I could try to find some sort of rubber...but I don't think that material should be too elastic.Re the Magico baffle system:

- I suspect that what Magico used for damping in between the 2 baffles is outside of my price range, so I used sorbithane instead when I tried to copy it (1/8" 40 durometer). My research suggested that the most important aspect is for the material to retain its damping properties while under compression, something that not very many materials do well.

- Notice that the woofers and mid are attached to the first baffle and the tweeter to the second. I believe that the mid is also decoupled via another ring of the sorbithane-like material. In my implementation, I attached both the tweeter and the mid to the second baffle using sorbathane gaskets which I found easier and also gave my mid more breathing room in the back.

- Also note that the threaded rods achieve a secondary function of raising the frequency of any resonances of the baffles involved (and perhaps the connecting side walls too when they are curved like the older Magico Minis) because the baffles are under tension.......

I think that cork or felt could do the job, something like 1 to 2mm in thickness.

So, lets say, if I'm gonna decouple front baffle from cabinet i should connect mid and bass units to the main cabinet and tweeter to the front/main baffle ?

Rods are not a problem....

As I will have amplifiers mounted on the back via aluminium plates, i can tighten all by screwing imbus via that plate...

First I will screw rod into front baffle, then place the this "joiner" and then screw imbus screw through AL plate and tighten everithing.

Attachments

I looked into rubber, silicone and latex caulking and I wasn't satisfied with any of those materials under compression. Cork I'm not sure about but I'm not holding my breath for it. All or any of those might be good in a CLD application but not so much in a compression application. That's just my experience anyways. YMMV. Again I chose sorbathane and I would use it again under the same conditions. Especially so with very high quality drivers.

Attached are a few pics of what I built. The cabinet was an experiment of sorts working with some alternate materials. I made the baffles with fiberglass and sand filled resin and embedded all the relevant fastening nuts right into the material when I cast it. In the 4th and 5th pics, you can see the sorbathane gaskets I cut to isolate the tweeter and mid from the baffle and to decouple 1 baffle from the other. That larger one also seals the mid chamber as well. Note that the fasteners used to secure the drivers also employ small pieces of sorbathane so that there are well and truly no contact points between those drivers and the baffle.

Attached are a few pics of what I built. The cabinet was an experiment of sorts working with some alternate materials. I made the baffles with fiberglass and sand filled resin and embedded all the relevant fastening nuts right into the material when I cast it. In the 4th and 5th pics, you can see the sorbathane gaskets I cut to isolate the tweeter and mid from the baffle and to decouple 1 baffle from the other. That larger one also seals the mid chamber as well. Note that the fasteners used to secure the drivers also employ small pieces of sorbathane so that there are well and truly no contact points between those drivers and the baffle.

Attachments

Yoke - on a more practical mundane consideration: Size and weight. On a speaker of this size, you need to be mindful of what the final weight will be, and what your strategy for maneuvering it around the workshop during construction and then placing it in your listening space. On my recent project, I was not mindful of this. I ended up with an 80 lb (36 kg), very smooth polished box with no place to get a grip for lifting. Once I got the veneer on it, it was both delicate and awkwardly heavy. I needed to frequently lift it up on my work table, lay it on its various sides, all without marring the bare wood veneer surface. After I got the varnish on, I was able to install some handles which are aesthetically OK, but this was not part of the original plan.

Maneuvering a massive speaker around the listening space is not too troublesome if you have a hand truck, but during construction it can be a real challenge.

It would have been easy for me to add up the published weight of the drivers and the estimated weight of the plywood in the cabinet, and I would have been within a few pounds of actual... Had I done so, I might have made the speaker in two boxes, a bass box and a mid-tweeter upper box.

I love your project. I will follow your progress with enthusiasm........ j.

Maneuvering a massive speaker around the listening space is not too troublesome if you have a hand truck, but during construction it can be a real challenge.

It would have been easy for me to add up the published weight of the drivers and the estimated weight of the plywood in the cabinet, and I would have been within a few pounds of actual... Had I done so, I might have made the speaker in two boxes, a bass box and a mid-tweeter upper box.

I love your project. I will follow your progress with enthusiasm........ j.

If all the drivers are mounted to the inner baffle, then the outer baffle only needs to serve as an acoustical radiation shape. I don't think it needs to add any stiffness to the inner baffle. It needs to be attached with a damping layer between it and the inner baffle, and attached just firmly enough to prevent any vibration. Since the drivers are not attached to it, it will not be experiencing any driver induced loading.

If it were to become structurally integral with the inner baffle, which a CLD approach would require, It would need a lot of mechanical attachment points (screws, bolts, or threaded rods).

The complexity of jReave's system leads me to believe that he probably did achieve a level of CLD effect. It looks like 10 attachment rods, which is a lot more than would be needed to merely hold the outer baffle in place. It is an impressive design.

So you will need to decide which approach to use.

If it were to become structurally integral with the inner baffle, which a CLD approach would require, It would need a lot of mechanical attachment points (screws, bolts, or threaded rods).

The complexity of jReave's system leads me to believe that he probably did achieve a level of CLD effect. It looks like 10 attachment rods, which is a lot more than would be needed to merely hold the outer baffle in place. It is an impressive design.

So you will need to decide which approach to use.

It is from the JBL PD6000 Series.Hi Rewind,

what is the low-frequency horn in the second video?

Sorry for the off-topic OP.

Kindest regards,

M

Wauuuu!!! Nice and complex build !!! Good one !!!I looked into rubber, silicone and latex caulking and I wasn't satisfied with any of those materials under compression. Cork I'm not sure about but I'm not holding my breath for it. All or any of those might be good in a CLD application but not so much in a compression application. That's just my experience anyways. YMMV. Again I chose sorbathane and I would use it again under the same conditions. Especially so with very high quality drivers.

..........

I will take all advices into count. Thanks.

I was thinking to make some parts, if not whole cabinet out if epoxy with sand filler but i give up.

Moulding mide be just above my head. 😉

Yoke - on a more practical mundane consideration: Size and weight. ..........

Thanks hifijim 😉

I do take care about weight as I tend to make loudpsekars with 1:1 ratio for volume to weight.

So for 45 litres cabinet, plan is to make speakers thay weight 45kg.

Long time ago I read someplace that thet ration is just about right for good sounding speakers. It have something with moving mass of cabinet amd movement of drivers.

Mide be totally of, but someone compared "good" sounding loudspekaers and thair volume/weight ration and come to this conclusion.

Now when I write this, it sound like bu%@££@, but once I build cabinets and with all drivers in place, with all that bracing, and 24mm baltic birch in combination with 18mm MDF, i usually end up with that ration.

And I'm happy with results.

Jea, they are a little hard to move around...but 😉

And I make some wheel base for moving from point A to B, like when I transport it from a car into building 😉

If all the drivers are mounted to the inner baffle, then the outer baffle only needs to serve as an acoustical radiation shape. ....

Thanks

Yes, I will have to make some decisions...and take all those advises, from all of you, into account.

In a week or so I will make test cabinets with planed volume and play a little with baffle geometry and measure results.

Could someone please comment driver spacing depending on crossover points ?

m'I too off or would this work ? Is spacing crucial or is there some tolerance

How do you determine distance between midrange (13) and bass units when you have too of them (2x19) ?

m'I too off or would this work ? Is spacing crucial or is there some tolerance

- 19TX / 13TX - around 500-600Hz ( at about baffle diffraction point ?) Baffle is 22cm.

- 13TX / RAAL - from 1.7-2.4kHz will see what sound best

How do you determine distance between midrange (13) and bass units when you have too of them (2x19) ?

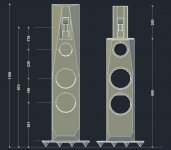

Attachments

I just had a peak at your video and looked at your design goals. If this is really your room and the placement of your loudspeakers my strongest advice is to separate the sub drivers from the rest because the position in the room where your speakers perform at their best is most of the time also not the place where subs perform at their best.

With speakers that are close to the side wall, don't you think you might probably be better of with dipole, cardioid, or horn loudspeakers. What you are trying to do now is to build another loudspeaker of almost exactly the same principle as your previous ones with more or less the same quality of drivers. It will turn out a little different but much better? I am afraid not by as much as you hope for. The position in the room and the power response is going to sound about the same

For years I have built loudspeakers the same way you did but for the last twenty years, I only focused on loudspeaker room interaction be it with horns, dipoles, cardioids, or whatever gets it right in the room. This has yielded much better results. In fact, I even use much cheaper drivers than I did back then

You are trying to combine a sub driver with an Rms of almost 5 (which is very high) to a mid-woofer with an Rms of 0,5 (which is nicely low)

That is a pretty hard combination to get sounding right on more than one volume setting. You are probably much better of with a sub driver with an Rms of max 2 or so. Unfortunately, that probably means bigger enclosures or compromises on low-end extension.

A couple of times I have been trying the same thing because it seems very attractive to get a lot of low-end extension from relatively small drivers in a small enclosure but it never ever turned out completely right, it's like trying to turn lead into gold. It always ended up that the speaker sounded very good on some recordings but bad on others. Now most audiophiles would say that the speakers are so good they let you hear how bad these recordings are but the truth is quite the opposite I'm afraid.

Be very very careful with 'waveguiding' the Raal tweeter like in pictures 4 and 6. This is not a proper waveguide and will only lead to nasty artifacts that can not be corrected by DSP afterward. Make a proper waveguide or a flat baffle for them. I know, I had a pair of them, they are very sensitive to that kind of thing.

Another valuable lesson I have learned with box constructions like yours. Don't use a double thickness of wood for your front baffle. In fact, make it as thin as possible, or else you are literally choking your drivers. You'll get a lot of frequency dependant compression and diffraction between the baffle and the drivers when mounted on a thick baffle. a 12 mm high-grade multiplex (no MDF please) baffle will sound quite a lot better than a 30 to 50 mm I see on many designs. Your drivers will thank you when they have room to breathe. You have to look at the sound of the back of the driver in the same way as you look at the sound of the front of the driver and never do anything to the back that you don't even think about doing at the front. Would you use your drivers back-mounted on a 50mm thick front? I guess not, not even with round-overs. Well, they don't like it at the back either, plus there is also a basket and a magnet in the way which make the situation even worse. I have made a lot of measurements of the back of drivers with different mounting methods and the thick baffles do a lot more harm than they do any good.

But anyways, nice drivers, nice amps, nice crossover, it has a lot of potential. Good luck designing and don't listen too much to what everyone else thinks, including me🙂

With speakers that are close to the side wall, don't you think you might probably be better of with dipole, cardioid, or horn loudspeakers. What you are trying to do now is to build another loudspeaker of almost exactly the same principle as your previous ones with more or less the same quality of drivers. It will turn out a little different but much better? I am afraid not by as much as you hope for. The position in the room and the power response is going to sound about the same

For years I have built loudspeakers the same way you did but for the last twenty years, I only focused on loudspeaker room interaction be it with horns, dipoles, cardioids, or whatever gets it right in the room. This has yielded much better results. In fact, I even use much cheaper drivers than I did back then

You are trying to combine a sub driver with an Rms of almost 5 (which is very high) to a mid-woofer with an Rms of 0,5 (which is nicely low)

That is a pretty hard combination to get sounding right on more than one volume setting. You are probably much better of with a sub driver with an Rms of max 2 or so. Unfortunately, that probably means bigger enclosures or compromises on low-end extension.

A couple of times I have been trying the same thing because it seems very attractive to get a lot of low-end extension from relatively small drivers in a small enclosure but it never ever turned out completely right, it's like trying to turn lead into gold. It always ended up that the speaker sounded very good on some recordings but bad on others. Now most audiophiles would say that the speakers are so good they let you hear how bad these recordings are but the truth is quite the opposite I'm afraid.

Be very very careful with 'waveguiding' the Raal tweeter like in pictures 4 and 6. This is not a proper waveguide and will only lead to nasty artifacts that can not be corrected by DSP afterward. Make a proper waveguide or a flat baffle for them. I know, I had a pair of them, they are very sensitive to that kind of thing.

Another valuable lesson I have learned with box constructions like yours. Don't use a double thickness of wood for your front baffle. In fact, make it as thin as possible, or else you are literally choking your drivers. You'll get a lot of frequency dependant compression and diffraction between the baffle and the drivers when mounted on a thick baffle. a 12 mm high-grade multiplex (no MDF please) baffle will sound quite a lot better than a 30 to 50 mm I see on many designs. Your drivers will thank you when they have room to breathe. You have to look at the sound of the back of the driver in the same way as you look at the sound of the front of the driver and never do anything to the back that you don't even think about doing at the front. Would you use your drivers back-mounted on a 50mm thick front? I guess not, not even with round-overs. Well, they don't like it at the back either, plus there is also a basket and a magnet in the way which make the situation even worse. I have made a lot of measurements of the back of drivers with different mounting methods and the thick baffles do a lot more harm than they do any good.

But anyways, nice drivers, nice amps, nice crossover, it has a lot of potential. Good luck designing and don't listen too much to what everyone else thinks, including me🙂

I just had a peak at your video and looked at your design goals. If this is really your room and the placement of your loudspeakers my strongest advice is to separate the sub drivers from the rest because the position in the room where your speakers perform at their best is most of the time also not the place where subs perform at their best.

With speakers that are close to the side wall, don't you think you might probably be better of with dipole, cardioid, or horn loudspeakers. What you are trying to do now is to build another loudspeaker of almost exactly the same principle as your previous ones with more or less the same quality of drivers. It will turn out a little different but much better? I am afraid not by as much as you hope for. The position in the room and the power response is going to sound about the same

...........................

Thank you Sjef for advices 😉

Now, the thing is that I was really satisfied with previous combination of BE+16TX+peerless XLS10 and I probable don't need anything better in my life.

Most people who heard it say that whole system sound like some of the top rooms on hifi shows. Now lets take that with little reserve, but for me, it played really nice, and I could live with them without problem.

(I know that you can't judge sound via youtube...but I record those to give a little ''taste'')

But 😉

Some how I miss the punch in bass area, something that I had with 2x21W8545 (scan speak). Now I'm sorry I sold them, but...

+ I wonted to try RAAL once again 😉

That is the only reason why I'm here, trying to make something ''new''.

(I could do some correction via DSP to get more bass out of 16TX but didn't wont to overstress it)

Yes, those, new loudspeakers, are more or less the sime as previous one, but just because I was happy with them 😉

I'm just in pursuit for something that I mide not get, but that's were all the fun is in this hobby 😉

Side firing subs have show as good choice in my room. I don't know how dual would act but will give it a try. It's just 20L for cabinet, or something like 30-40Euro in MDF.

With 2x21W8545 I had some bass cancelation problems as I have strange living place, which I can't change.

With side firing, everything sounded more ''right''...

Test cabinets will be like separate box for 13+2x19, separate box for 2xSW, with RAAL on top of box for mid/bass. It will be like modular, nothing fancy, but will give me freedom to play 😉

( I have already cut it, just need to glue it )

For bass I could go with one 19TX but I like to use 2x19TX for Allison Effect, again as I have ''bad room'', just to be on safe side 😉

And I could go with 19P, which could be better and chipper choice but...

About baffle thickness, yes, I have some experience with that too. First loudspeakers I made have midbass driver in a 5cm tunnel which give me rise at around 850Hz or so...I think it was rise...it was long ago, but I know the problems it create.

Now, baffle will be made of two pieces, so that I can slice them and get the baffle shape I need/like, but the thickness where drives will be mounted will bi like 10-15mm with 45* chamfer (will done that via CNC on beck side)

And again, it all will depend on final design, but I got that in minde.

About WG on RAAL, I give up on that idea, but will se how this false WG will have effect. It's more for the look then the WG function. I will try to make it the way it effect FR the less posibile.

I really don't know what relation does RMS of driver have.

I'm looking at subwoofers more like filler drivers. And during the DSP setup I'm setting things at the levels I like to listen, so at the end, it all mide just come right.

And yes, I chose them as they need small box 🙁.

As I wrote, I'm not an expert in any way, I have no knowledge in designing loudspeakers, i don't like horn's, for OB I don't have space (never really was into OB), cardioids is interesting but I have no idea how to execute that...

so at the end, I'm gonna stick with what I have, with something I have some experience and try to get the best of it with knowledge I have (which is really, really low)😉

That is main reason why I ''repeat'' my self with redesign.

Other wise, I mide try cardioids or some other idea 😉

If this come out as total disaster, I will sell some stuff and build SBA SASANDU in TX version, or buy bose and finish with it all 😀

Thanks once again Sjef for all advices, I appreciate it !

It's not the room alone, it's the interaction between the room and the loudspeakers. The biggest advantage of DIY is that you can design your loudspeakers for your room instead of designing them for the average room like manufacturers do, if they even take the room into account in the first place. That's why placing your subs in another place than the midbass-highs can improve things a lot when you have little freedom in placing your loudspeakers. I once made a coffee table sub for a friend who was also fighting to get the sub-bass right and he was very happy with it. In another room I used three small subs and in my main room I use dipole subs. All these solutions sounded better than reflex or closed boxes close to the front and side walls.With 2x21W8545 I had some bass cancelation problems as I have strange living place, which I can't change.

With side firing, everything sounded more ''right''...

Rms is the mechanical resistance a driver has. Look at it as the rolling resistance of a bicycle tire. With high rolling resistance it takes more effort to get rolling than on a tire with low rolling resistance. Now you could think it is just a matter of adding more power but with loudspeakers it is more subtle than that. Of course, Rms is not the only parameter that makes the driver sound like it does but low Rms drivers tend to sound more vivid but it depends on other parameters if that leads to coloration or not. It's all about finding the right balance as always.I really don't know what relation does RMS of driver have

Have you done any baffle simulations with VituixCad? If not, it is a good place to start.Could someone please comment driver spacing depending on crossover points ?

m'I too off or would this work ? Is spacing crucial or is there some tolerance

It's not the room alone, it's the interaction between the room and the loudspeakers. The biggest advantage of DIY is that you can design your loudspeakers for your room instead of designing them for the average room like manufacturers do, if they even take the room into account in the first place. That's why placing your subs in another place than the midbass-highs can improve things a lot when you have little freedom in placing your loudspeakers. I once made a coffee table sub for a friend who was also fighting to get the sub-bass right and he was very happy with it. In another room I used three small subs and in my main room I use dipole subs. All these solutions sounded better than reflex or closed boxes close to the front and side walls.

Rms is the mechanical resistance a driver has. Look at it as the rolling resistance of a bicycle tire. With high rolling resistance it takes more effort to get rolling than on a tire with low rolling resistance. Now you could think it is just a matter of adding more power but with loudspeakers it is more subtle than that. Of course, Rms is not the only parameter that makes the driver sound like it does but low Rms drivers tend to sound more vivid but it depends on other parameters if that leads to coloration or not. It's all about finding the right balance as always.

Thanks

will look more into it.

Have you done any baffle simulations with VituixCad? If not, it is a good place to start.

I have not, but will give it a try 😉

tnx

Test cabinets

And amplifiers (nc100hf+nc252mp and nc500mp)

Still some work to do...pffff...

And amplifiers (nc100hf+nc252mp and nc500mp)

Still some work to do...pffff...

Attachments

Hi,

if this is all about appearances, then you should probably start from scratch and consider something else and grand, imo.

Good luck with sonics!

if this is all about appearances, then you should probably start from scratch and consider something else and grand, imo.

Good luck with sonics!

Will have to see the results once I start to play with this.

I'm not an expert in any way, but I did like my previous builds

So this is the last one for me no meter the results 😉

I'm not an expert in any way, but I did like my previous builds

So this is the last one for me no meter the results 😉

Look, if you are to make an impression on your audiophile friends, get working on a clone, something everyone wished in their possession, and then, after you get the sonics right, you will sell these way easier, and we all know that in the end this will end up being sold, either in pieces or as a whole. 🙂

edit: Why a clone? Because advertising was already covered for.

edit: Why a clone? Because advertising was already covered for.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- 3.5/4 way loudspeakers insanity check