Hi,

Could a T aluminium profile be used as an effective brace in an enclosure built?

I was thinking about something like that, 30mm x 30mm, 3mm Alu:

https://www.commentfer.fr/t-en-alu/...tres/47-epaisseur-3_mm/587-section-30_x_30_mm

I would like to use it like Linkwitz described here to rise resonnance in freq: https://www.linkwitzlab.com/frontiers_2.htm#N

And wonder how it could compare versus wood brace?

An other possibility is same kind of profile but in steel. Way heavier and needs bigger tools though... which could be nice or not. Cheaper option.

Could a T aluminium profile be used as an effective brace in an enclosure built?

I was thinking about something like that, 30mm x 30mm, 3mm Alu:

https://www.commentfer.fr/t-en-alu/...tres/47-epaisseur-3_mm/587-section-30_x_30_mm

I would like to use it like Linkwitz described here to rise resonnance in freq: https://www.linkwitzlab.com/frontiers_2.htm#N

And wonder how it could compare versus wood brace?

An other possibility is same kind of profile but in steel. Way heavier and needs bigger tools though... which could be nice or not. Cheaper option.

Linkwitz was an electrical engineer and there is some misleading information on the page you cite concerning mechanical and acoustical engineering. Not necessarily wrong (apart from the odd thing like rigidly mounting the magnet eliminating vibration) but more a lack of appreciation of the relative importance of modes, frequency, displacement, mass, stiffness, damping,... in reducing the sound radiated from a cabinet.

Raising the resonant frequency of panels will not in general make a speaker cabinet quieter if that is your objective. Aluminium with effective damping is a nice way to make speaker cabinets (e.g. Genelec) but is difficult to achieve for us DIYers in our sheds and garages. How would you propose rigidly bonding the aluminium brace to the wood or aluminium panel?

Raising the resonant frequency of panels will not in general make a speaker cabinet quieter if that is your objective. Aluminium with effective damping is a nice way to make speaker cabinets (e.g. Genelec) but is difficult to achieve for us DIYers in our sheds and garages. How would you propose rigidly bonding the aluminium brace to the wood or aluminium panel?

You could use a aluminum strip.

Then again it is so easy to just use a double panel baffle.

and use common window braces.

Then again it is so easy to just use a double panel baffle.

and use common window braces.

For damping, use a foam pipe to cover the aluminum (the kind used to insulate air conditioner pipes).

Bonding....use screws, or epoxy.

Bonding....use screws, or epoxy.

Hi Andy,

Thank you for your answer. It rise interesting points.

The magnet mounting i would try implement too but not for eliminating vibration but to try to get rid of the basket resonance he describe which is a driver related issue ( built material and geometry).

That said i think that a coupling to the box through another panel than the front plate isn't a bad thing. It could offer a way to 'distribute' vibration to other panels thanks to cross bracing or a 'rigid' matrix approach.

Not vey different than Planet10 approach with minionken's and such small box full rangers.

A layer of sorbothane could be introduced in place of felt in his sketch and could offer decoupling if you want to, as well as a 'lossy' matrix ( kef style of constrained layer/ bracing).

Yes my goal is to rise resonant freq as it is easier to tame through use of a damping material ( BBC approach), and push them right at the limit of the bandpass of enclosure ( or way out it for a sub/bass dedicated box).

I would use some boat structural glue. I've got some friend into this and this is the kind of thing he use for deck on boat structure. From it's experience the glue will be stronger than the material they will keep together. I believe him.

My question is more related to the T profile and if it can be compared to a ply or mdf of equivalent size or not.

My initial plan is to gain on weight and size used into the enclosure.

18mm single mdf or ply for the panels is planed.

As i will use separate sub/bass ( up to 250hz) and (from 250hz and up) mid/high enclosure i'm interested in your thoughts ( even on strategy to apply) on both scenario.

White dragon, by strips you mean what? A square profile or a plain square?

NareshBrd, yes i'am aware there is materials to damp metal. Exist in 'gel' like a thick paint and very effective.

Thank you for your answer. It rise interesting points.

The magnet mounting i would try implement too but not for eliminating vibration but to try to get rid of the basket resonance he describe which is a driver related issue ( built material and geometry).

That said i think that a coupling to the box through another panel than the front plate isn't a bad thing. It could offer a way to 'distribute' vibration to other panels thanks to cross bracing or a 'rigid' matrix approach.

Not vey different than Planet10 approach with minionken's and such small box full rangers.

A layer of sorbothane could be introduced in place of felt in his sketch and could offer decoupling if you want to, as well as a 'lossy' matrix ( kef style of constrained layer/ bracing).

Yes my goal is to rise resonant freq as it is easier to tame through use of a damping material ( BBC approach), and push them right at the limit of the bandpass of enclosure ( or way out it for a sub/bass dedicated box).

I would use some boat structural glue. I've got some friend into this and this is the kind of thing he use for deck on boat structure. From it's experience the glue will be stronger than the material they will keep together. I believe him.

My question is more related to the T profile and if it can be compared to a ply or mdf of equivalent size or not.

My initial plan is to gain on weight and size used into the enclosure.

18mm single mdf or ply for the panels is planed.

As i will use separate sub/bass ( up to 250hz) and (from 250hz and up) mid/high enclosure i'm interested in your thoughts ( even on strategy to apply) on both scenario.

White dragon, by strips you mean what? A square profile or a plain square?

NareshBrd, yes i'am aware there is materials to damp metal. Exist in 'gel' like a thick paint and very effective.

Last edited:

That said i think that a coupling to the box through another panel than the front plate isn't a bad thing. It could offer a way to 'distribute' vibration to other panels thanks to cross bracing or a 'rigid' matrix approach.

Thinking in terms of panel stiffness is part of not understanding what is relatively important and what less so I was referring to earlier. Not sure what you understand by 'distributing' vibration but mechanical energy enters the cabinet where the drivers perform work on it. The amount follows from the force from the driver (fixed but could be isolated at the price of the driver then moving around) and the deflection at the mounting. Stiffening the mounting will reduce the energy entering the cabinet. The energy in the structure will then be removed by cabinet damping or radiating away as sound. Stiffening panels away from the mounting point will have no direct effect on the level of energy in the cabinet. It can have an indirect one via changes in the cabinet mode shapes and frequencies. Stiffness reduces deflection but at higher frequencies one needs less deflection to get the same SPL so the radiated sound is not necessarily reduced. Measurements (e.g. BBC) and simulations (e.g. KEF) show around the same level but it is likely to be influenced a bit by details. The same SPL level at higher frequencies can be perceptually more intrusive depending on the frequency region. It is reasonable to expect stiffening a cabinet to make sound radiation worse if there are resonances in the passband of the driver but not if the lowest resonant frequency is above the passband of the driver.

Yes my goal is to rise resonant freq as it is easier to tame through use of a damping material ( BBC approach), and push them right at the limit of the bandpass of enclosure ( or way out it for a sub/bass dedicated box).

Easy for subwoofer cabinet, doable for woofer cabinet but good luck with trying to push the lowest frequency above the passband for a midrange driver. If you fail how intrusive is the lowest frequency resonance going to be? Plus the lowest frequency resonance is unlikely to be related to a panel resonance.

My question is more related to the T profile and if it can be compared to a ply or mdf of equivalent size or not.

My initial plan is to gain on weight and size used into the enclosure.

Not sure I wholly understand the question but aluminium is stiffer in bending than wood by perhaps 4 to 40 times depending on the type of wood. MDF being relatively poor. In use one tends to use more wood leading to the difference not being large but with aluminium having the edge. One can make aeroplanes and boats out of aluminium or good quality wood (not MDF).

That kind of depends on the context. If the context is a (sub)woofer or a FAST system, it's very effective.Raising the resonant frequency of panels will not in general make a speaker cabinet quieter if that is your objective. Aluminium with effective damping is a nice way to make speaker cabinets (e.g. Genelec) but is difficult to achieve for us DIYers in our sheds and garages. How would you propose rigidly bonding the aluminium brace to the wood or aluminium panel?

If the context is a 2-way system were the woofer plays from say 45Hz to 2kHz, it's a different story.

Bracing is more to prevent mechanical losses (= Q factor of the cabinet), not really the mechanical vibrations inside the walls of the cabinet.

So say roughly till about 2-3 times Fs. (although it really depends on the volume vs length of the cabinet itself).

The contribution of secondary vibrations from the walls of a loudspeaker cabinet are small at best above say 300-500Hz.

Above damping material will get rid of the majority of the energy.

Sandwich panels are otherwise very effective.

There are some vibrations leaking from the loudspeaker frame directly into the front baffle.

But most speakers have some rubber/foam seal ring, so most of it will only go through the screws.

In the end it's choosing between the less evil.

In theory one could mount a speaker driver totally floating (rubbers etc), but this will cost good coupling, meaning the mechanical loss (Q) for lower frequencies will be higher and vice versa.

Using, or rather not using, a certain woofer above (or below) a certain frequency can be as effective as well.

Extra bonus points since that option also has a lot less inter-modulation distortion.

btw, from a practical point of view, one has to be aware of something called "droop" in wood (aka sagging).

Especially wood types like MDF have a tendency to sag when being loaded after a while.

So make sure that you don't preload the (side) walls to much.

Something like birch plywood is a lot more stable.

For ease of mounting, I personally would go for 30x30mm aluminum extrusion instead of a T profile.

Especially wood types like MDF have a tendency to sag when being loaded after a while.

So make sure that you don't preload the (side) walls to much.

Something like birch plywood is a lot more stable.

For ease of mounting, I personally would go for 30x30mm aluminum extrusion instead of a T profile.

likelihood in what context?I am a strong believer in pushing (potential) resonances up in frequency where they are much less likely to be excited.

dave

If anything, a cavity wall would be extremely effective.

Downside is that it's quite a challenge to make plus the cabinet will be bigger.

It's also rather difficult to predict the results beforehand, you don't want to be in the resonance region or coincidence region.

edit; although this is about cavity walls, the same idea also counts for single walls. (I guess a cabinet is basically 2 walls in parallel, so the same thing again)

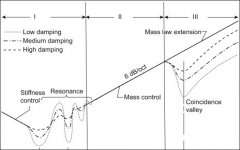

Up to a certain frequency it's the stiffness that counts, than we get a region that is one big mess, after the mass controls the amount of vibrations, followed by the upper region were local vibrations inside the material itself start to occur.

The issue with a 2-way system is that resonance region between stiffness control and mass control.

Attachments

Last edited:

I am a strong believer in pushing (potential) resonances up in frequency where they are much less likely to be excited.

Your plot makes no sense to me. Above the frequency of the lowest resonance it is certain that resonances are being driven. Mathematically speaking we are also driving resonances below this frequency since the cabinet motion is a sum of the modes at all frequencies.

Bracing is more to prevent mechanical losses (= Q factor of the cabinet), not really the mechanical vibrations inside the walls of the cabinet.

So say roughly till about 2-3 times Fs. (although it really depends on the volume vs length of the cabinet itself).

I don't understand this point. Mechanical loss of what? Adding damping to a cabinet increases the mechanical loss, reduces the size of the resonances and makes it quieter. I presume you mean something else?

The contribution of secondary vibrations from the walls of a loudspeaker cabinet are small at best above say 300-500Hz.

What are secondary vibrations?

Liklihood in terms of a specific frequency having sufficient energy to get a resonance going. If you can get teh Q up that makes it even less likely to be excited as it is rare, in music, to have the same HF (500 Hz+) note playing continuously long enuff in such a narrow band to pump energy into the resonance to get it going.

If you wanted to be anal you could further enhance things by ensuring the (potental) resonance to fall somewhere where the standard musical forms do not place ant (or many) notes. In praactice that is probably unnesesary.

dave

If you wanted to be anal you could further enhance things by ensuring the (potental) resonance to fall somewhere where the standard musical forms do not place ant (or many) notes. In praactice that is probably unnesesary.

dave

... since the cabinet motion is a sum of the modes at all frequencies.

And if you can move them all up to where they are unlikely to occur then it is as if they do not exist.

Note for instance that a tuning fork is excited by inputting a broadband signal but only the bits at the right frequency cause the fork to move. If you notched out the fundemental frequency of the fork from the broadband the fork would not get excited.

dave

There is no way a box made of wood will EVER get the panel resonances above the typical passband of woofer (say <2khz). I'll bet anyone here 50 USDT that they cannot build such a box.

planet10> you always post that theoretical plot, but have you ever actually measured box radiation? It behaves nothing like what that plot implies is the situation.

planet10> you always post that theoretical plot, but have you ever actually measured box radiation? It behaves nothing like what that plot implies is the situation.

In the piston region of the woofer you ideally need an enclosure that is infinite stiff.I don't understand this point. Mechanical loss of what? Adding damping to a cabinet increases the mechanical loss, reduces the size of the resonances and makes it quieter. I presume you mean something else?

What are secondary vibrations?

In practice this is not the case and you will lose energy, which result in a lower total Q as well as a slight frequency shift (since the volume isn't constant).

This effect is very noticeable in very cheap and crappy speakers (with quite literally cardboard walls).

Secondary resonances are the vibrations inside the material itself (caused by the vibrations of the speaker), the coincidence region.

There is no way a box made of wood will EVER get the panel resonances above the typical passband of woofer (say <2khz).

I figure if you can push up to over 500 Hz the liklihood of excitation plummets.

planet10> you always post that theoretical plot, but have you ever actually measured box radiation? It behaves nothing like what that plot implies is the situation.

true, but i did dig deep into the basic theory to come up with that illustrative graph. The 2nd order curve is easy to support. The 4th order curve requires a bit more esoteric thinking and is still up in the air.

dave

At those frequencies, most of the energy is already being absorbed by the damping material. So the only path is from the (speaker) frame directly into the baffle (and the rest of the cabinet).

Excitation (excursion) vs frequency always goes down btw.

Excitation (excursion) vs frequency always goes down btw.

Last edited by a moderator:

- Home

- Loudspeakers

- Multi-Way

- Aluminium profile as brace?