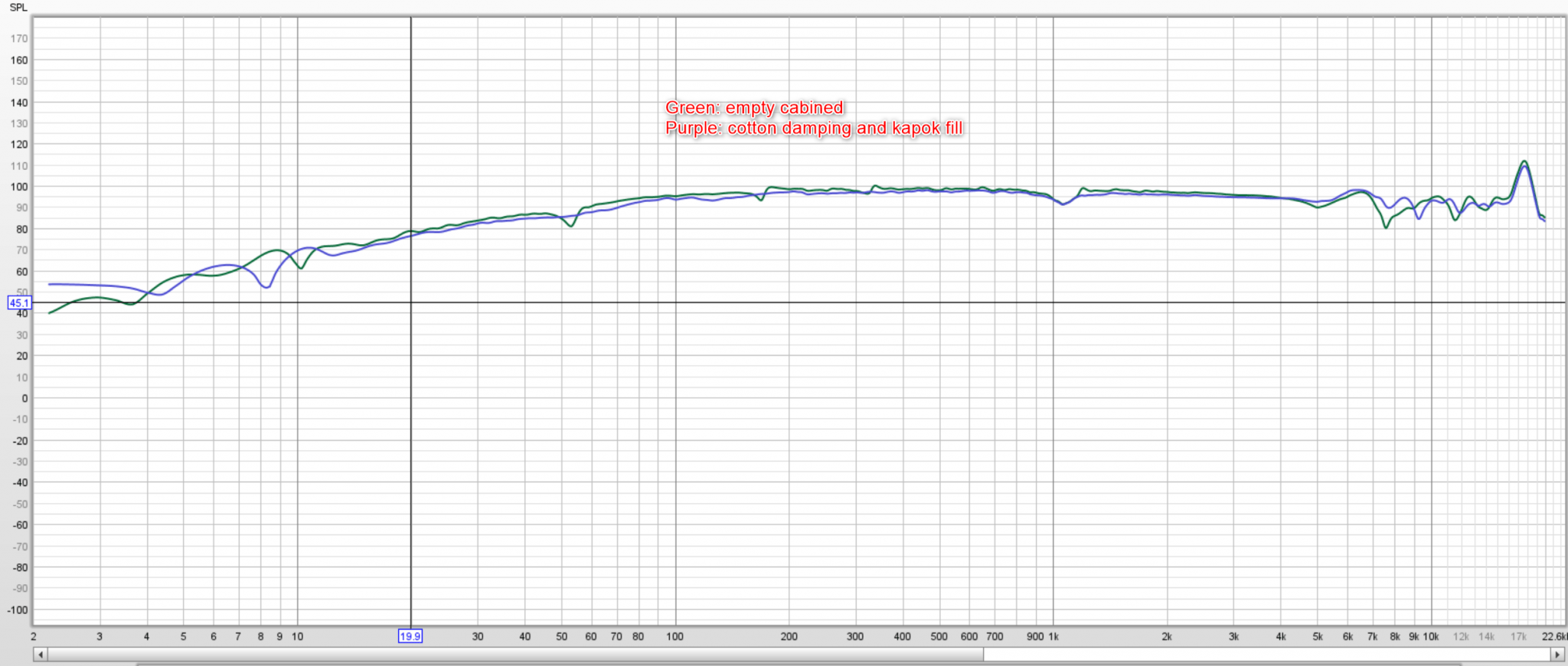

The first sweep tests were with an empty box for reference (see following image for empty vs current state).

The curve was very similar to current, but with a few peaks and valleys along the graph.

Next I installed the 15mm cotton damping, this smoothed out the curve slightly, leaving clean defined valleys between 10hz and 4khz.

I then tested 70g of polyfill in the narrow end of the pipe, followed by the Kapok.

After several tests, I found while the polyfill smoothed the valleys considerably, I was only about to completely eradicate them using the kapok. As stated by Nandappe, 70g was the ideal amount in my case as well.

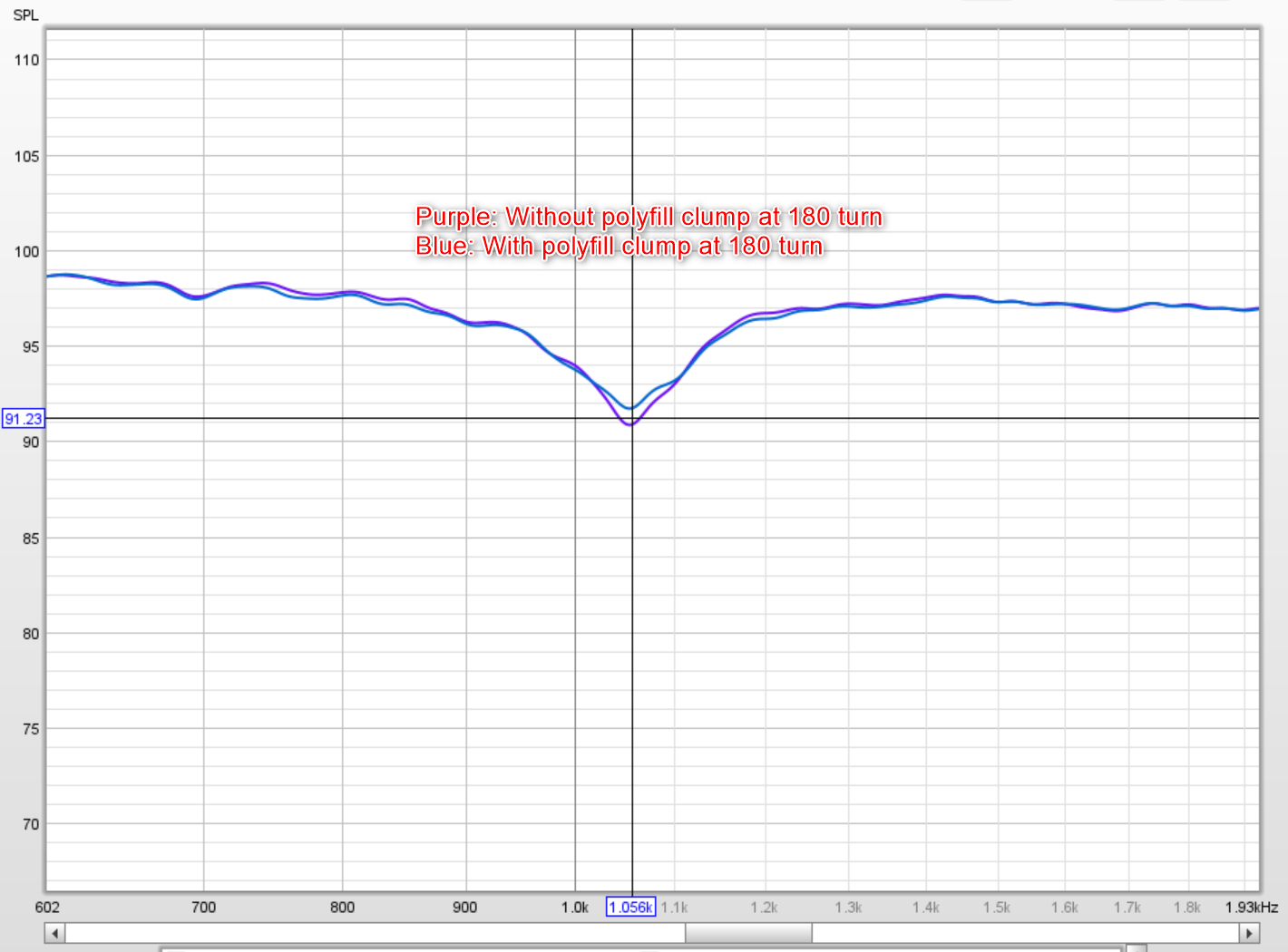

The final modification as suggested by xrk971 was a ball of polyfill at the 180 degree turn. This did not affect the frequency response at all, other than to minimize the valley at 1k (you can see this in the final image). It also seemed to noticeably improve the bass somehow, although that may just be in my head.

Currently I'm trying to solve the valley at 1k.

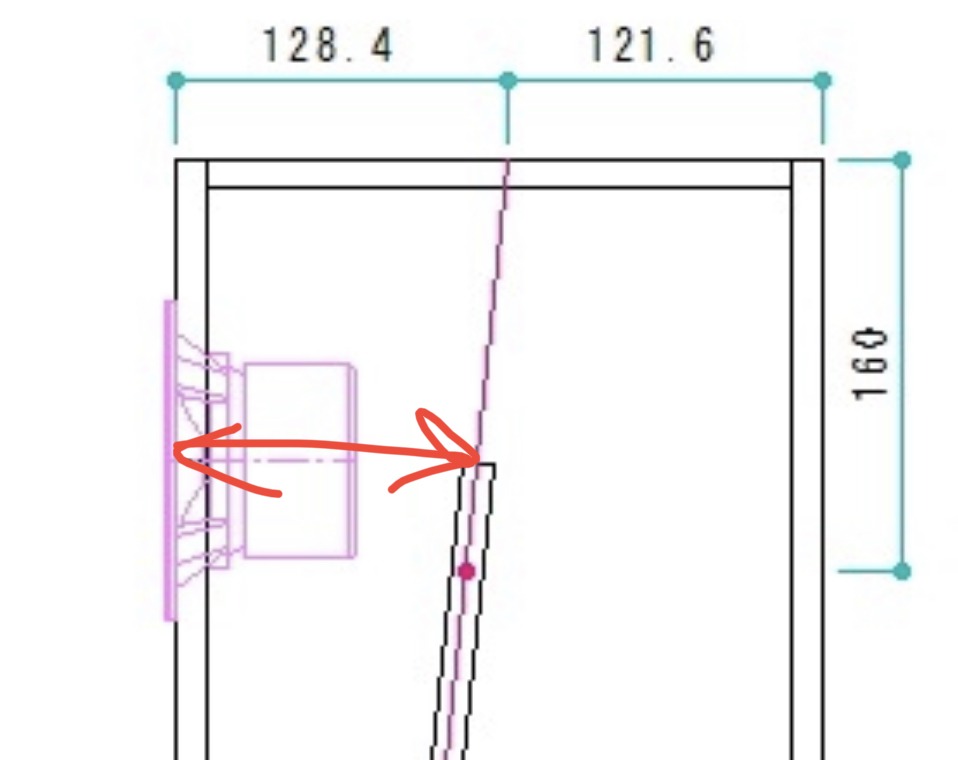

A fundamental frequency calculator suggests that standing waves of 1k would occur between surfaces of around 17cm apart, so I'm assuming this could be caused by the two side panel surfaces near driver (18cm apart), is that plausible? I'm waiting for some melamine pads to arrive so I can try the suggestion by xrk971.

I guess the affect of the polyfill at the 180 would also suggest that is the cause.

Aside from that, there are the peaks and valleys at 5k and above, is it worth trying to iron those out as well? (or is it even possible?)

The Kapok filling definitely seems to have an affect on that frequency range, although it seems very unruly and unpredictable.

I hope these tests are of interest to someone, and please share any other thoughts or suggestions!

Best

Jules

I bought a cheapish calibrated measurement mic and have been using REW to test the different options.

I'm a novice at this, learning as I go so please forgive my ignorance.

Here is how things are looking currently:

For testing, I have been using clamps to hold the side panel in place, with a thin strip of foam running around the edges hoping to create a reasonable seal.

The first sweep tests were with an empty box for reference (see following image for empty vs current state).

The curve was very similar to current, but with a few peaks and valleys along the graph.

Next I installed the 15mm cotton damping, this smoothed out the curve slightly, leaving clean defined valleys between 10hz and 4khz.

I then tested 70g of polyfill in the narrow end of the pipe, followed by the Kapok.

After several tests, I found while the polyfill smoothed the valleys considerably, I was only about to completely eradicate them using the kapok. As stated by Nandappe, 70g was the ideal amount in my case as well.

The final modification as suggested by xrk971 was a ball of polyfill at the 180 degree turn. This did not affect the frequency response at all, other than to minimize the valley at 1k (you can see this in the final image). It also seemed to noticeably improve the bass somehow, although that may just be in my head.

Currently I'm trying to solve the valley at 1k.

A fundamental frequency calculator suggests that standing waves of 1k would occur between surfaces of around 17cm apart, so I'm assuming this could be caused by the two side panel surfaces near driver (18cm apart), is that plausible? I'm waiting for some melamine pads to arrive so I can try the suggestion by xrk971.

I guess the affect of the polyfill at the 180 would also suggest that is the cause.

Aside from that, there are the peaks and valleys at 5k and above, is it worth trying to iron those out as well? (or is it even possible?)

The Kapok filling definitely seems to have an affect on that frequency range, although it seems very unruly and unpredictable.

I hope these tests are of interest to someone, and please share any other thoughts or suggestions!

Best

Jules

Please plot the total response on scale 50dB to 110dB with 5dB major and 1dB minor increments.

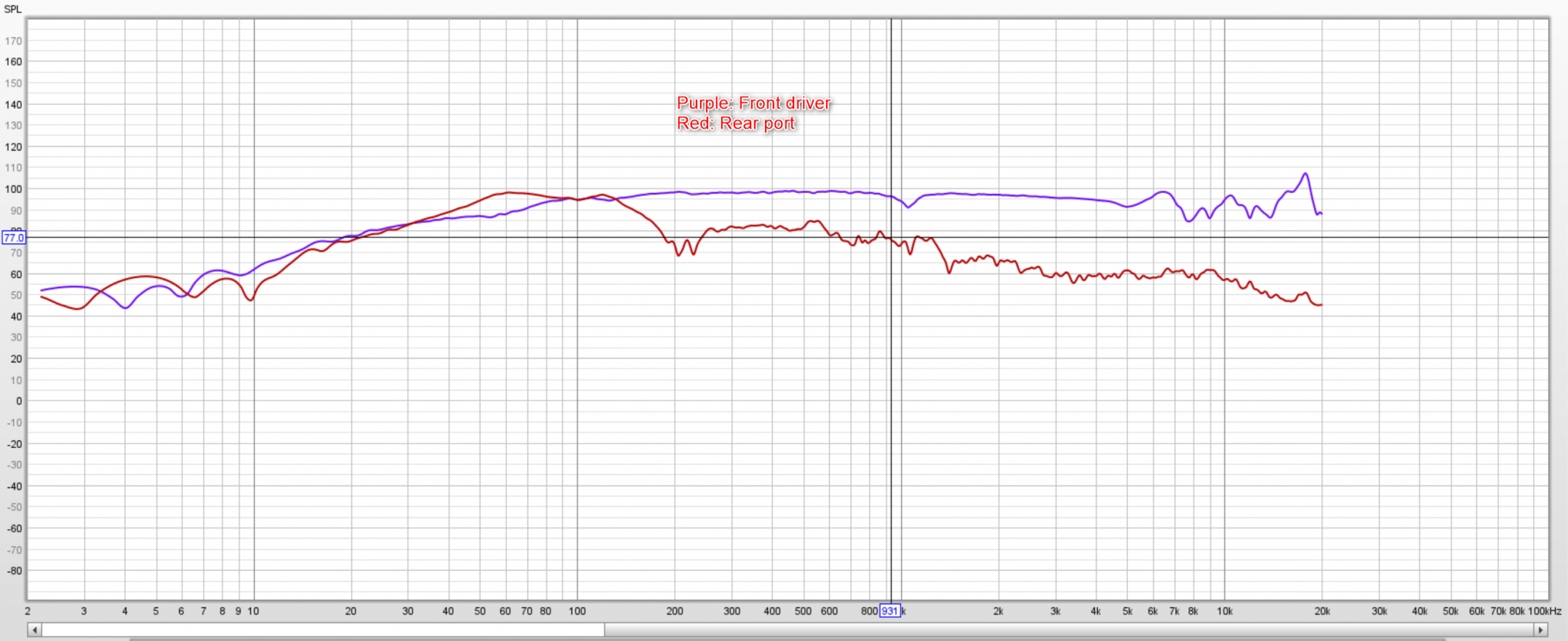

The 1k dip might be intrinsic to the driver? For a 1k 8dB dip to happen it would require a 6.7in half wave cancellation reflection. That might correspond to the distance from the driver to the side wall. Some melamine pads on the sides near the driver might help that. It might be the reflection off the back divider.

Both of these are smaller than 6.7in though. Or it could be a diffraction from front baffle step edge?

On the other hand, a dip is not as audible as a peak. It will reduce some forewardness.

The 1k dip might be intrinsic to the driver? For a 1k 8dB dip to happen it would require a 6.7in half wave cancellation reflection. That might correspond to the distance from the driver to the side wall. Some melamine pads on the sides near the driver might help that. It might be the reflection off the back divider.

Both of these are smaller than 6.7in though. Or it could be a diffraction from front baffle step edge?

On the other hand, a dip is not as audible as a peak. It will reduce some forewardness.

The graph of stuffed and unstuffed seem to indicate reducing some fill would maybe get you closer to the middle of both graphs. That would be extremely flat! Worth a try. Maybe even a different type and not stuffed so dense. Especially the tapered chamber that effectively is helping to reduce standing waves, resonance, etc. Something about quarter or half wave design. Built a 3.5 foot Voigt and vented at top made a big difference. Just experiment since you has test mic now. Have fun let me know when finishedToo full or noto fill.? All my experience in hobby speaker designs employ a cavity fill consideration. Totally imparts it's impact on sound quality.

Just noticed you used Kapok. Have made several pillows with it. You can really pull it apart thinly so it can go a long way. Pretty dense if put in un pulled. It makes the most awesome pillows. I like them way better than expensive real down fill.. made 2 with schreaded latex like $100 + Avacodo Co. Pillows and others. Use nice zipper cover at Walmart cotton or polyester for a few $ and have awesome adjustable fill pillow.Please plot the total response on scale 50dB to 110dB with 5dB major and 1dB minor increments.

The 1k dip might be intrinsic to the driver? For a 1k 8dB dip to happen it would require a 6.7in half wave cancellation reflection. That might correspond to the distance from the driver to the side wall. Some melamine pads on the sides near the driver might help that. It might be the reflection off the back divider.

View attachment 1092320

Both of these are smaller than 6.7in though. Or it could be a diffraction from front baffle step edge?

On the other hand, a dip is not as audible as a peak. It will reduce some forewardness.

In youtube there is a video with the title "second best speaker in the world" that is somehow identical to your proposition.Something about quarter or half wave design. Built a 3.5 foot Voigt and vented at top made a big difference. Just experiment since you has test mic now. Have fun let me know when finished

Yes built a smaller 3.5 foot version narrowed and bottom port is tall not wide. 3" Hi Vi B3n put slit vent at top that helped alot. Very minimal fiberglass fill. Impressed with the midrange quality open and airy. Highs need a small tweeter and an also pleased with the lows. Pretty natural and not boomy or exaggerated. Will build another because so easy to build and tweek with fill after built through Large port. Love the single driver concept. Dayton ps95 point source 3.5 next that one is a way better driver and actually full range. Had B3n left over out of ported box it sounded real muddy in a box.In youtube there is a video with the title "second best speaker in the world" that is somehow identical to your proposition.

but what Mr. nandappe is thinking about that ? This speaker is his design and I think he has the last word

H

I will see how the melamine pads affect the graph when they arrive in the post.

What are your thoughts on the response over 5K it's obviously very wavy, but I'm not sure how I would go about tackling that frequency range.

Like this?Please plot the total response on scale 50dB to 110dB with 5dB major and 1dB minor increments.

The 1k dip might be intrinsic to the driver? For a 1k 8dB dip to happen it would require a 6.7in half wave cancellation reflection. That might correspond to the distance from the driver to the side wall. Some melamine pads on the sides near the driver might help that. It might be the reflection off the back divider.

View attachment 1092320

Both of these are smaller than 6.7in though. Or it could be a diffraction from front baffle step edge?

On the other hand, a dip is not as audible as a peak. It will reduce some forewardness.

I will see how the melamine pads affect the graph when they arrive in the post.

What are your thoughts on the response over 5K it's obviously very wavy, but I'm not sure how I would go about tackling that frequency range.

I think you might be right. I was looking back at previous tests I made, (without the fill at the 180) and I found this:The graph of stuffed and unstuffed seem to indicate reducing some fill would maybe get you closer to the middle of both graphs. That would be extremely flat! Worth a try. Maybe even a different type and not stuffed so dense. Especially the tapered chamber that effectively is helping to reduce standing waves, resonance, etc. Something about quarter or half wave design. Built a 3.5 foot Voigt and vented at top made a big difference. Just experiment since you has test mic now. Have fun let me know when finished

Perhaps I should start at 70g Kapok, and gradually reduce. What do you think would be the approach to iron out those last valleys at 5k and above? just fine tuning of the fill?

Yeah, it was from your mention of it that I decided to test it. A relative had some in the attic which apparently belonged to my grandmother so probably very old. Good to know it doesn't deteriorate quickly and that moths aren't interested in it.Just noticed you used Kapok. Have made several pillows with it. You can really pull it apart thinly so it can go a long way. Pretty dense if put in un pulled. It makes the most awesome pillows. I like them way better than expensive real down fill.. made 2 with schreaded latex like $100 + Avacodo Co. Pillows and others. Use nice zipper cover at Walmart cotton or polyester for a few $ and have awesome adjustable fill pillow.

You're right, it can fill a large volume if you tease it out. Seems like very good speaker fill, but easily become air born will have to spray the top layer with something to stop it getting into the voice coil

Julesm knows way more technical aspects and how to correct problems. I don't follow plans closely and try unorthodox tweeks. I remember that it was important to attach the Hi Vi b3n with the inside edge cut beveled. The driver has a bucking magnet so needed alot of room on edged for back waves to move away from driver. Since after 4 k things turn ugly it probably has alot to do with driver. Not up on x over design but maybe a notch filter is in order? My Voigt has bad upper end too. Seems most of these full range drivers could use some top end help with tweeter that rolls of smoothly that only needs a simple filter. Also roll the full rage with same idea. It's alot to expect out of a whizzer cone to sound great.I think you might be right. I was looking back at previous tests I made, (without the fill at the 180) and I found this:

View attachment 1092608

Perhaps I should start at 70g Kapok, and gradually reduce. What do you think would be the approach to iron out those last valleys at 5k and above? just fine tuning of the fill?

Julesm, quick question, did you chamfer the back of the driver hole out to let the back of the cone get less back wave?

I’m sure you know about that, just curious.

I’m sure you know about that, just curious.

Yes, good points. The data sheet I received of the driver isn't perfect in that range either.Julesm knows way more technical aspects and how to correct problems. I don't follow plans closely and try unorthodox tweeks. I remember that it was important to attach the Hi Vi b3n with the inside edge cut beveled. The driver has a bucking magnet so needed alot of room on edged for back waves to move away from driver. Since after 4 k things turn ugly it probably has alot to do with driver. Not up on x over design but maybe a notch filter is in order? My Voigt has bad upper end too. Seems most of these full range drivers could use some top end help with tweeter that rolls of smoothly that only needs a simple filter. Also roll the full rage with same idea. It's alot to expect out of a whizzer cone to sound great.

Julesm, quick question, did you chamfer the back of the driver hole out to let the back of the cone get less back wave?

I’m sure you know about that, just curious.

Good point, I didn't put a chamfer on the back face. I recessed the driver around 5mm into the ply so the front surfaces would be flush.

I was actually adding additional pieces of ply at the screw locations, since they now have only 10mm behind them.

I guess I really should chamfer the edges in the areas away from the screw locations... Just wish I had done it before gluing to the side panel!

Do you think this might be partially responsible?

I just know I’ve seen a bunch of people including Dave & Scott recommending chamfering the back of driver holes to avoid reflections back in to the cone. They leave just little built up areas for the screws and chamfer the rest out heavily.

Do those reflections cause the problems you are seeing? No idea sorry. I’m merely parroting info, I don’t have the technical know how to ID problems yet.

Do those reflections cause the problems you are seeing? No idea sorry. I’m merely parroting info, I don’t have the technical know how to ID problems yet.

Thanks, I appreciate the comment. I think you are right, and will definitely look into chamfering them. In all honesty, it's a detail I missed but it makes sense to do that if only to rule out the possibility of interference.I just know I’ve seen a bunch of people including Dave & Scott recommending chamfering the back of driver holes to avoid reflections back in to the cone. They leave just little built up areas for the screws and chamfer the rest out heavily.

Do those reflections cause the problems you are seeing? No idea sorry. I’m merely parroting info, I don’t have the technical know how to ID problems yet.

That's a beefy basket good air flow too. Looked up tech on it and agree it isn't going to behave up top. Should Excell at midbsss. I still think this project would sound awsome with a tweeter. SB acoustics has a nice ring radiator tweeter , dimple in center that specs good and looks real easy to x over . Anything you like would be good. Air motion transformer from zDayton is cheap and hear good things about it.Thanks, I appreciate the comment. I think you are right, and will definitely look into chamfering them. In all honesty, it's a detail I missed but it makes sense to do that if only to rule out the possibility of interference.

And down the rabbit hole I go haha. This thread was started by Nandappe who inspired me to build his design, I feel like I'm hijacking his thread now. I think maybe I already disregarded his philosophy of great sounding "low end loudspeaker design" by opting for top end drivers and birch ply. Truth is, they already sounded excellent when empty. From there on, it's just me indulging my interest to learn. For now I will see what I can achieve with these drivers alone, then maybe look at double bass array subs to fill the curve under 200hz, and after this suggestion perhaps to clean the upper frequencies. Down I go.That's a beefy basket good air flow too. Looked up tech on it and agree it isn't going to behave up top. Should Excell at midbsss. I still think this project would sound awsome with a tweeter. SB acoustics has a nice ring radiator tweeter , dimple in center that specs good and looks real easy to x over . Anything you like would be good. Air motion transformer from zDayton is cheap and hear good things about it.

Historically, cheesecloth was used to cover the components.Seems like very good speaker fill, but easily become air born will have to spray the top layer with something to stop it getting into the voice coil

- Home

- Loudspeakers

- Full Range

- Tapered Wave Tube with Damp-Duct (TWTD) + Pluvia7HD