Hi, sorry for posting a newbie question...

I'm buying a used portable PA system package (Fender Passport PD-150 - similar to the one shown in this video), but it's missing the two accessory speaker cables.

I've soldered a couple of guitar cables before, so I'm thinking I could buy speaker cable wires and connectors on Amazon and try to make replacement speaker cables for the PA system myself.

So I've found connectors like these and speaker wires like this one. Will these work for the above-mentioned PA system?

I'm assuming TS is the connection type, not TRS, correct?

Is a speaker patch cable soldered the same way as a guitar cable?

I see that the wires have "AWG" ratings, I don't know what this means, but should I go for above certain rating for live sound use?

Perhaps home audio systems use different ratings?

These are probably very basic questions to you, but if anyone would be kind enough to enlighten me, I'd appreciate it! 🙂

I'm buying a used portable PA system package (Fender Passport PD-150 - similar to the one shown in this video), but it's missing the two accessory speaker cables.

I've soldered a couple of guitar cables before, so I'm thinking I could buy speaker cable wires and connectors on Amazon and try to make replacement speaker cables for the PA system myself.

So I've found connectors like these and speaker wires like this one. Will these work for the above-mentioned PA system?

I'm assuming TS is the connection type, not TRS, correct?

Is a speaker patch cable soldered the same way as a guitar cable?

I see that the wires have "AWG" ratings, I don't know what this means, but should I go for above certain rating for live sound use?

Perhaps home audio systems use different ratings?

These are probably very basic questions to you, but if anyone would be kind enough to enlighten me, I'd appreciate it! 🙂

The wire's OK, but I MUCH prefer round, neoprene-insulated cable, SO or SJO.

I would NOT TOUCH ¼-phone plugs for speakers, now that Neutrik speakONs have become widely accepted.

There are 3 BIG shortcomings to the Switchcraft-designed ¼-phone plug:

- there is 100% probability that a momentary (read 'anything more than a few microseconds') short will occur within one years' use

- the strain relief (cable clamp) is woefully inadequate

- sooner or later, some well-meaning cable-coiler will drop the end on a concrete floor shattering the phenolic insulator; it will never be reliable after that

If you simply have to use ¼-phone connectors, track down some mil-spec M642/4-1's -- it's the newer-number-equivalent of the former mil-spec PJ-055B. I'm old enough to have some of each still providing reliable service at almost 50 years. They're machined solid brass, molded insulators, have a proper/reliable strain relief, and screw terminals. The one drawback is you have to carry Brasso or equivalent to clean them now and then.

"AWG" is the wire gauge; you'll want to become familiar with that at some point. For now, 14 gauge is fine.

"TRS" is the abbreviation for 'tip, ring, sleeve' -- a 3-circuit connector. Speakers only need 2. More and more line-level stuff, even consumer gear, is using balanced interconnect. That's what the 3rd contact is for.

Cheers

I would NOT TOUCH ¼-phone plugs for speakers, now that Neutrik speakONs have become widely accepted.

There are 3 BIG shortcomings to the Switchcraft-designed ¼-phone plug:

- there is 100% probability that a momentary (read 'anything more than a few microseconds') short will occur within one years' use

- the strain relief (cable clamp) is woefully inadequate

- sooner or later, some well-meaning cable-coiler will drop the end on a concrete floor shattering the phenolic insulator; it will never be reliable after that

If you simply have to use ¼-phone connectors, track down some mil-spec M642/4-1's -- it's the newer-number-equivalent of the former mil-spec PJ-055B. I'm old enough to have some of each still providing reliable service at almost 50 years. They're machined solid brass, molded insulators, have a proper/reliable strain relief, and screw terminals. The one drawback is you have to carry Brasso or equivalent to clean them now and then.

"AWG" is the wire gauge; you'll want to become familiar with that at some point. For now, 14 gauge is fine.

"TRS" is the abbreviation for 'tip, ring, sleeve' -- a 3-circuit connector. Speakers only need 2. More and more line-level stuff, even consumer gear, is using balanced interconnect. That's what the 3rd contact is for.

Cheers

Last edited:

Yes TS - tip/sleeve And AWG is American Wire Gauge, as Rick pointed out

While Speakons are great and reliable, the Passport system does not have them. He needs 1/4 to 1/4 cables. The Passport is a low power system. I don't recall there being room for Speakons on the mixer part and the molded plastic speakers lack same. And unless you have bench experience, taking apart a Passport is not for the novice.

Soldering is soldering, the plug has no idea what the wire connects to.

These are just speakers, so yes, that basic 14ga wire will work. It may not be convenient to use however. The insulation might make it too fat to fit into the plug housing for example. I also would prefer a jacketed cable over the zip cord. Zip cord is fine for permanent or semi-permanent installations, like a home stereo. But zip cord generally sucks (in my view) for cables you will set up and strike over and over. Jacketed cable is round and will coil up nicely for storage, plus it protects the wire better. You can run wheels over it or set a chair leg on it without damage, while zip cord may be damaged by such. I can't say about GHS, but Switchcraft makes a #70 plug, which is the same 1/4" shaft, but the body of the plug is wider with a larger hole. I don't recall the jacks on the speakers being recessed, but if they are, then first look at how wide a plug can be used.

I don't personally think you need 14ga wire, 16 would be fine. This is a light duty portable PA, not a snorting home theater system. Any tiny bit of power lost to cables will not be missed.

And while the concerns listed in the prior post are legitimate, I have cables I have been using for 50 years myself, and I have had very few outright plug failures. Much more common is wires inside breaking and needing a patch.

And just one quick look and I found"

https://www.musiciansfriend.com/acc...MI8Zb68aKx-QIVShTUAR1qpQvxEAQYBCABEgK32PD_BwE

SO you might go to your local music store and see what they have already made. And they will generally have a warranty too.

When I ran my shop, I used to build cables. I bought large orders of wire and connectors often from Rapco/Horizon, but then I found that they sold made up cables for just about the same price as the materials, so I stopped building my own. And they were nice enough that if I wanted some odd combination of ends, they were happy to make them that way. I might have to wait two extra days, but why not, no extra charge.

While Speakons are great and reliable, the Passport system does not have them. He needs 1/4 to 1/4 cables. The Passport is a low power system. I don't recall there being room for Speakons on the mixer part and the molded plastic speakers lack same. And unless you have bench experience, taking apart a Passport is not for the novice.

Soldering is soldering, the plug has no idea what the wire connects to.

These are just speakers, so yes, that basic 14ga wire will work. It may not be convenient to use however. The insulation might make it too fat to fit into the plug housing for example. I also would prefer a jacketed cable over the zip cord. Zip cord is fine for permanent or semi-permanent installations, like a home stereo. But zip cord generally sucks (in my view) for cables you will set up and strike over and over. Jacketed cable is round and will coil up nicely for storage, plus it protects the wire better. You can run wheels over it or set a chair leg on it without damage, while zip cord may be damaged by such. I can't say about GHS, but Switchcraft makes a #70 plug, which is the same 1/4" shaft, but the body of the plug is wider with a larger hole. I don't recall the jacks on the speakers being recessed, but if they are, then first look at how wide a plug can be used.

I don't personally think you need 14ga wire, 16 would be fine. This is a light duty portable PA, not a snorting home theater system. Any tiny bit of power lost to cables will not be missed.

And while the concerns listed in the prior post are legitimate, I have cables I have been using for 50 years myself, and I have had very few outright plug failures. Much more common is wires inside breaking and needing a patch.

And just one quick look and I found"

https://www.musiciansfriend.com/acc...MI8Zb68aKx-QIVShTUAR1qpQvxEAQYBCABEgK32PD_BwE

SO you might go to your local music store and see what they have already made. And they will generally have a warranty too.

When I ran my shop, I used to build cables. I bought large orders of wire and connectors often from Rapco/Horizon, but then I found that they sold made up cables for just about the same price as the materials, so I stopped building my own. And they were nice enough that if I wanted some odd combination of ends, they were happy to make them that way. I might have to wait two extra days, but why not, no extra charge.

Thank you for educating me! I appreciate walking me through these different connector types. With the model names and numbers you mentioned, I can do my own research to further my knowledge. I see those circular Neutrik connectors used more on speakers they use on bigger live stages. I guess they have to use cheaper parts options when they design inexpensive portable PA systems. Now I see why the AWG numbers are smaller for bigger cables. Good to know TS is what I need. The less complicated, the less room for error for novice soldering.The wire's OK, but I MUCH prefer round, neoprene-insulated cable, SO or SJO.

I would NOT TOUCH ¼-phone plugs for speakers, now that Neutrik speakONs have become widely accepted.

There are 3 BIG shortcomings to the Switchcraft-designed ¼-phone plug:

- there is 100% probability that a momentary (read 'anything more than a few microseconds') short will occur within one years' use

- the strain relief (cable clamp) is woefully inadequate

- sooner or later, some well-meaning cable-coiler will drop the end on a concrete floor shattering the phenolic insulator; it will never be reliable after that

If you simply have to use ¼-phone connectors, track down some mil-spec M642/4-1's -- it's the newer-number-equivalent of the former mil-spec PJ-055B. I'm old enough to have some of each still providing reliable service at almost 50 years. They're machined solid brass, molded insulators, have a proper/reliable strain relief, and screw terminals. The one drawback is you have to carry Brasso or equivalent to clean them now and then.

"AWG" is the wire gauge; you'll want to become familiar with that at some point. For now, 14 gauge is fine.

"TRS" is the abbreviation for 'tip, ring, sleeve' -- a 3-circuit connector. Speakers only need 2. More and more line-level stuff, even consumer gear, is using balanced interconnect. That's what the 3rd contact is for.

Cheers

That's wonderful, you ran an audio equipment shop, then I know your advice is coming from years of professional experience. Interesting, one of my friends had a side hustle buying Mogami wire in bulk rolls and making custom cables for buddy musicians, but come to think of it, that was many years ago. It's probably not that viable these days, like you say. Since all I'm looking for is amplification for a small restaurant etc. for background type of live music, I'll first try 16 AWG. Thank you for the link for those speaker cables. I might just buy those as well... but my idea was to come up with replacement speaker cables compact enough to fit into the small compartment on the backside of the Passport mixer unit. But you always have to improvise when shopping for used gears. Anyway, I surely appreciate you sharing your knowledge and experience!Yes TS - tip/sleeve And AWG is American Wire Gauge, as Rick pointed out

While Speakons are great and reliable, the Passport system does not have them. He needs 1/4 to 1/4 cables. The Passport is a low power system. I don't recall there being room for Speakons on the mixer part and the molded plastic speakers lack same. And unless you have bench experience, taking apart a Passport is not for the novice.

Soldering is soldering, the plug has no idea what the wire connects to.

These are just speakers, so yes, that basic 14ga wire will work. It may not be convenient to use however. The insulation might make it too fat to fit into the plug housing for example. I also would prefer a jacketed cable over the zip cord. Zip cord is fine for permanent or semi-permanent installations, like a home stereo. But zip cord generally sucks (in my view) for cables you will set up and strike over and over. Jacketed cable is round and will coil up nicely for storage, plus it protects the wire better. You can run wheels over it or set a chair leg on it without damage, while zip cord may be damaged by such. I can't say about GHS, but Switchcraft makes a #70 plug, which is the same 1/4" shaft, but the body of the plug is wider with a larger hole. I don't recall the jacks on the speakers being recessed, but if they are, then first look at how wide a plug can be used.

I don't personally think you need 14ga wire, 16 would be fine. This is a light duty portable PA, not a snorting home theater system. Any tiny bit of power lost to cables will not be missed.

And while the concerns listed in the prior post are legitimate, I have cables I have been using for 50 years myself, and I have had very few outright plug failures. Much more common is wires inside breaking and needing a patch.

And just one quick look and I found"

https://www.musiciansfriend.com/accessories/musicians-gear-16-gauge-speaker-cable-black-25-feet-2-pack/582057000000000?cntry=US&cur=USD&utm_content=582057000000000--Musician's+Gear+16+Gauge+Speaker+Cable+Black+25+Feet+2-Pack&source=3WWRWXGS&gclid=EAIaIQobChMI8Zb68aKx-QIVShTUAR1qpQvxEAQYBCABEgK32PD_BwE

SO you might go to your local music store and see what they have already made. And they will generally have a warranty too.

When I ran my shop, I used to build cables. I bought large orders of wire and connectors often from Rapco/Horizon, but then I found that they sold made up cables for just about the same price as the materials, so I stopped building my own. And they were nice enough that if I wanted some odd combination of ends, they were happy to make them that way. I might have to wait two extra days, but why not, no extra charge.

You may want to use TRS plugs anyway because with an open Ring connection, shorting tip and sleave is not as likely. If you have the choice, use plastic jacks and not metal. This not only isolates the sleave from metal chassis, but also avoids shorting as they are inserted / removed, but the contact can still sit between the tip and sleave on TS plugs. https://www.parts-express.com/Rean-NYS2122-1-4-Mono-Jack-Switched-092-120

Round cables are better than zip cord because you may need to wipe them down after a party to remove rave sludge or poop or dead vultures, depending on the event. I couldn't resist going with industrial-grade SO cable, but that resulted in 4-conductor cables almost the size of garden hose, so a sensible person would settle for the SJ. (I used 4-conductor with Speakons so I could run one cable to each speaker stack.)

I used #12, since my bass bins were 4 ohms. With 50' cables, that's 100' of wire, and that amounts to 0.4 ohms for #16, 0.25 ohms for #14; 0.16 ohms with #12. Looking at those numbers, though, the differences are less than I expected, so any of those are gonna be just fine, especially if your speakers are 8 ohms.

Switchcraft makes a plug with a wide insulator so it can't short out:

https://www.switchcraft.com/1-4-mon...ug-in-3-conductor-jack-without-shorting-/288/

Here's some NOS at a fraction of the new price:

https://marvac.com/products/switchc...onductor-cable-mount-plug-nickel-metal-handle

I used #12, since my bass bins were 4 ohms. With 50' cables, that's 100' of wire, and that amounts to 0.4 ohms for #16, 0.25 ohms for #14; 0.16 ohms with #12. Looking at those numbers, though, the differences are less than I expected, so any of those are gonna be just fine, especially if your speakers are 8 ohms.

Switchcraft makes a plug with a wide insulator so it can't short out:

https://www.switchcraft.com/1-4-mon...ug-in-3-conductor-jack-without-shorting-/288/

Here's some NOS at a fraction of the new price:

https://marvac.com/products/switchc...onductor-cable-mount-plug-nickel-metal-handle

Look at Amazon Basics 14ga speaker wire. It’s jacketed so it will take more abuse and it’s cheap. $38 for 100 feet! Don’t waste money on fancy cable it will make no difference in your situation. Get quality 1/4” plugs that can take some abuse, stick to Nuetrik or Switchcraft. Make sure to use the strain relief within the connector to hold the wires. Most fail because they are yanked on and the strain relief helps keep them together. If you use the jacketed wire make sure the jacket is held by the strain relief not just the wires.

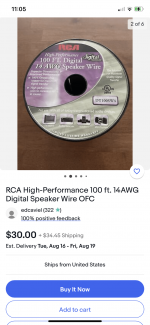

The best cables I have used to date that made a huge difference is the RCA speaker cables At 14 gauge for a P.A. System at work. Here a picture and link for you. It’s to long of a story but, The best bulk cable for P.A. Speakers in wire by the foot was the this cable at parts express. Here’s a picture and link for you. Decent cabling and rugged to. Plus it’s OFC Oxygen free copper. Good luck. Jeff

Attachments

https://www.google.com/url?sa=t&rct...org/wiki/RCA&usg=AOvVaw3yQ9CJhVqXl-NBk0ipMlGY

RCA defunct in 1987, many people are using the trade mark in different categories.

The wire is 30 USD, + $34.45 shipping, so 64.45 USD landed at your door in the USA.

RCA defunct in 1987, many people are using the trade mark in different categories.

The wire is 30 USD, + $34.45 shipping, so 64.45 USD landed at your door in the USA.

Looks very similar to the Amazon cable. Red and black wires in a poly jacket making a round cable.

Personally. I would prefer a standard name rather than a brand which is defunct, so the quality is anybody's guess.

Buy double insulated (jacketed) wire from electrical parts sellers, see if you get in military surplus places.

Buy double insulated (jacketed) wire from electrical parts sellers, see if you get in military surplus places.

Yah, it's like Bell+Howell, Kodak's Vivitar, and countless others -- the once-reputable names/trademarks were sold off long ago.

Ya' gotta be at least a little bit suspicious when they tout it as 'Digital Speaker Wire' . .

Any electrical supply house will sell quality cable by the foot -- ask for 'portable cordage'. Neoprene makes a big difference in durability. But it does increase the challenge to properly match a suitable connector. The railroad uses a 6-conductor, locking-shell connector that I've used to great advantage for many years now.

Forget Oxygen Free Copper. There isn't a PA system or venue in the world that you, OR the audience, can hear the difference. It is more resistant to fatigue-fracture. But a properly-matched connector with a proper strain relief remedies that.

85% to 95% of all PA failures can be traced to interconnect. Save yourself countless headaches, and maybe a court appearance, by careful matching of quality appropriate connectors to quality cabling.

Y'all do know that the Switchcraft 288F only thwarts shorts at the Source end, right !? At the driven (speaker) end, same problem as the original design.

Still glad to see that they're finally molding the insulator. Dunno how many failures came of the stupid phenolic insulator that, first time it's dropped on a hard floor, impairs contact pressure for the signal.

Cheers

Ya' gotta be at least a little bit suspicious when they tout it as 'Digital Speaker Wire' . .

Any electrical supply house will sell quality cable by the foot -- ask for 'portable cordage'. Neoprene makes a big difference in durability. But it does increase the challenge to properly match a suitable connector. The railroad uses a 6-conductor, locking-shell connector that I've used to great advantage for many years now.

Forget Oxygen Free Copper. There isn't a PA system or venue in the world that you, OR the audience, can hear the difference. It is more resistant to fatigue-fracture. But a properly-matched connector with a proper strain relief remedies that.

85% to 95% of all PA failures can be traced to interconnect. Save yourself countless headaches, and maybe a court appearance, by careful matching of quality appropriate connectors to quality cabling.

Y'all do know that the Switchcraft 288F only thwarts shorts at the Source end, right !? At the driven (speaker) end, same problem as the original design.

Still glad to see that they're finally molding the insulator. Dunno how many failures came of the stupid phenolic insulator that, first time it's dropped on a hard floor, impairs contact pressure for the signal.

Cheers

Last edited:

Yes, I've been trying to sort that since Radio Shack was schtupping (probably wrong spelling) their crap using it back in the 1990's.

That is a Yiddish word whose slang meaning is fu**ing...., sometimes in an adulterous way.

Please be a little careful, mistakes do happen.

Please be a little careful, mistakes do happen.

Ooo boy. I didn’t know that. Thanks for the letting me know.https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwjT3rDNq8D5AhUFUGwGHS3GASoQFnoECA8QAQ&url=https://en.wikipedia.org/wiki/RCA&usg=AOvVaw3yQ9CJhVqXl-NBk0ipMlGY

RCA defunct in 1987, many people are using the trade mark in different categories.

The wire is 30 USD, + $34.45 shipping, so 64.45 USD landed at your door in the USA.

Google-is-your-friend [tm] 😉I see that the wires have "AWG" ratings, I don't know what this means,

https://en.wikipedia.org/wiki/American_wire_gauge

Same feeling here 😉 but IF both amp and cabinet have 1/4" jacks installed ... what else can you use?I would NOT TOUCH ¼-phone plugs for speakers, now that Neutrik speakONs have become widely accepted.

New builds are fine, but on existing equipment, telephone patchcord plugs and jacks have been the standard for almost 100 years now.

^^^^^that.While Speakons are great and reliable, the Passport system does not have them. He needs 1/4 to 1/4 cables.

Don´t know what Country are you in (it´s always important to state that) but if a Metric one (easy, anywhere outside USA) , standard speaker cable for PA/MI use is 2 wire round sleeve "appliance" wire (power drills, vacuum cleaners, etc.)

Size is by square mm.

In general maximum you can fit through plug cover caps is 2 x 1 mm^2 , equivalent to about 18AWG; so 16AWG and even 18AWG are hard to impossible to use.

Premade commercial speaker cables beat that by using custom molded oversized plugs, nt much of an option for a home builder.

Although if you search around you may find spare oversized plugs.

Neutrik and Switchcraft both make 1/4” plugs that will take 20mm diameter cable and are designed for “speaker cables”. Saw them at PE when looking for plugs big enough for two mic cables, so its not just something custom only an OEM can get. Wish they would make a TRS version.

12/3 would be tight (its tight for 2 pole speakons), but 14/2 SJ or SJOW no problem.

12/3 would be tight (its tight for 2 pole speakons), but 14/2 SJ or SJOW no problem.

FWIW I use "regular" plugs but drill end hole up to internal cover diameter, guaranteeing maximum possible wire diameter.

Standard guitar plugs get up to 2 x 1 square mm round power cable, when drilled up they take up to 2 x 1.5 square mm type.

Original size:7.9mm diameter, internal barrel size 10.2 mm, a significant difference when you are trying to squeeze cable there; I use a 10mm or 10.25mm drill, just enough to drill narrow rim out.

Remember to deburr it, use some fine emery paper or cloth, and of course you lose the cheesy "spring relief" ... no big deal.

You may add your own by heat-shrinking around barrel end and inserted cable, it helps some.

After final assembly of course.

Useful diameter increase is substantial and justifies extra job.

Of course, If you can order oversized plugs, by all means use them.

Here I try to work with what´s easily available over the counter, so all standard stuff is cheap and plentiful; anything else a PITA.

Oh well.

Standard guitar plugs get up to 2 x 1 square mm round power cable, when drilled up they take up to 2 x 1.5 square mm type.

Original size:7.9mm diameter, internal barrel size 10.2 mm, a significant difference when you are trying to squeeze cable there; I use a 10mm or 10.25mm drill, just enough to drill narrow rim out.

Remember to deburr it, use some fine emery paper or cloth, and of course you lose the cheesy "spring relief" ... no big deal.

You may add your own by heat-shrinking around barrel end and inserted cable, it helps some.

After final assembly of course.

Useful diameter increase is substantial and justifies extra job.

Of course, If you can order oversized plugs, by all means use them.

Here I try to work with what´s easily available over the counter, so all standard stuff is cheap and plentiful; anything else a PITA.

Oh well.

- Home

- Live Sound

- PA Systems

- DIY speaker cables for PA system