Sorry, I was thinking about a pyramid - 3 sides and a base 🙂 driver is mounted in the base... this to avoid parallel surfaces...It was my first reflex too but no, 3, 9, 15 ,... have axial symmetry: choose an angle, draw the tangent to the other facing side and you have two identical triangle: there is symetry).

5,7,11 don't have this.

//

Of course, this is exactly what KEF did ion the LS50 meta

Yep. I wish more people would try this. IMHO, there's almost no good reason NOT to do this. You can 3D print a metamaterial absorber for under $5.

Tnt, yes. There is another point to be taken into account: lost space.

Try it a circle into a triangle : make you loose in CTC distance compared to a circle into 5 or 7.

Try it a circle into a triangle : make you loose in CTC distance compared to a circle into 5 or 7.

Have you investigated such absorber for mid / woofer? I think it should be applicable directly, although perhaps not as effective? If looking at the paper posted #25 it says about wavefront of the backwave and waveguide leading to the metamaterial device, which is not very easy or even possible with cone driver, unless sticking the frame and magnet outside? Anyway, the mentioned yamaha ns-5000 is doing something along the lines, as well as any of the other resonant devices I guess, for lower frequencies than tweeter. Perhaps dome mid could also work out just as well with the metamaterial device? Yamaha ns-5000 has interesting pressure equalizing vessels behind domes, might be as effective as metamaterial?Yep. I wish more people would try this. IMHO, there's almost no good reason NOT to do this. You can 3D print a metamaterial absorber for under $5.

In general it looks like different kinds of drivers and wavelengths would have more or less effective solutions. While the metamaterial might be superior for tweeter some damping material is also very effective for high frequencies, at least any damping material is more effective on high frequencies than on low frequencies. For the low frequencies some resonant device would perhaps be more effective than damping material.

To continue thought process I hinted earlier with the G and H options to handle the back wave, it doesn't always have to be an issue. Anyone wondering about the various solutions to brute force back wave (or any other problem) should think if the problem could be removed instead, in which case no solutions are needed 😉 Because, if only thinking what happens inside the box don't forget what happens outside the box. The back wave is very effective cancelling the front wave and vice versa, why not take advantage of, affect the acoustic output and room interaction? Well, there are always some cases that would require enclosure and in that case some of the back wave handling techniques are needed. Perhaps the age old "enough damping material" is the best as it is simplest treatment for most cases. At least all of them make good marketing material if not anything else.

Last edited:

The metamaterial disk on the back of the UniQ KEF tweeter is a number of folded, narrow band tuned traps stacked in frequency to absorb 850Hz upwards. I remember hearing Jack Oclee-Brown talking about it on I think a John Darko Podcast. He said the really tricky bit was to get the tweeter's backwave not to reflect when transitioning from the rear of the dome, through the motor, to the labyrinth. I guess doing this for a mid or woofer would be a whole different ball game, the wavelength numbers start to really work against you.Yep. I wish more people would try this. IMHO, there's almost no good reason NOT to do this. You can 3D print a metamaterial absorber for under $5.

Personally I could listen to Jack all day, he has both humility and an incredible engineering talent.

Work originally started by Hegeman, 3D printers made it possible to do at a scale applicable to tweeters, HF.a number of folded, narrow band tuned traps stacked in frequency to absorb 850Hz upwards

dave

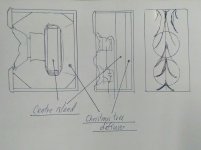

Sorry, but the Christmas tree diffuser isn't that epic, the sound is deflected around a central island and into the diffuser. I have also attached a picture of a tapering absorber and a perforated baffle spaced slightly from the rear wallChristmess tree diffuser sounds epic!

Attachments

Hello,Sorry, but the Christmas tree diffuser isn't that epic, the sound is deflected around a central island and into the diffuser. I have also attached a picture of a tapering absorber and a perforated baffle spaced slightly from the rear wall

I am not sure to catch the idea of central island... Is it closed volume behind the drivers so that the sound has to go around to go in the rear Christmas tree diffuser?

That's pretty much the idea, however I've drilled holes in it ( and added strips of carpet tile ) so it isn't too much of a reflective surface directly behind the driver, also so it doesn't rob too much internal volume. I've added a cork layer between the Christmas tree diffuser and island to try and damp cabinet vibrations, however I strongly doubt that it will make much difference.Hello,

I am not sure to catch the idea of central island... Is it closed volume behind the drivers so that the sound has to go around to go in the rear Christmas tree diffuser?

I am interested in any measurements which show the effect of diffusing/absorbing/meta-material-labyrinth'ing the driver backwave. Surely someone has measured the effect... yes?

j.

j.

FYI/FWIW,YMMV, W.E. concluded that wool batten (sadly can only guess its density TTBOMK unless Silbatone knows, will share) was best for compression drivers, but due to the environment of the times finally concluded 4/0 stainless steel wool packing was the best overall compromise (or at least was in the few 555 drivers I've been exposed to and have consequently used to my satisfaction), so what material(s) or a combination thereof comes closest (or better) would be where I'd start.

- Home

- Loudspeakers

- Multi-Way

- Suppressing Driver Back Wave- Poll